Patents

Literature

387results about "Laboratory cleaning apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

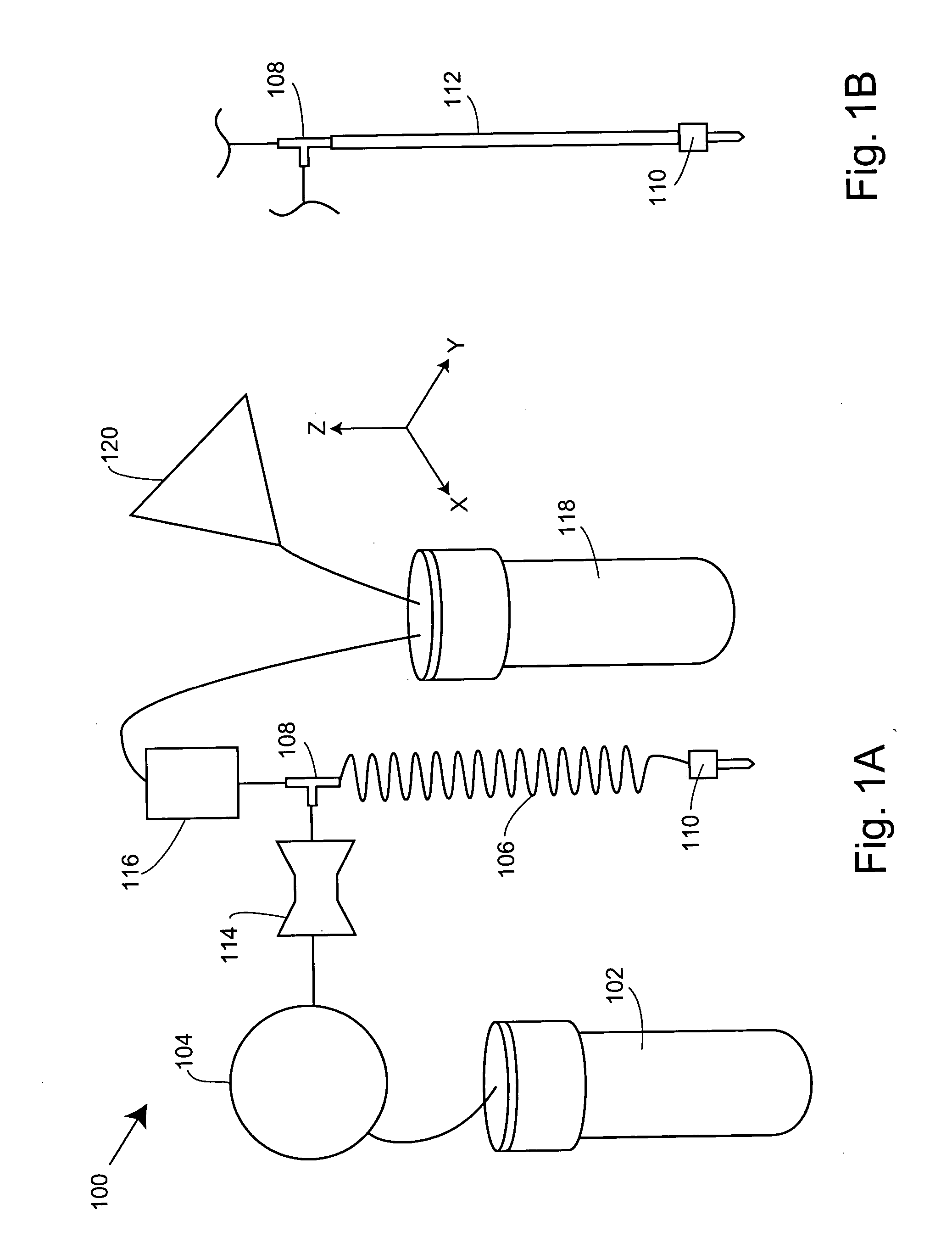

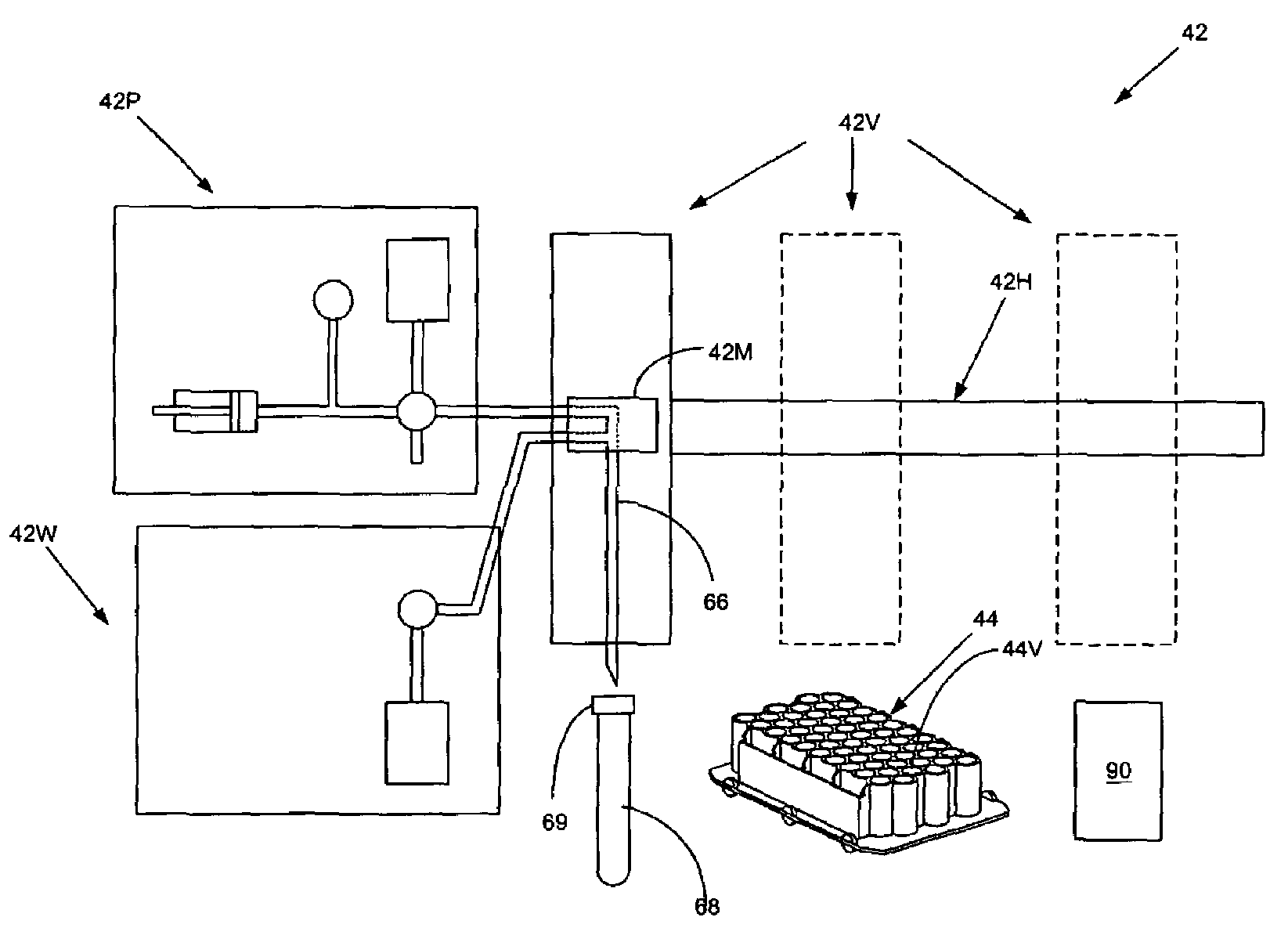

Dispensing systems, software, and related methods

InactiveUS20060002824A1Minimize disruptionReduce foamingAnalysis using chemical indicatorsAnalysis by subjecting material to chemical reactionPeristaltic pumpSubstrate surface

The present invention provides dispensing systems that include peristaltic pumps and other pressure sources for the efficient delivery of accurate volumes of fluidic materials into the wells of multi-well containers or onto substrate surfaces. These systems are typically configured to dispense volumes of fluid having substantially uniform densities. Related computer program products and methods of dispensing fluidic materials are also provided.

