Ultraviolet illumination DIC (digital image correction)-based mechanical property loading measuring system and method for high-temperature material

A technology of mechanical properties and high-temperature materials, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, and analyzing materials. Harsh requirements and other issues to achieve the effect of avoiding thermal radiation interference, reducing test difficulty, and real-time accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

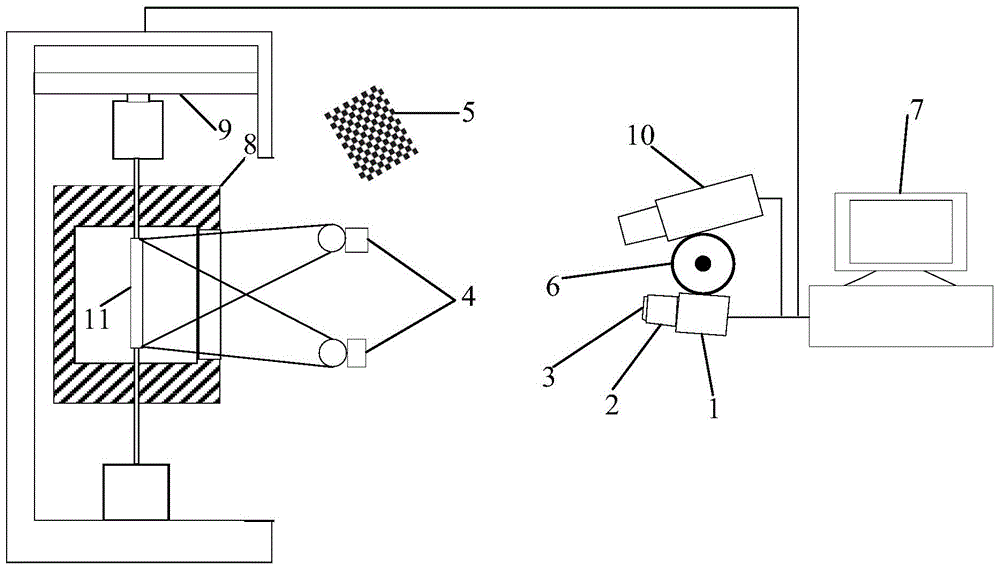

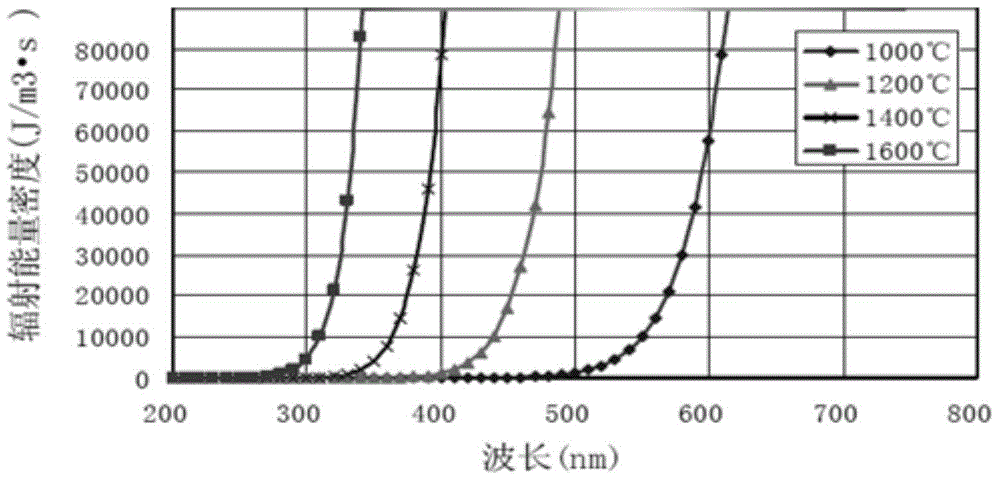

[0028] In this embodiment, the method for measuring the mechanical properties of high-temperature materials based on ultraviolet illumination DIC is: for the tested sample in a set temperature environment and in a set loading state, project an ultraviolet light source with a wavelength of less than 380nm on the The surface of the tested sample; use the ultraviolet sensitive image acquisition module to carry out image acquisition on the surface of the tested sample 11, and obtain each collected image corresponding to the surface of the tested sample at different temperatures, at different times, and under different loading forces, by Each collected image is subjected to DIC image processing to obtain the full-field thermal deformation information of the surface of the tested sample.

[0029] The measurement method in this embodiment is suitable for the measurement process in which the temperature environment is 1000°C to 3000°C.

[0030] see figure 1 , the system composition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com