Soft package power battery production line

A power battery and production line technology, applied in battery assembly, secondary battery manufacturing, final product manufacturing, etc., can solve the problems of unstable quality, consumption of manpower and material resources, and large floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

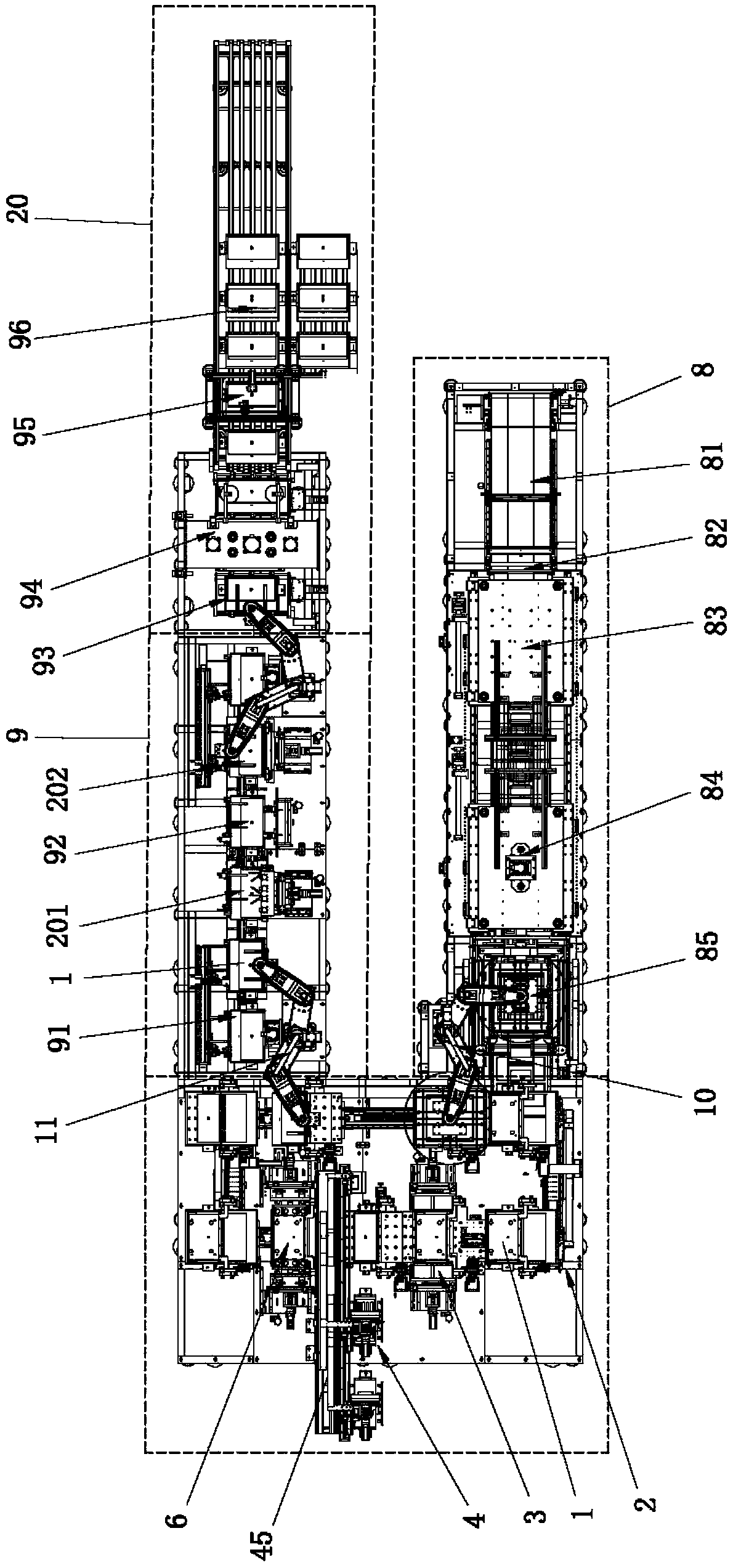