Owner:IRM

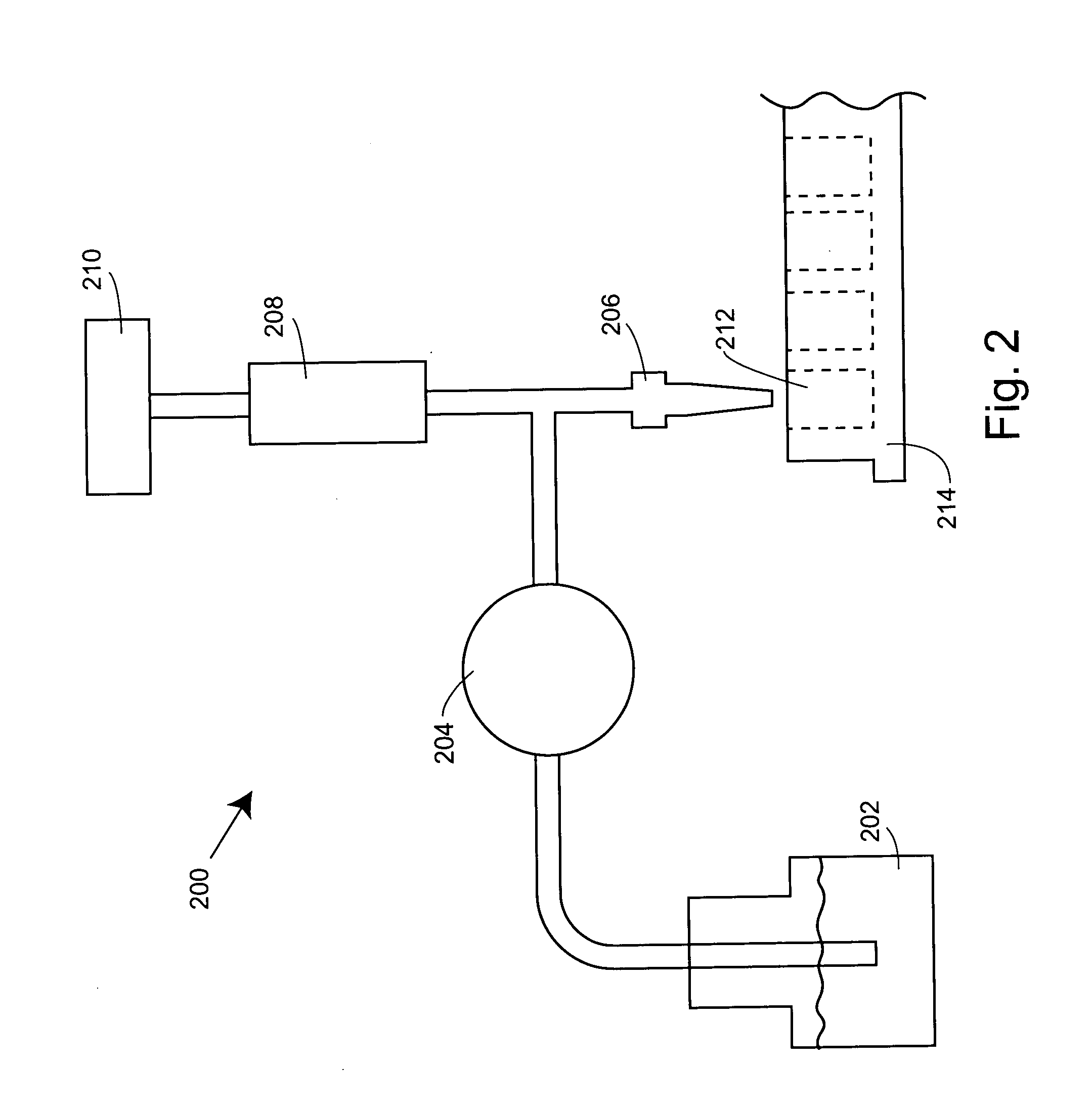

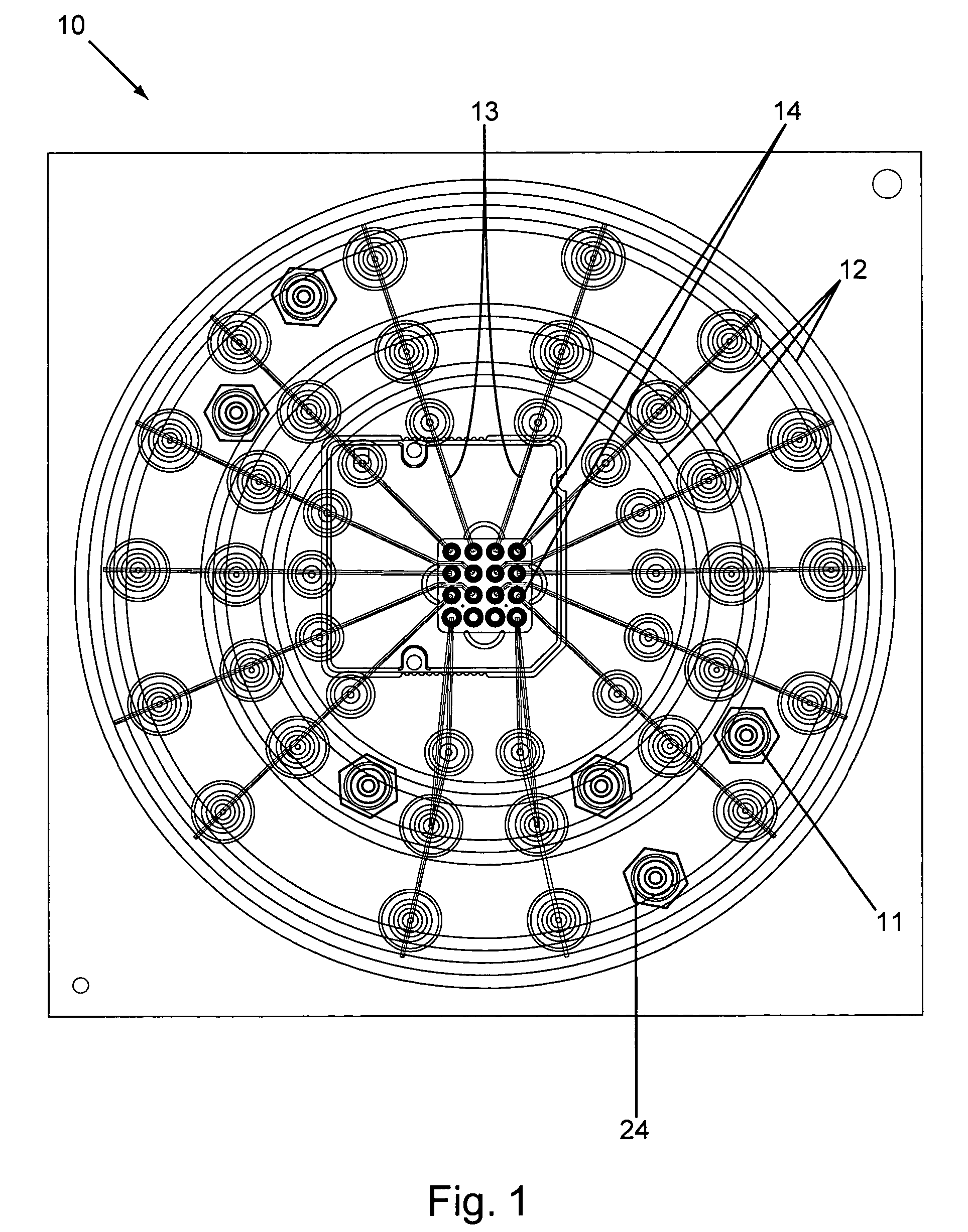

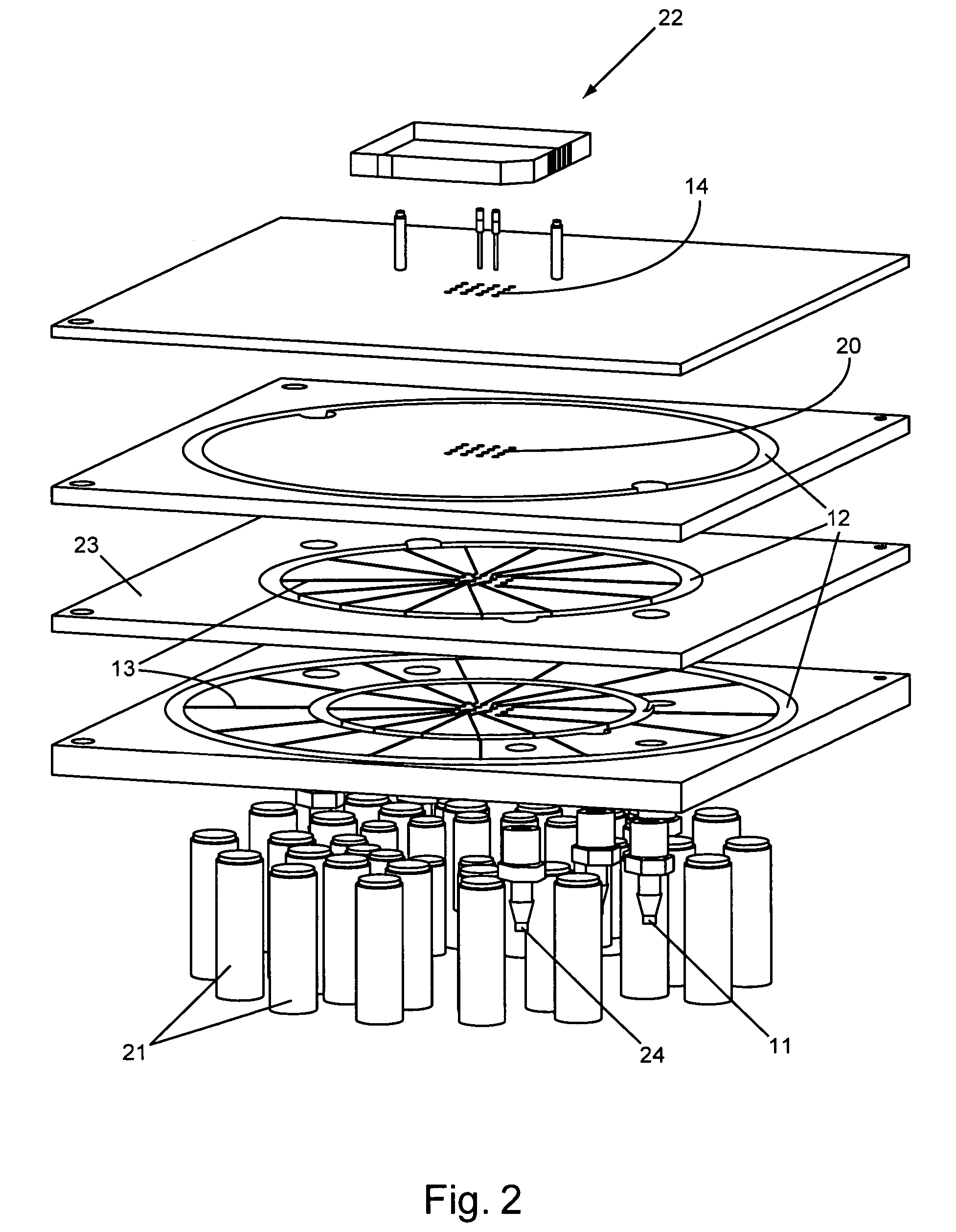

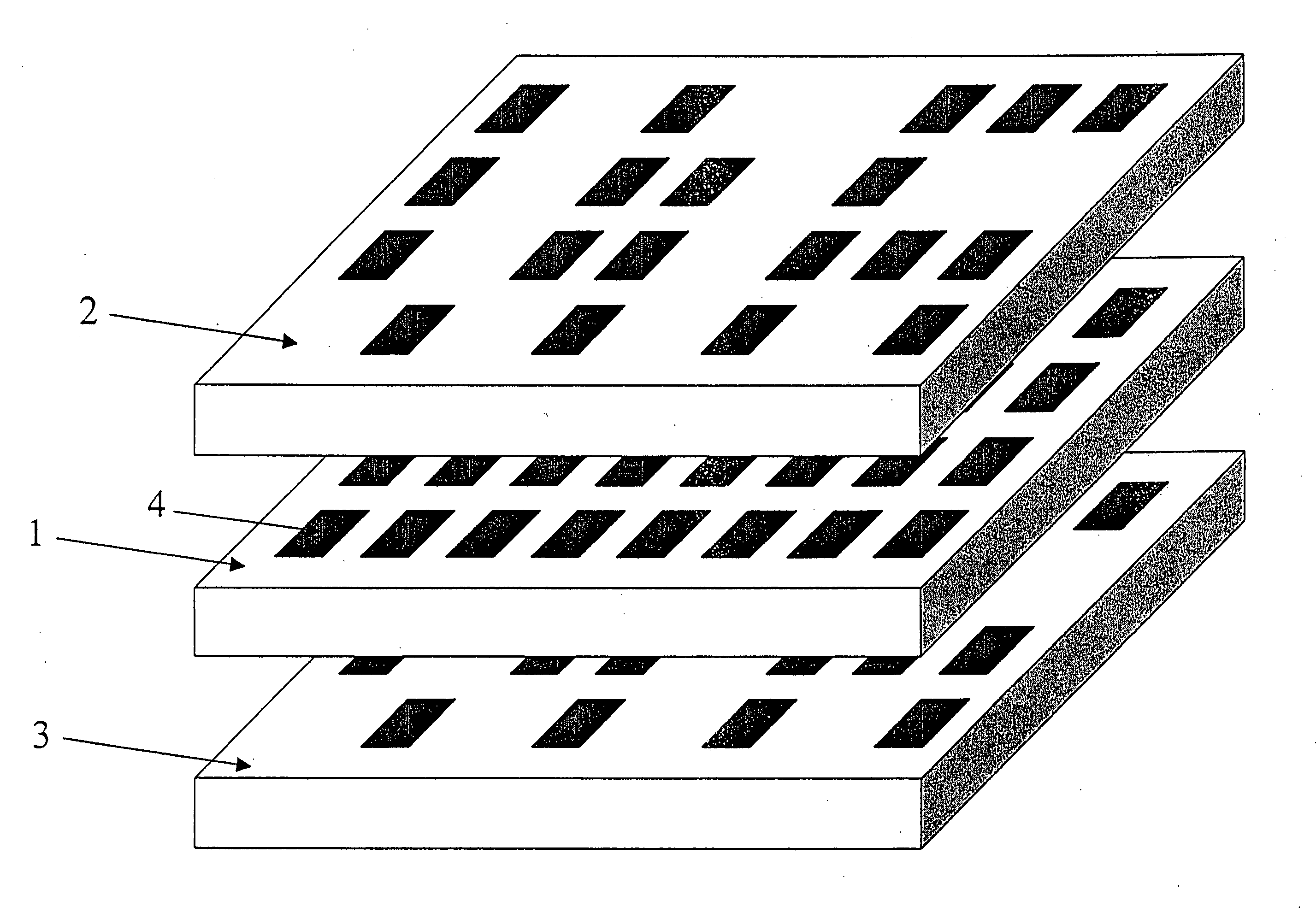

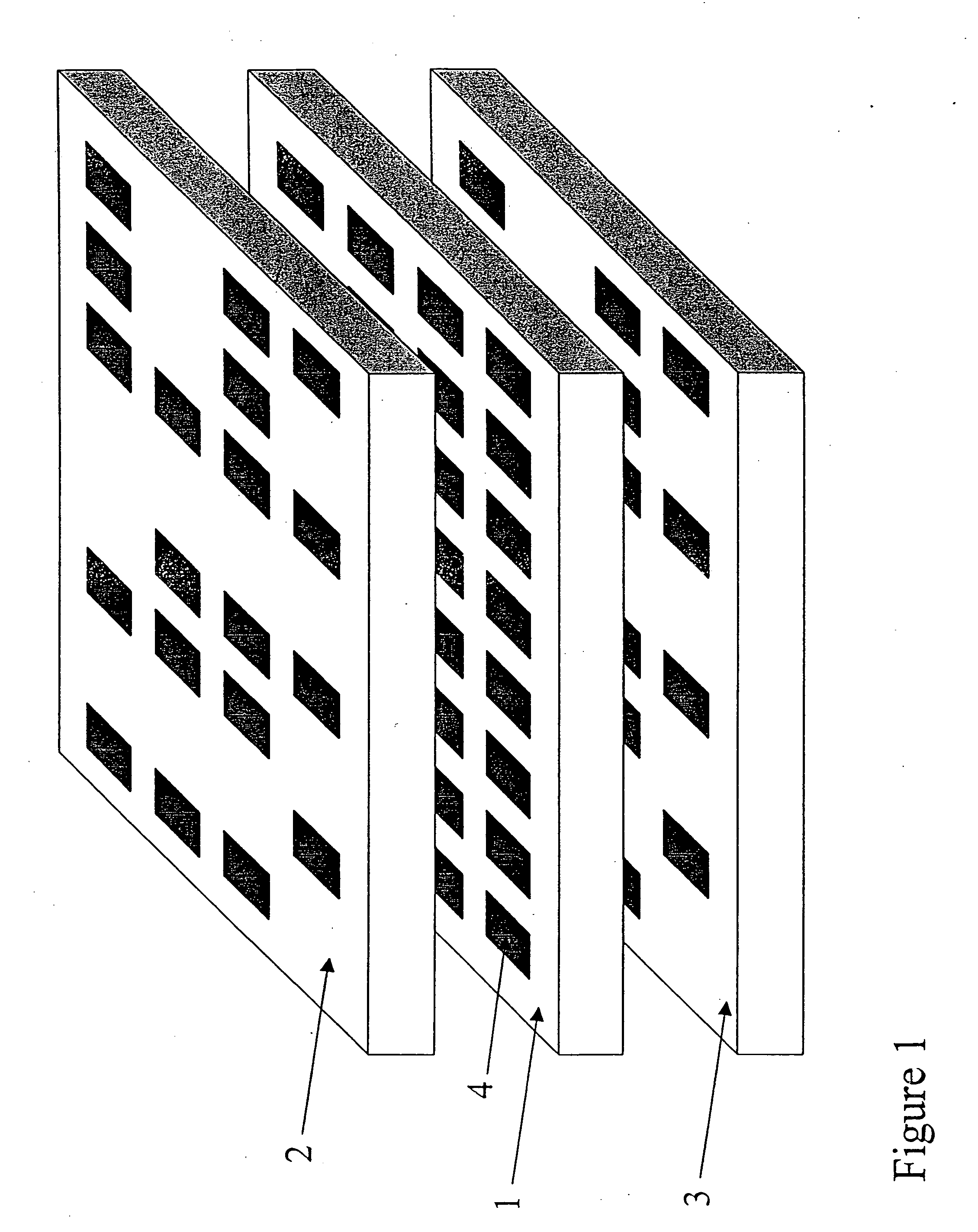

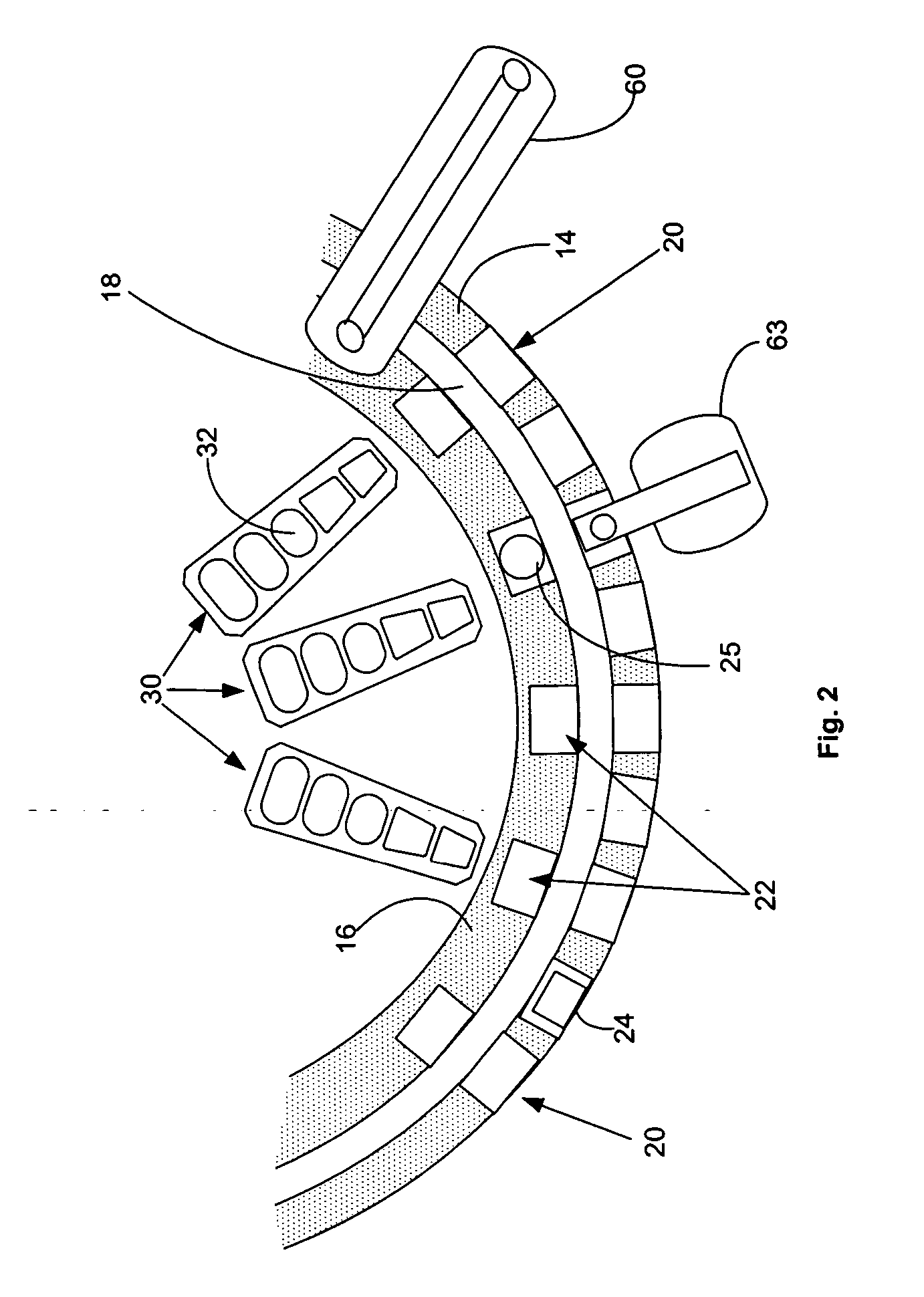

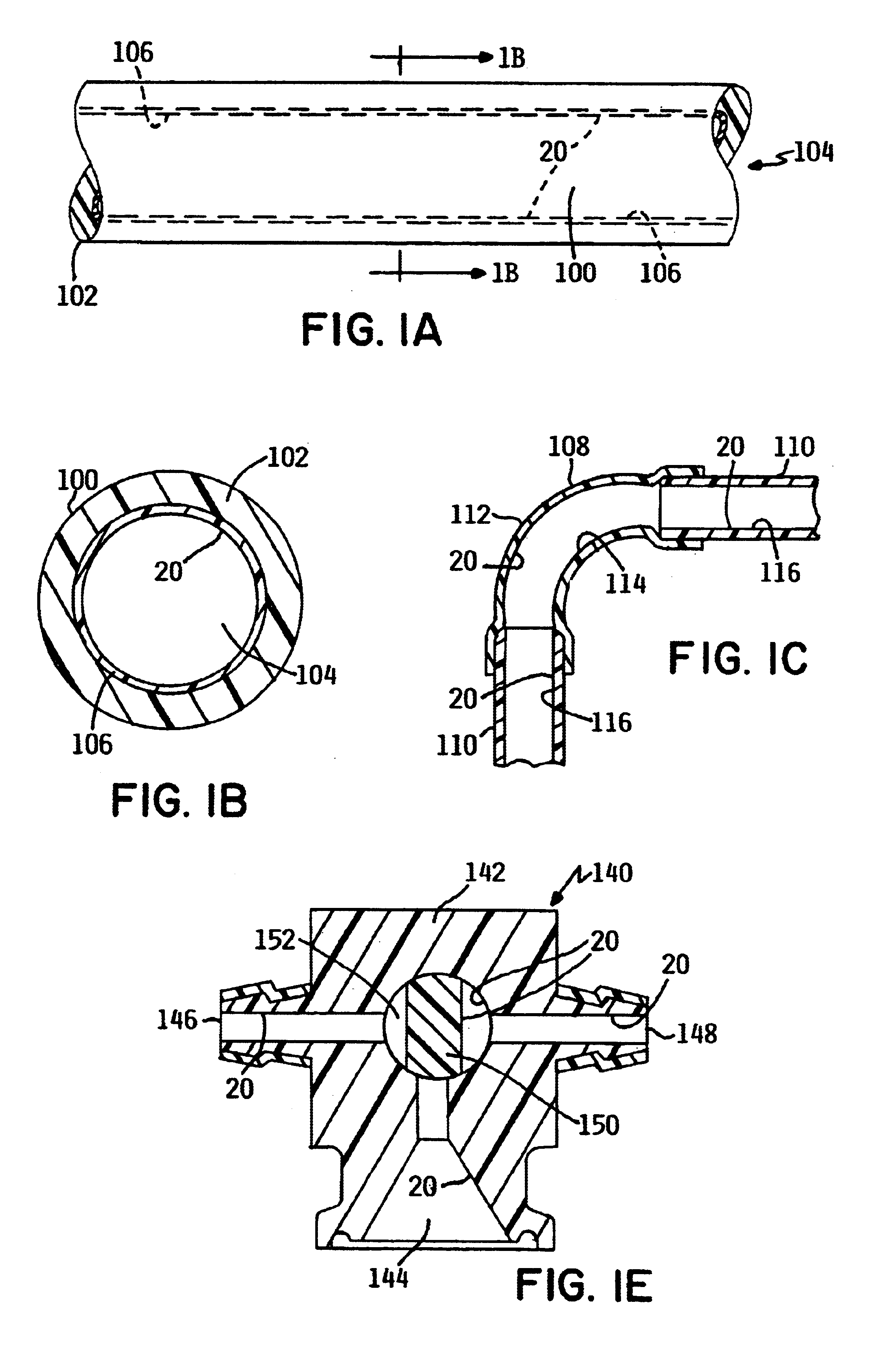

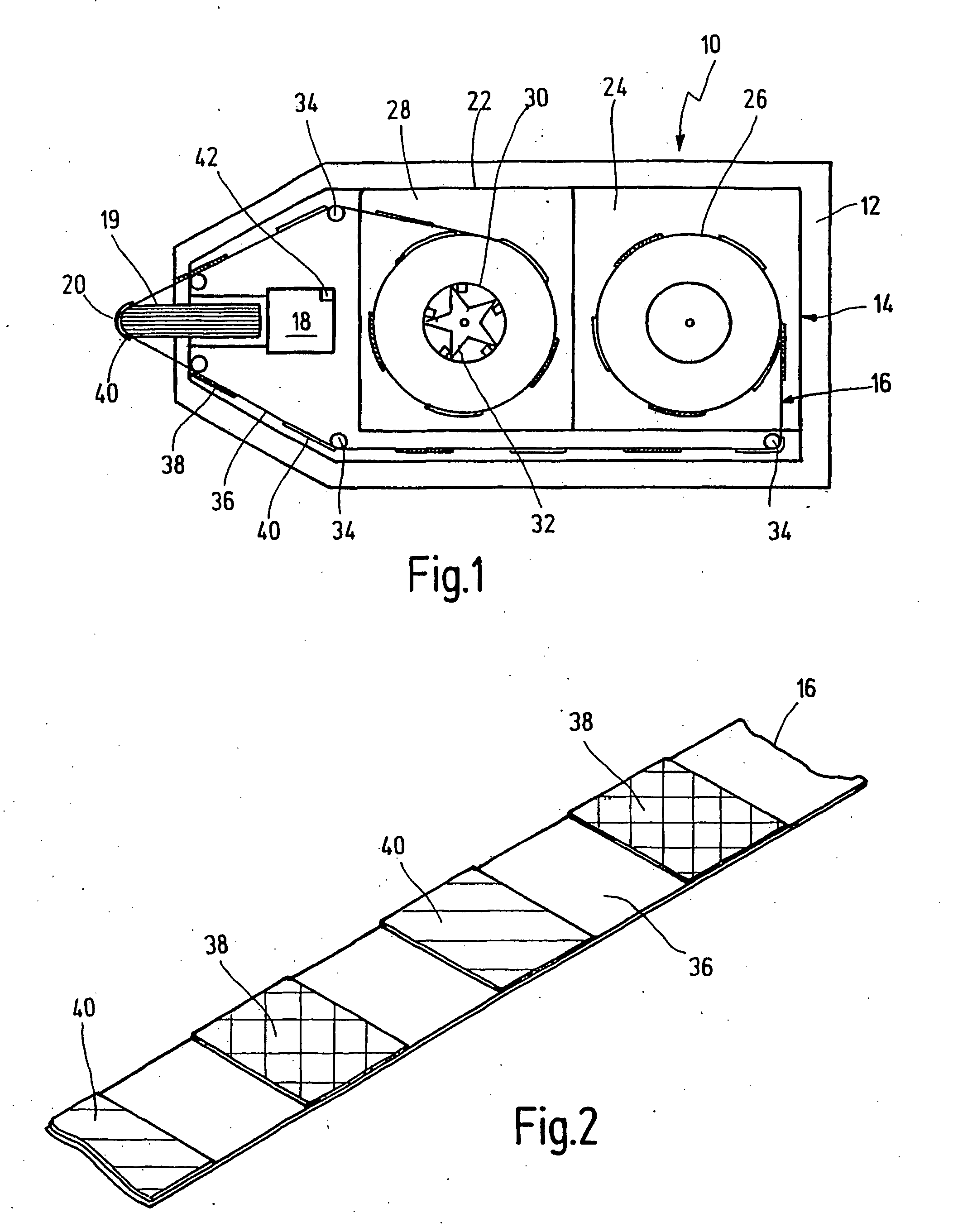

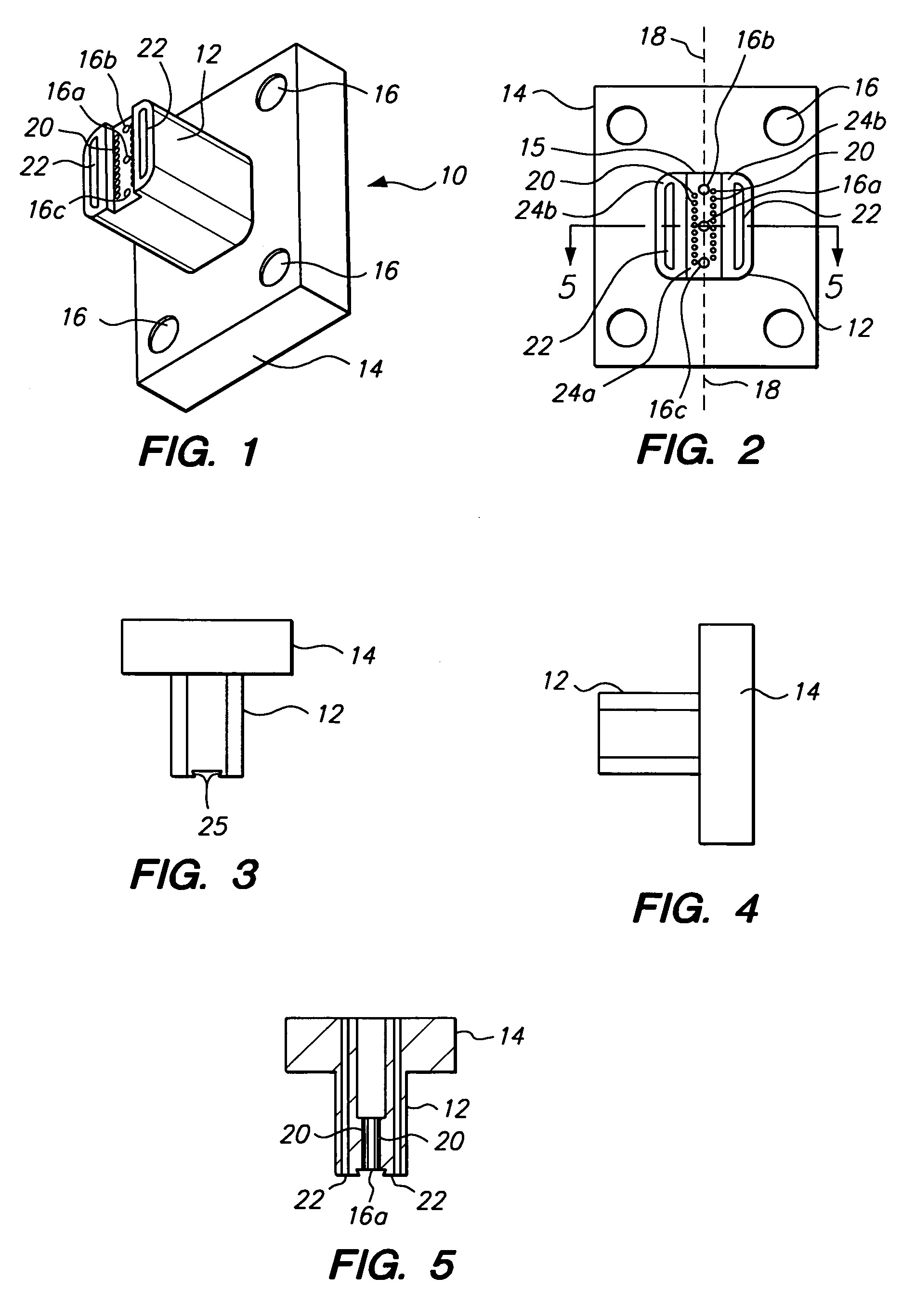

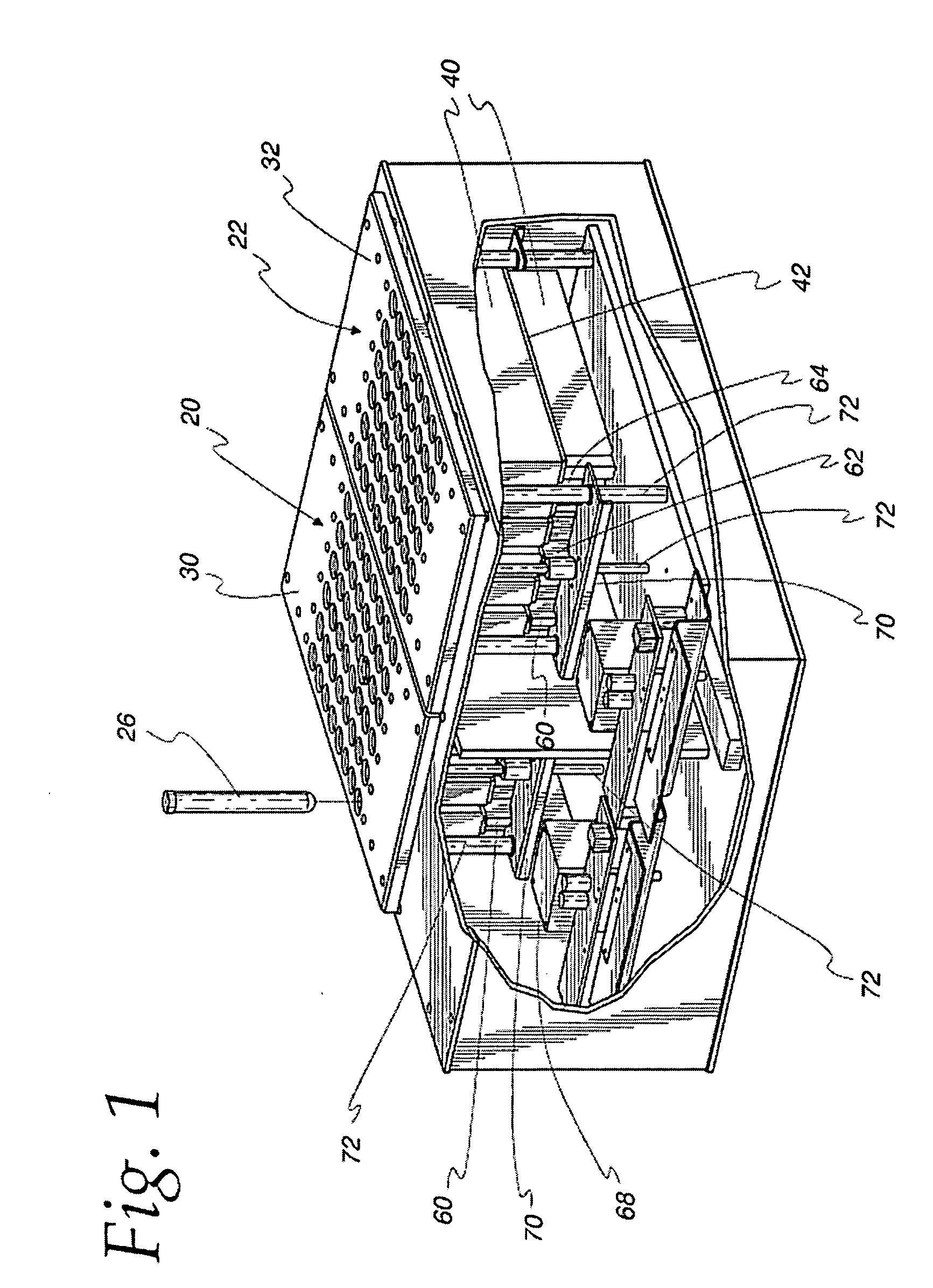

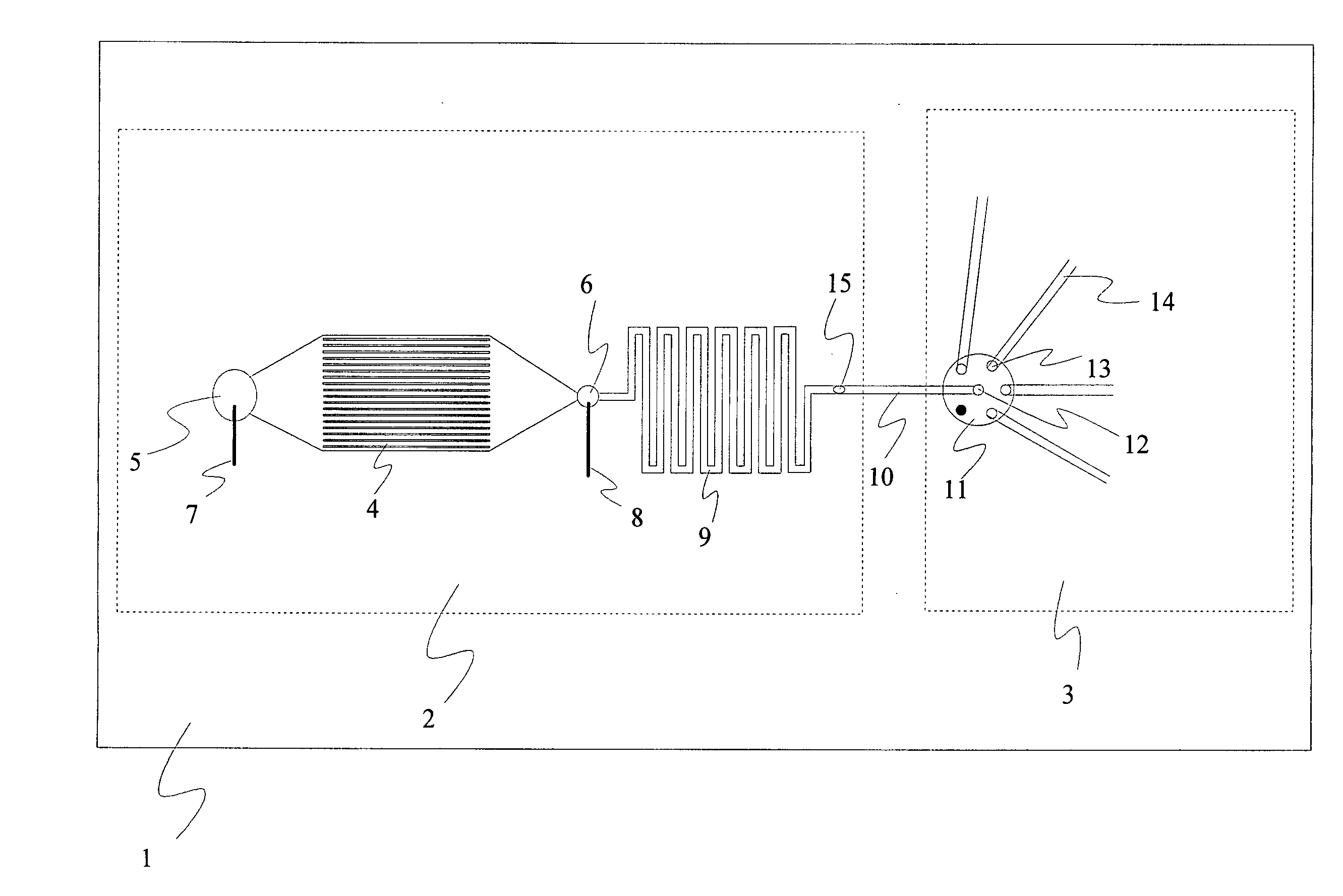

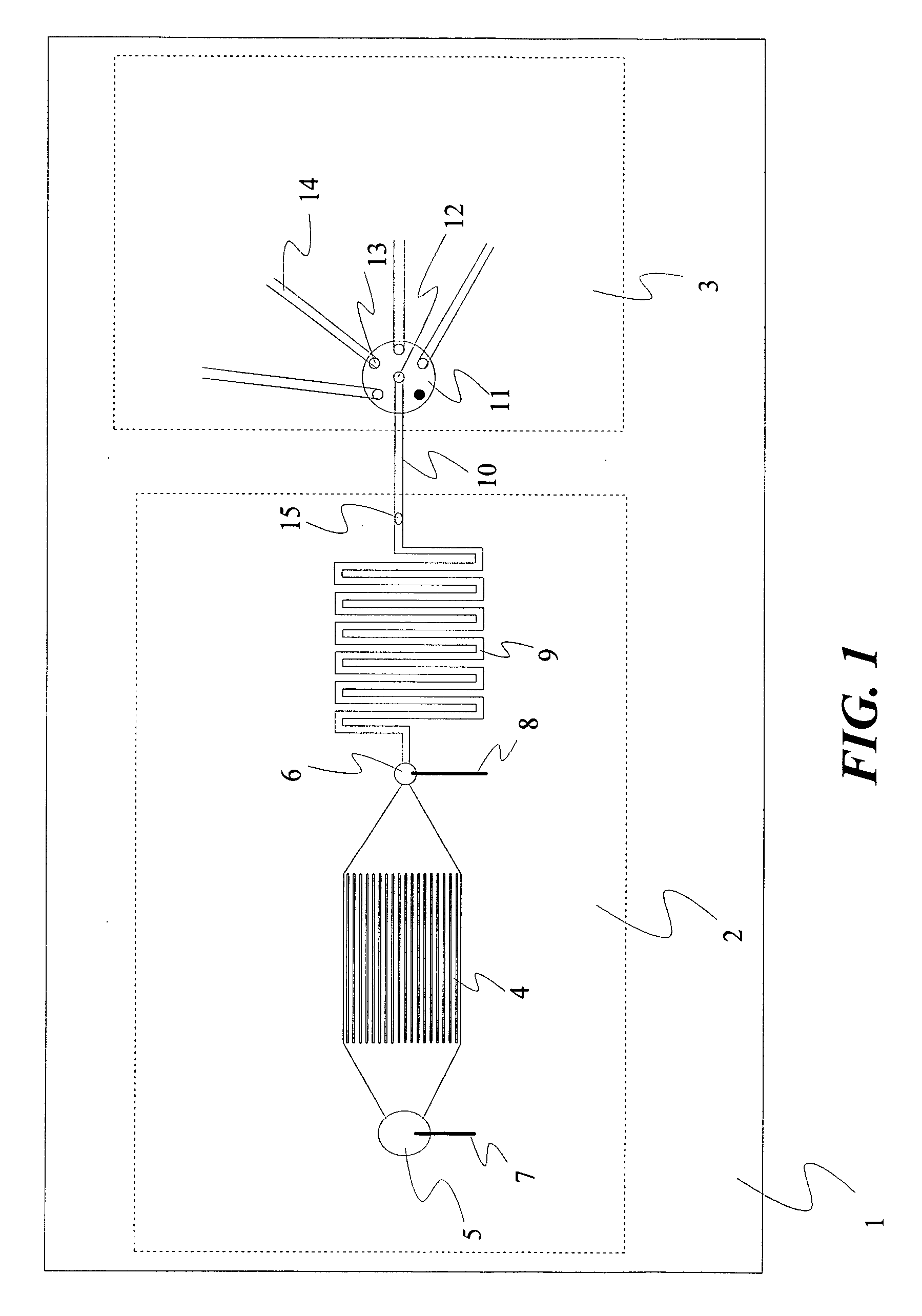

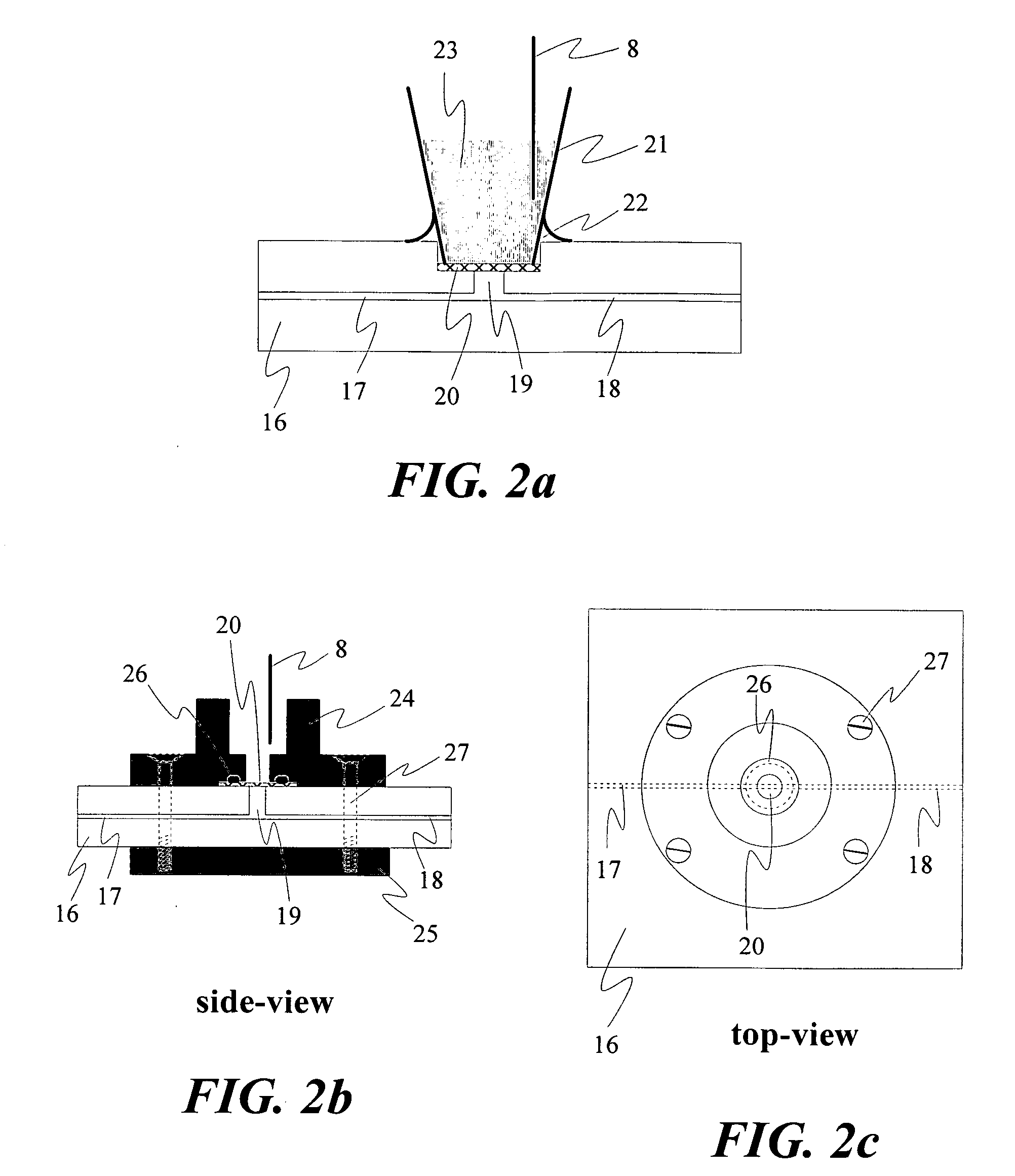

Methods and systems for processing microscale devices for reuse

InactiveUS7514046B2Efficient processingImprove efficiencyFixed microstructural devicesVolume/mass flow by thermal effectsBiomedical engineeringMicrofluidic chip

This invention provides methods and systems for flushing, washing, and priming microscale devices for reuse. Washing and priming methods include flowing solutions from a manifold to flush wells and microchannels of a microfluidic chip. Systems include manifolds adapted to seal and flow solutions or gasses into chip wells. Devices include microfluidic devices with data storage modules to track the reprocessing status of the microscale devices.

