Closed conveyor

A conveyor and closed technology, which is applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., can solve the problems of inability to realize airtight transportation and the inability to change the direction of transportation, and achieve high cleanliness requirements, strong adhesion, and reduced The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

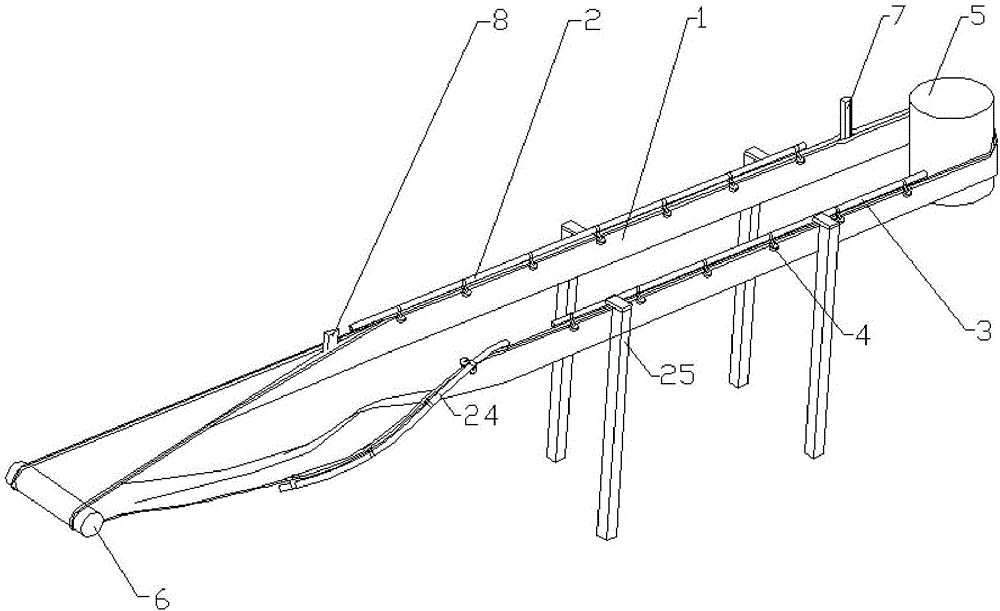

[0041] Specific implementation mode one: combine figure 1 and figure 2Describe this embodiment, a closed conveyor in this embodiment includes a conveyor belt 1, and also includes a left mounting frame 2, a right mounting frame 3, several transmission mechanisms 4, steering wheels 5, discharge rollers 6, and a feeding pipe 7. The left and right mounting frames are arranged in parallel. Several transmission mechanisms are fixedly installed under each mounting frame. Several transmission mechanisms are evenly distributed on the mounting frames where they are located. The steering wheels are located on the left and right mounting frames. The front of the conveyor belt and its axis are vertical, the unloading roller is located behind the left and right mounting frames and its axis is horizontal, the left and right sides of the conveyor belt are rolled up and tightly sealed to form a tubular or cylindrical shape, In order to be able to load the materials to be conveyed, when the p...

