High-energy-saving type cloth pressing electric equipment

An electric equipment and energy-saving technology, which is applied in the field of cloth pressing equipment, can solve the problems of many safety hazards, air pollution, and low heat energy utilization, and achieve the effects of small occupied area, less pollution, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

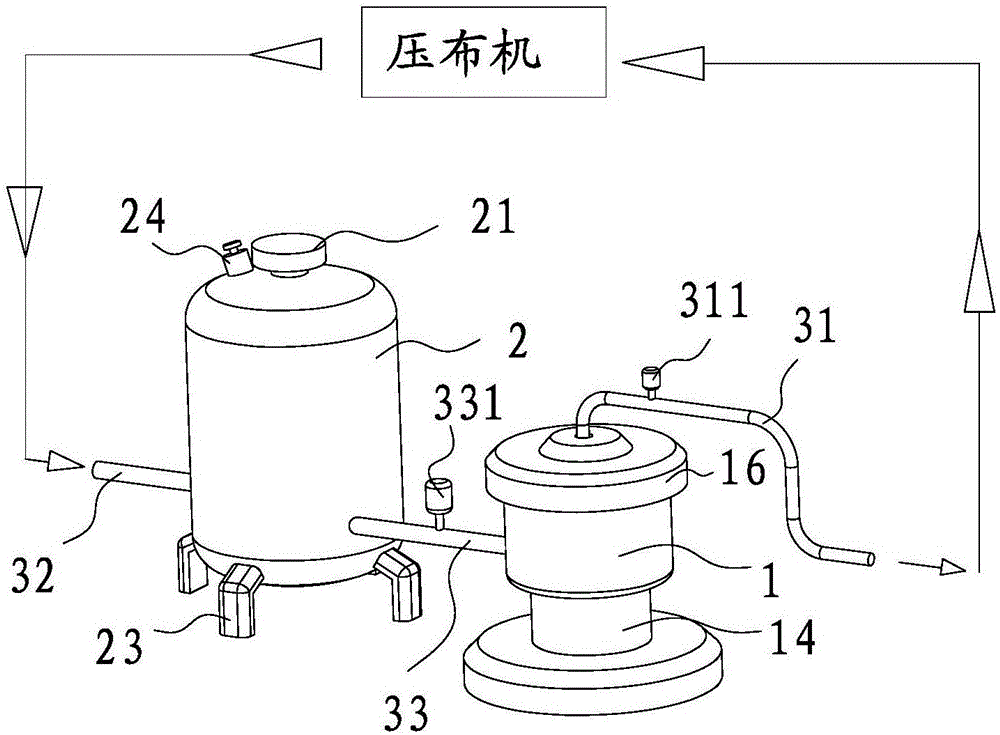

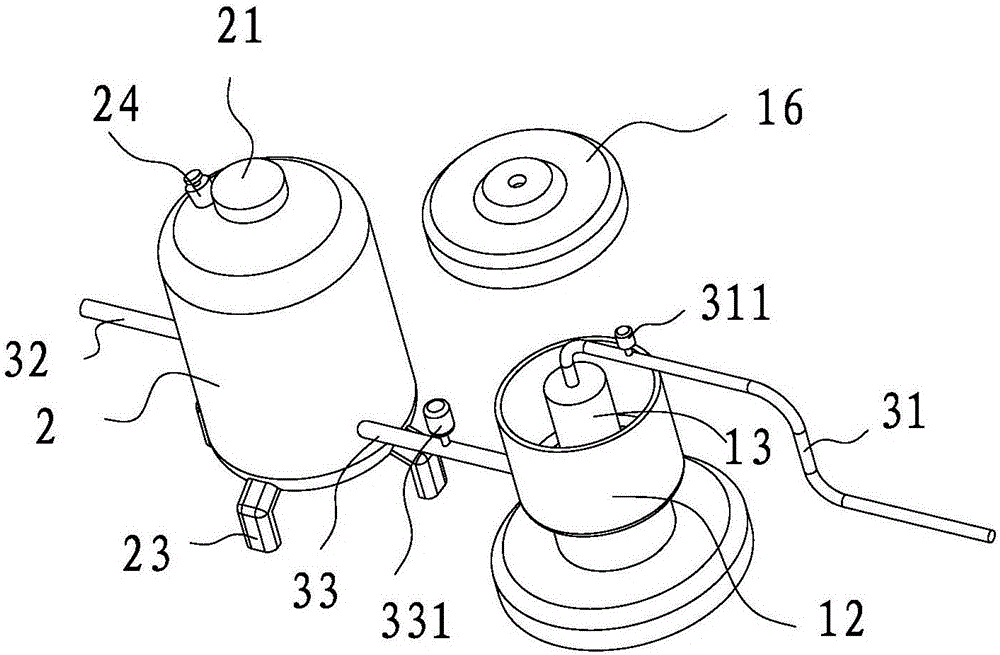

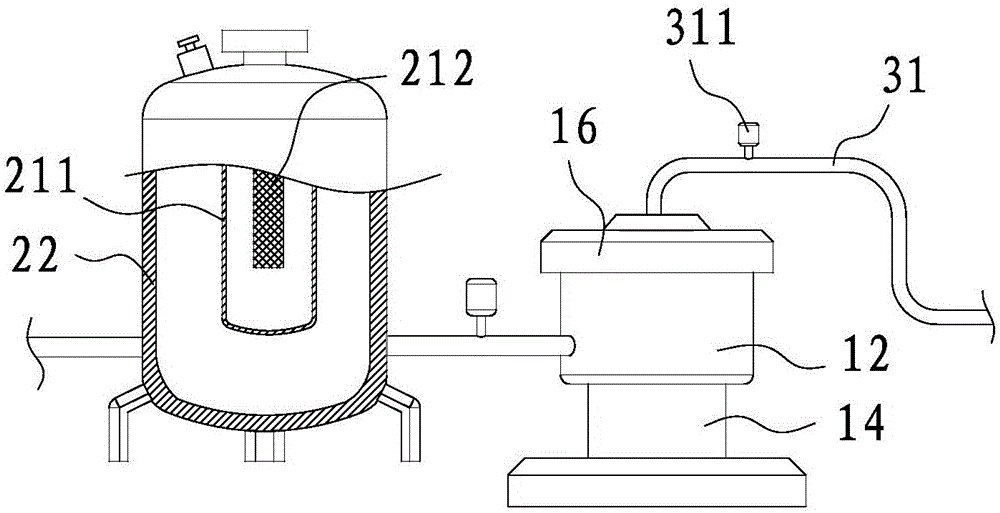

[0034] Such as Figure 1 to Figure 6 As shown, a kind of electrical equipment for pressing cloth is used for pressing cloth onto bamboo products, including a cloth pressing machine, and the cloth pressing machine is connected with heating equipment for heating the cloth pressing machine. The heat supply equipment is an electric boiler. The electric boiler heats the heat-conducting fluid, and then transports the heat-conducting fluid to the cloth press to provide heat for the cloth press. The electric boiler includes a heating furnace 1 and a holding furnace connected to the heating furnace 1 2. The heating furnace 1 is provided with a heating assembly 11 for heating the heat transfer fluid, and the holding furnace 2 is provided with a heat preservation assembly 21 for insulating the heat transfer fluid. The heating furnace 1 transports the heated heat transfer fluid to In the cloth press, the heat transfer fluid flows back to the holding furnace 2 after the cloth press works, ...

Embodiment 2

[0048] Such as Figure 7 As shown, the difference from Embodiment 1 is that the main heating chamber 13 in this embodiment is a hollow cylinder, the convection channel 15 is arranged at the bottom of the side wall of the cylinder, and the heating assembly 11 is also arranged at the main Below the heating chamber 13, the volume of the main heating chamber 13 is larger than that of the first embodiment, and the heat transfer fluid that can be transported at one time is more, which is suitable for a large cloth press.

Embodiment 3

[0050] Such as Figure 8 As shown, the difference with Embodiment 1 is that the structure of the micro-pressure valve 24 is different. The micro-pressure valve 24 in this embodiment includes a shell 246, and the heat preservation cavity 22 is provided with a vent hole 221, and the inner wall of the shell 246 A conical ring wall 247 is provided, and a ball 248 is placed on the conical ring wall 247. When the ball 248 is pressed onto the conical ring wall 247, it just blocks the vent hole from the outside air pressure. When the air pressure is high, the ball 248 is pushed away, and the gas is discharged from the gap between the ball 248 and the conical ring wall 247; The vent hole 221 is isolated from the external air pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com