Circulating conveying device for materials

A conveying device and material circulation technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems affecting processing efficiency and waste of manpower, and achieve the effects of improving processing efficiency, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below.

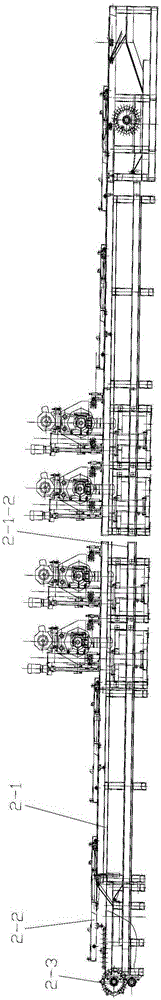

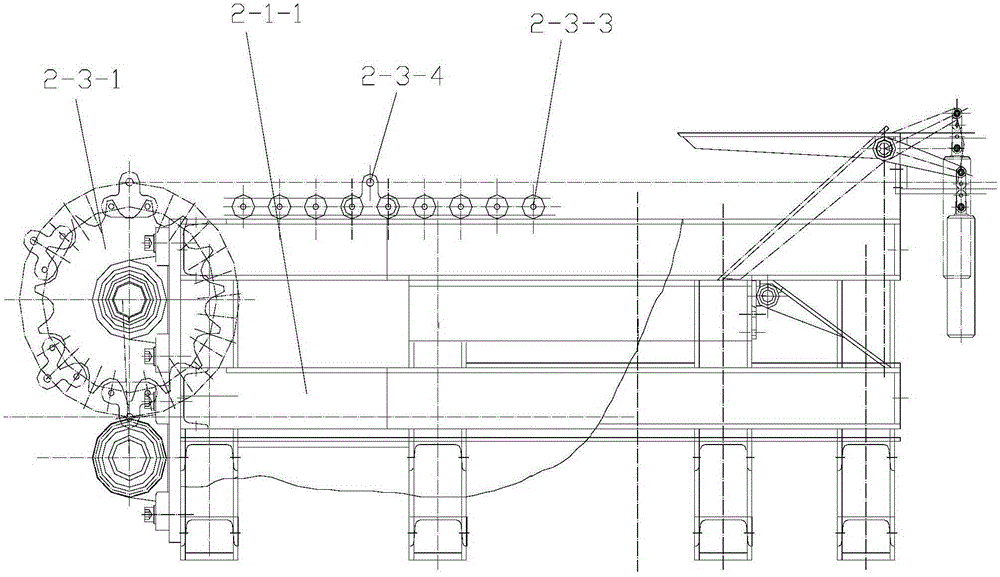

[0047] The material circulation conveying device includes: conveying frame, conveying vehicle, chain transmission mechanism, motor, upper guide rail, lower guide rail, front middle guide rail, rear middle guide rail, rear sinking guide rail, front upper inclined bridge, front lower inclined bridge, rear downward inclined Bridge, back down ramp, back up ramp, back up valve.

[0048] The conveying frame includes a head frame, a tail frame and a plurality of intermediate frames. The head frame, the middle frame connected in series, and the tail frame are connected in series from front to back. When the present invention is used in a polishing machine, the polishing machine has a plurality of polishing units, so a plurality of intermediate frames are selected to build a certain conveying length compatible with the polishing units.

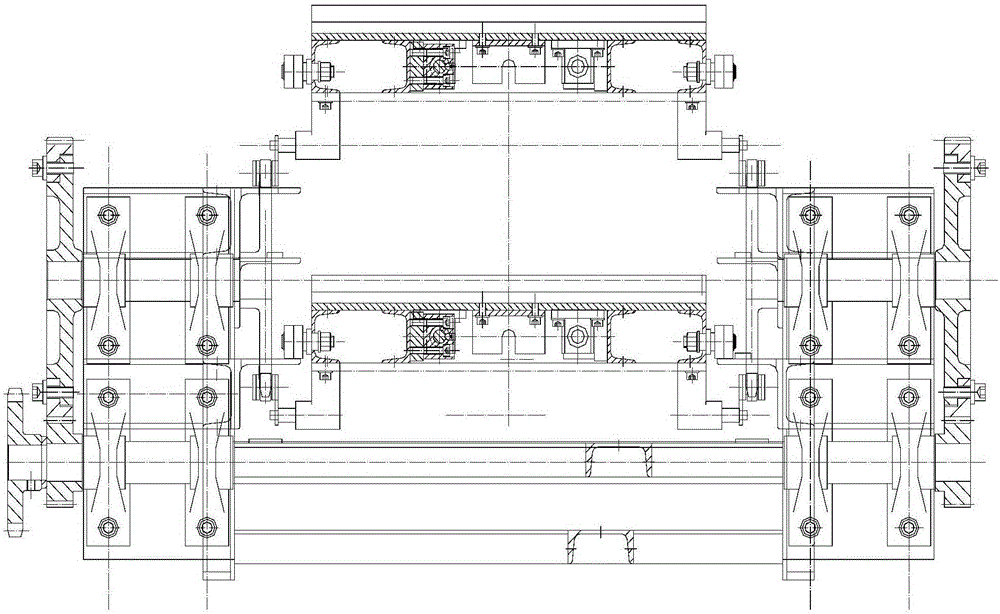

[0049] The number of conveying vehicles is multiple, driven by the same ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com