Waste gas treatment and waste heat recovery device and method thereof

A waste heat recovery device, waste gas treatment technology, applied in the direction of heat exchanger type, indirect heat exchanger, heating/cooling fabric, etc., can solve the problems of insufficient utilization of thermal energy, waste of thermal energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

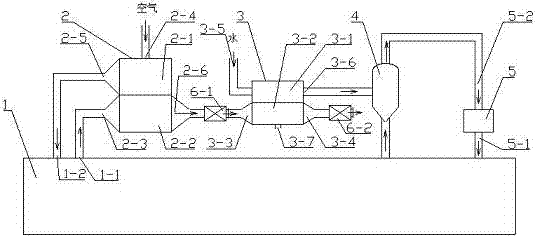

[0027] Such as figure 1 The exhaust gas treatment and waste heat recovery device shown includes: a setting machine 1 , a heat transfer medium heater 5 , a steam generator 4 and an air-air exchanger 2 .

[0028] The sizing machine 1 has an exhaust gas outlet 1-1 and a fresh air inlet 1-2.

[0029] The air-air exchanger has a new air chamber 2-1 and a waste air chamber 2-2 which are independent of each other; the new air chamber 2-1 has an air inlet 2-4 and an air outlet 2-5, and the air outlet 2 -5 is connected with the fresh air inlet 1-2 of the sizing machine 1; The exhaust gas outlet 1-1 is connected. The gas-gas exchanger 2 can adopt any kind of exchanger that can realize heat exchange between gases, preferably, such as figure 1 As shown, the air-gas exchanger 2 is divided into an upper fresh air chamber 2-1 and a lower exhaust gas chamber 2-2 by a tube sheet, the fresh air chamber 2-1 is a heat absorption section, and the exhaust gas chamber 2- 2 is the exothermic sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com