Circulating material taking and discharging equipment for battery infiltration

A technology for picking and discharging materials and batteries, which is applied to lithium batteries, battery pack components, lighting and heating equipment, etc. It can solve the problems of low production efficiency, high labor intensity of operators, and shorten the soaking time of electrolyte, so as to improve efficiency , The effect of reducing labor intensity and labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below with reference to the embodiments and the accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

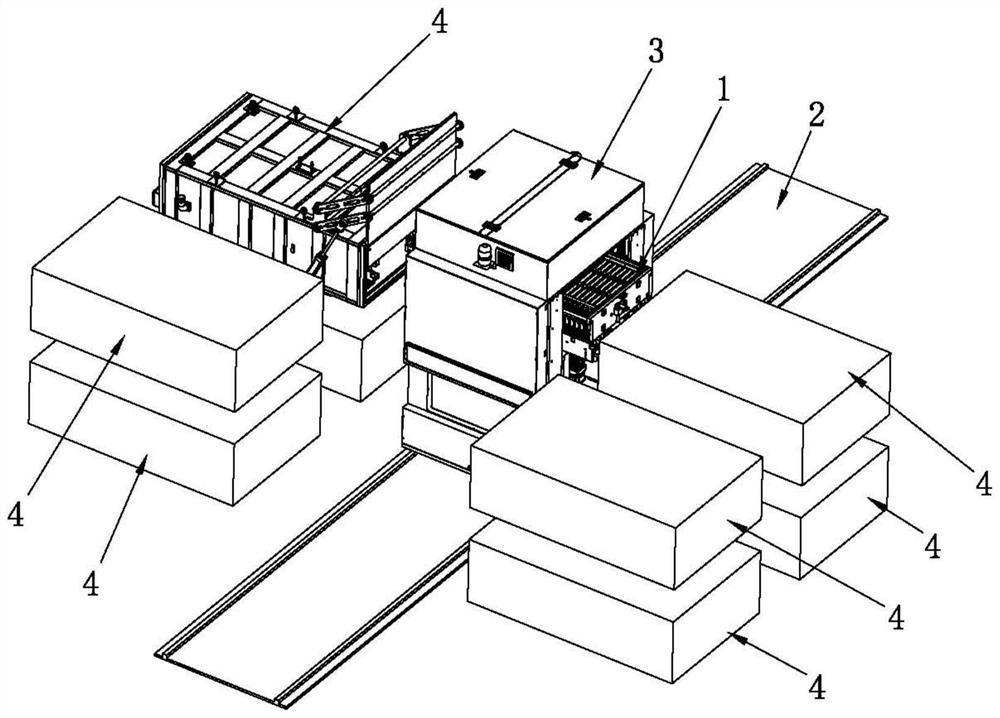

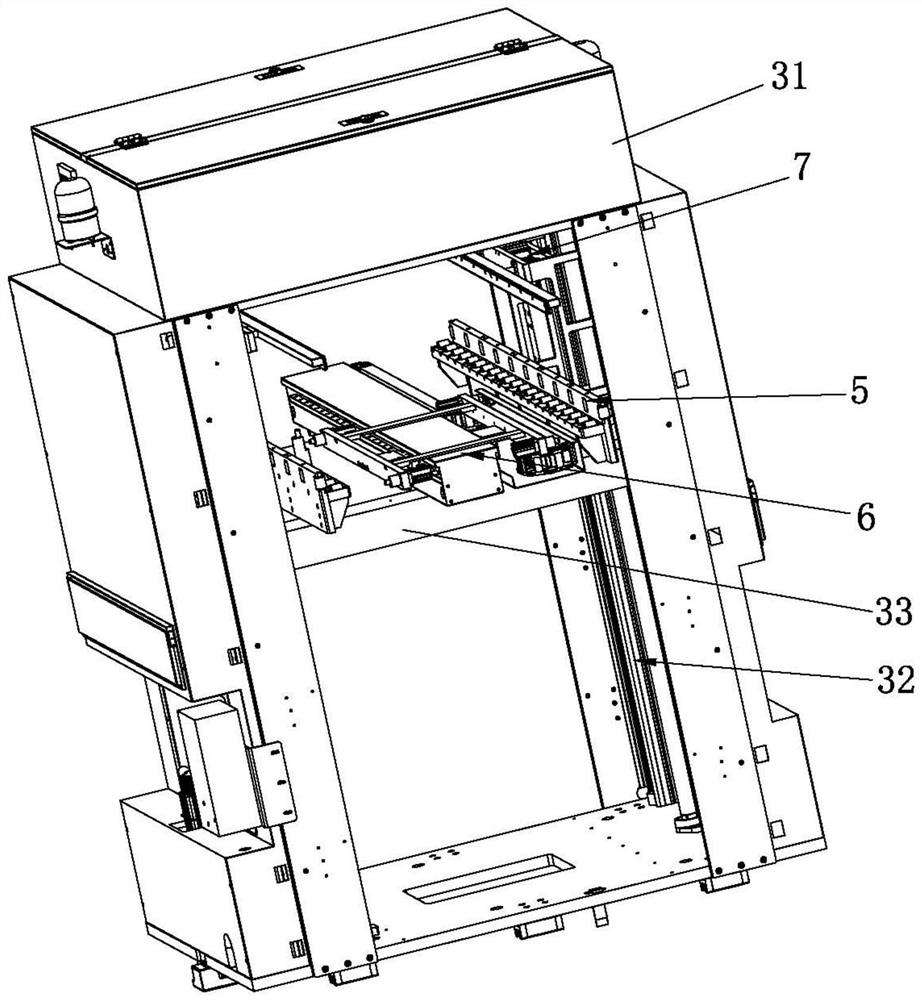

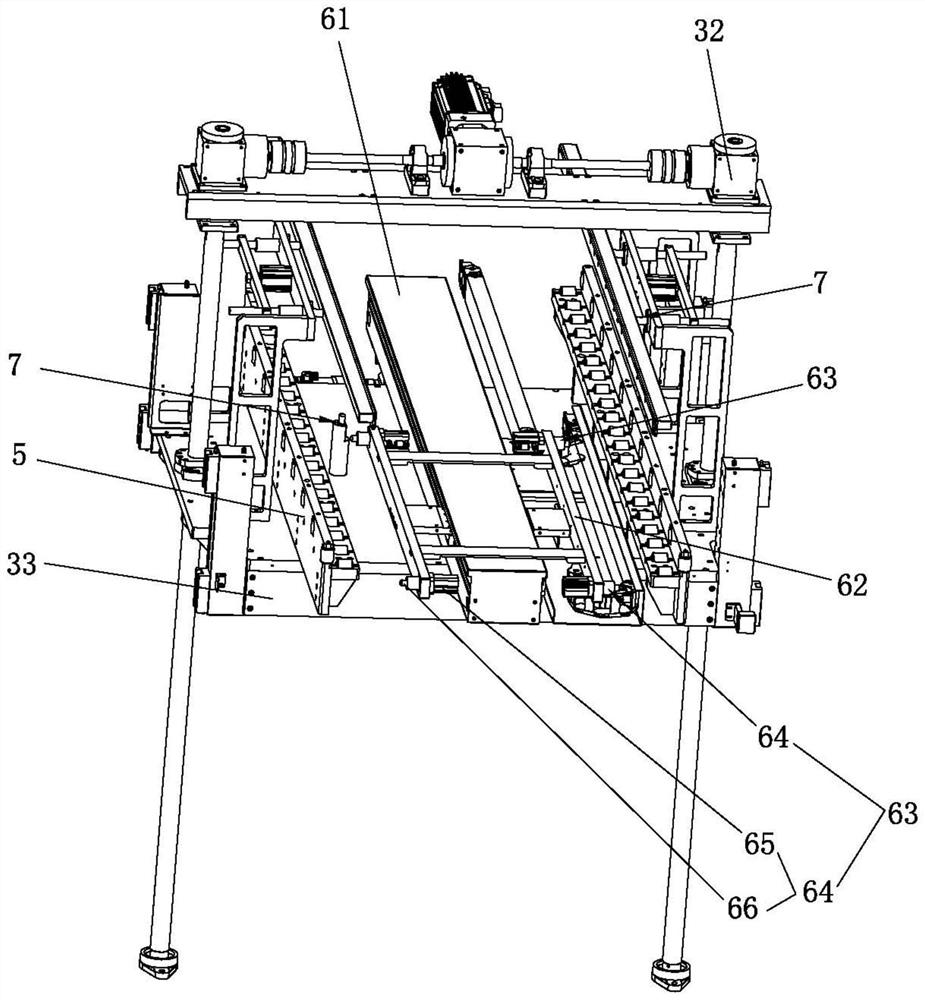

[0026] like Figure 1 to Figure 7 As shown in the figure, the present invention provides a battery infiltration cycle picking and discharging equipment, which includes an infiltration fixture 1, a conveying drive mechanism 2, a conveying vehicle 3 connected to the conveying end of the conveying drive mechanism 2, and a lateral side of the conveying vehicle 3. The external infiltration box 4, the first carrying slide 5 arranged in the conveying car 3, the pick-and-place mechanism 6 telescopically arranged in the conveying car 3, and the infiltration jig 1 arranged in the conveying car 3 and used for positioning the infiltration fixture 1 on the first carrying slide. The first positioning me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com