Owner:CAPLIPER LIFE SCI INC +1

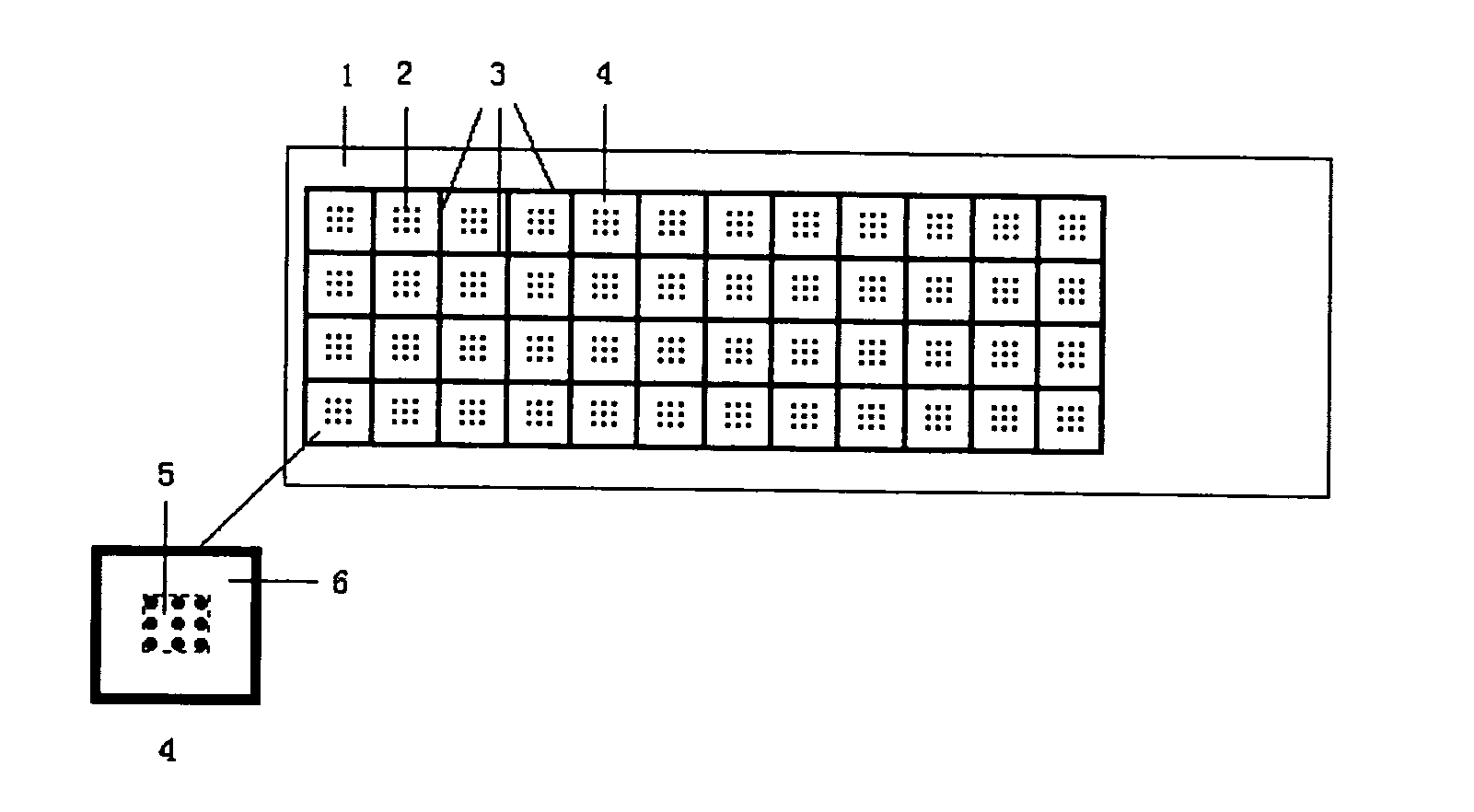

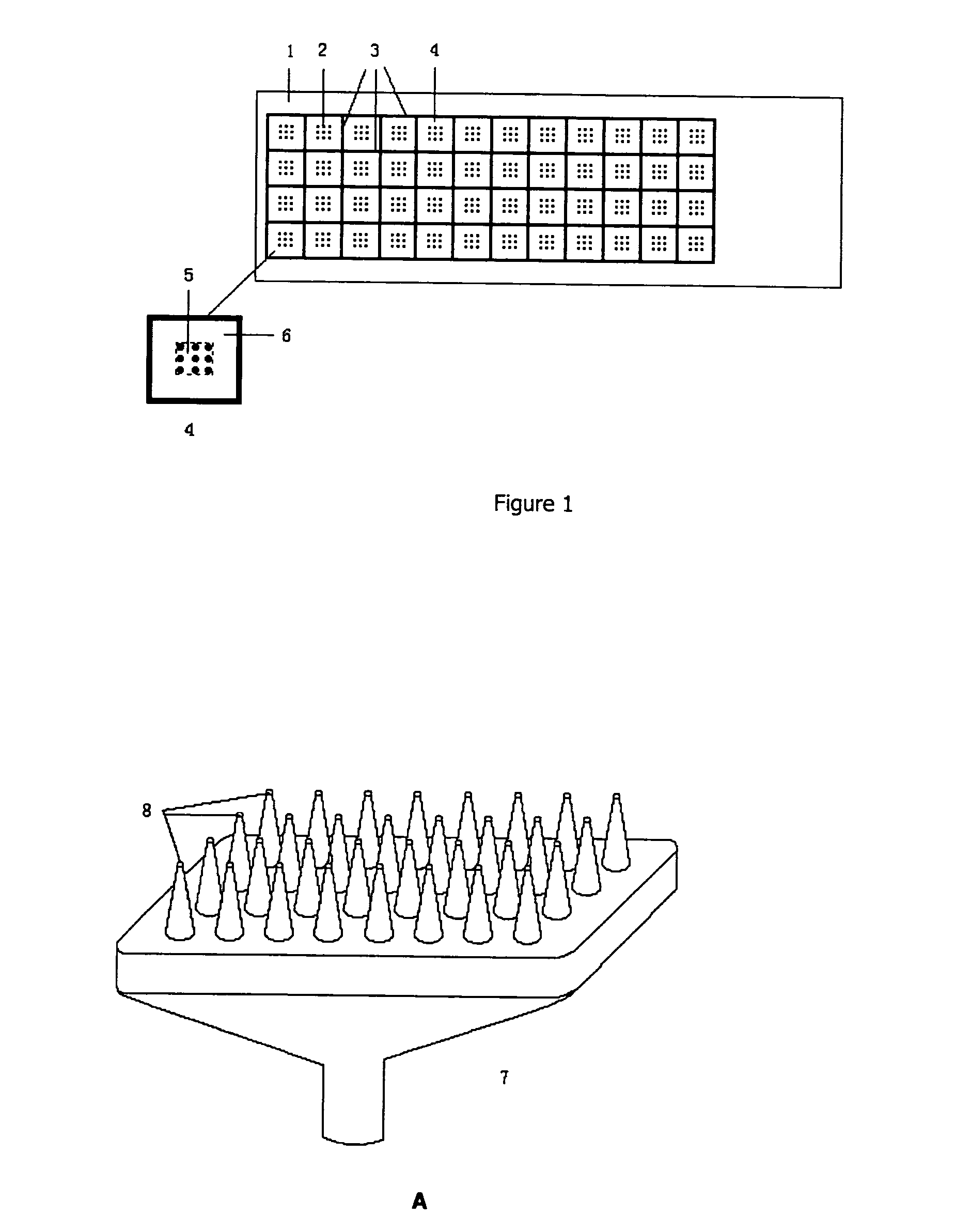

Testing method of analytic chip of multiple reactors, the analytic chip, and the testing device

InactiveUS20070207060A1Easy to integrateEfficient testingLaboratory glasswaresColor/spectral properties measurementsComputer scienceTest set

This invention involves the testing device of analytic chip with multiple reactors, which includes a). one-way-cleaning system for one-way-cleaning of remnant sample in said reactor; or / and b).fluidity-decreasing system for fluidity-decreasing of remnant sample; or / and c). sample spotting system for sample subjecting by spotting. With the said testing device, analytic chip testing can be easily conducted with high integration, high efficiency and safety.

Owner:CHENGDU KUACHANG MEDICAL IND CO LTD

Methods and systems for processing microscale devices for reuse

ActiveUS20050019213A1Effective flushingImprove efficiencyFixed microstructural devicesVolume/mass flow by thermal effectsBiomedical engineeringMicrofluidic chip

This invention provides methods and systems for flushing, washing, and priming microscale devices for reuse. Washing and priming methods include flowing solutions from a manifold to flush wells and microchannels of a microfluidic chip. Systems include manifolds adapted to seal and flow solutions or gasses into chip wells. Devices include microfluidic devices with data storage modules to track the reprocessing status of the microscale devices.

Owner:CAPLIPER LIFE SCI INC +1

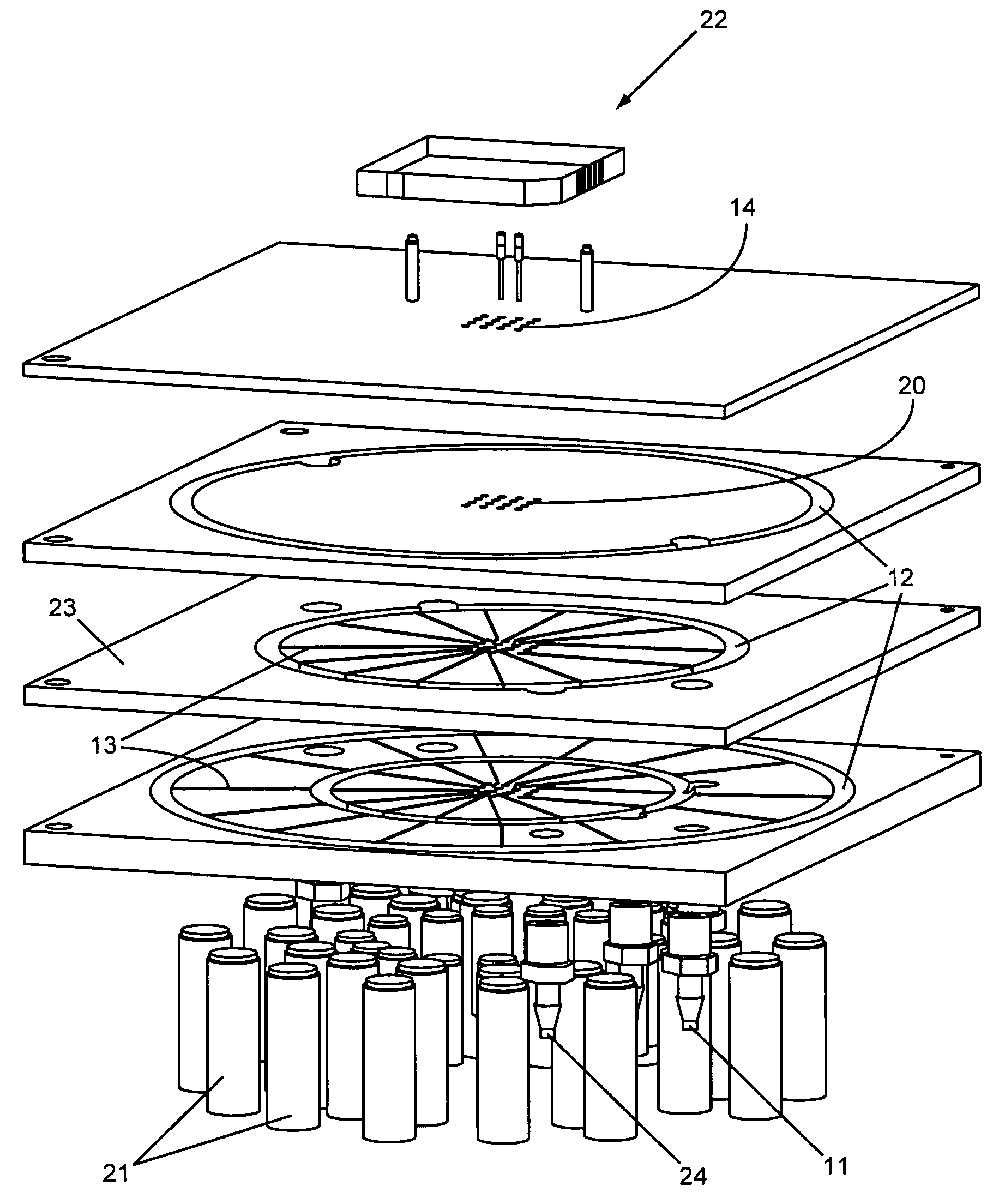

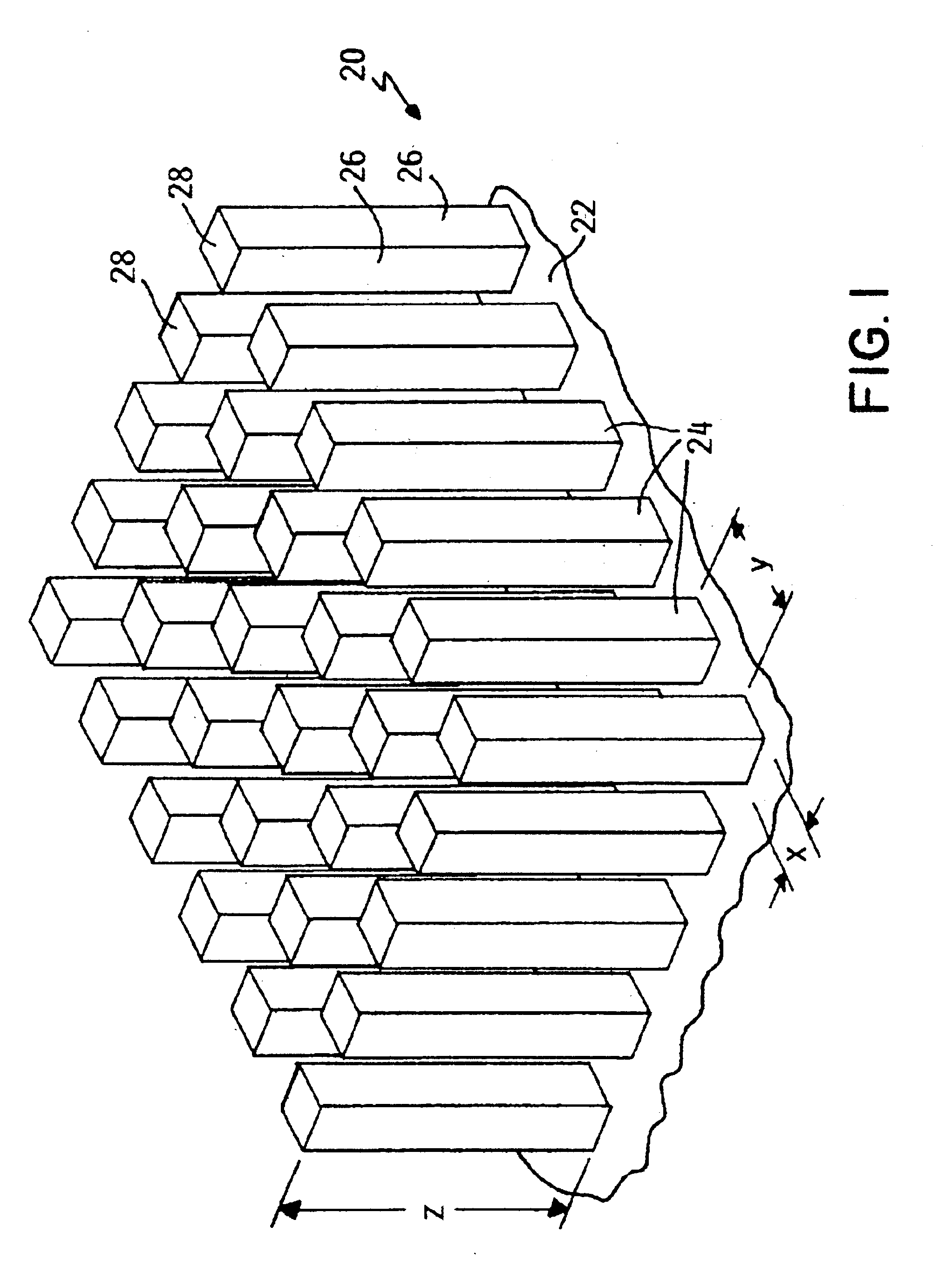

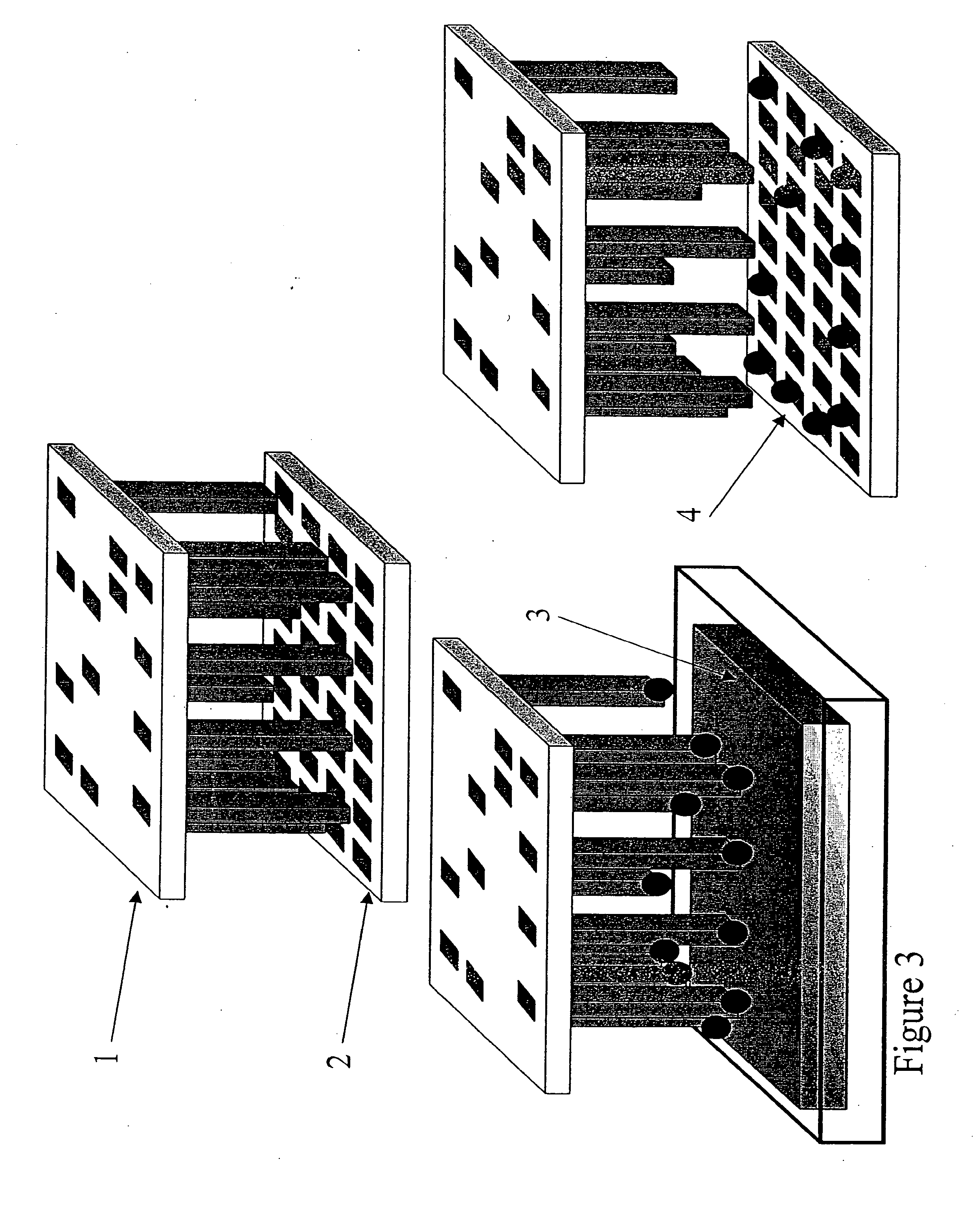

Apparatus for assay, synthesis and storage, and methods of manufacture, use, and manipulation thereof

InactiveUS20100261159A1Avoid cross contaminationAmplification of signalBioreactor/fermenter combinationsSequential/parallel process reactionsHigh densityVolumetric Mass Density

