Method for extracting metallic lead from alkaline leaching solution of waste lead-containing glass

A technology for extracting metal and leaching solution, applied in the field of extracting metal lead and producing metal lead, can solve the problems of difficult direct leaching of alkaline solution, high consumption of cleaning water, difficult cleaning, etc. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

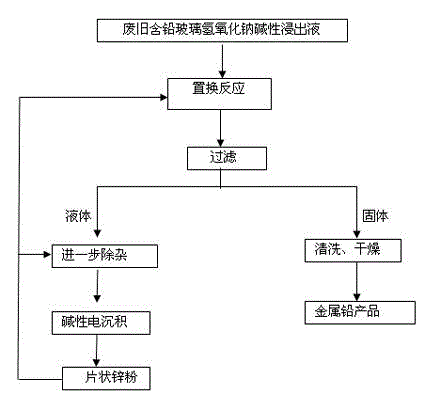

Image

Examples

Embodiment 1

[0020] The sodium hydroxide alkaline leaching solution of waste cathode ray tube (CRT) cone glass is used as raw material, and its lead concentration is 18.5g / L. Add 500ml of the above leaching solution into a beaker and heat to 70°C, add 2.8g of electrodeposited flake metal zinc powder and 2mg of fatty alcohol phosphate (Jiangsu Haian Petrochemical Factory) while stirring, and the stirring speed is 300 r / min , reacted for 90 min. After the replacement reaction is completed, filter, wash and dry the solid to obtain metallic lead products, and the direct recovery rate of lead is greater than 90%. Then add 0.3g metallic zinc powder to the liquid to remove the remaining lead impurities, and then electrodeposit to obtain flake metallic zinc powder. Electrodeposition After completion of filtration, the solution returns to leach the lead-containing glass, and the metal zinc powder returns to the replacement reaction.

Embodiment 2

[0022] The sodium hydroxide alkaline leaching solution of waste crystal glass is used as raw material, and its lead concentration is 16.7g / L. Add 500ml of the above leaching solution into a beaker and heat it to 80°C. While stirring, add 2.45g of flake metal zinc powder obtained by electrodeposition, 1mg of fatty alcohol ether phosphate (Jiangsu Haian Petrochemical Factory) and 1mg of dodecylsulfuric acid Sodium (Sinopharm Group Chemical Reagent Co., Ltd.), the stirring speed is 400 r / min, and the reaction is 60 min. After the replacement reaction is completed, filter, wash and dry the solid to obtain metallic lead products, and the direct recovery rate of lead is greater than 90%. Add 0.5g metallic zinc powder to the liquid to remove the remaining lead impurities, and then electrodeposit to obtain flake metallic zinc powder. Electrodeposition After completion of filtration, the solution returns to leach the lead-containing glass, and the metal zinc powder returns to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com