Automatic continuous drying system for large ocean-going fishing vessels

A drying system and ocean-going technology, applied in the field of automatic continuous drying systems for large-scale ocean-going fishing vessels, can solve the problems of increasing the transportation burden, occupying the volume of the vessel, and unfavorable for the preservation of fishing goods, and achieves instant processing, uniform and continuous cycle drying processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

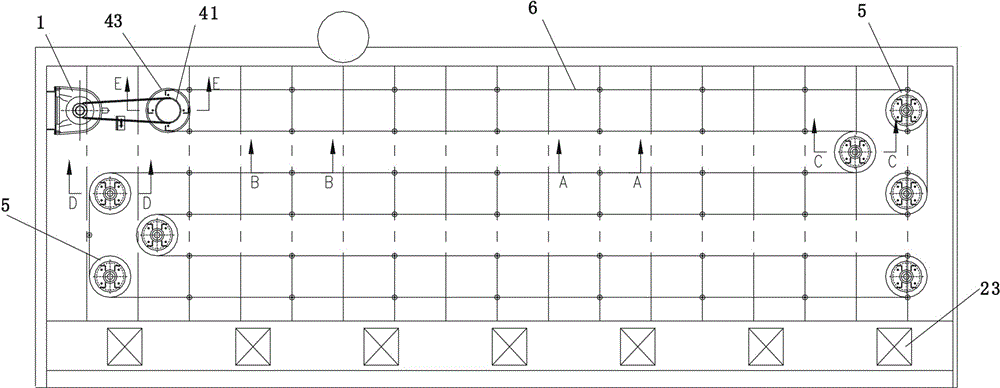

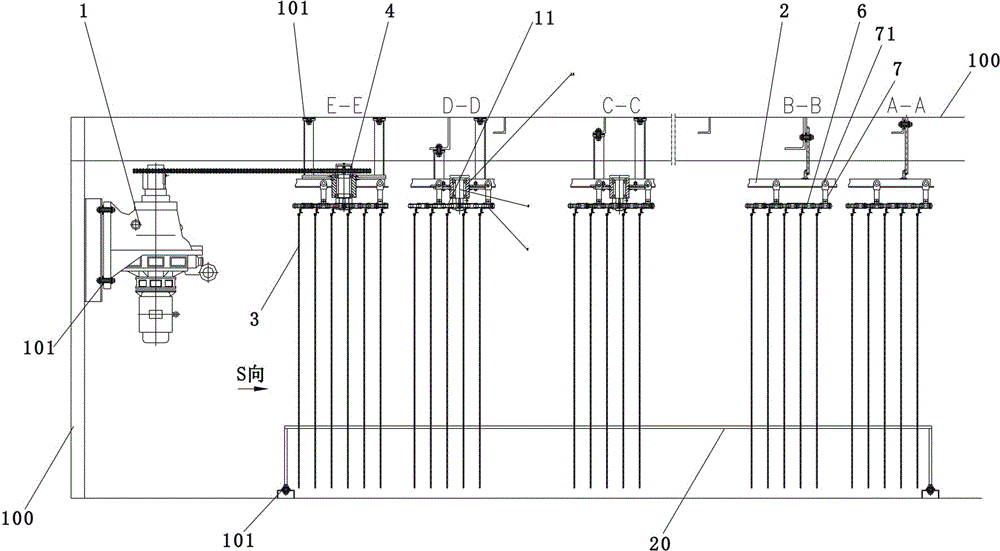

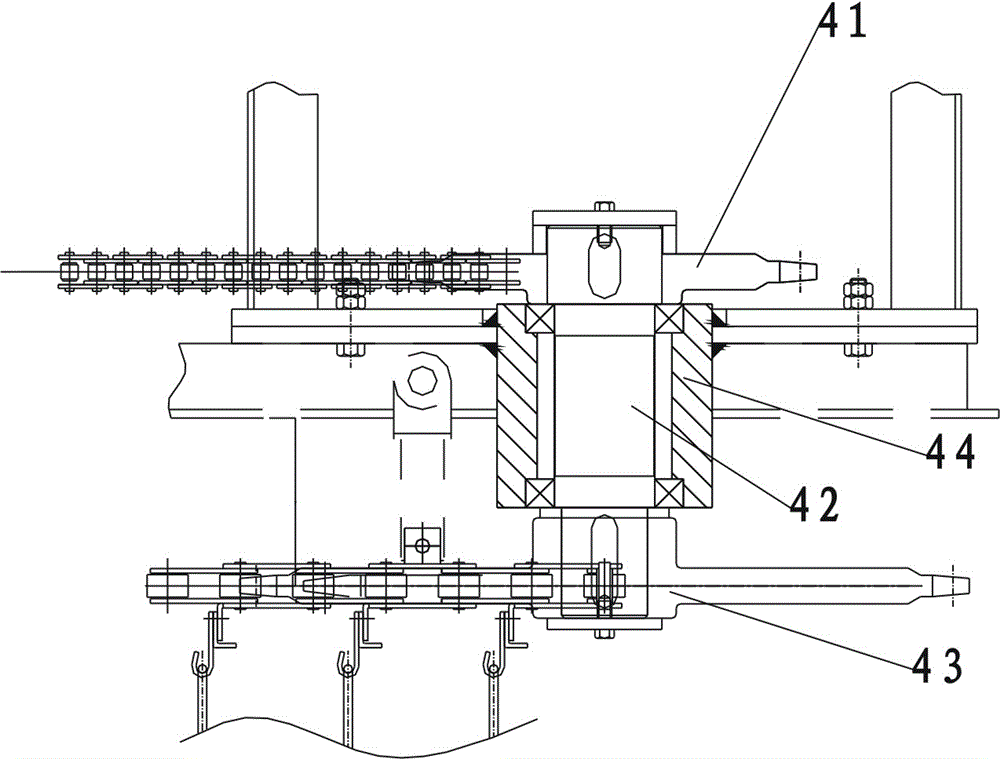

[0023] Below in conjunction with specific embodiment and accompanying drawing ( Figures 1 to 7 ), further elaborating the essence of the present invention.

[0024] An automatic continuous drying system for large ocean-going fishing boats involved in the present invention includes a fixed warehouse 100, a driver 1, a sprocket, a track 2, and a mesh plate 3. The driver 1 is fixedly connected to the fixed warehouse 100, and the track 2 is connected to the fixed warehouse 100 The fixed warehouse 100 is fixedly connected, and the sprocket is connected to the driver 1 in transmission. The sprocket includes the first driving wheel 4 and the supporting wheel 5. The first driving wheel 4 and the supporting wheel 5 are in different positions according to the spatial layout. Set the required number, the first driving wheel 4 and the supporting wheel 5 are connected through the chain belt 6, and the first driving wheel 4 and the supporting wheel 5 are fixedly connected with the fixed wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com