Product transport apparatus

A technology for conveying equipment and products, applied in conveyors, vibrating conveyors, transportation and packaging, etc., can solve the problems of high manufacturing cost of product conveying equipment, increase the number of vibration applying mechanisms, etc., and achieve low product conveying equipment and realization cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

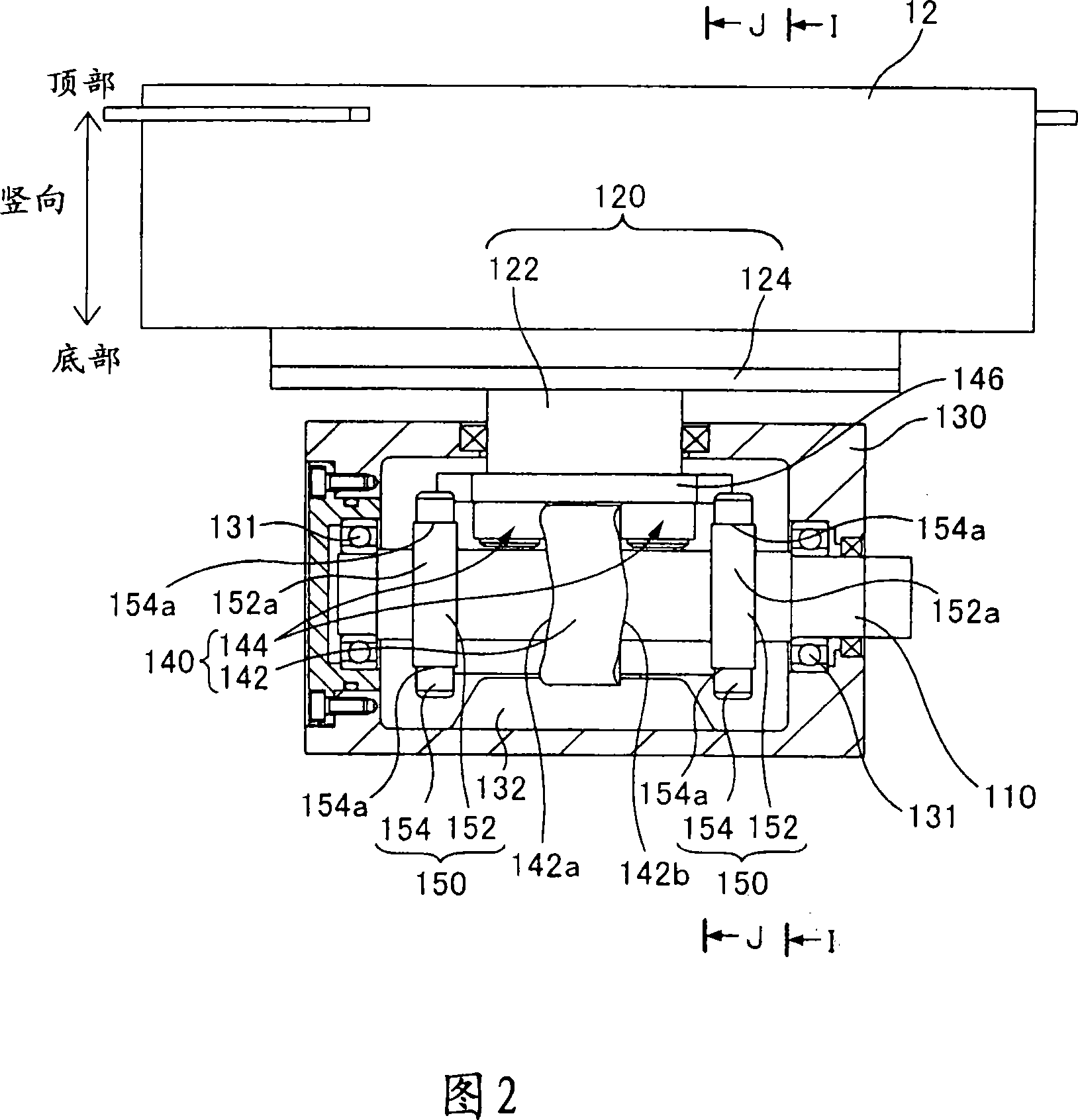

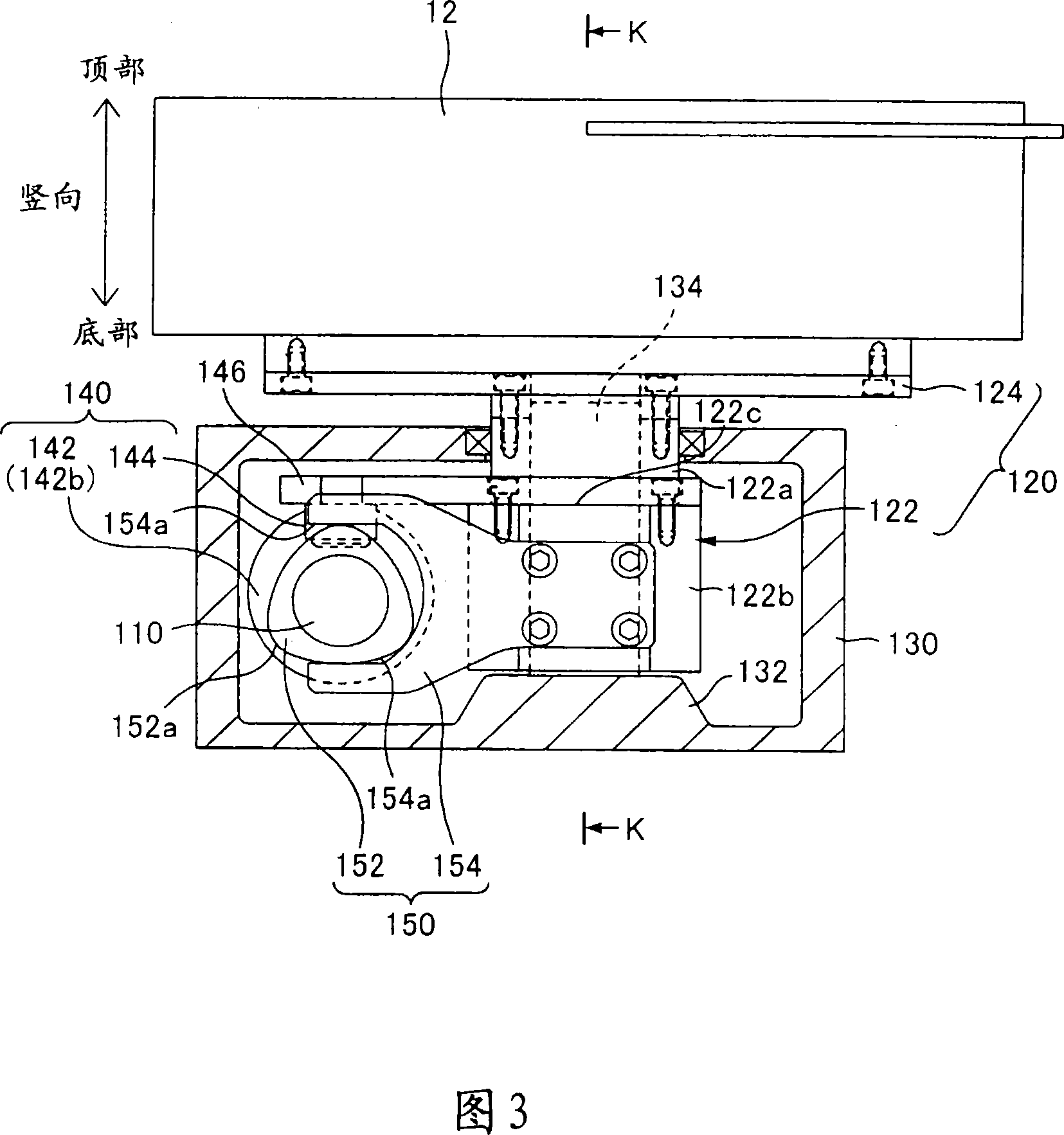

[0135] (1) Construction example of product conveying equipment

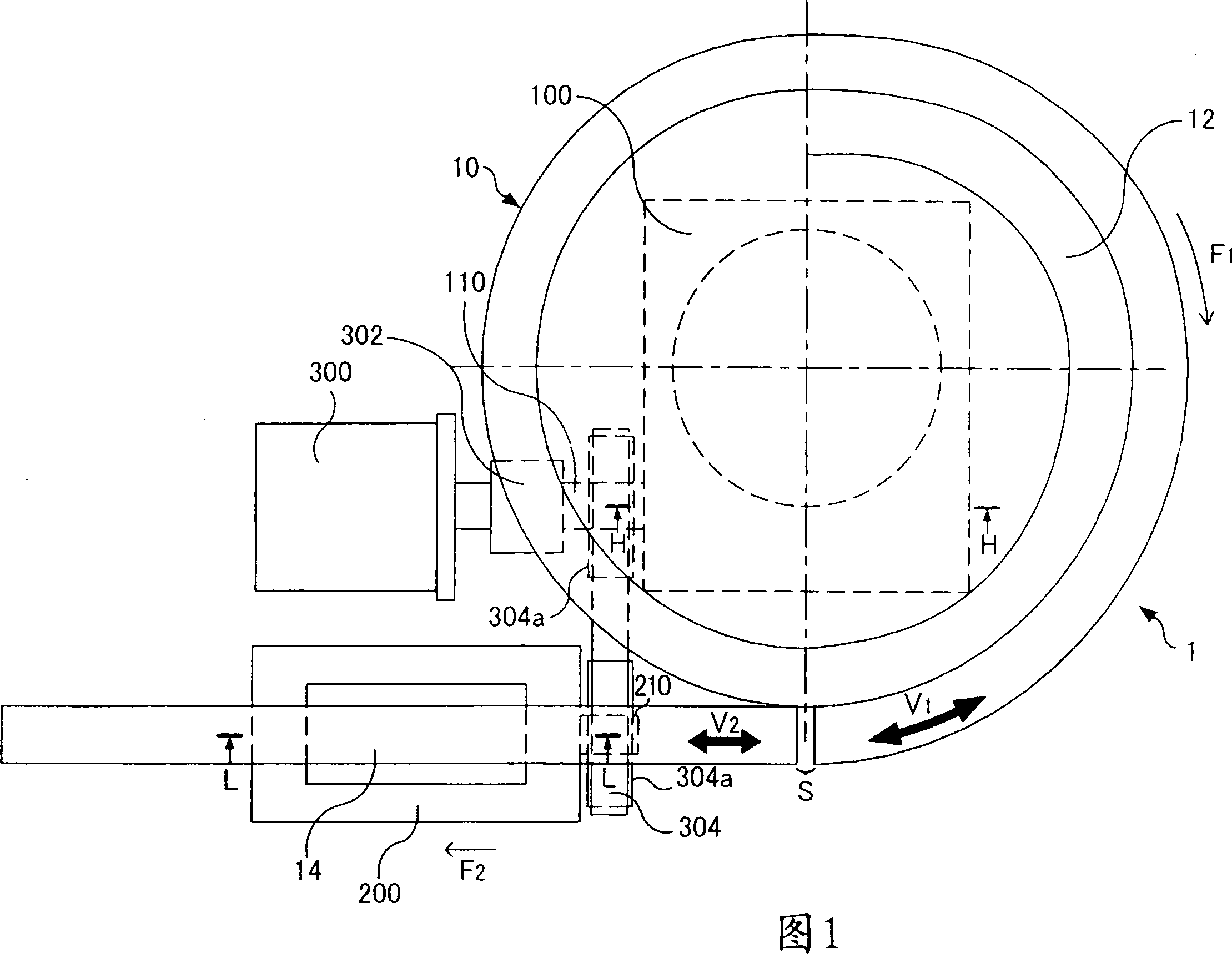

[0136] First, an example of the configuration of the product delivery device 1 according to the present embodiment is explained with reference to FIG. 1 . FIG. 1 is a schematic top view of the product conveying device 1 .

