Automatic sampling needle cleaning device and method

A technology for automatic cleaning and sampling needles, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of difficult cleaning of samples and inaccurate test results of instruments, and achieve stable automatic cleaning devices and prevent The effect of inaccurate instrument test results and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

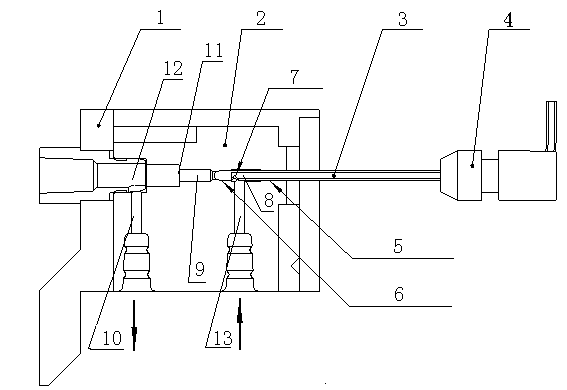

[0031] Such as figure 1 with figure 2 As shown, the sampling needle cleaning device of the present invention includes: a sampling needle 3 and a mouthpiece 2, the mouthpiece 2 is provided with a sampling needle movement channel, and the sampling needle movement passage is sequentially provided with a first sealing node 5, The first cavity 8, the second sealing node 6, the second cavity 9, the capillary sampling tube sealing node 11 and the mouthpiece housing 1 are connected to the sealing node 12, and the first cavity 8 is provided with a The cavity 8 communicates with a liquid inlet channel 13 , and the mouthpiece housing 1 is connected with a sealing node 12 to be provided with a liquid outlet channel 10 communicated with the sampling needle movement channel.

[0032] The cleaning device also includes a moving structure 4 fixed to the sampling needle 3 for pushing the sampling needle 3 .

[0033] The movement channel of the sampling needle is set horizontally.

[0034] T...

Embodiment 2

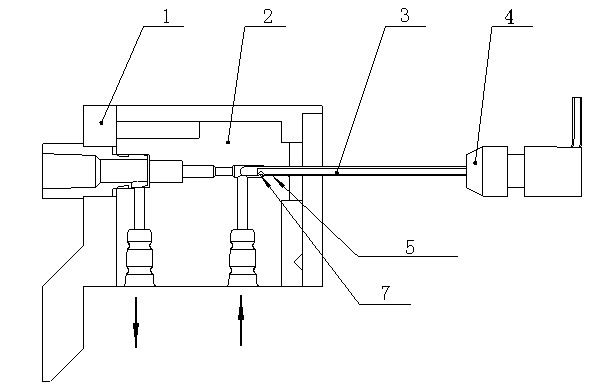

[0037] Such as figure 1 As shown, it is the cleaning of the inner wall of the sampling needle: when the sampling needle 3 needs to be cleaned after sampling, the sampling needle 3 returns from the left to the right, the front pinhole 7 moves into the first cavity 8 and the front end of the sampling needle 3 is in the second cavity. The sealing node 6 is sealed with the mouthpiece 2. At this time, the first sealing node 5 and the second sealing node 6 at both ends of the pinhole 7 at the front end of the sampling needle 3 are sealed, the liquid enters the channel 13 and is filled with cleaning liquid, and the sampling needle 3 is extracted and cleaned. The liquid can wash the inner wall of the pipe clean.

Embodiment 3

[0039] figure 2 For the cleaning of the inner and outer walls of the sampling needle 3 and the nozzle 2: when the sampling needle 3 needs to be cleaned after sampling, the sampling needle 3 returns from the left to the right, the front pinhole 7 moves into the first cavity 8 and the sampling needle 3. The front end is also in the first cavity 8. At this time, the sampling needle 3 is only sealed by the first sealing node 5, and then the liquid inlet channel 13 is filled with cleaning liquid. The sampling needle 3 extracts the cleaning liquid to clean the inner wall. The sampling needle 3 If the cleaning liquid is not extracted and the cleaning liquid flows out from the liquid discharge channel 10, the outer wall of the sampling needle 3 and the channel of the mouthpiece 2 can be washed clean.

[0040] Example 3

[0041] 1. Fill the liquid inlet channel 13 and the liquid outlet channel 10 with cleaning liquid;

[0042] 2. The movement structure controls the sampling needle t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com