Owner:LIFE TECH CORP

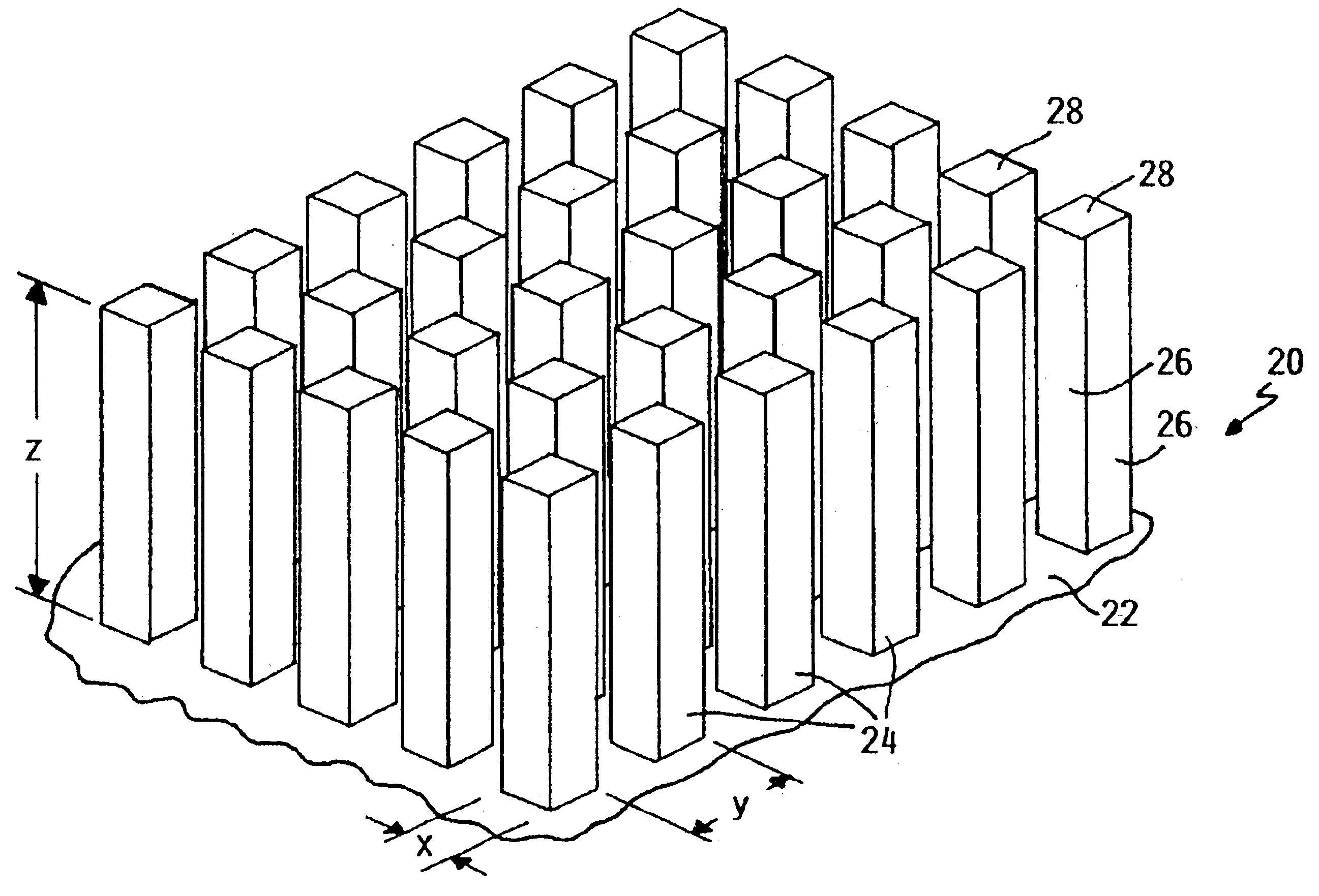

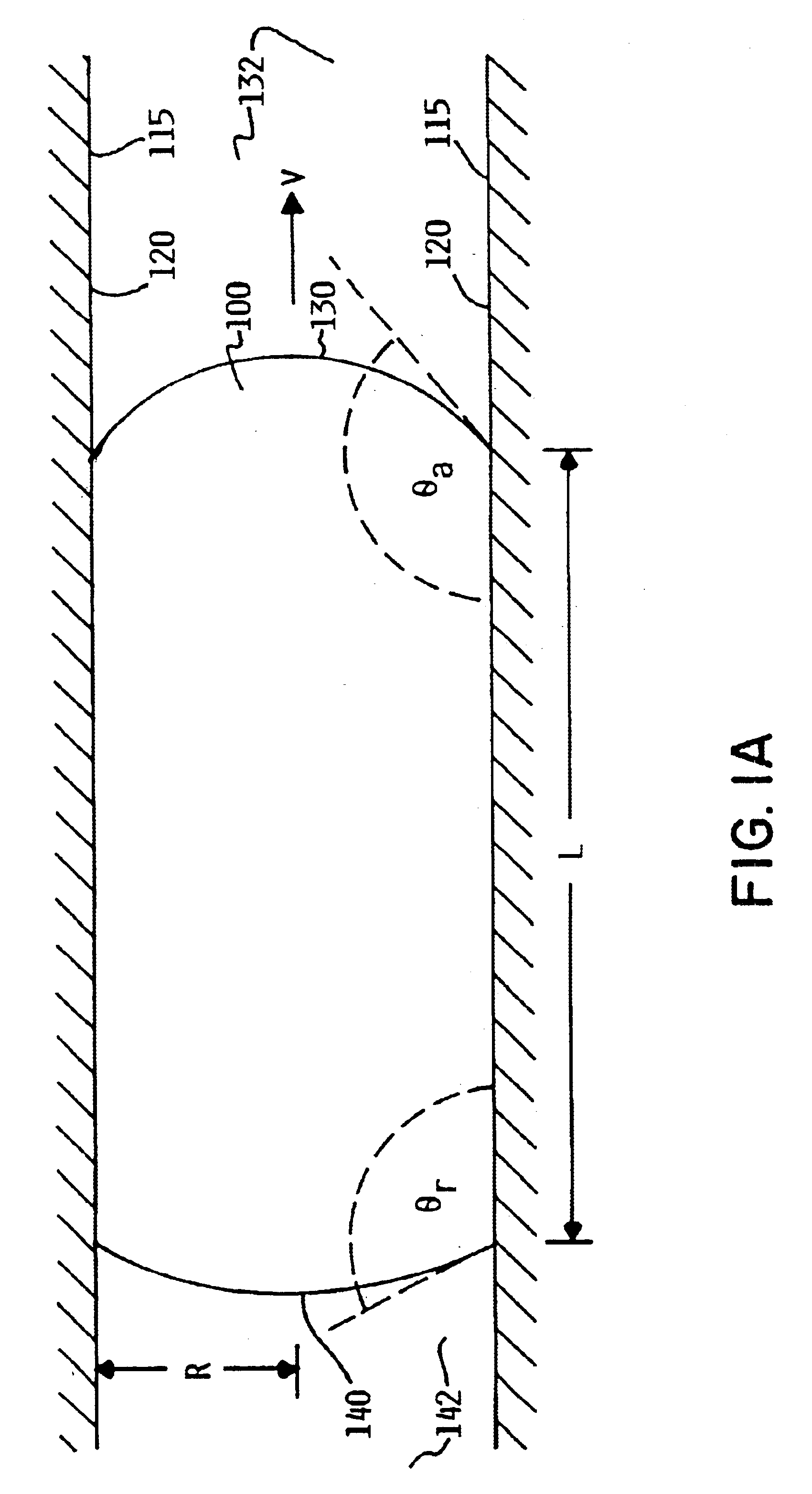

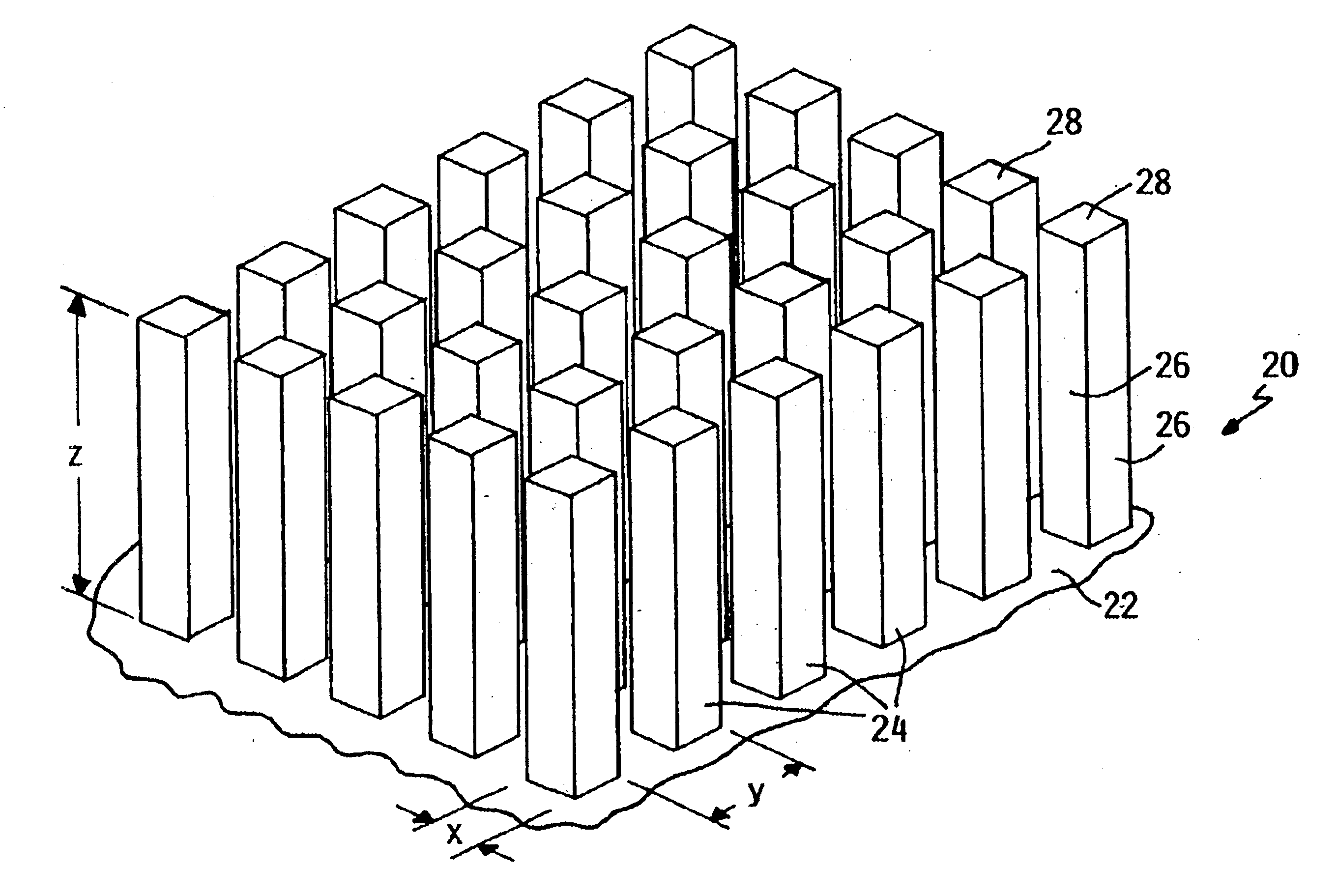

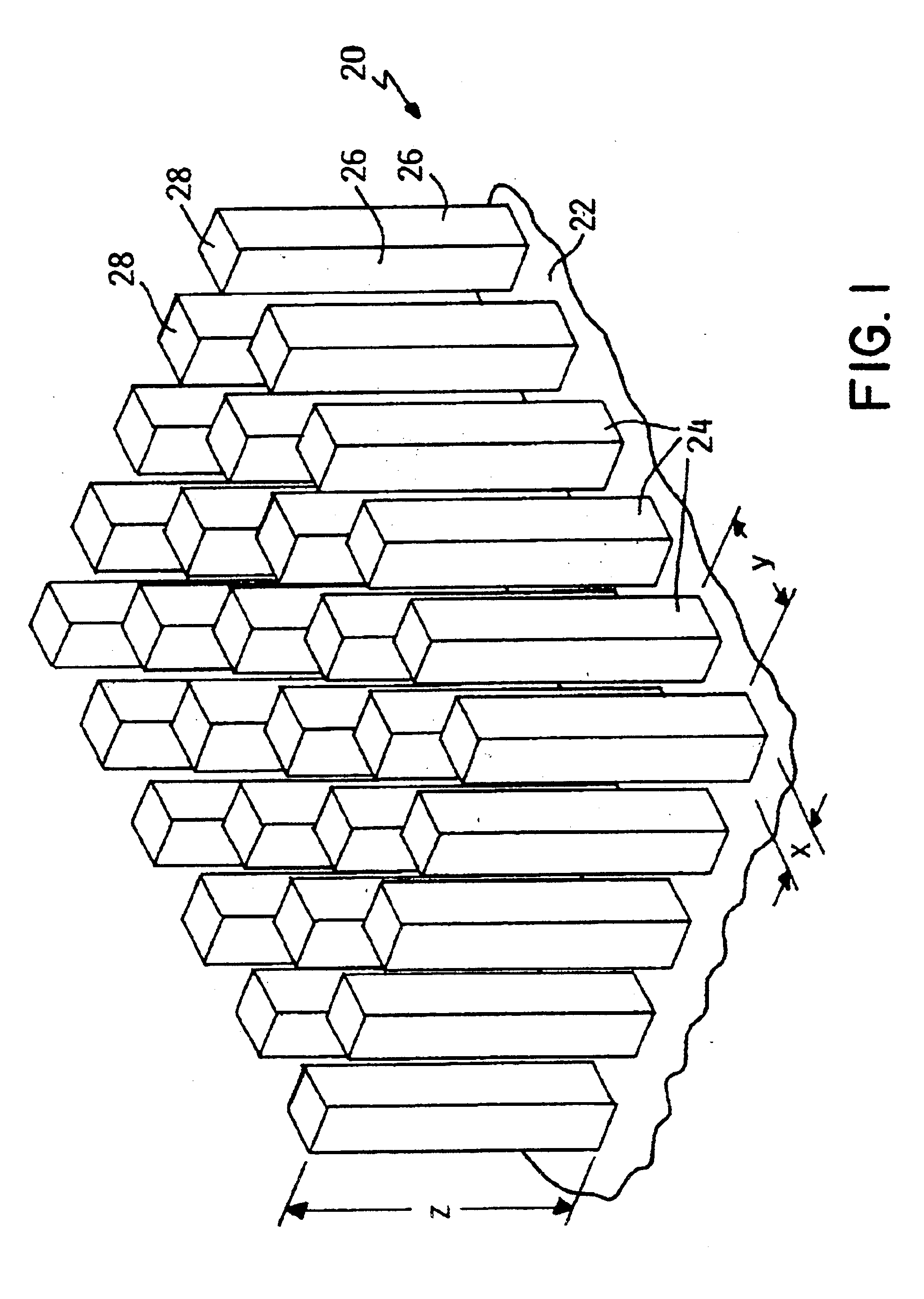

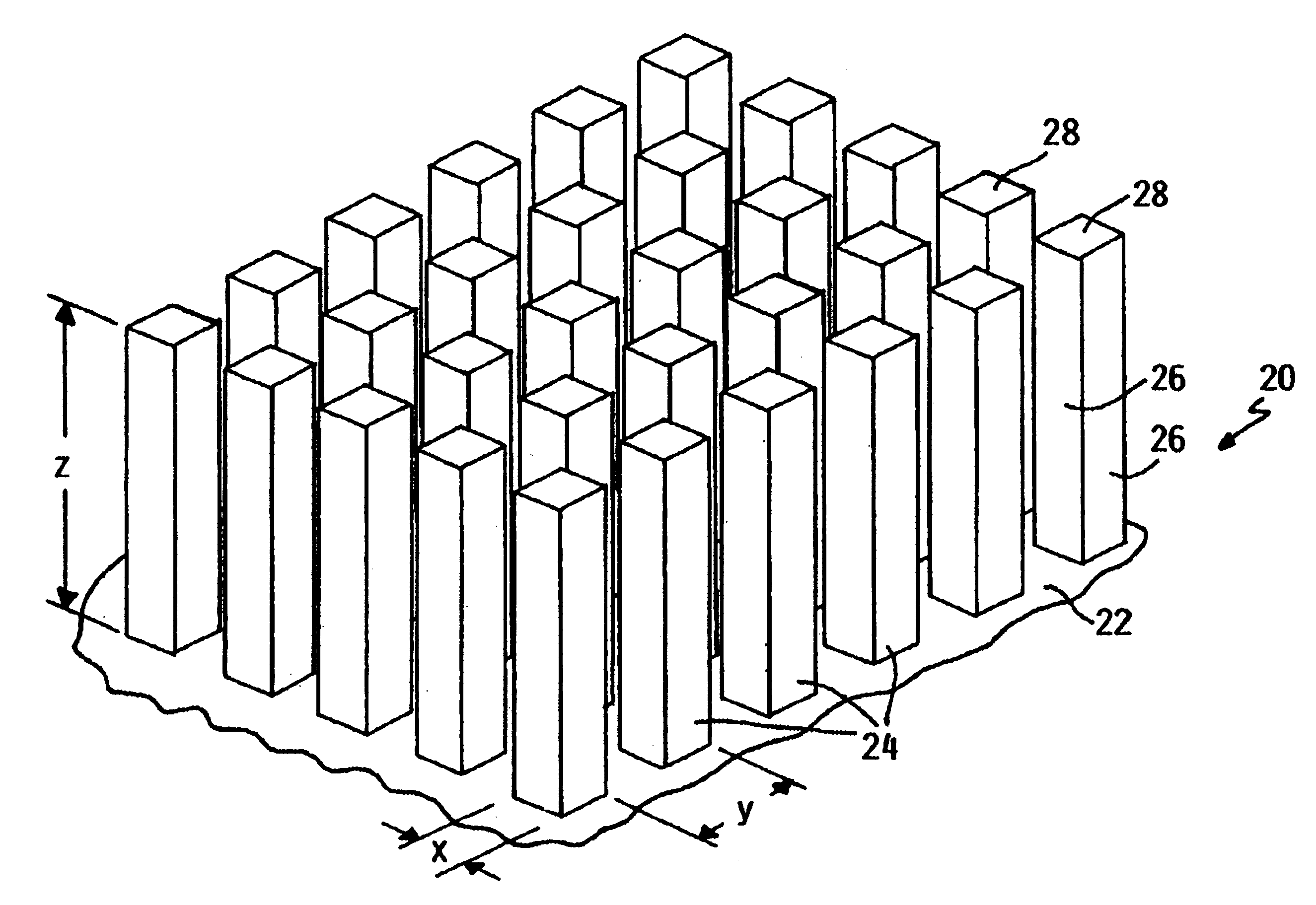

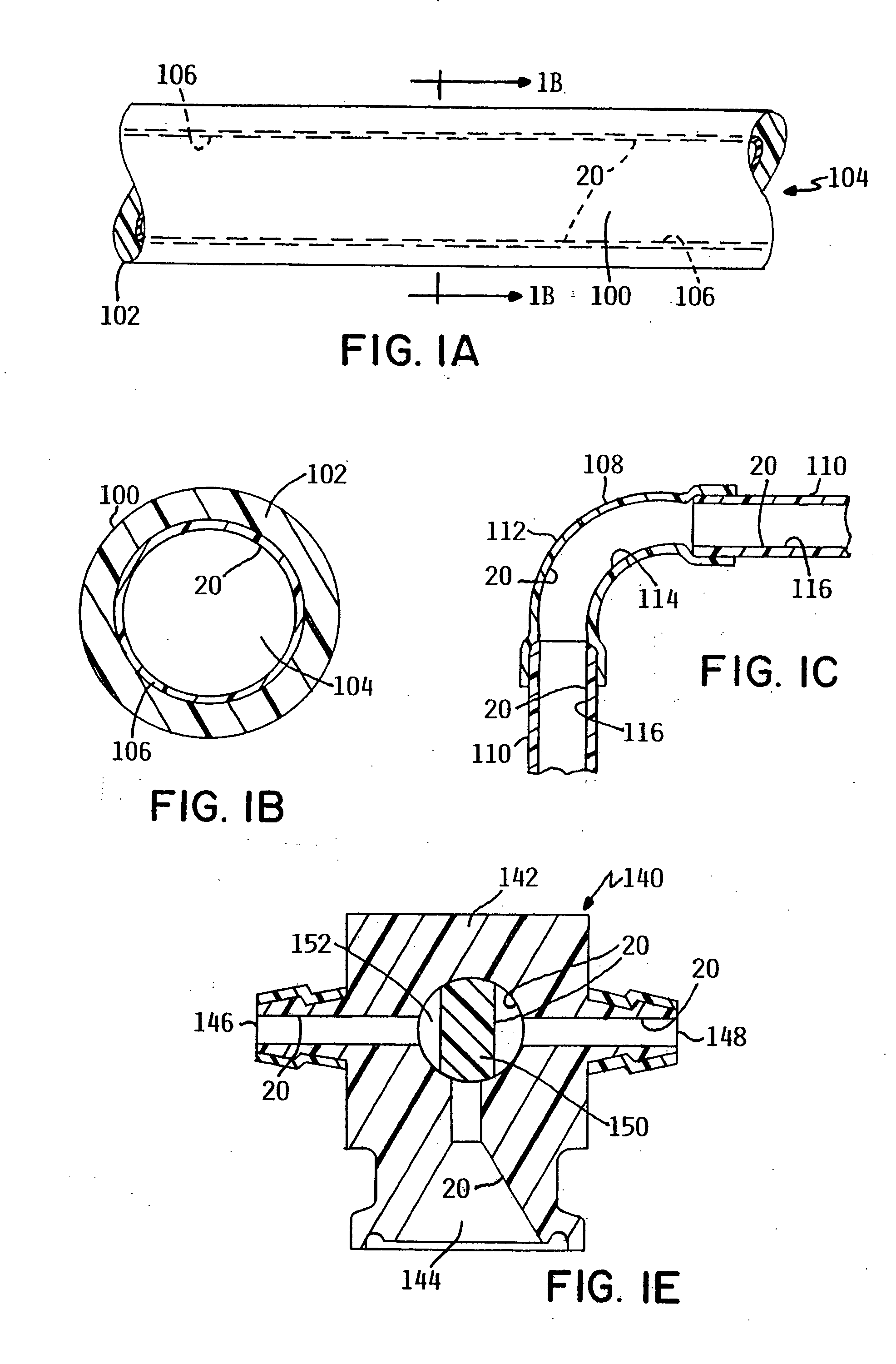

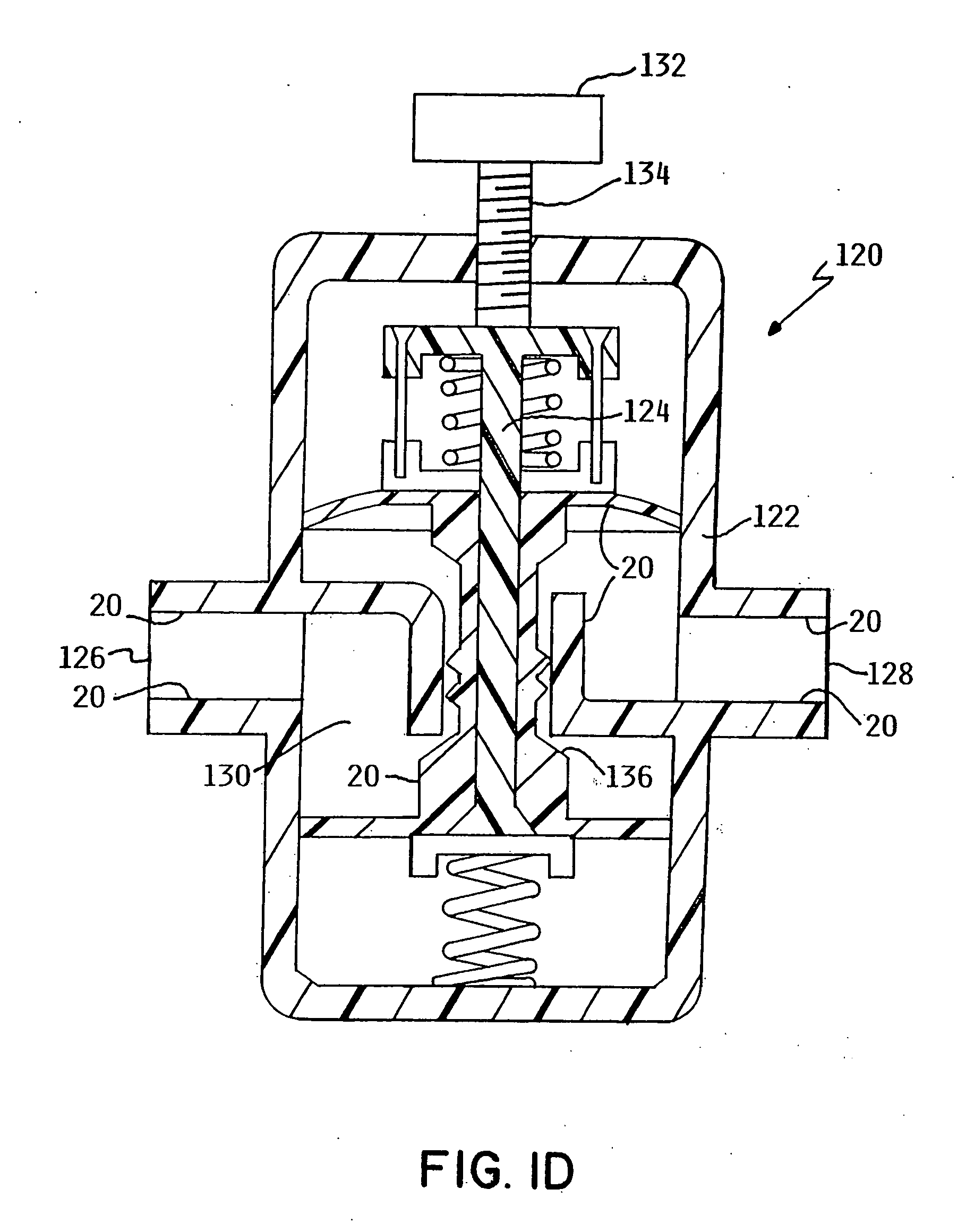

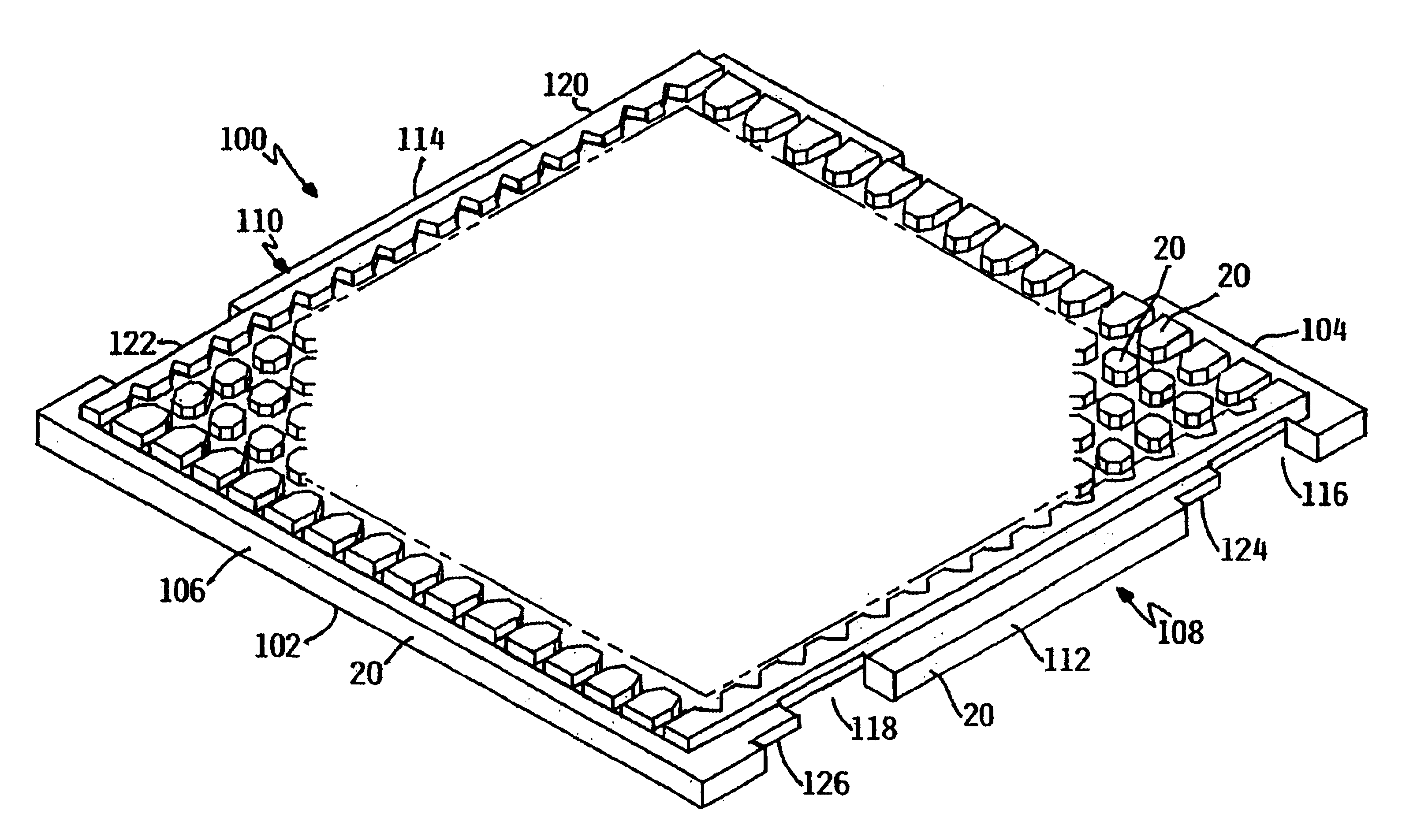

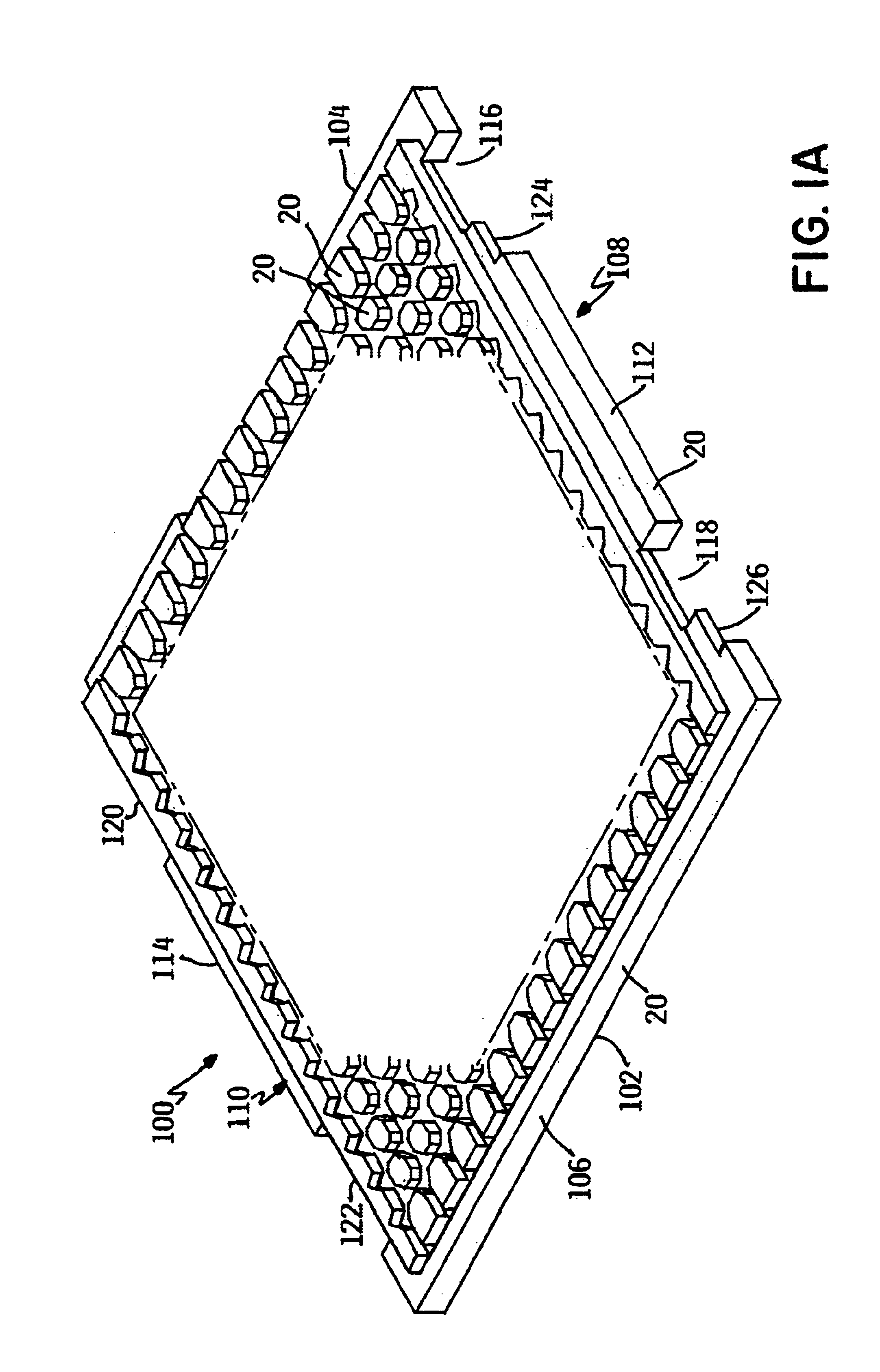

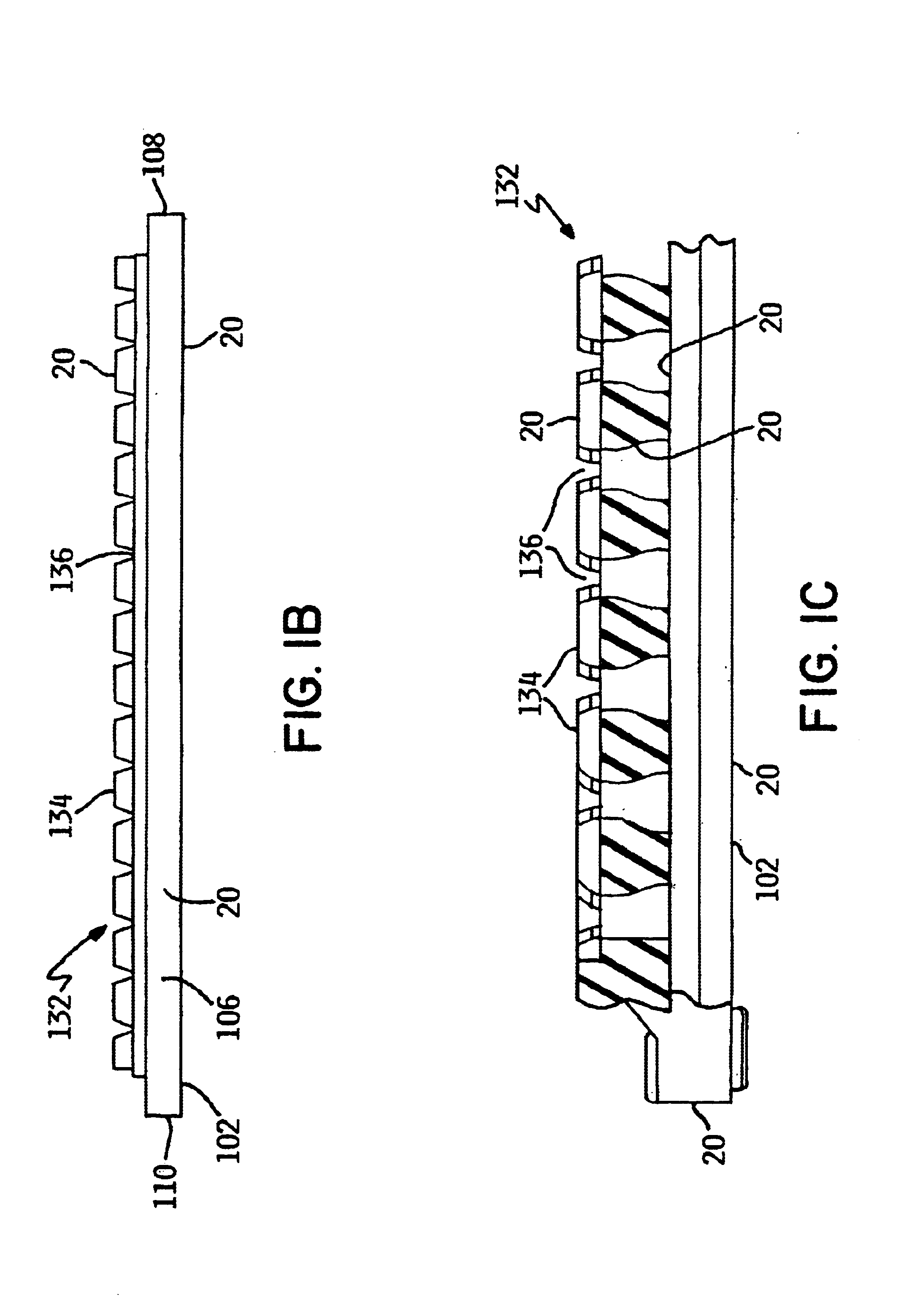

Microfluidic device with ultraphobic surfaces

ActiveUS6923216B2Improve equipment efficiencyReduce resistanceFouling preventionConveyorsEngineeringVolumetric Mass Density