[0137] As shown in FIG. 1 , the product conveyance apparatus 1 includes: a conveyance part 10 ; a rotary feeder 100 ; a linear feeder 200 ; and a drive motor 300 serving as a single drive source. The rotary feeder 100 and the linear feeder 200 are examples of a vibration applying unit. That is, the product conveyance apparatus 1 is arranged with a plurality of (two in this embodiment) vibration applying sections. In this product conveying apparatus 1, the products W placed on the conveying portion 10 (more specifically, the conveying surface located at the upper end of the conveying portion 10) are conveyed in a state that they are in a predetermined conveying direction (arrow in FIG. 1 The...

no. 3 example

[0331] (3) Construction example of product conveying equipment

[0332] First, the product delivery device 2001 according to the present embodiment will be explained in general with reference to FIG. 29 . Accompanying drawing 29 is the schematic diagram of the product delivery device 2001 of this embodiment, schematically shows the top view (upper view) and the side view (lower view) of the product delivery device 2001 in the figure. In the lower view in Figure 29, the arrows indicate the vertical direction.

[0333] The product conveying device 2001 of this embodiment includes an elliptical conveying path (also referred to as an "elliptical track") as shown in FIG. 29 , which is a device for conveying products along the elliptical track. The elliptical circular path is formed by a plurality of delivery platforms (more specifically, a first delivery platform 2012 , a second delivery platform 2014 , a third delivery platform 2016 and a fourth delivery platform 2018 which will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com