specific Embodiment approach 2

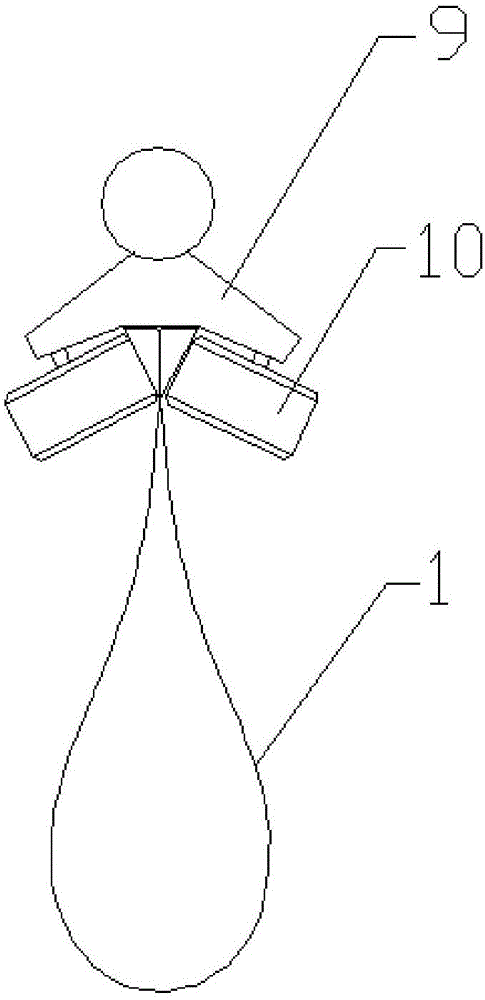

[0044] Specific implementation mode two: combination image 3 and Figure 4 Describe this embodiment, the transmission mechanism of this embodiment includes a connecting frame 9 and two rollers 10, the connecting frame is fixedly connected to the mounting frame where it is located, and the two rollers are installed on the connecting frame, the direction of rotation The same as the conveying direction of the conveyor belt, the installation method of the rollers on the connecting frame can adopt the following method: the two rollers are installed symmetrically on the left and right, and the axes of the two have an included angle and are from top to bottom from outside to inside Inclined, or the two rollers are installed symmetrically up and down, and the axes of the two are horizontal, or the two rollers are installed in a dislocation up and down, wherein the axis of the upper roller is vertical, and the axis of the lower roller is horizontal. There is a gap between the two rol...

specific Embodiment approach 3

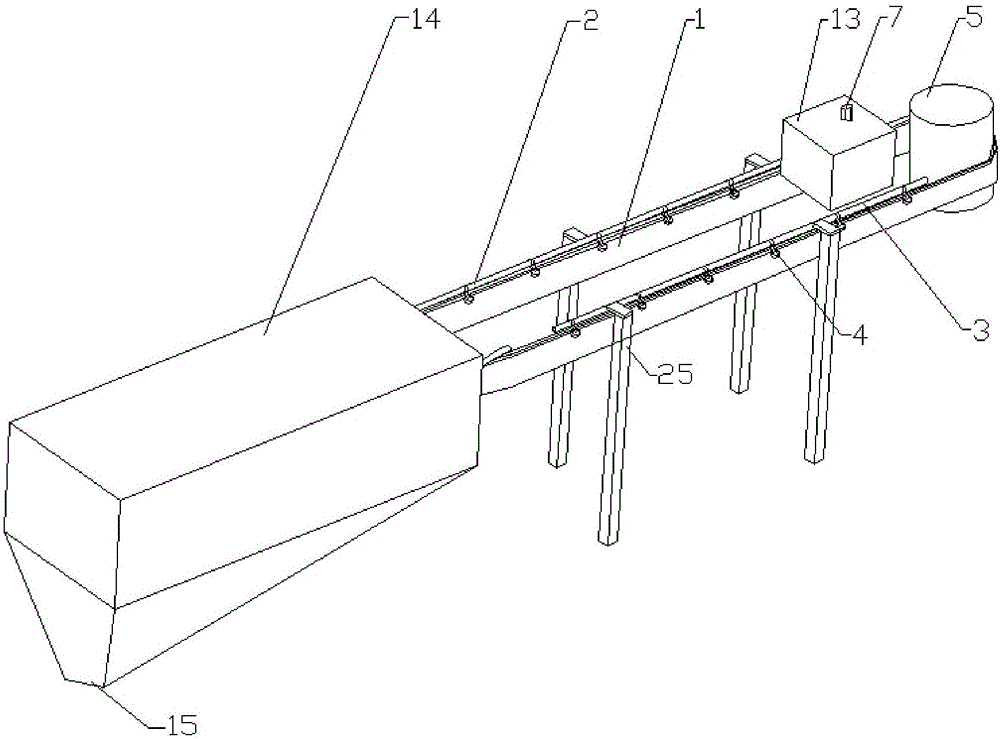

[0046] Specific implementation mode three: combination figure 1 Illustrate this embodiment, present embodiment also comprises feed box 13, the outlet of described feed pipe and the conveyor belt part that communicates with it are positioned at described feed box, described feed box is provided with for described conveyor belt and installation. The through hole through which the frame passes, and the inside of the feed box is in a negative pressure state. Of course, the steering wheel can also be located in the feed box. The setting of the feed box can ensure that when the material is conveyed to the conveyor belt (the connection between the conveyor belt and the feed pipe is in an open state), the material will not escape out of the feed box and cause pollution to the external environment. This embodiment is mainly applicable to materials to be transported that are prone to dust, strong adhesion, toxicity or irritating odor, etc. that are likely to pollute the environment. Ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com