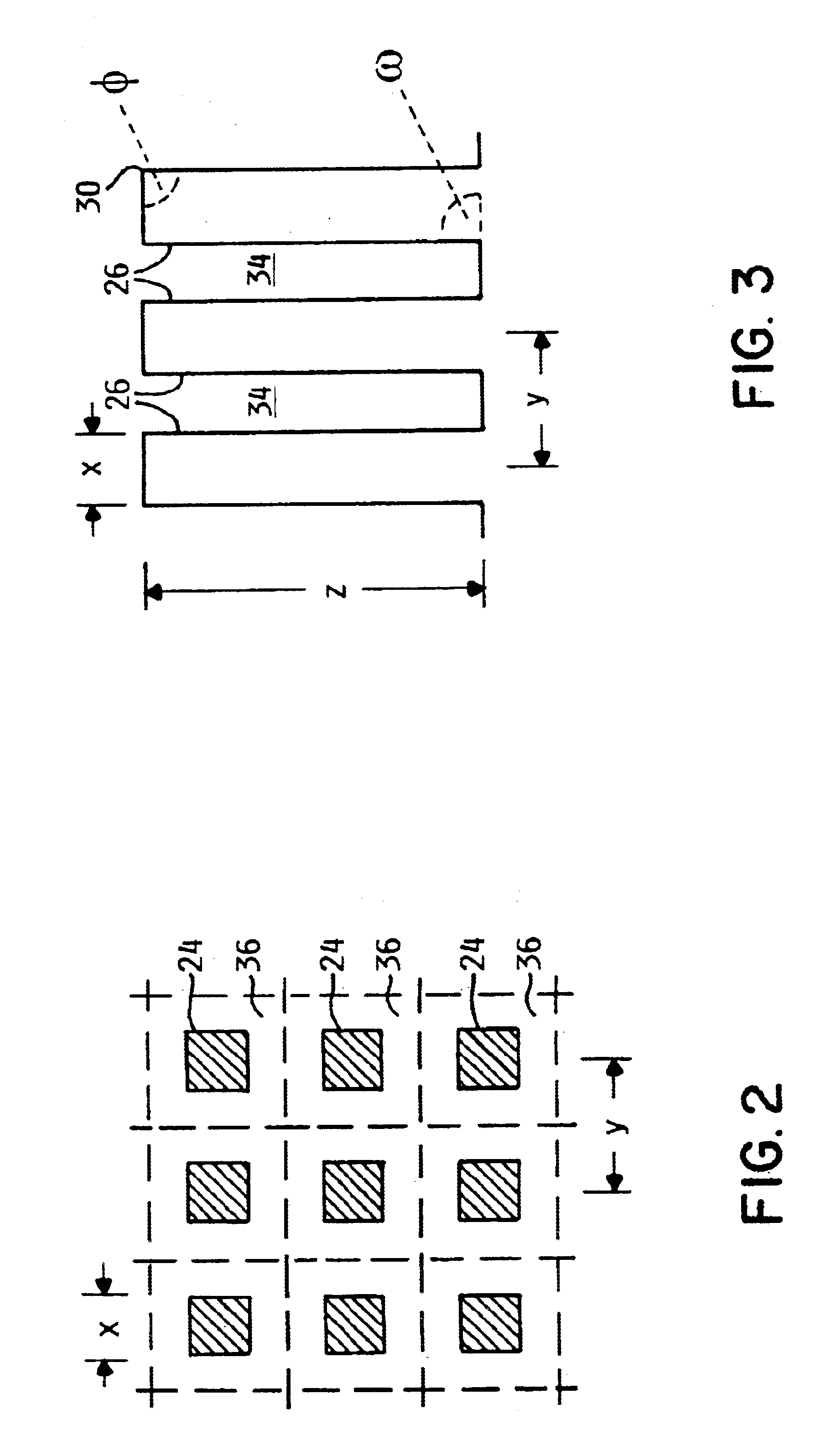

A microfluidic device having durable ultraphobic fluid contact surfaces in the fluid flow channels of the device. The ultraphobic surface generally includes a substrate portion with a multiplicity of projecting regularly shaped microscale or nanoscale asperities disposed in a regular array so that the surface has a predetermined contact line density equal to or greater than a critical contact line density, and so that the ratio of the cross-sectional dimension of the asperities to the spacing dimension of the asperities is less than or equal to 0.1.