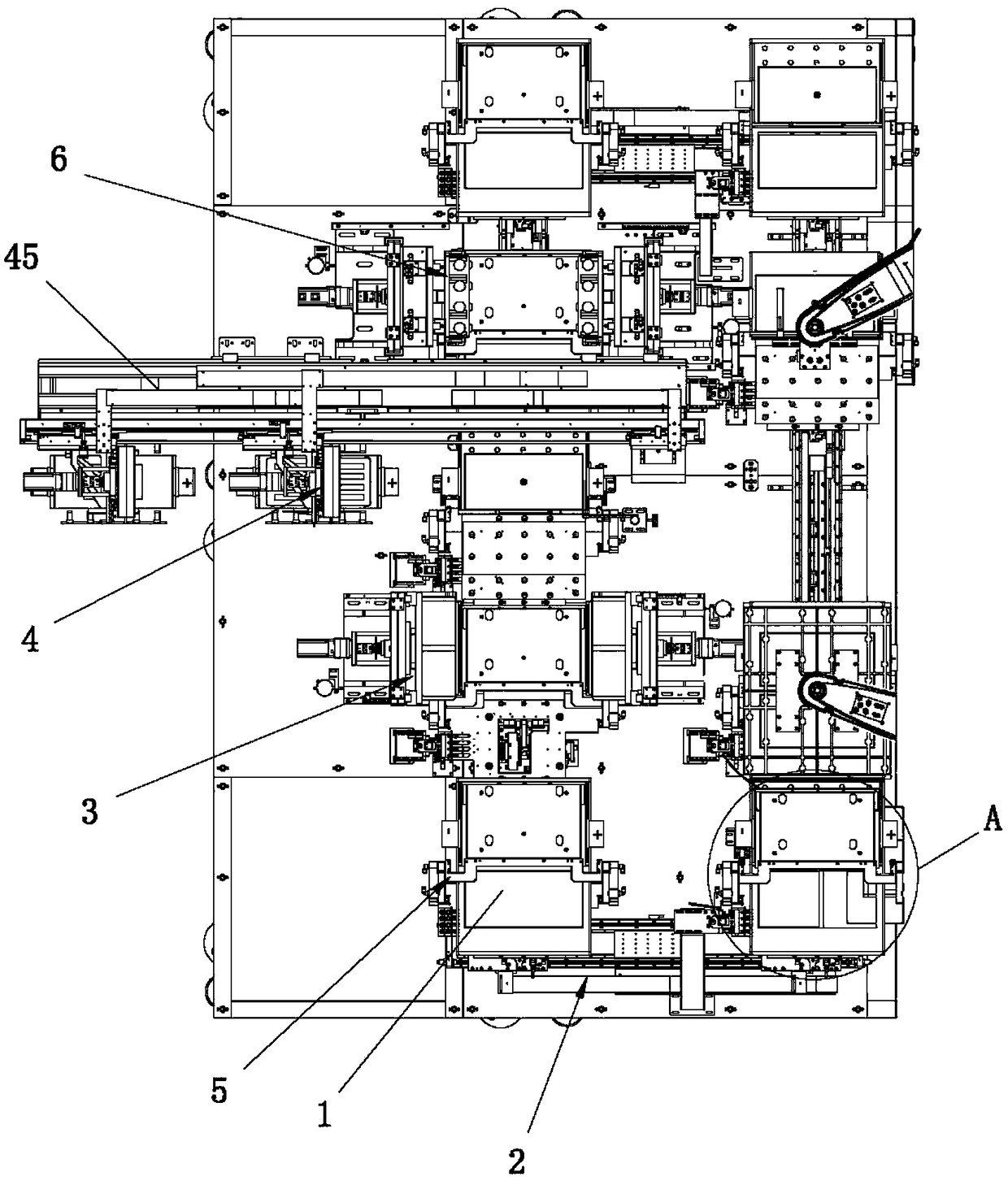

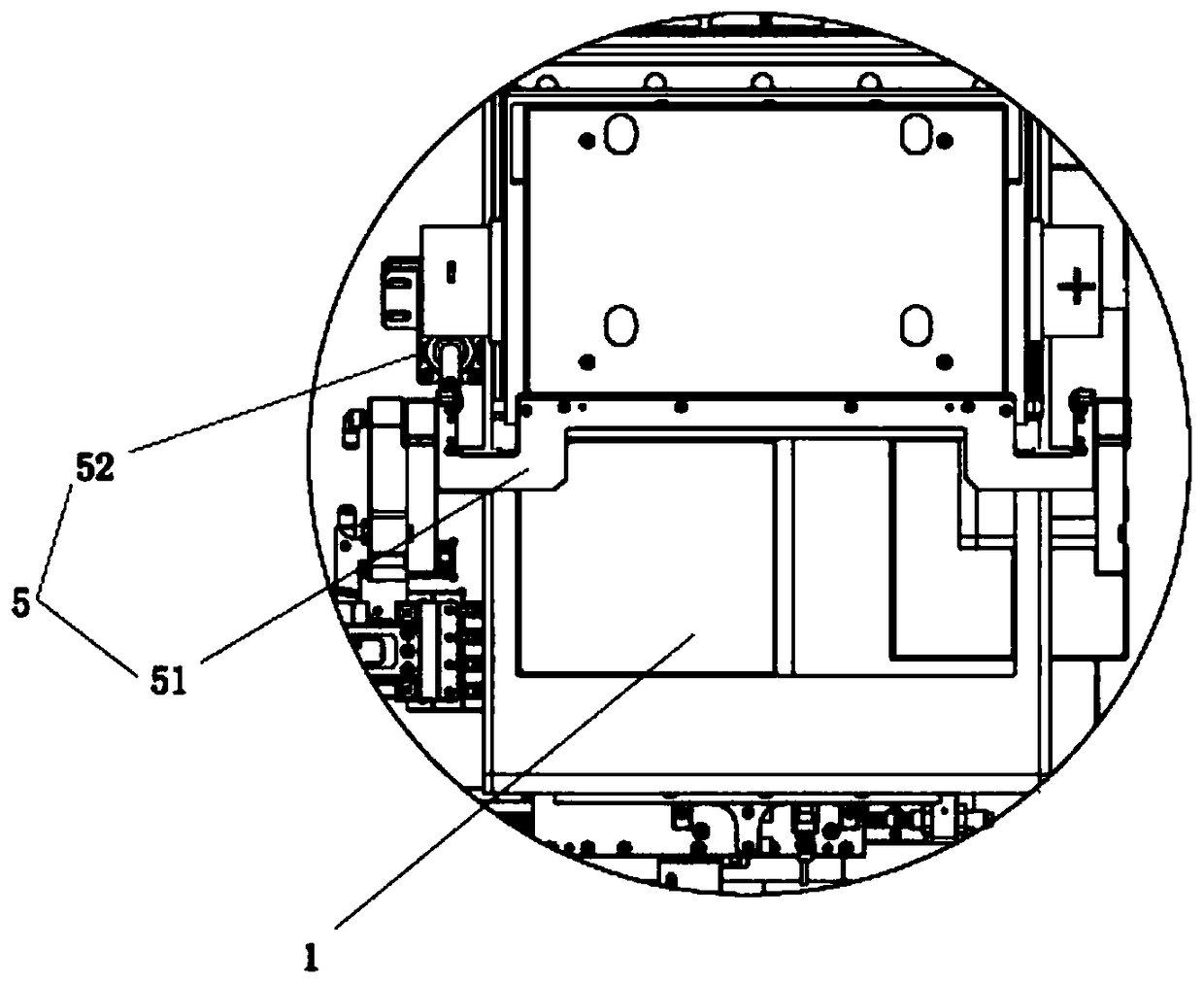

[0053] Such as Figure 1 to Figure 14 As shown, a soft pack power battery production line provided by the present invention includes a battery packaging circulation section for packaging the aluminum-plastic film casing and the battery cell 7, and an aluminum-plastic film connected to the feed end of the battery packaging circulation section. The forming feeding section 8, the battery unloading cycle section 9 connected to the discharge end of the battery packaging cycle section, and the battery unloading test section 20 for performing performance tests on the batteries output by the battery unloading cycle section 9, said The formed aluminum-plastic film case output by the aluminum-plastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com