Air-cooling and water-cooling combined electronic radiator

A radiator and cold water technology, applied in cooling/ventilation/heating renovation, electrical components, electrical equipment structural parts, etc., can solve the problems of inconvenient disassembly and installation, reduction of fan installation diameter, slow heat transfer of profiles, etc. Prevent dislocation or bending deformation, improve air circulation performance, and increase the effect of contact heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

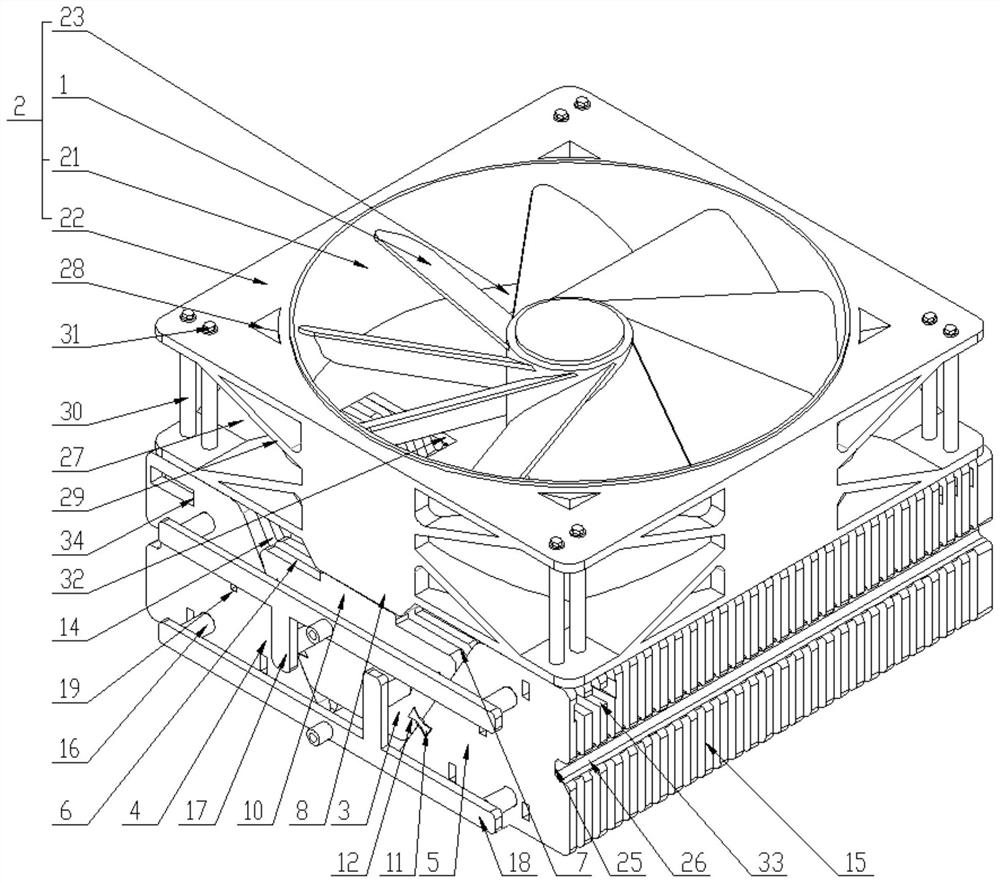

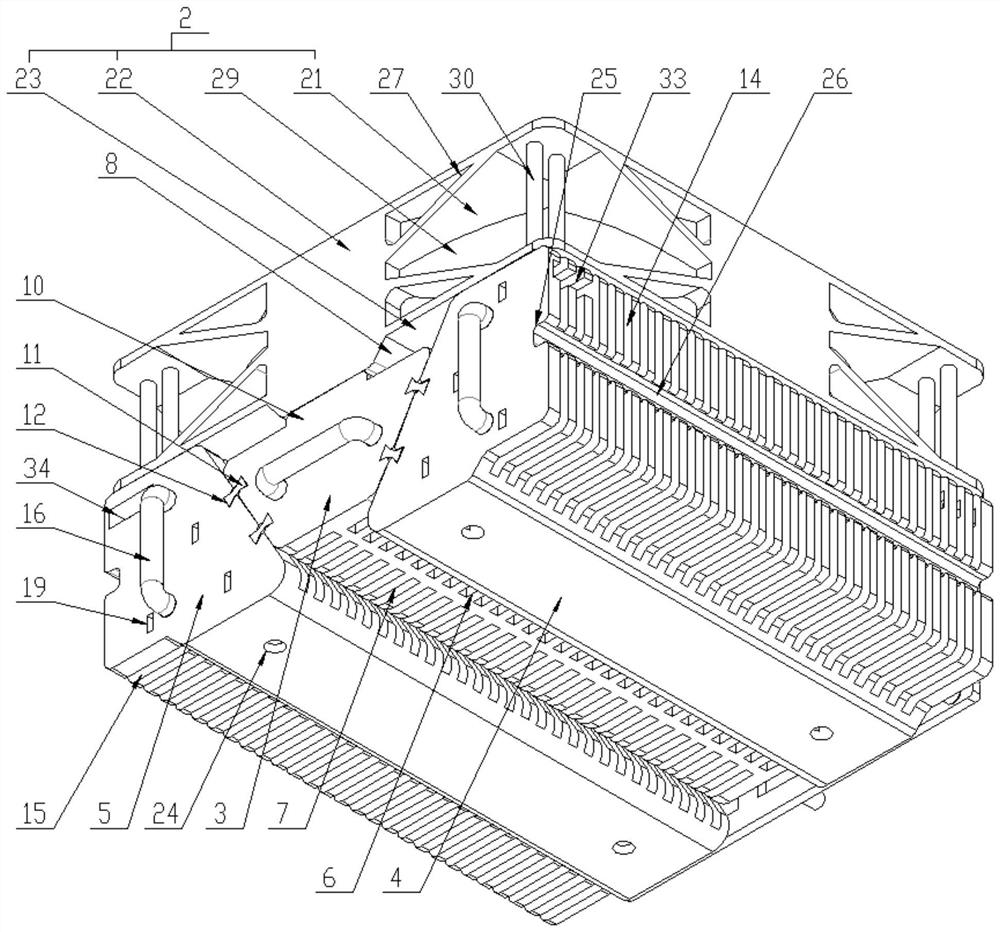

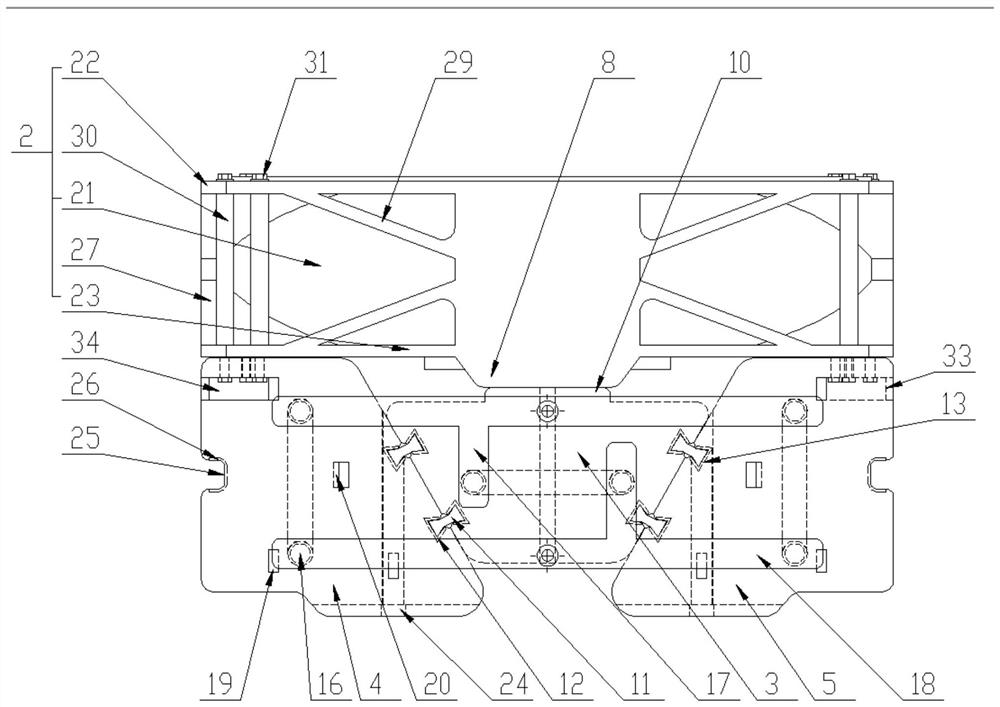

[0029] An air-cooled and water-cooled electronic radiator includes a fan 1 and a windshield 2 located outside the fan 1, wherein the bottom of the windshield 2 is provided with a first radiator 3 with an isosceles trapezoidal structure in cross section, and a first radiator 3 located at the second A second heat sink 4 and a third heat sink 5 on both sides of the heat sink 3 with a cross-section in a right-angled trapezoidal structure, and a plurality of first notches 6 and second notches arranged at intervals on both sides of the first heat sink 3 7;

[0030] The bottom of the windshield 2 is provided with a first boss 8, the top of the side of the first boss 8 is provided with a wire hole 9, and the top of the first heat sink 3 is provided with a second boss that fits in a gap with the first boss 8. platform 10, a plurality of first notche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com