Owner:ENTEGRIS INC

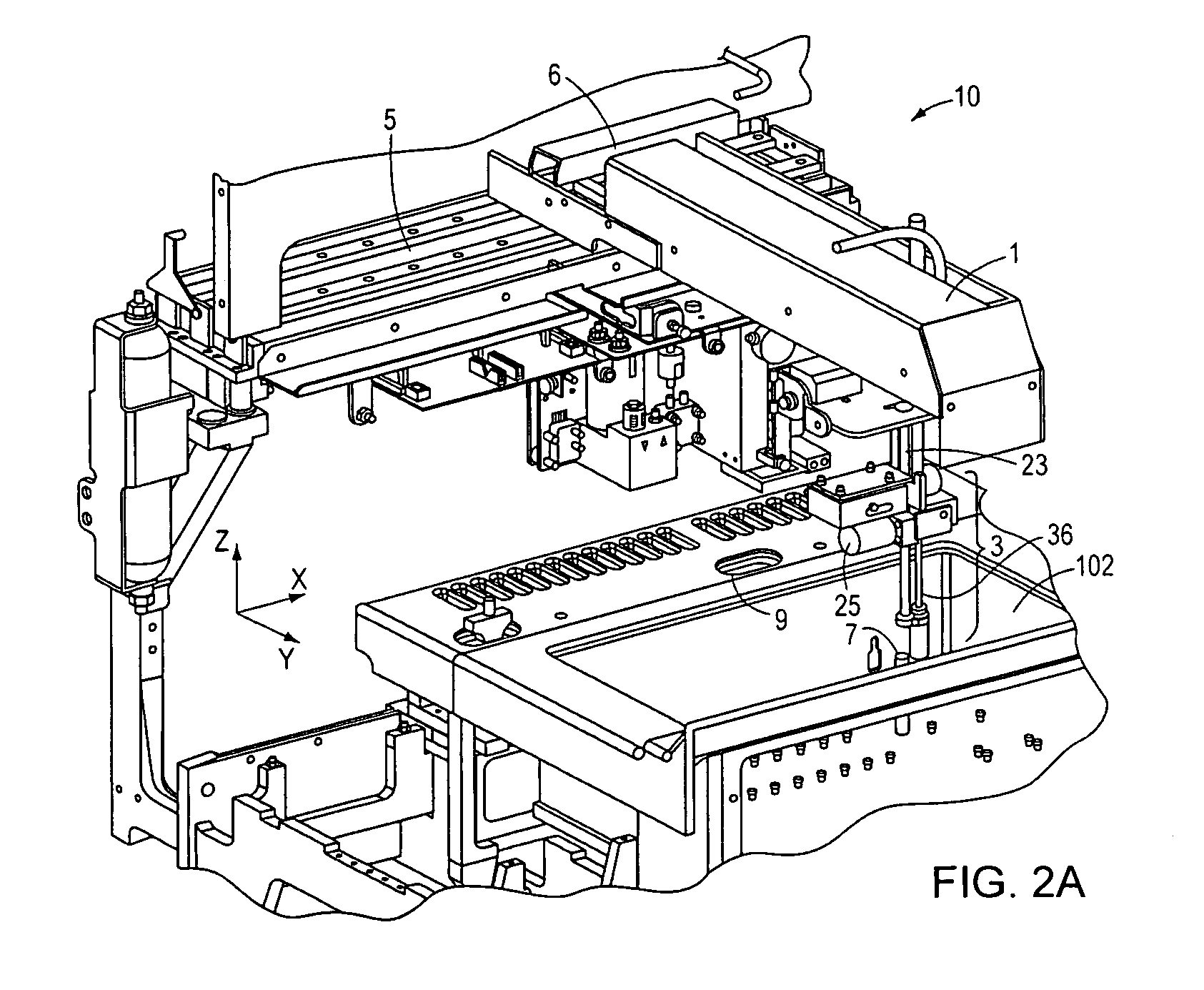

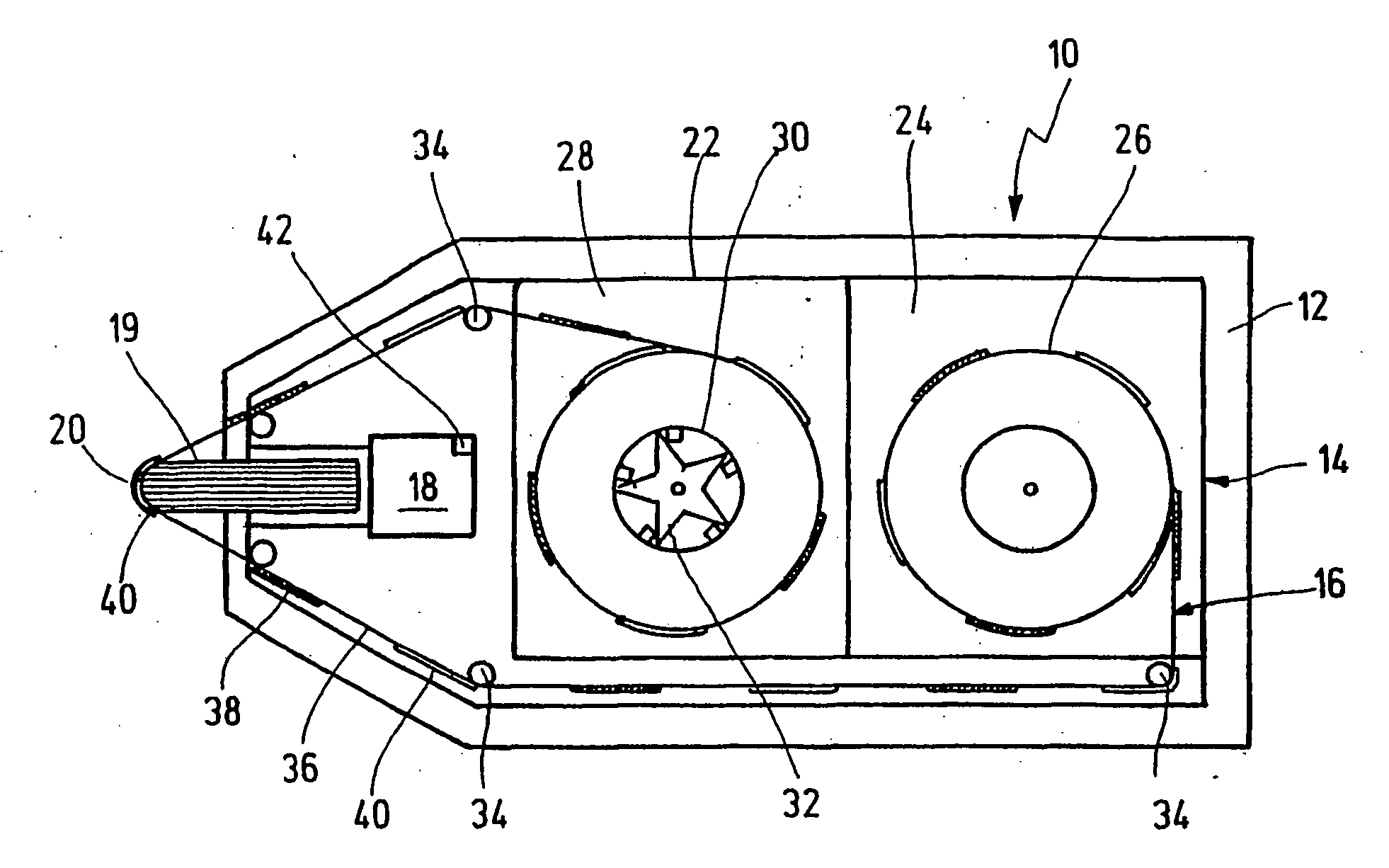

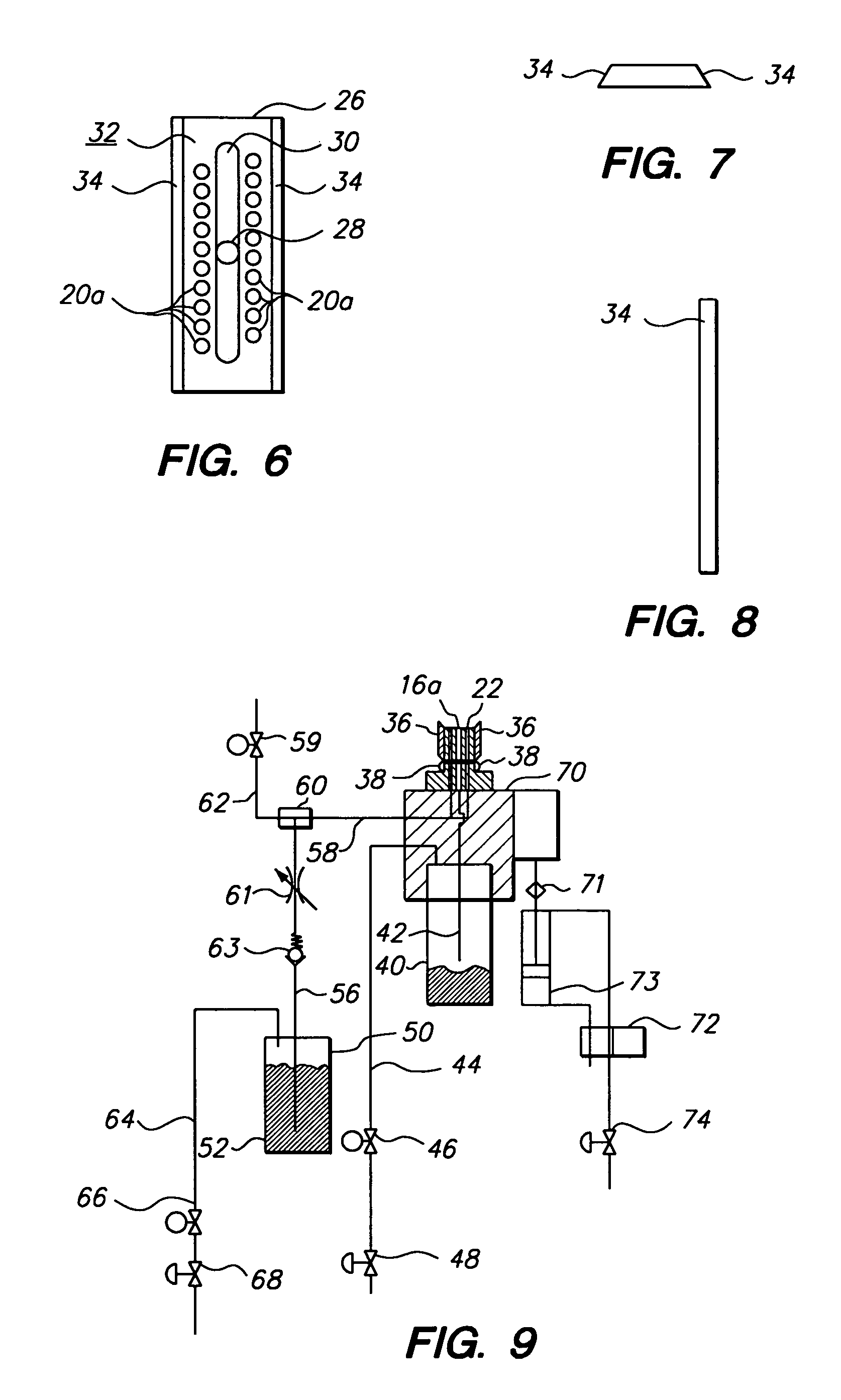

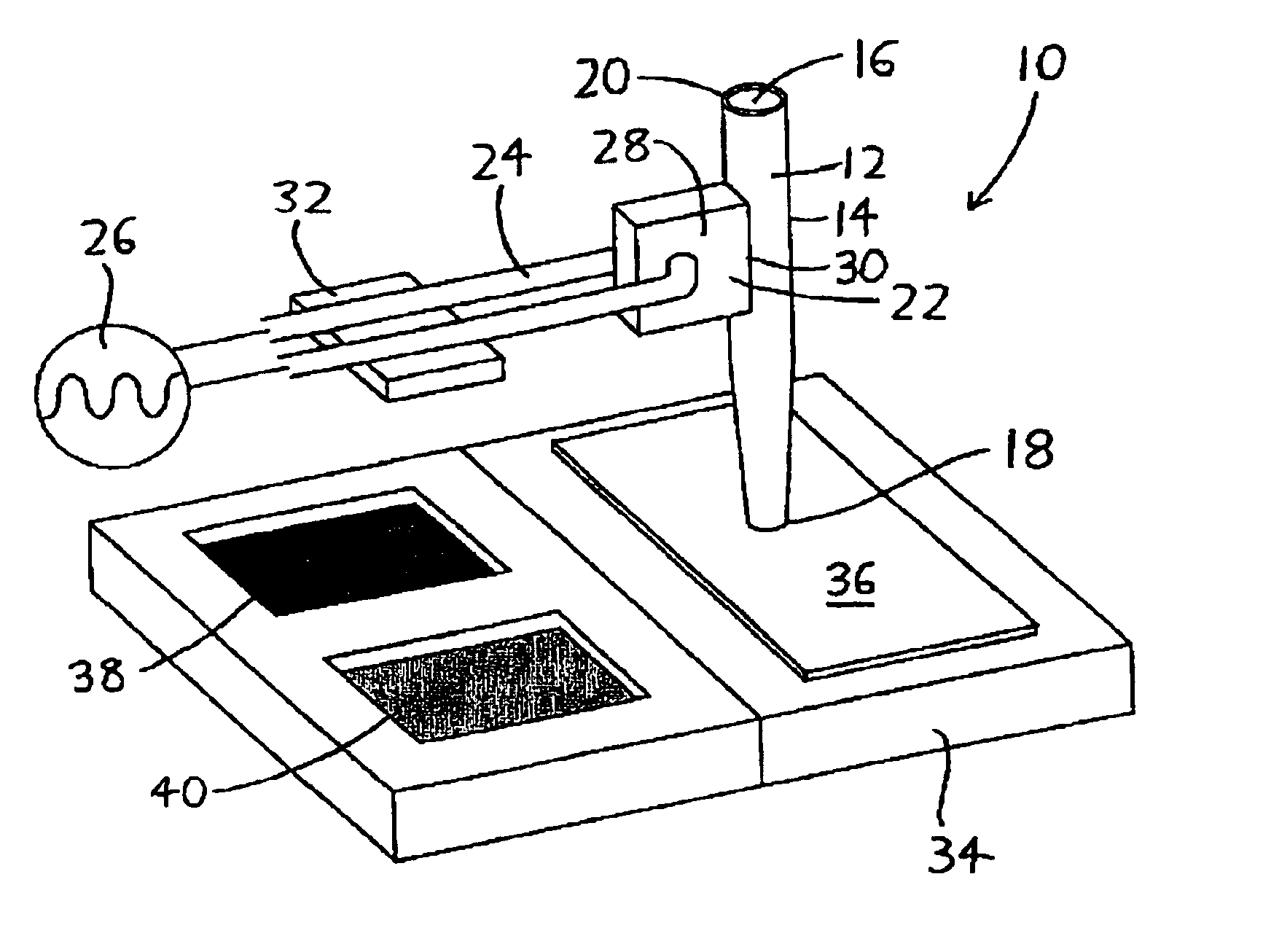

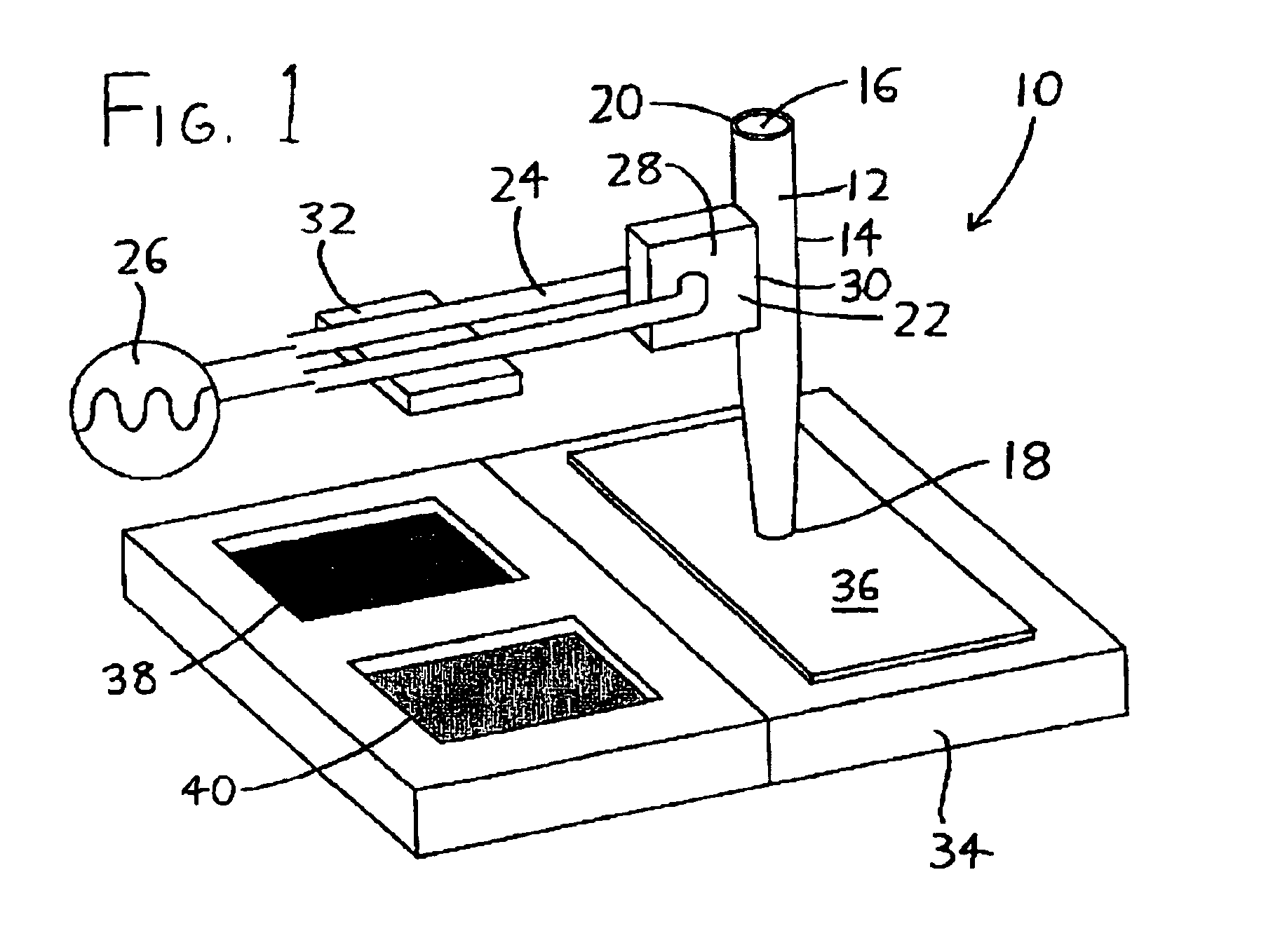

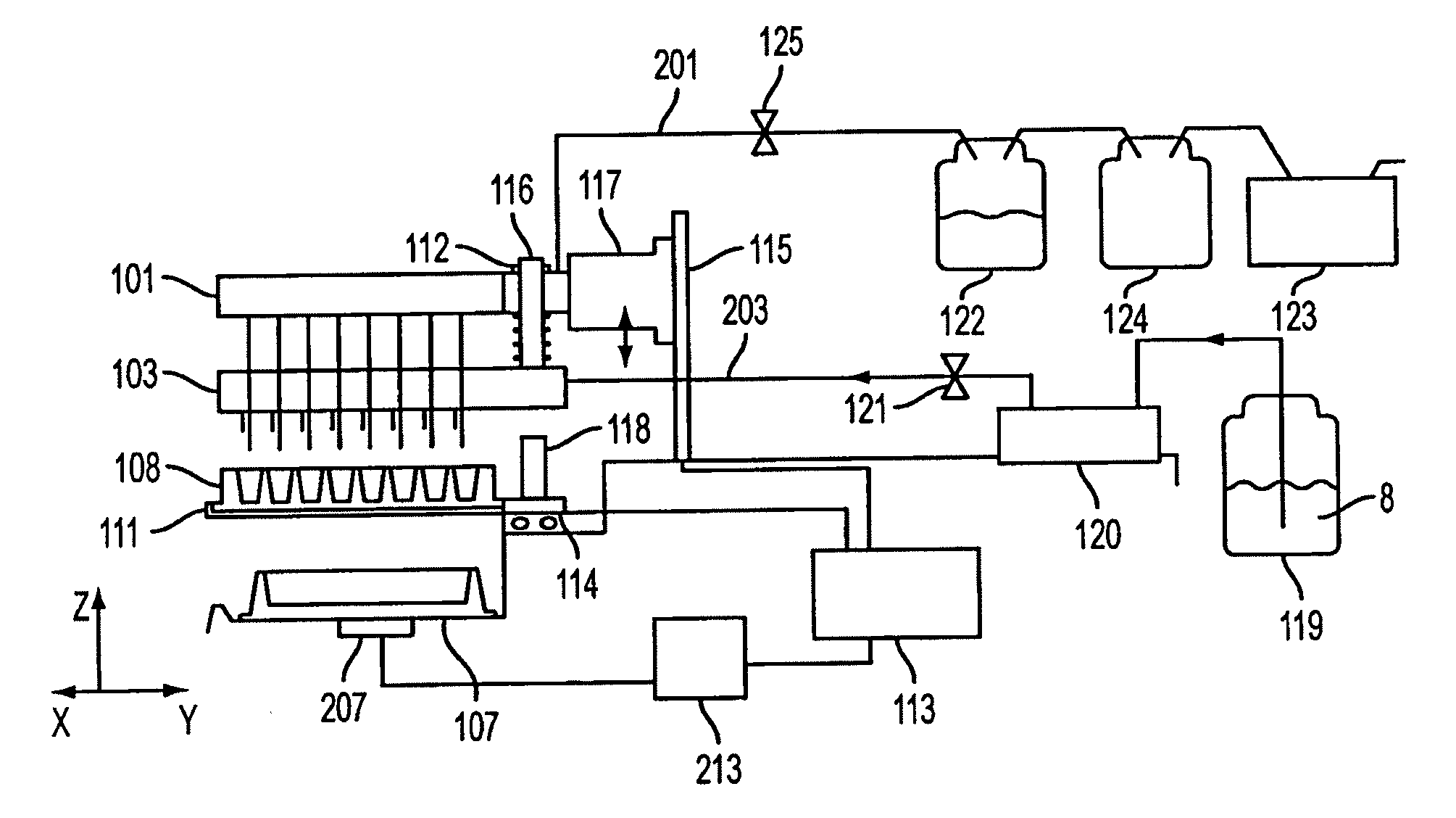

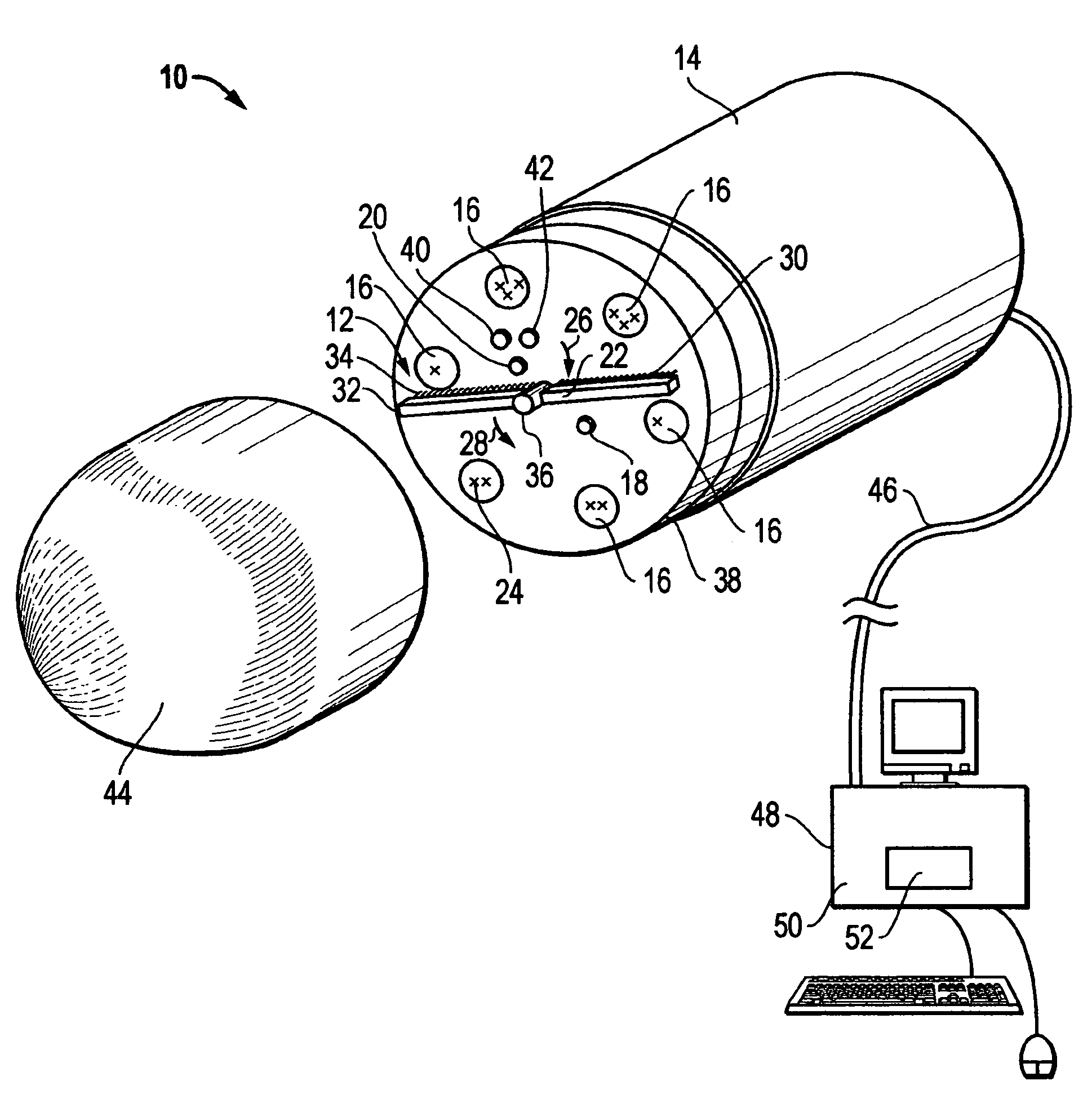

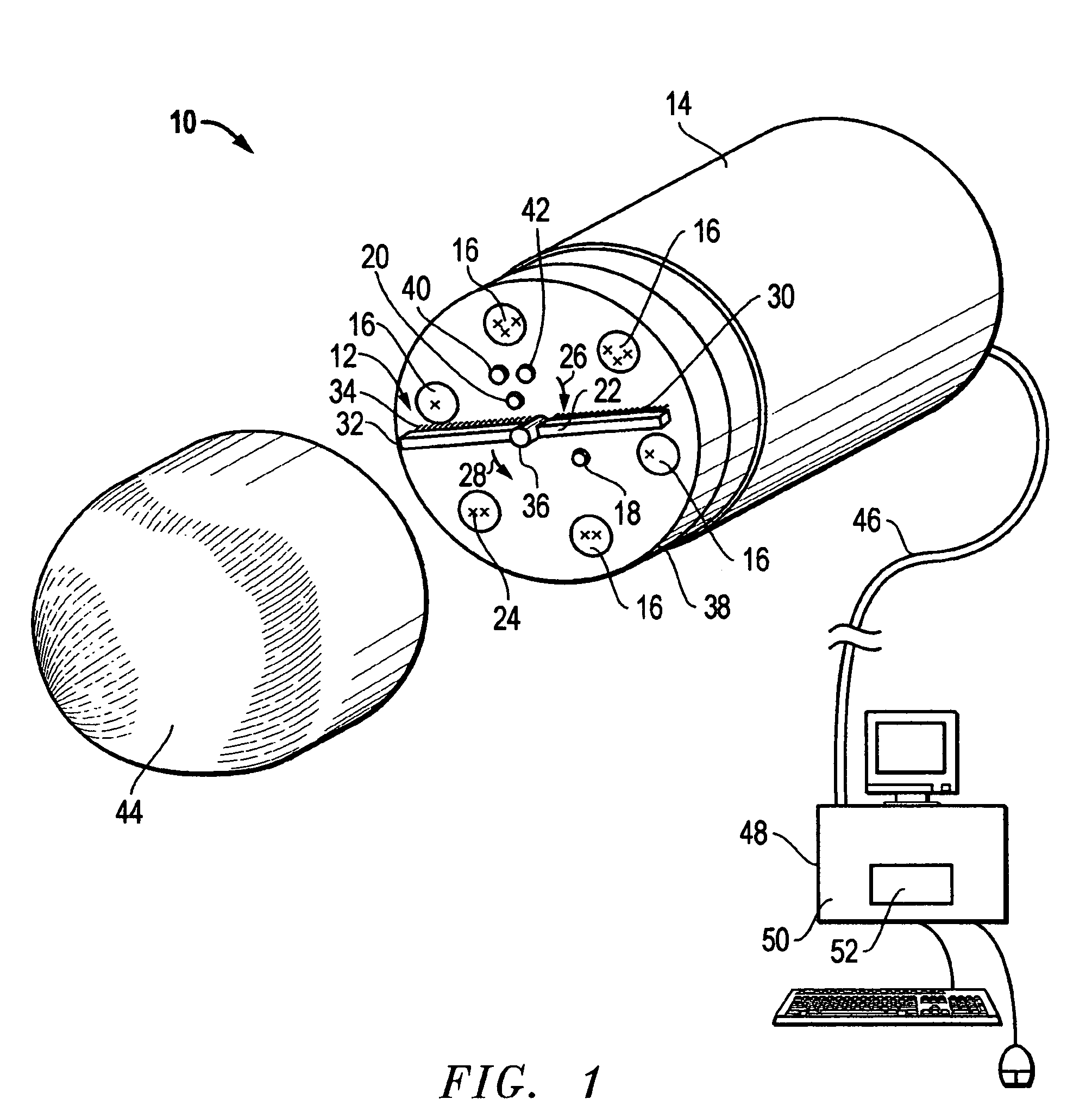

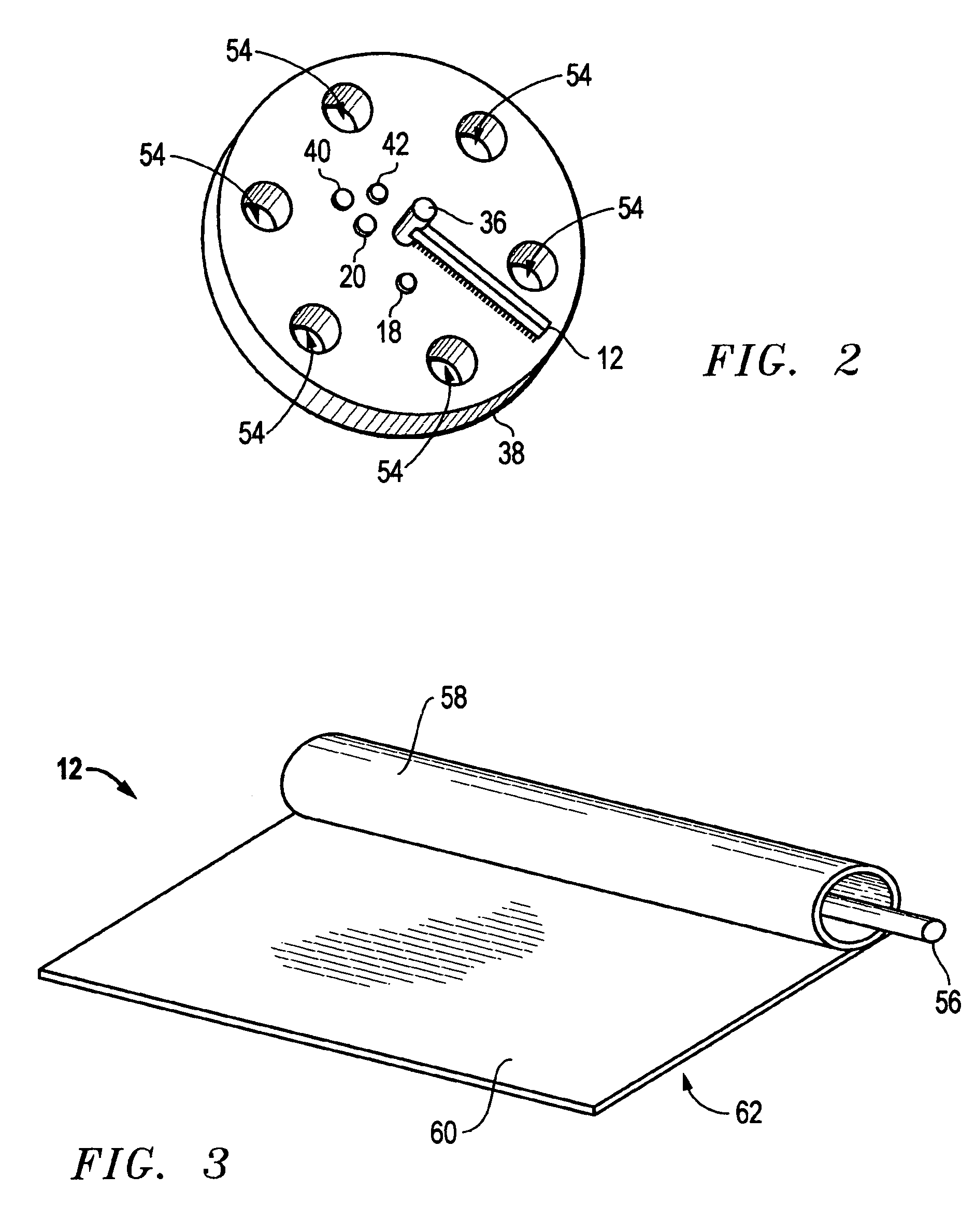

Microarray dispensing with real-time verification and inspection

InactiveUS7025933B2Improve spotImprove accuracySequential/parallel process reactionsElement comparisonAnalysis dataReal time validation

A microarrayer for spotting solution onto a receiving surface in an automated microarray dispensing device. Elements of the present invention include: at least one dispense head for spotting the receiving surface, at least one light source capable of illuminating the receiving surface, at least one camera operating in conjunction with the at least one light source. The at least one camera is capable of acquiring and transmitting surface image data to a computer. The computer is programmed to receive the surface image data and analyze it. The computer will then generate post analysis data based on the analysis of the surface image data. The post analysis data is available for improving the spotting of the solution onto the receiving surface. In a preferred embodiment, the surface image data includes information relating to receiving surface alignment, information relating to spot quality, and receiving surface identification information. In a preferred embodiment, the analysis of the information relating to receiving surface alignment enables the computer to make automatic adjustments to the relative positions of the at least one dispense head and the receiving surface to increase the accuracy of the spotting. In a preferred embodiment, the analysis of the information relating to spot quality identifies a spot as pass or fail. An operator is then able to rework the spot. In a preferred embodiment, the analysis of the receiving surface identification information enables the computer to track each receiving surface. In a preferred embodiment the receiving surface is a plurality of slides.

Owner:AGENA BIOSCI

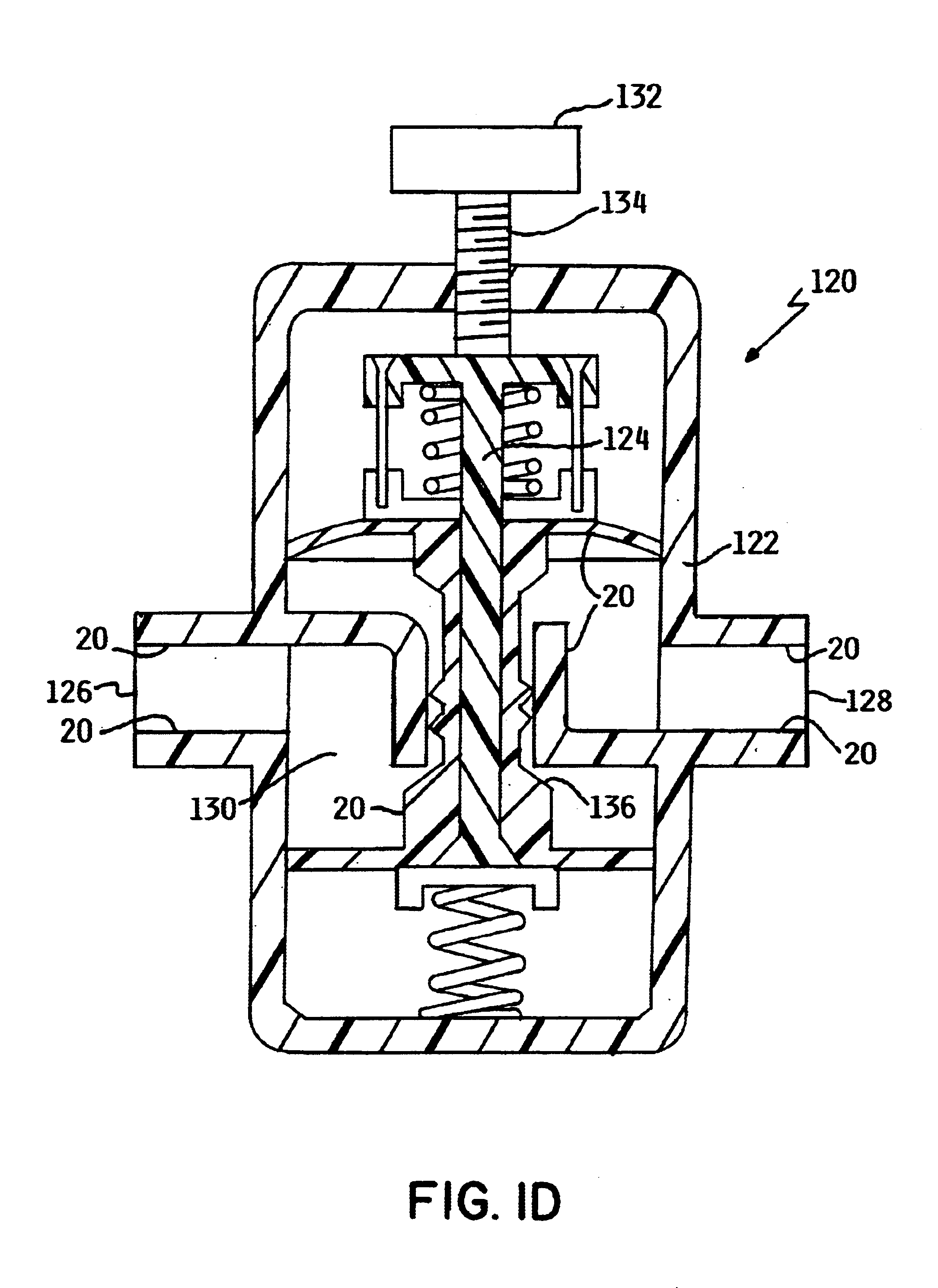

Telescoping closed-tube sampling assembly

A clinical diagnostic sample analyzer for analyzing a sample of a patient is disclosed. The analyzer includes a telescoping closed-tube sampling assembly with a sample probe concentrically housed within a piercing probe and a venting mechanism. The closed-tube sampling assembly is used for aspirating a sample from a sample tube for analysis by a clinical diagnostic sample analyzer.

