An air-cooled and water-cooled electronic radiator

A radiator and cold water technology, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve the problems of inconvenient disassembly and replacement, reduce the installation diameter of fans, and affect the heat dissipation efficiency, etc., so as to prevent Dislocation or bending deformation, improving air circulation performance, and meeting heat dissipation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

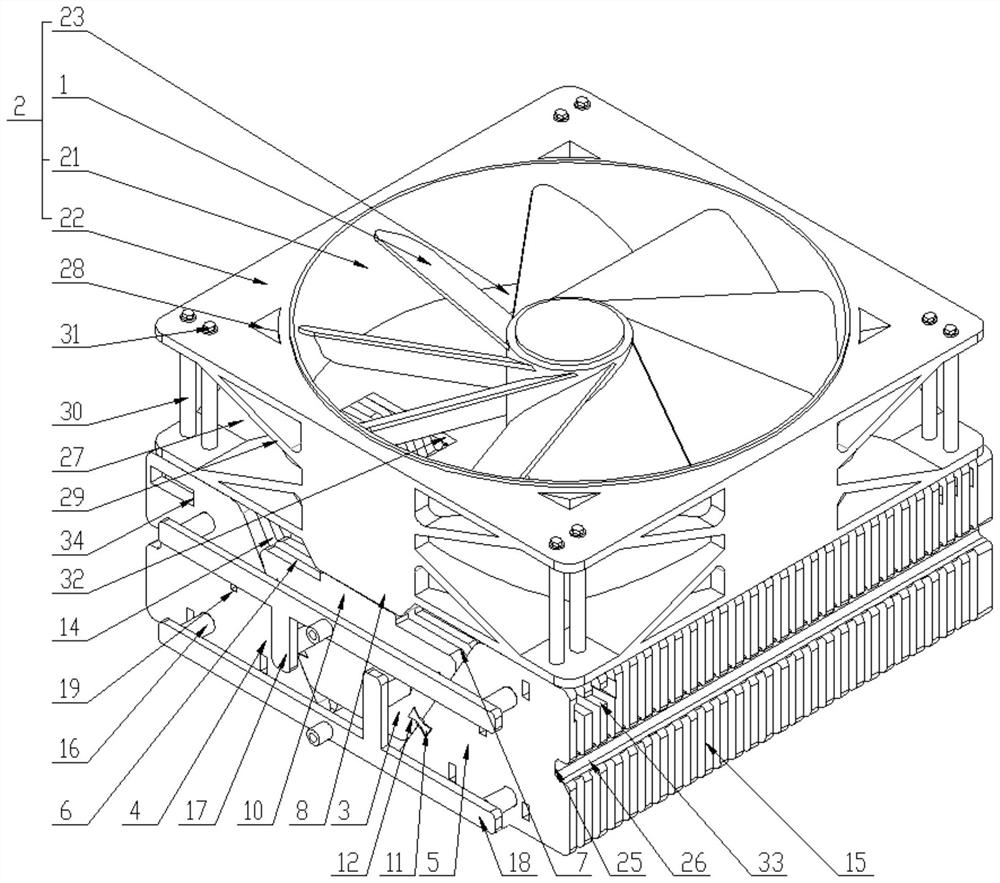

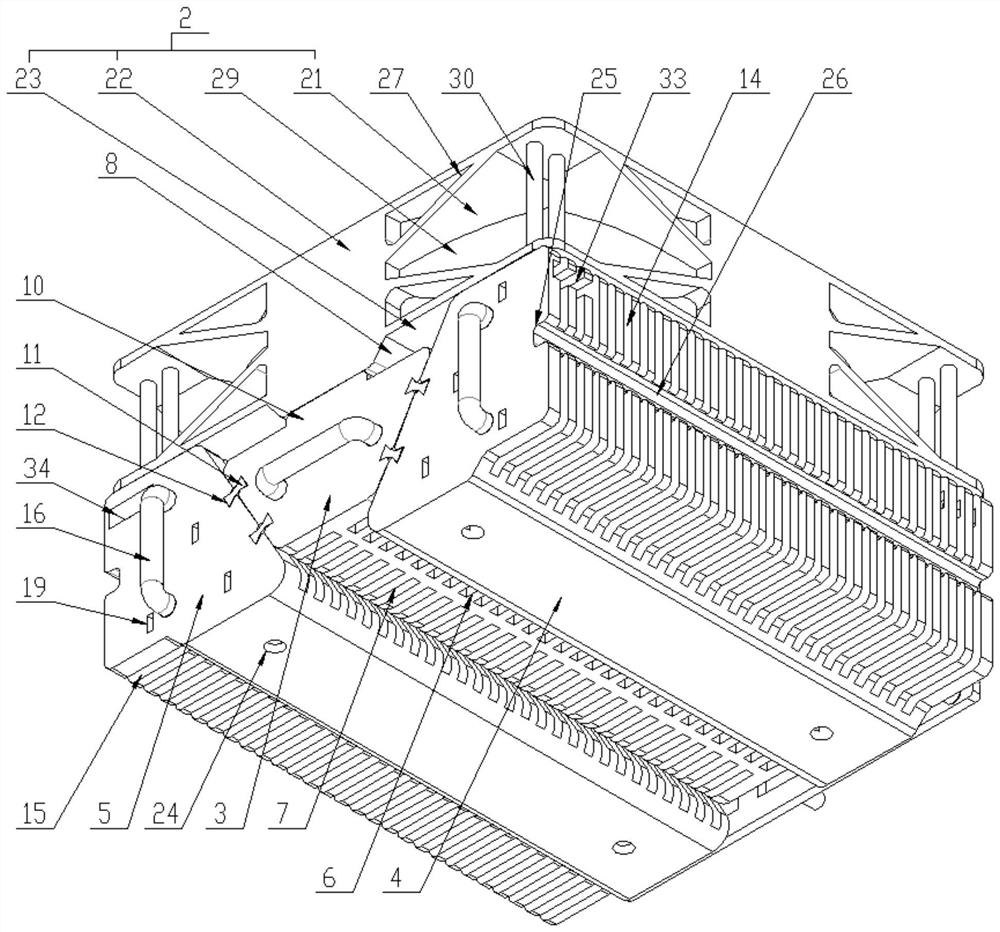

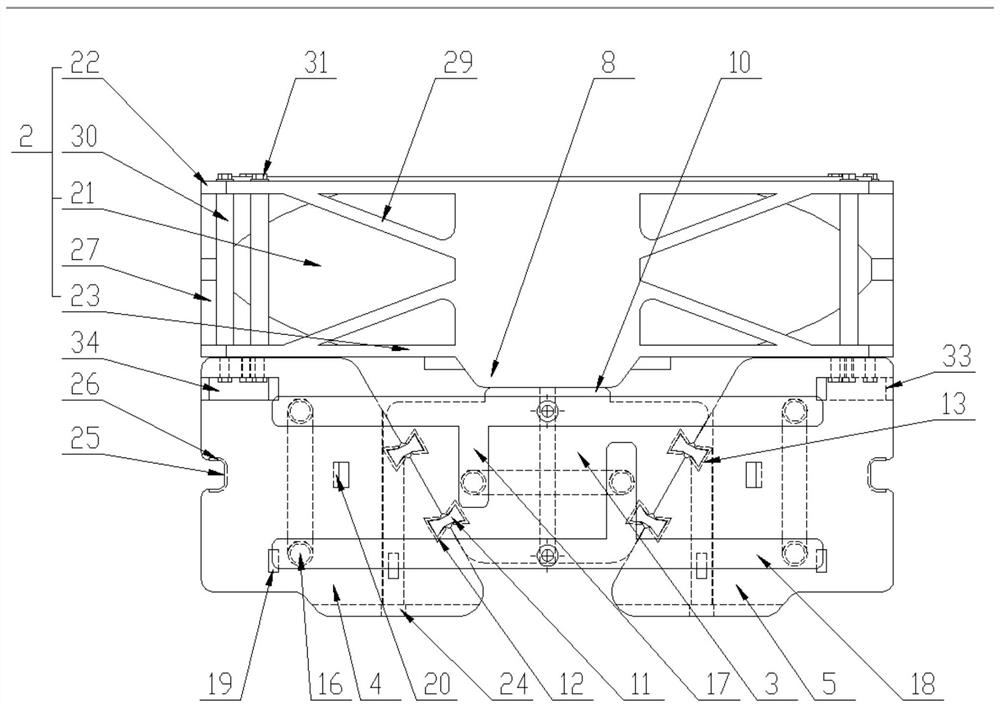

[0028] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

[0029] An electronic radiator combining air and cold water cooling, comprising a fan 1 and a wind cover 2 located outside the fan 1, wherein the bottom of the wind cover 2 is provided with a first heat sink 3 with an isosceles trapezoid structure, and a A second radiator 4 and a third radiator 5 having a right-angled trapezoid structure on both sides of the radiator 3, and a plurality of first notches 6 and second notches arranged at intervals on both sides of the first radiator 3 7;

[0030] A first boss 8 is provided at the bottom of the wind hood 2 , a wire hole 9 is provided on the top of the side of the first boss 8 , and a second boss that is gap-fitted with the first boss 8 is provided on the top of the first heat sink 3 . Table 10, a plurality of first recesses 6 and second recesses 7 extend to the top of the first boss 8;

[0031] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com