Heat resistance measurement method for pseudomorphic high electron mobility transistor (PHEMT)

A high electron mobility and testing method technology, applied in the field of semiconductor thermal testing, can solve the problems of insufficient speed, poor operability, and high testing cost, and achieve short reverse recovery time, avoid poor operability, and good switching characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

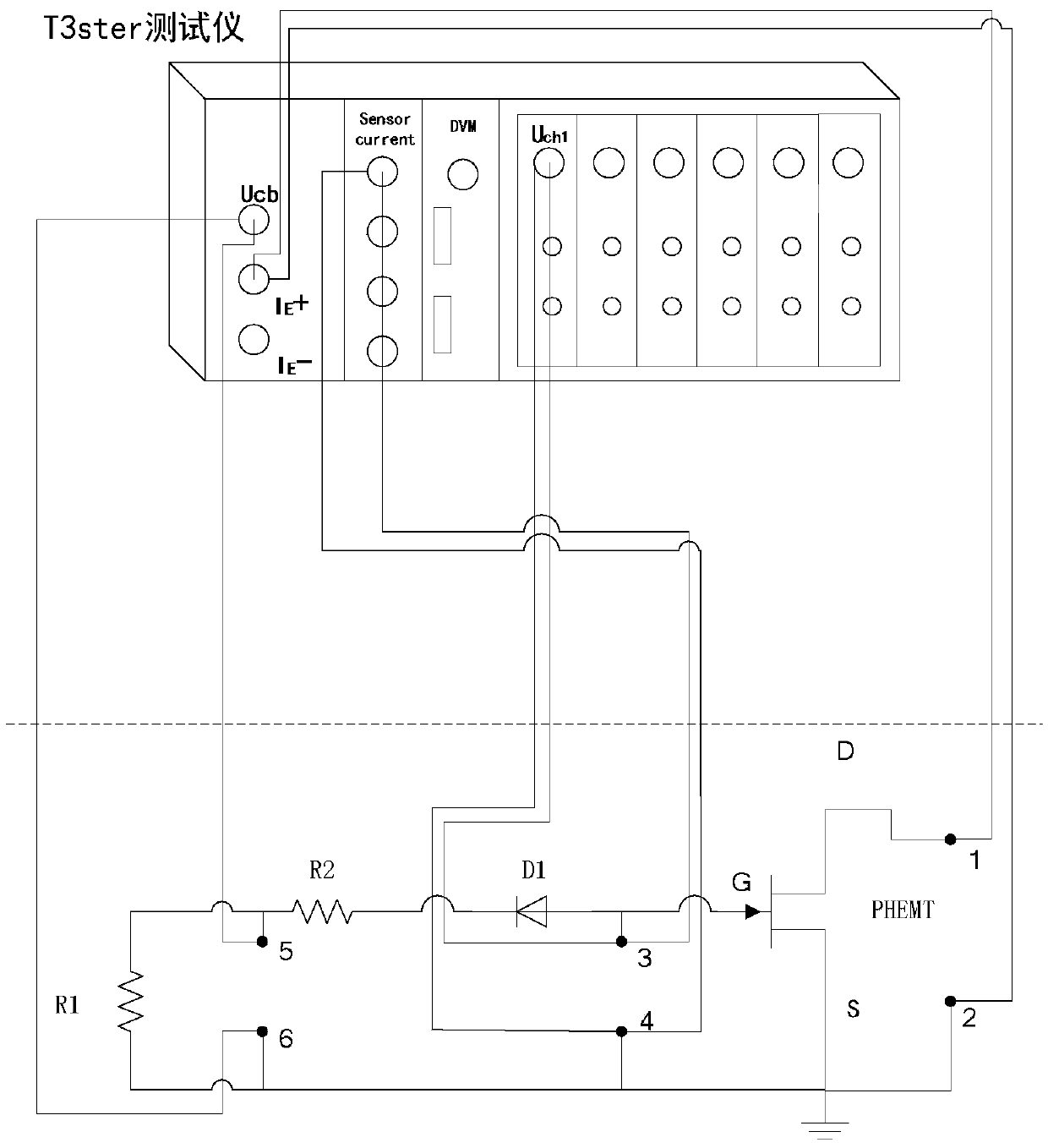

[0024] refer to figure 1 . In the embodiments described below, the peripheral control circuit is below the dotted line, and the commercial T3ster semiconductor thermal resistance tester is above the dotted line. High electron mobility transistor PHEMT thermal resistance testing device, including: PHEMT thermal resistance testing circuit and peripheral control circuit for thermal resistance testing of PHEMT using semiconductor thermal resistance testing instrument T3ster, wherein: PHEMT thermal resistance testing circuit consists of two voltage divider resistors R1, R2 and the fast recovery diode FRD are connected in series with the gate G of the PHEMT transistor. The anode IE+ of T3ster is electrically connected to the drain D of the PHEMT and the resistor R1 respectively through the terminal contacts 1 and 2 between the drain D and the source S of the PHEMT transistor. , the voltage output terminal Ucb is electrically connected to the terminal contact 5 between the resistor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com