Owner:INSTR LAB

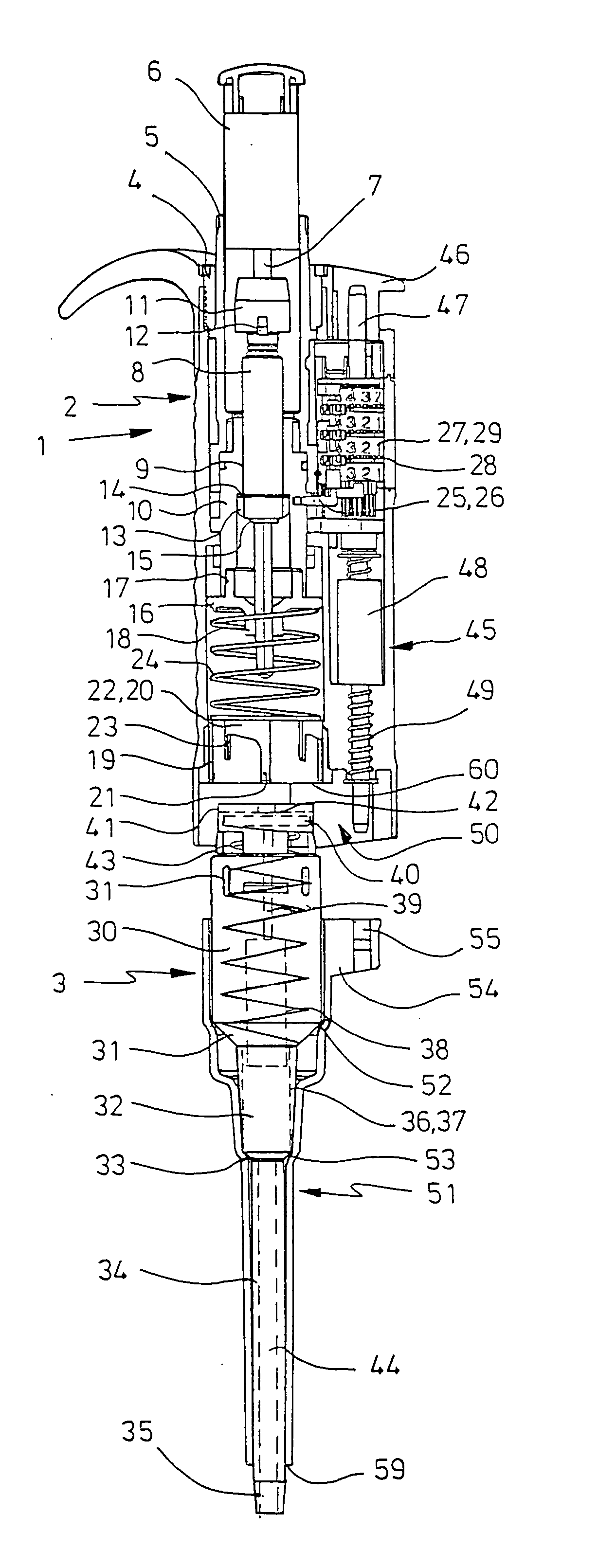

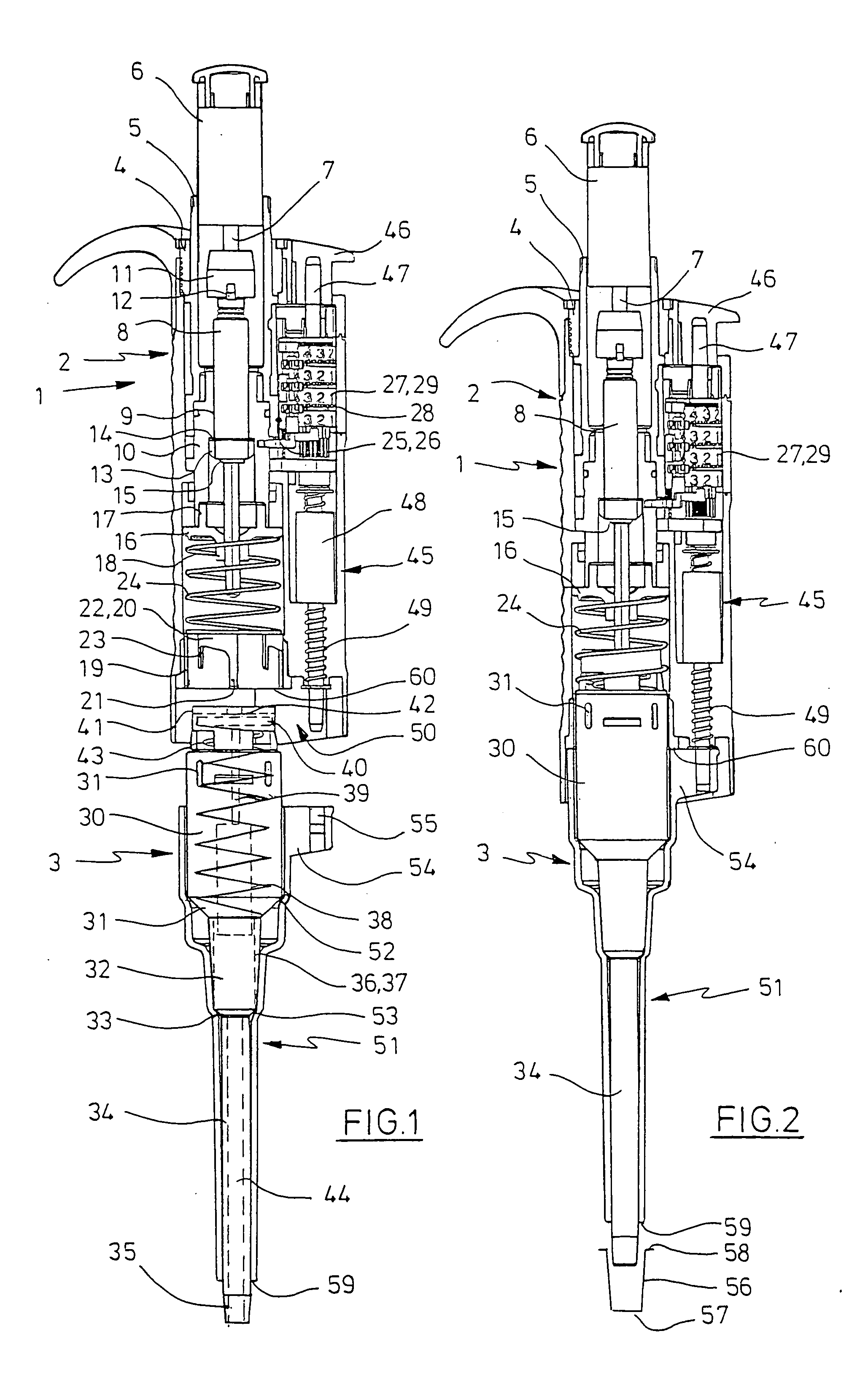

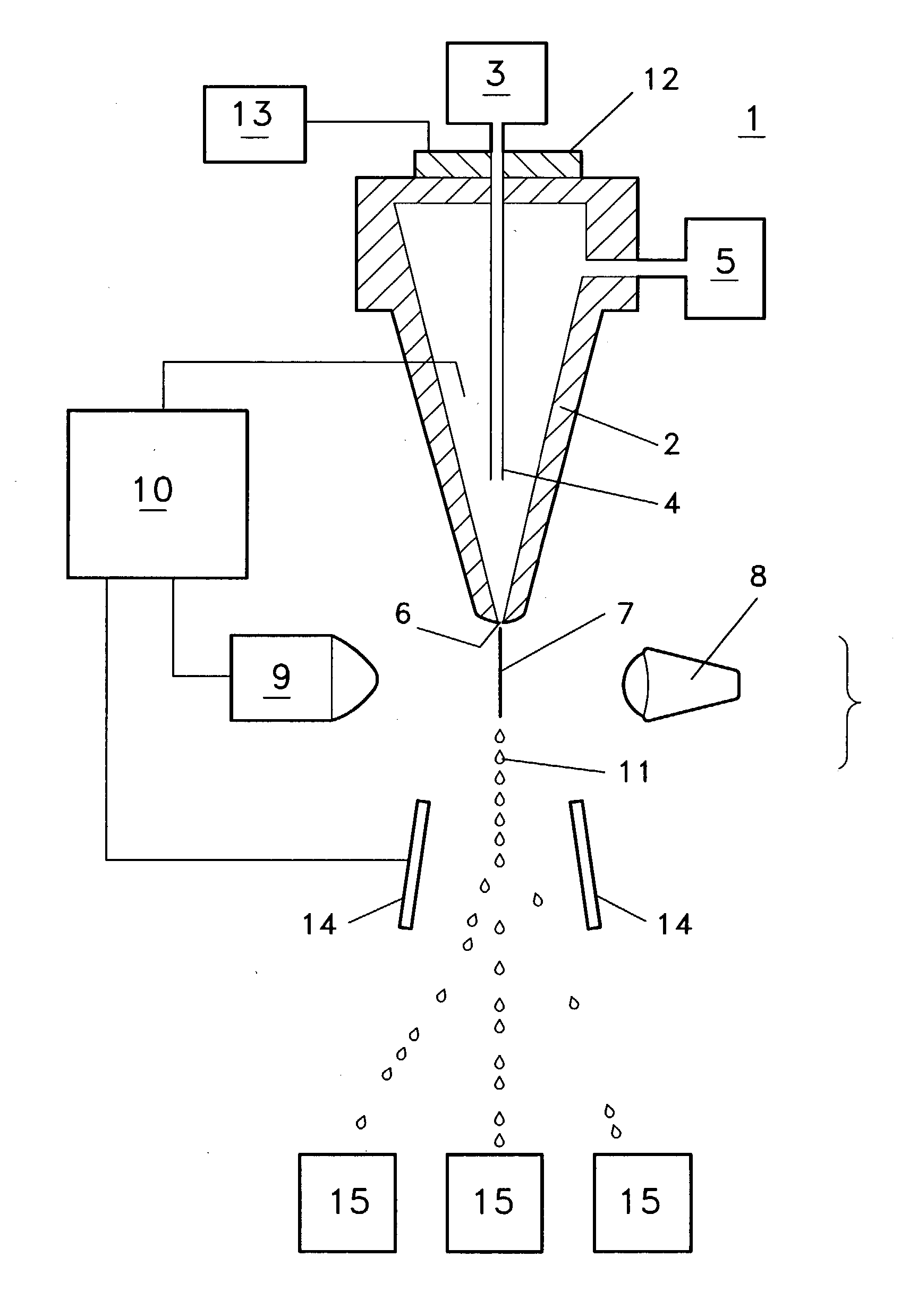

Device for aspirating and dispensing liquid samples

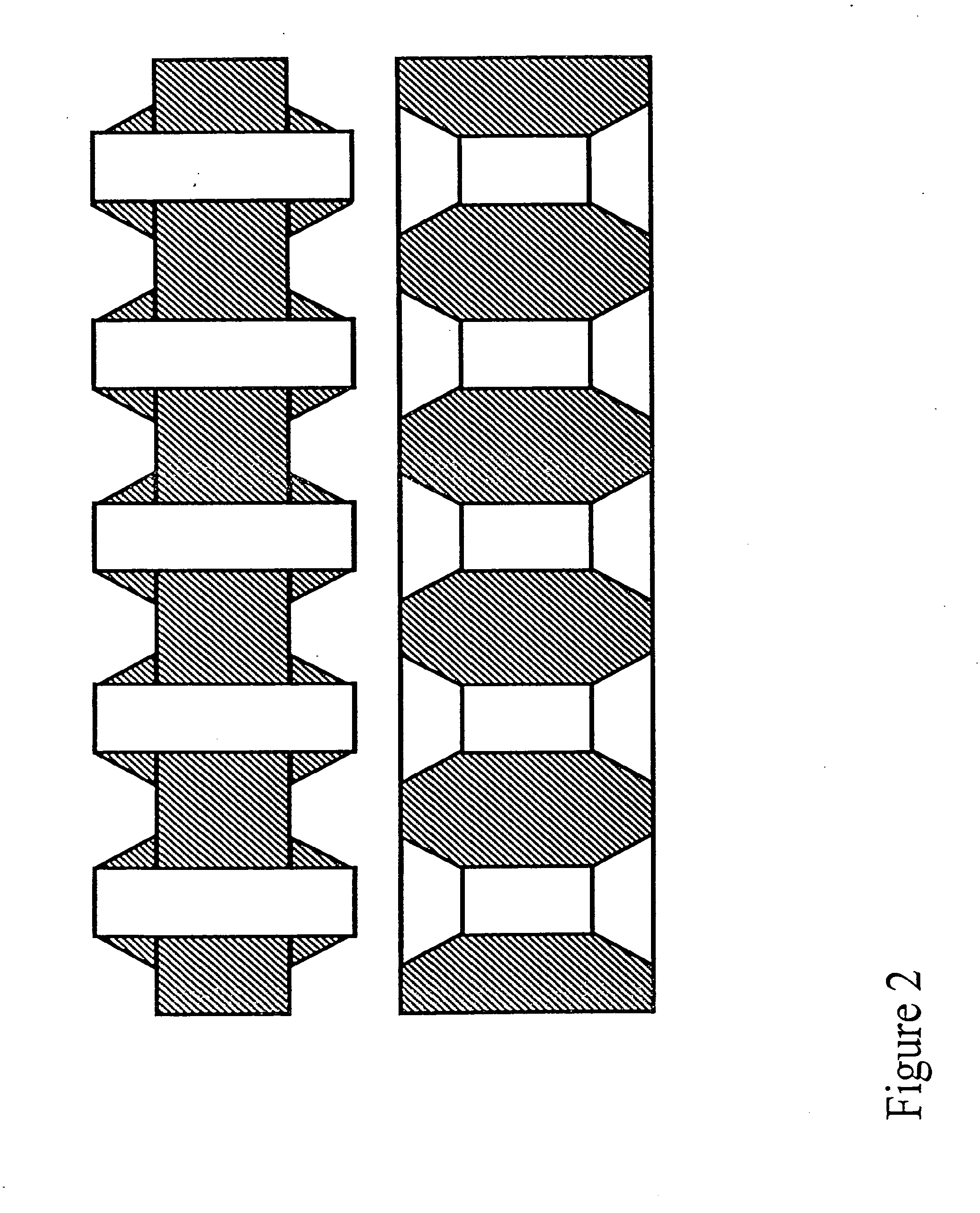

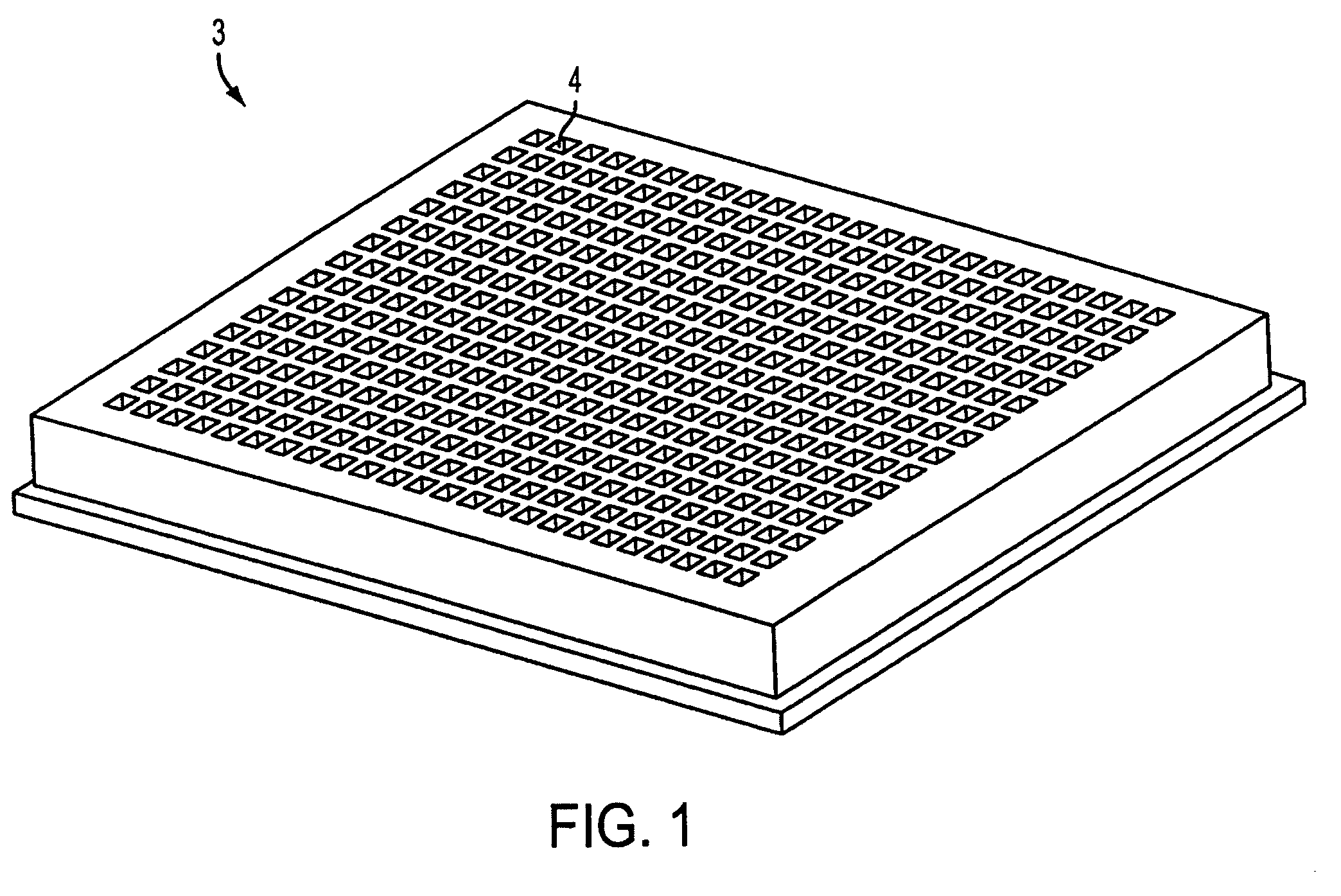

InactiveUS6869571B2Chemical analysis using titrationWithdrawing sample devicesEngineeringMechanical engineering

