Gearbox gear shaft chamfering and forming device

A molding device, gearbox technology, applied in positioning devices, turning equipment, clamping and other directions, can solve the problems of wasted labor, limited clamping force, insufficient clamping force, etc., to achieve fully automatic processing, realize feeding and unloading materials, the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

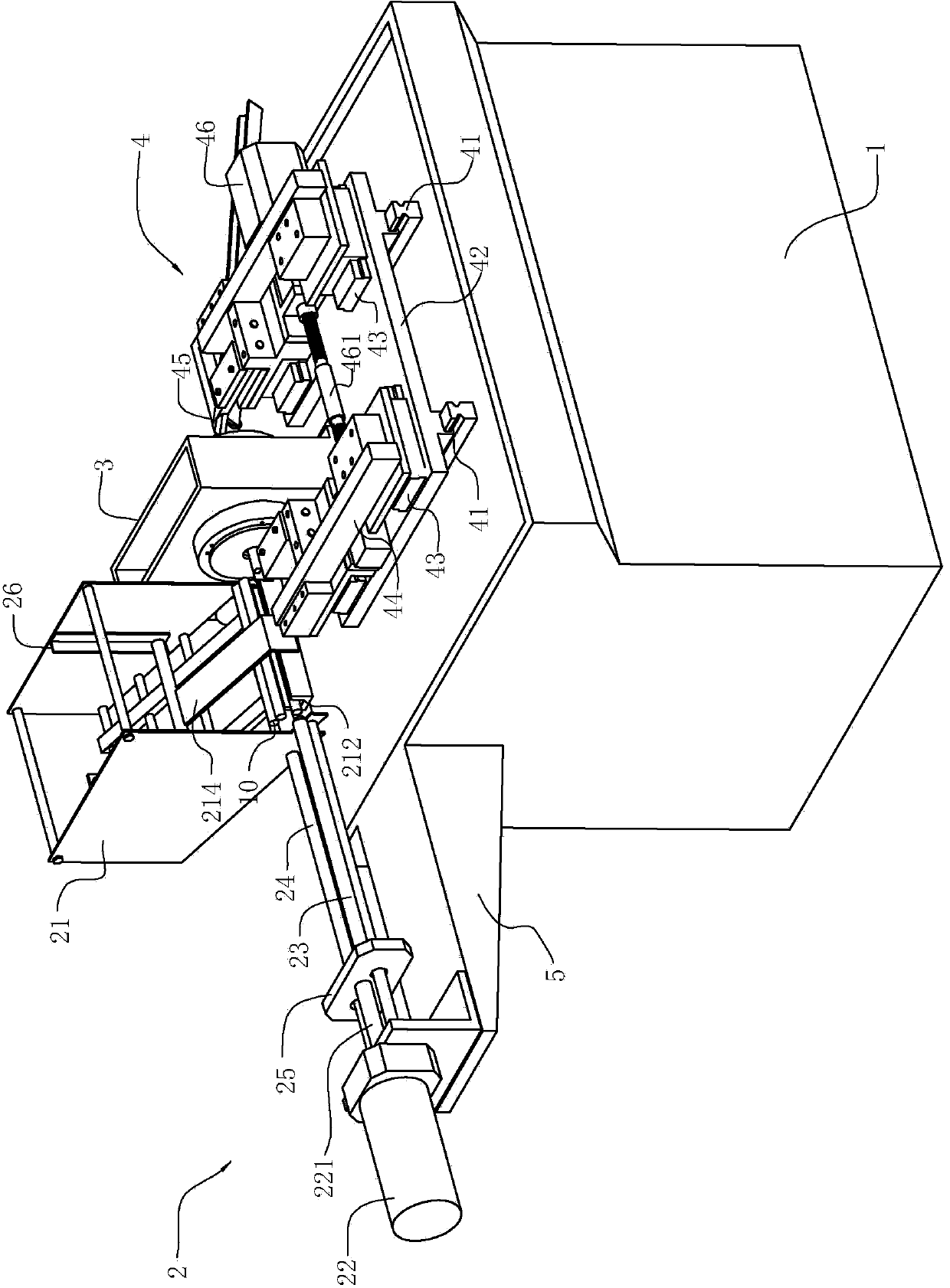

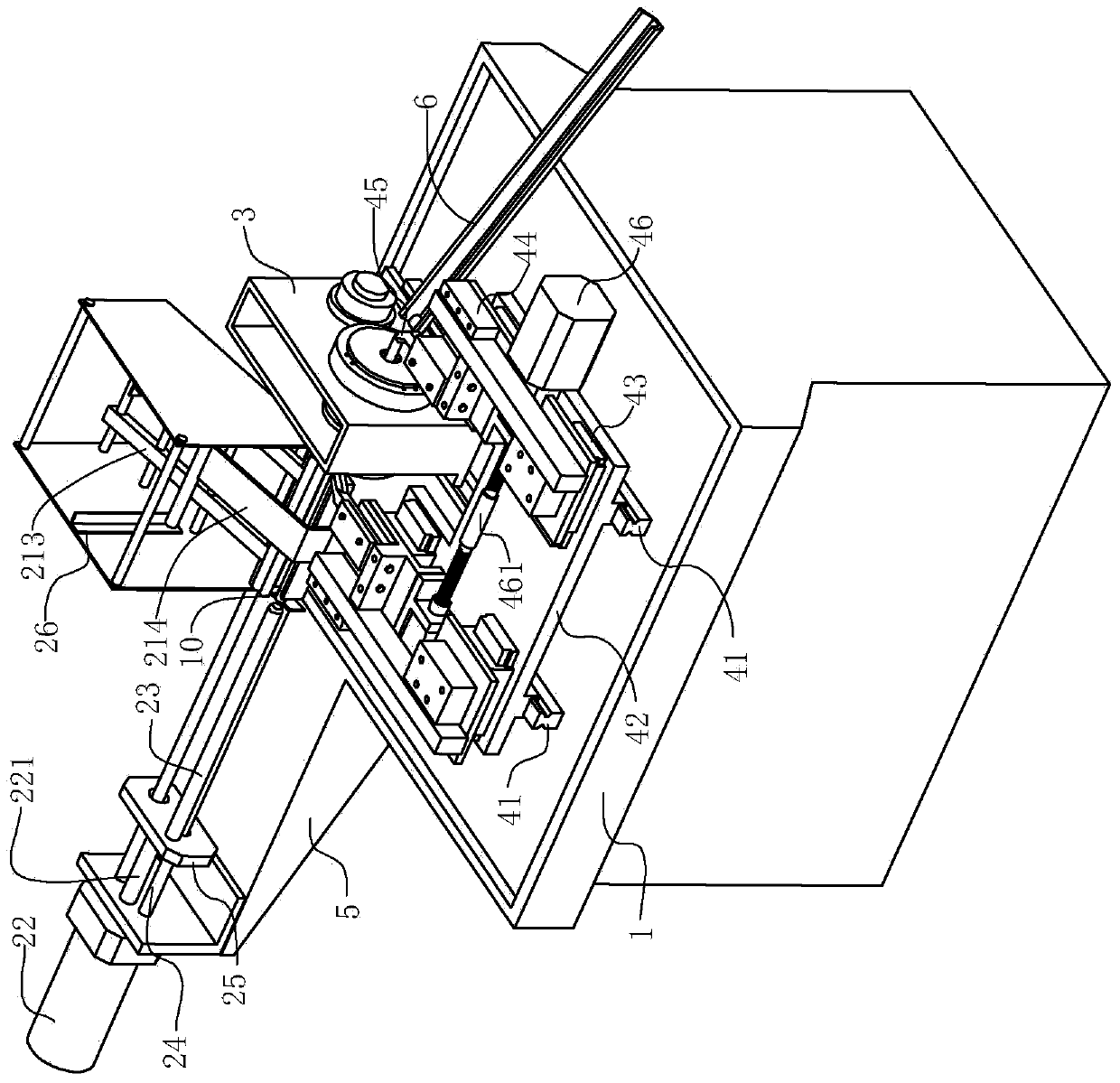

[0029] like Figure 1-2 As shown, the flat-end chamfering forming device of the gearbox gear shaft according to the embodiment of the present invention includes a base 1 , a feeding device 2 and a clamp 3 fixed on the base, and a cutting device 4 located on the base 1 . The feeding device 2 is used for automatic feeding and unloading of the gear shaft 10 , the clamp 3 clamps the gear shaft 10 to be processed, and drives the gear shaft 10 to rotate during cutting, and cooperates with the cutting device 4 to process the end face of the gear shaft 10 the chamfer.

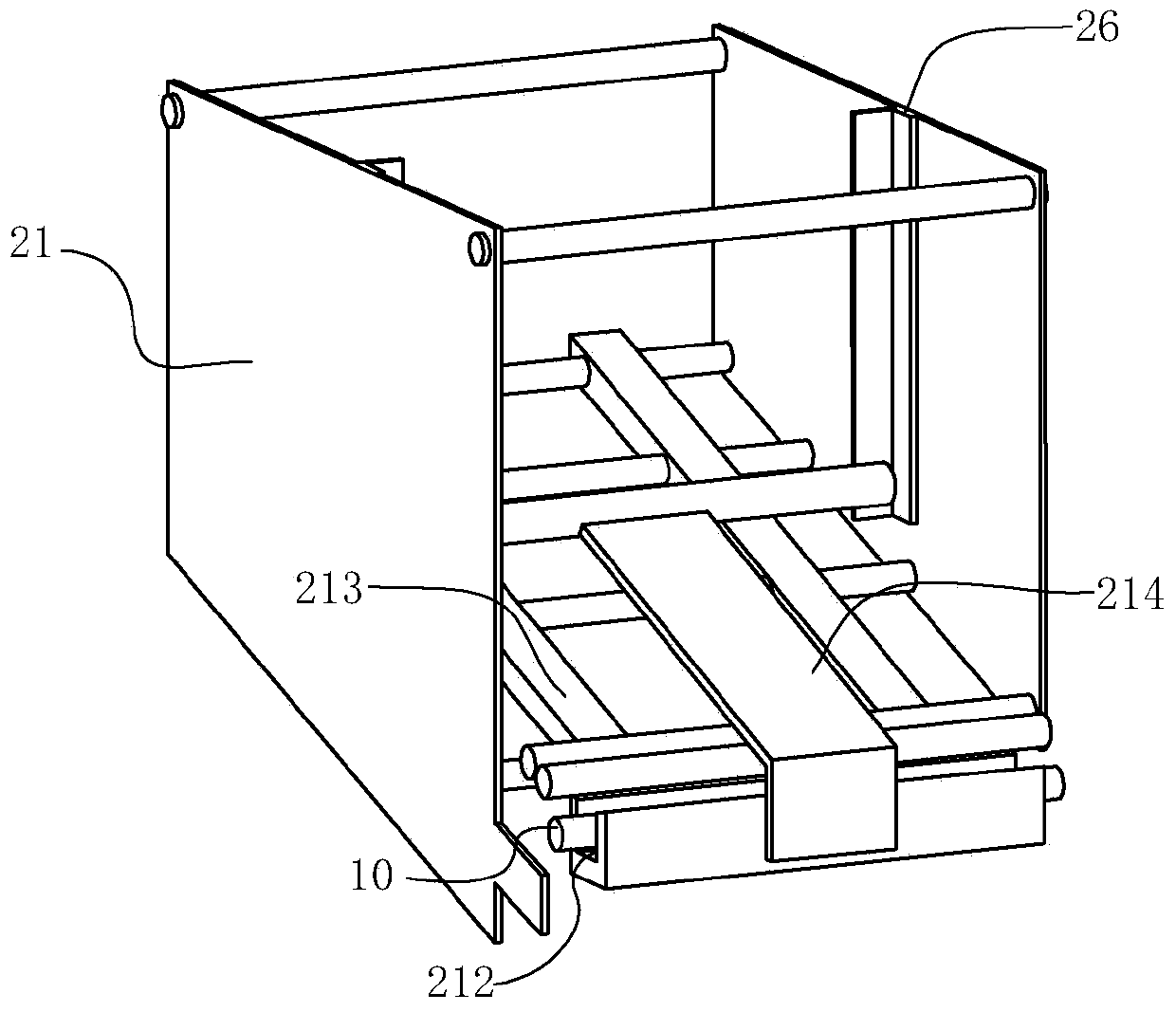

[0030] like Figure 1-4 As shown, the feeding device 2 includes a feeding hopper 21, and a horizontal driving device 22 located on one side of the bottom of the feeding hopper 21. The bottom of the feeding hopper 21 has a discharging port, which is aligned with the The jig 3 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com