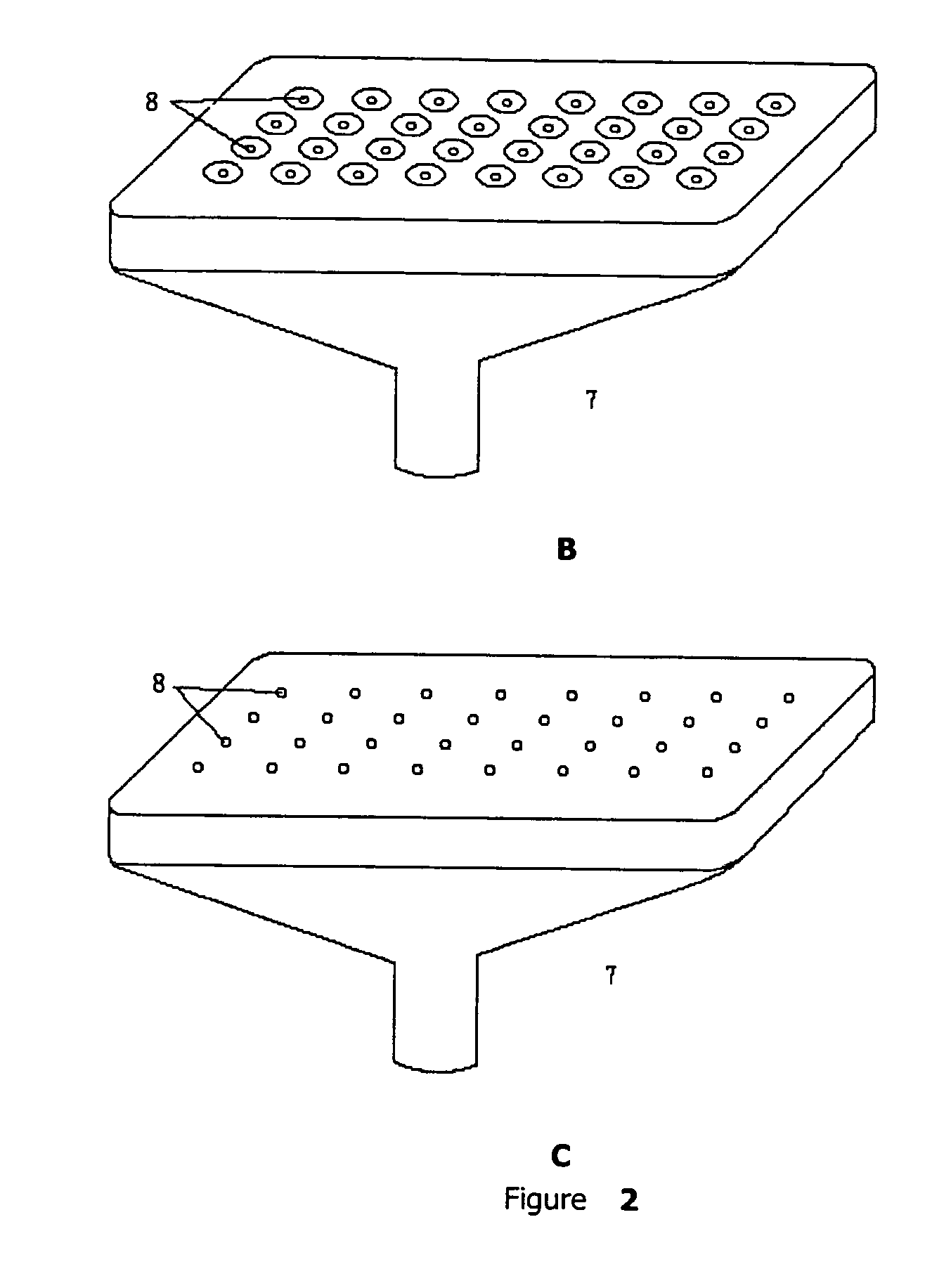

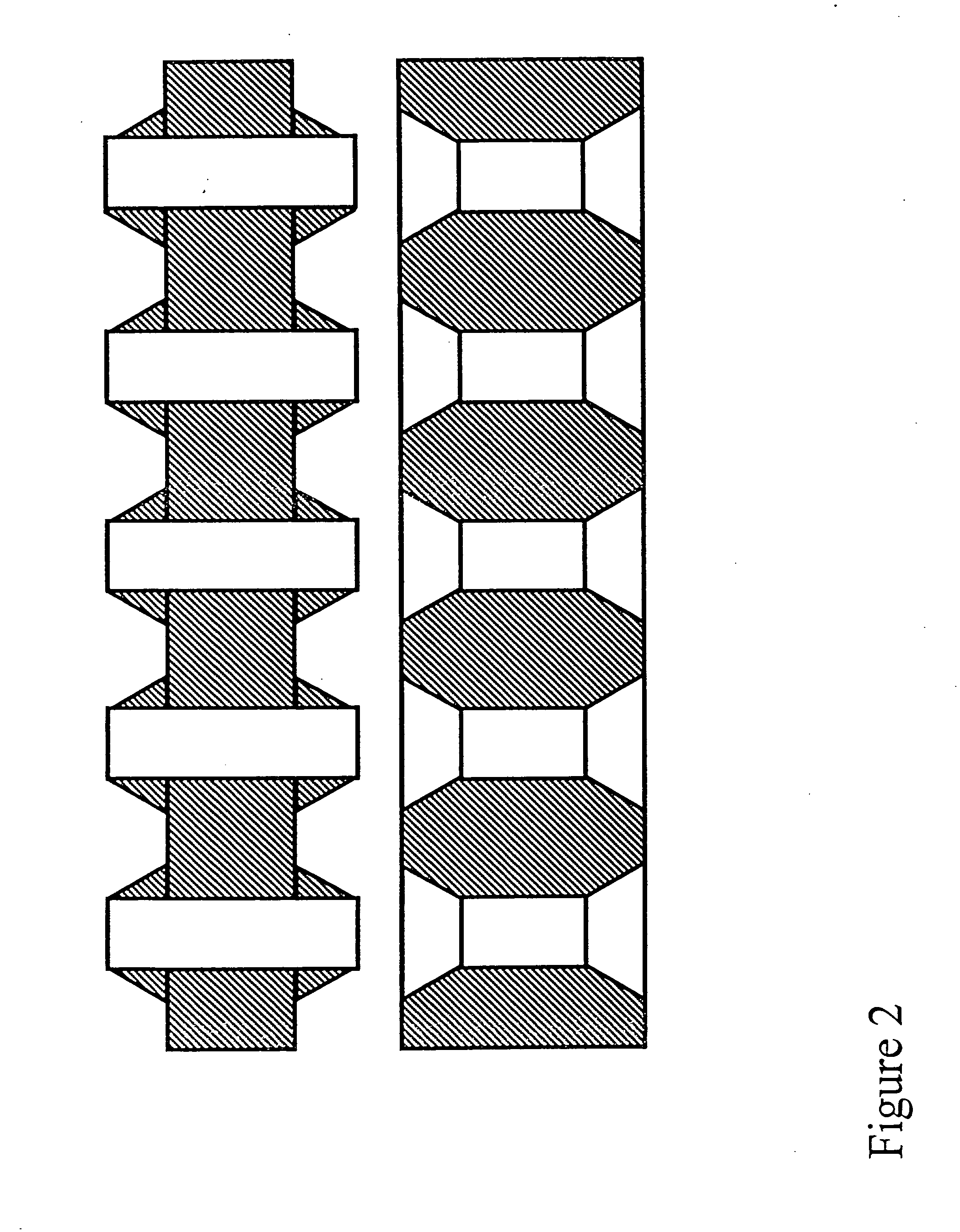

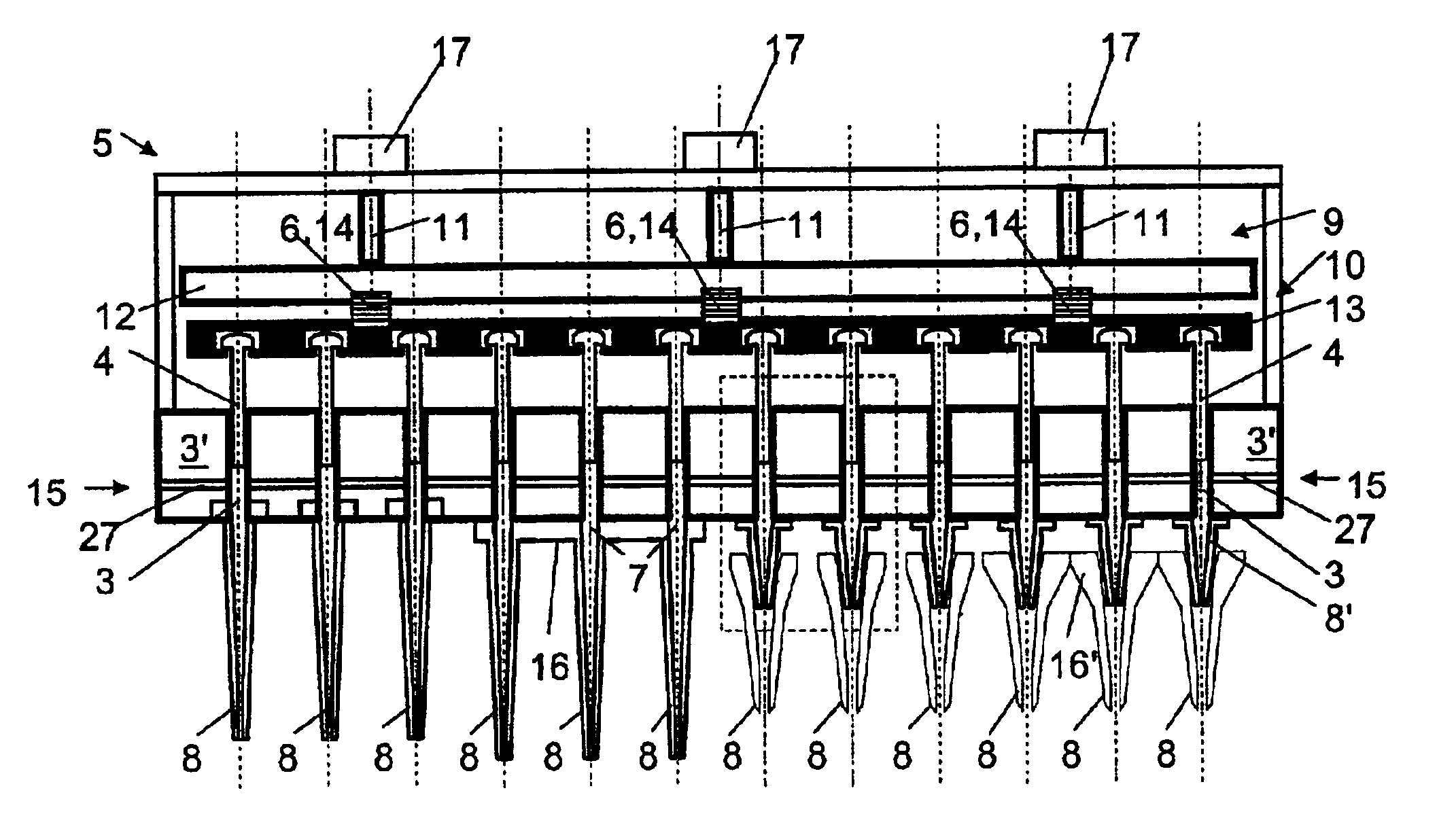

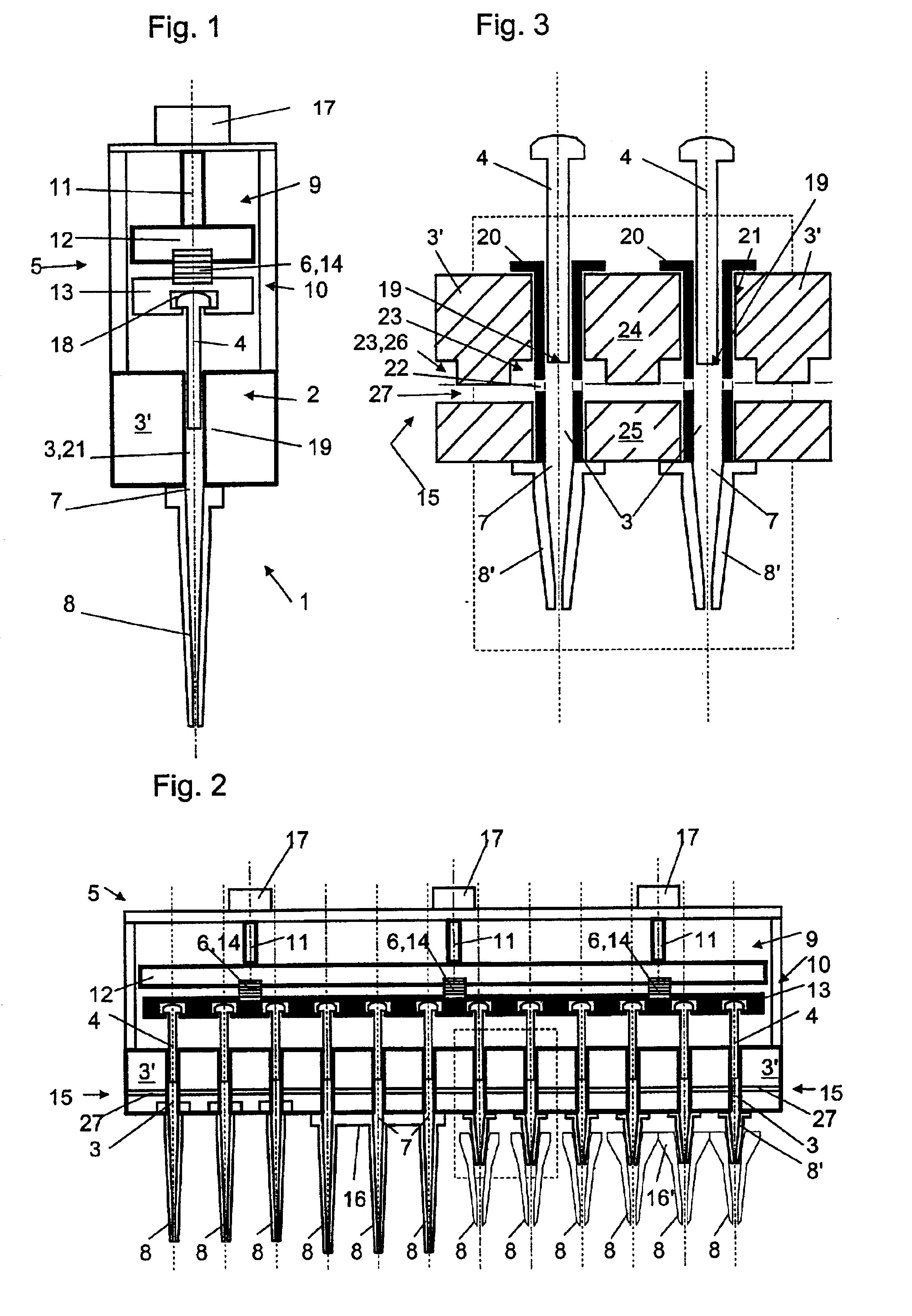

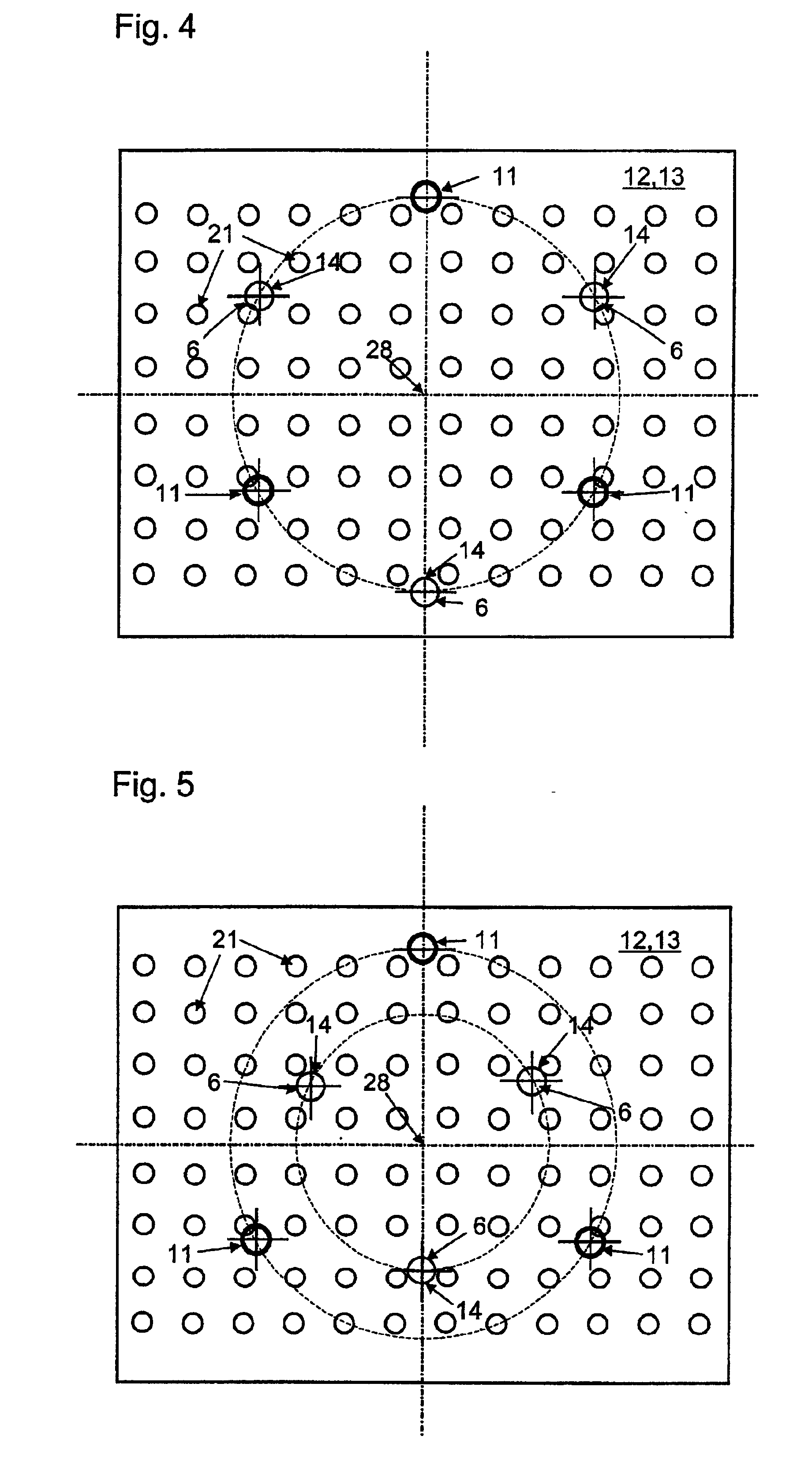

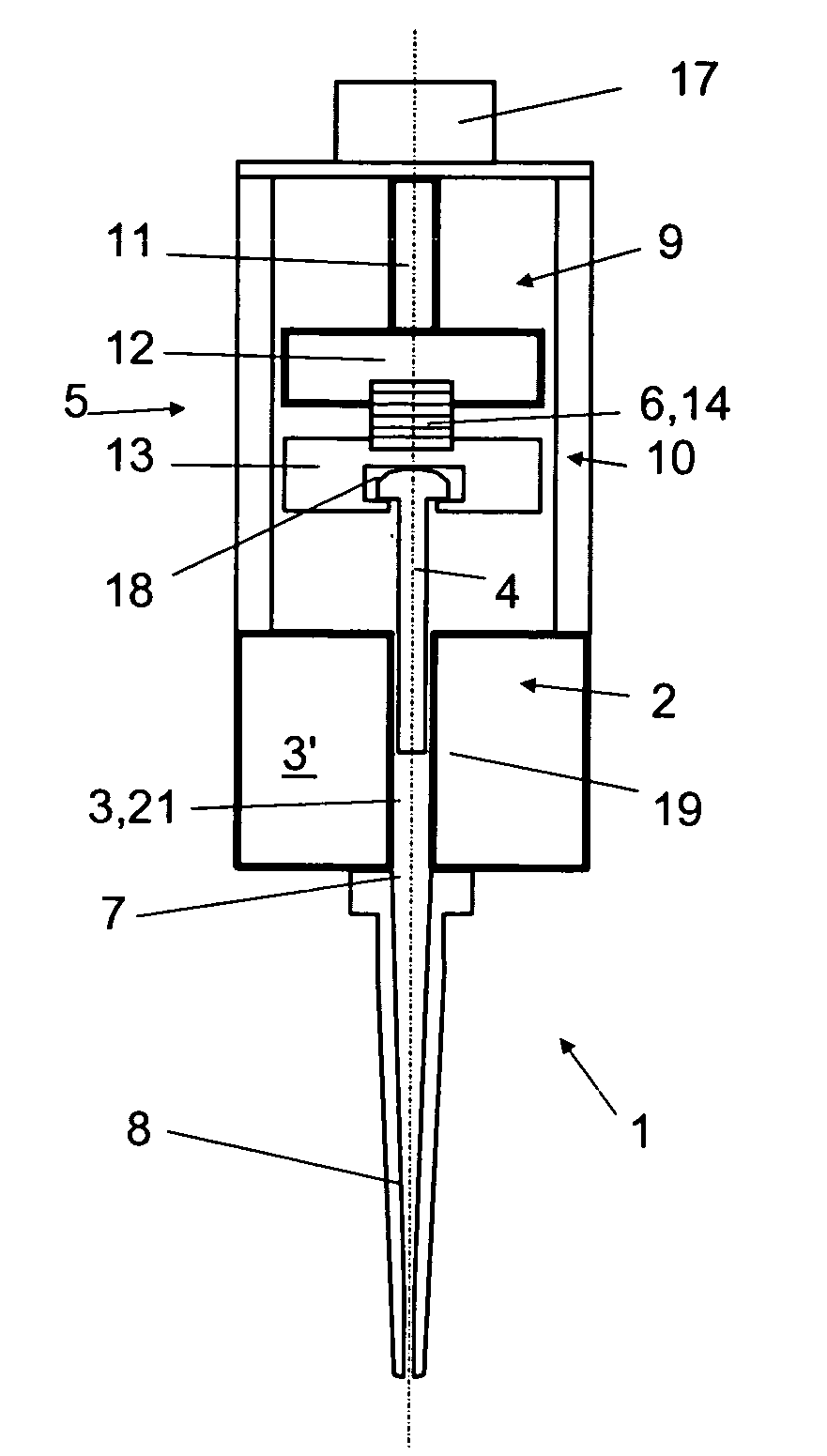

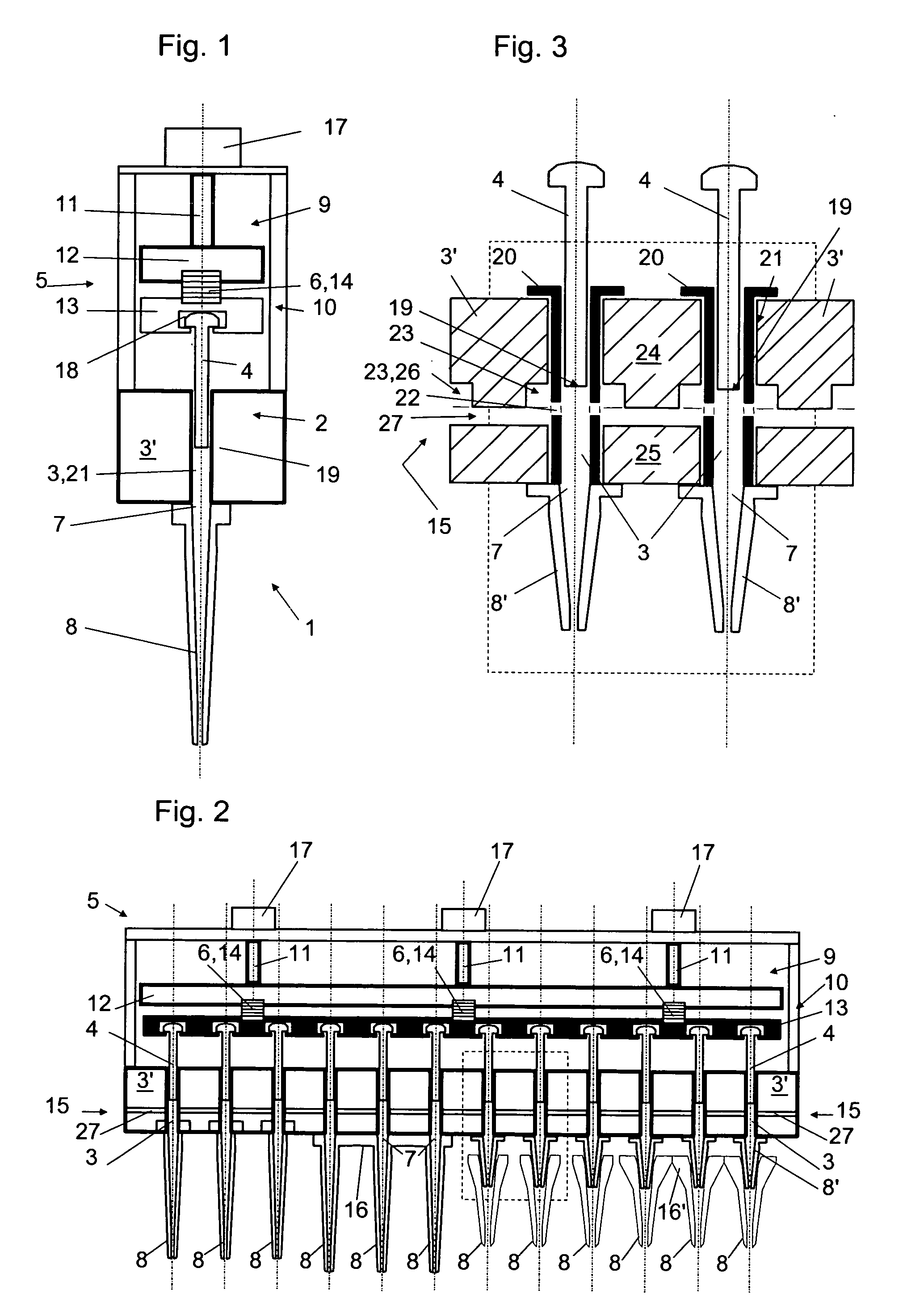

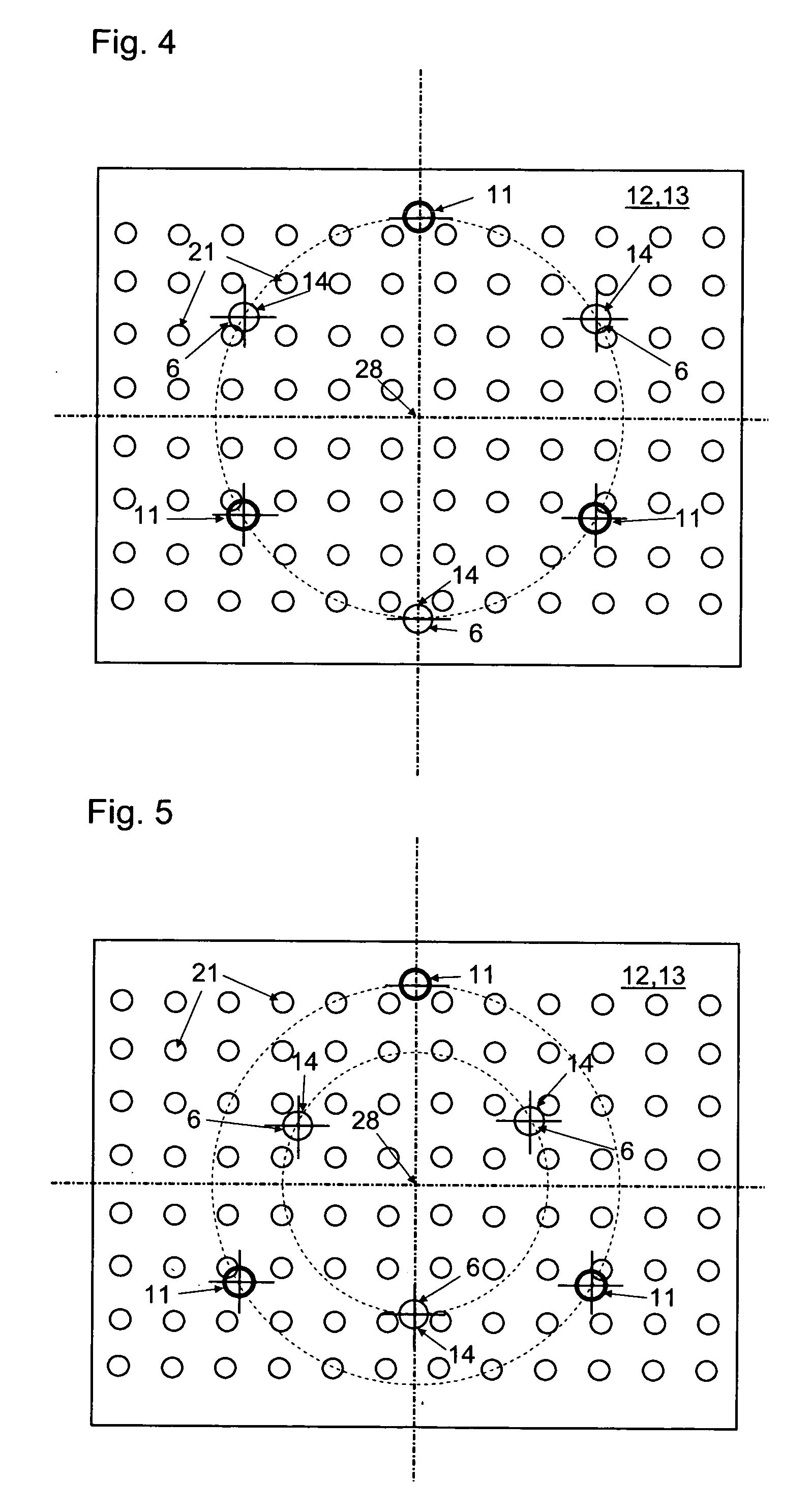

A device (1) for aspirating and dispensing liquid samples having a pump (2), which comprises a cylindrical chamber (3), a piston (4) movable in this cylindrical chamber, and a piston drive (5) engaging on the piston. The device additionally comprises a pulse generator (6), which effects dispensing of samples from a liquid by generating pressure waves in this liquid and a tip (8) connected via a line (7) with the cylindrical chamber (3), with the piston drive (5) comprising a first drive (9) and a second drive (10), implemented as a pulse generator (6). Such a device comprises a channel (27) for rinsing or flushing the cylindrical chamber (3), with the channel (27) discharging into the cylindrical chamber (3). Furthermore, the invention also concerns systems with, for example, 384 or more such devices that are arranged in an array.

Owner:TECAN TRADING AG

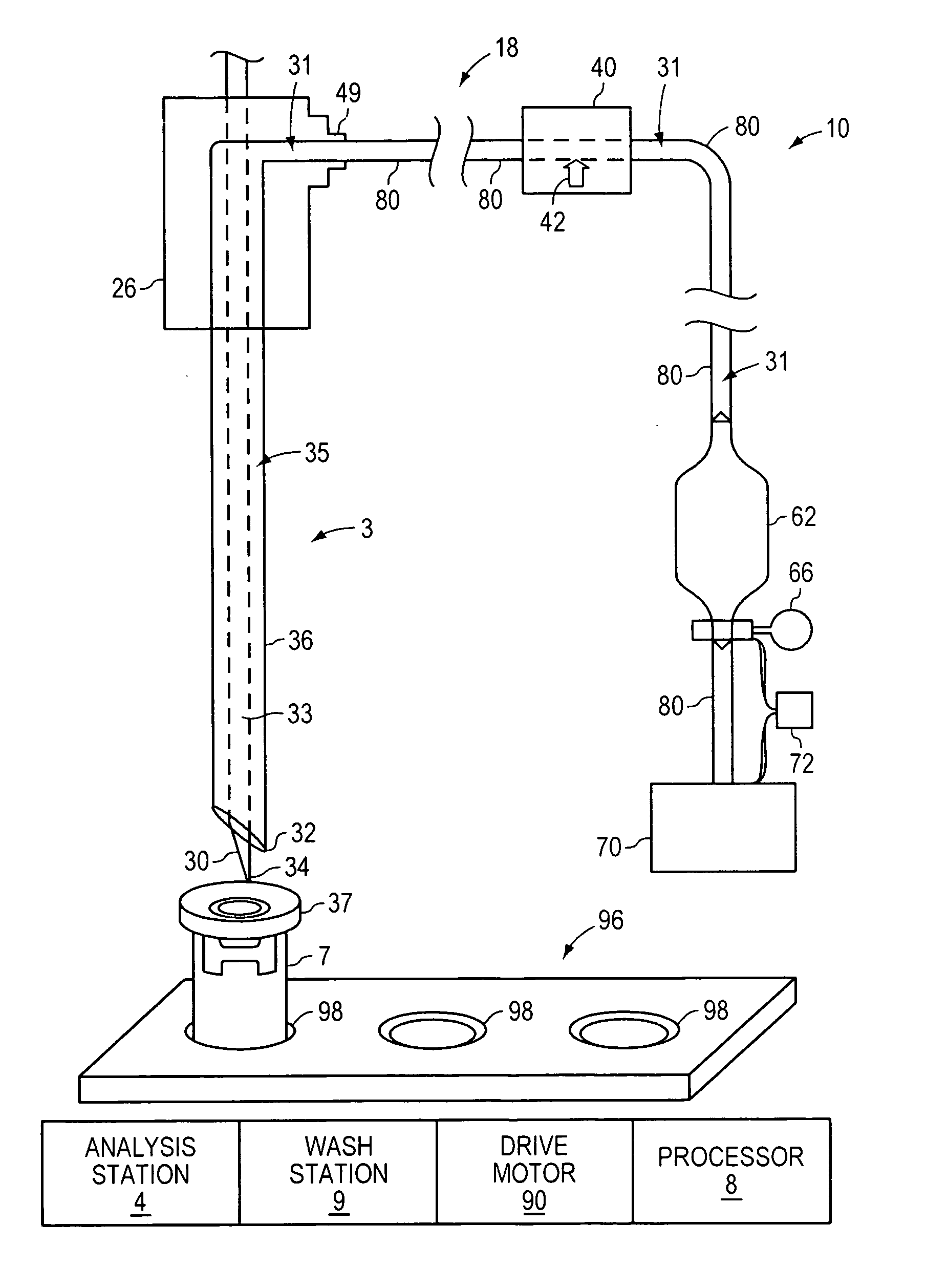

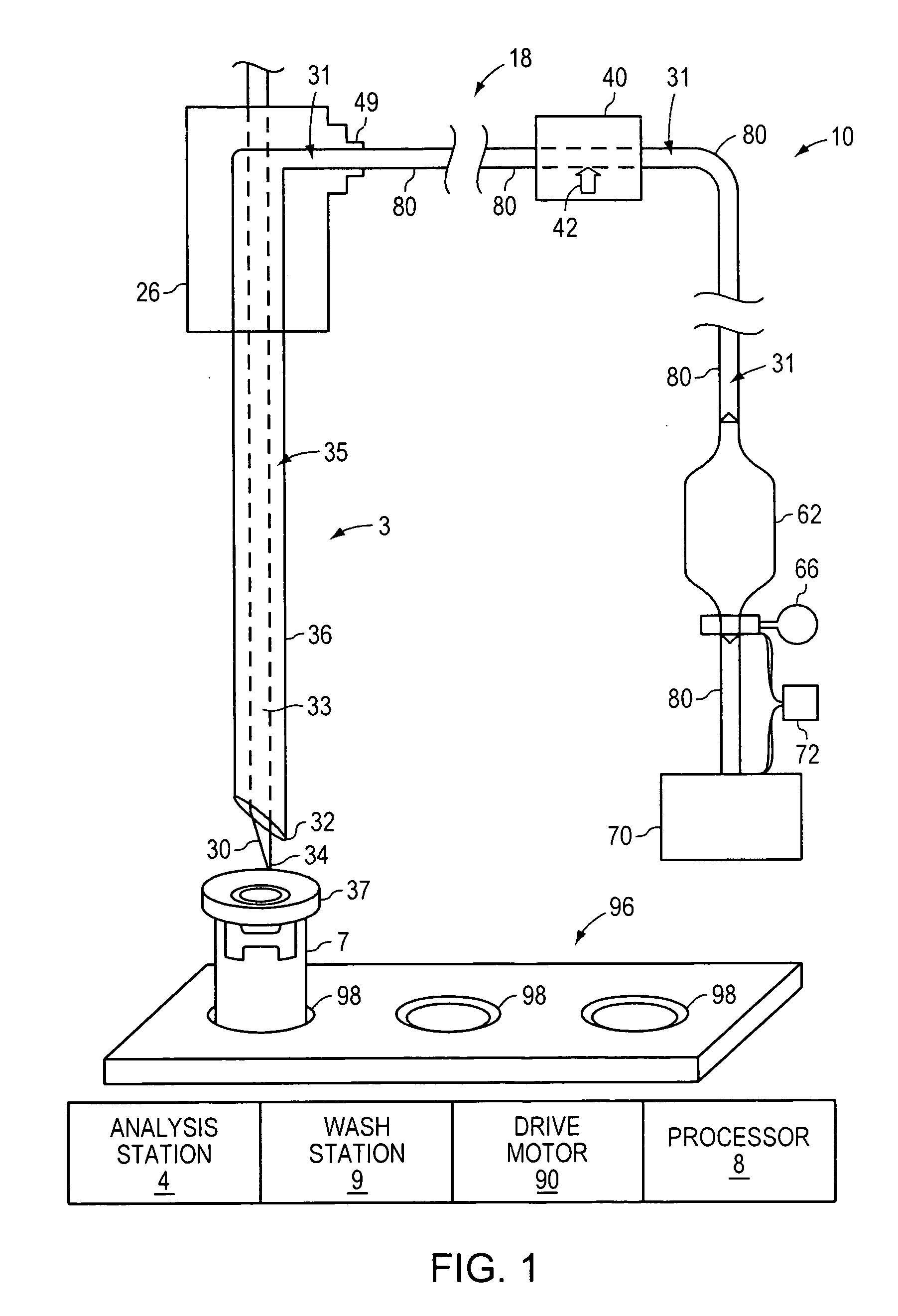

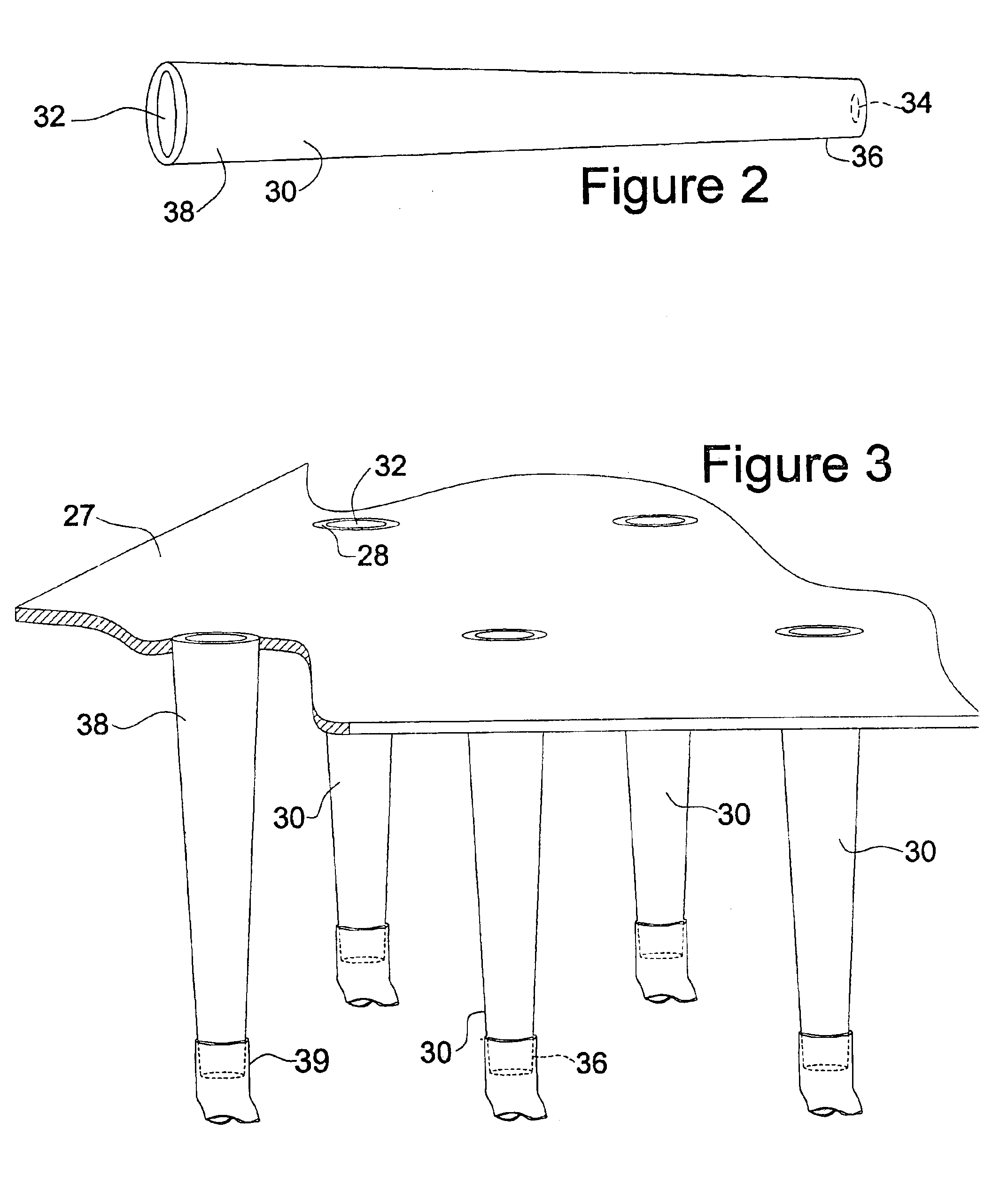

Liquid sampling probe and cleaning fluidics system

A sampling aliquotter for aspirating aliquot portions of sample fluid from a closed container and for dispensing aliquot portions into a vessel using horizontal and vertical drives to drive a probe into the closed container, to position the probe above the vessel, and to lower the probe into a cleansing module.

Owner:SIEMENS HEALTHCARE DIAGNOSTICS INC

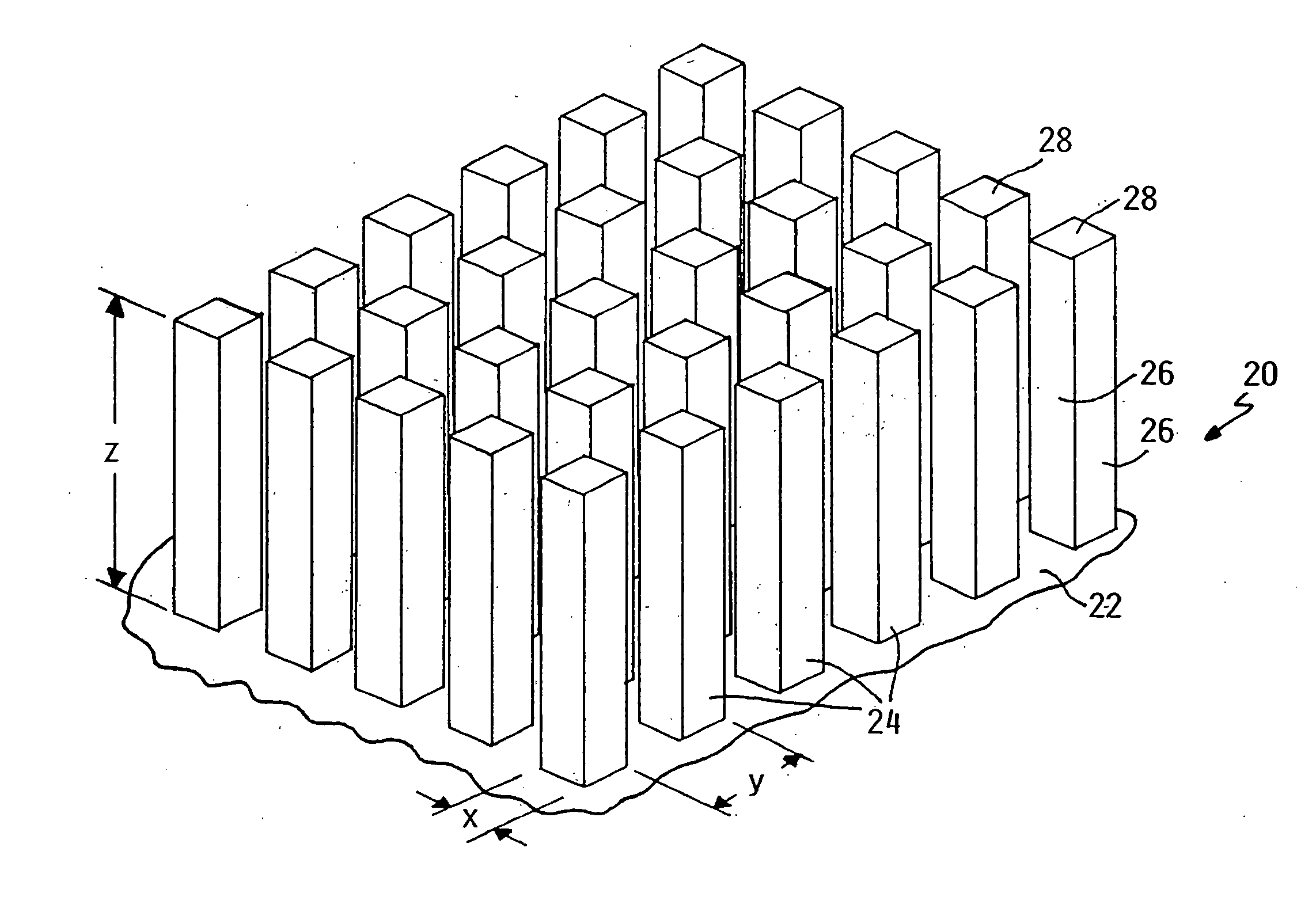

Ultraphobic surface for high pressure liquids

A durable ultraphobic surface that is capable of retaining ultraphobic properties at liquid pressures of one atmosphere and above. The surface generally includes a substrate portion with a multiplicity of projecting regularly shaped microscale or nanoscale asperities disposed so that the surface has a predetermined contact line density measured in meters of contact line per square meter of surface area equal to or greater than a contact line density value “ΛL” determined according to the formula: ΛL=-10,330γcos(θa,0+ω-90°)where γ is the surface tension of the liquid in Newtons per meter, θa,0 is the experimentally measured true advancing contact angle of the liquid on the asperity material in degrees, and ω is the asperity rise angle in degrees.

Owner:ENTEGRIS INC

Device for aspirating and dispensing liquid samples

A device for aspirating and dispensing liquid samples comprising a pump that comprises a cylindrical chamber, a piston movable in this cylindrical chamber, and a piston drive that engages the piston. The device further comprises a tip connected to the cylindrical chamber with a line, and a channel system that discharges into the cylindrical chamber for flushing or rinsing the latter. The device is characterized in that the piston entirely seals this cylindrical chamber from the channel system, if the piston is positioned in the cylindrical chamber in such a way that a free piston end comes to rest between the channel system and the line. Preferably, the cylindrical chamber is located in a cylinder block, which comprises two parts that are separated by and enclosing an intermediate channel system. The channel system most preferably is implemented as a coherent cavity. According to a first embodiment, the cylindrical chamber is implemented as a sleeve that is inserted in a boring located in a cylinder block. According to a second embodiment, the cylindrical chamber is implemented as a boring located in a cylinder block. Furthermore, the invention also concerns systems with, for example, 384 or more such devices that are arranged in an array.

Owner:TECAN TRADING AG

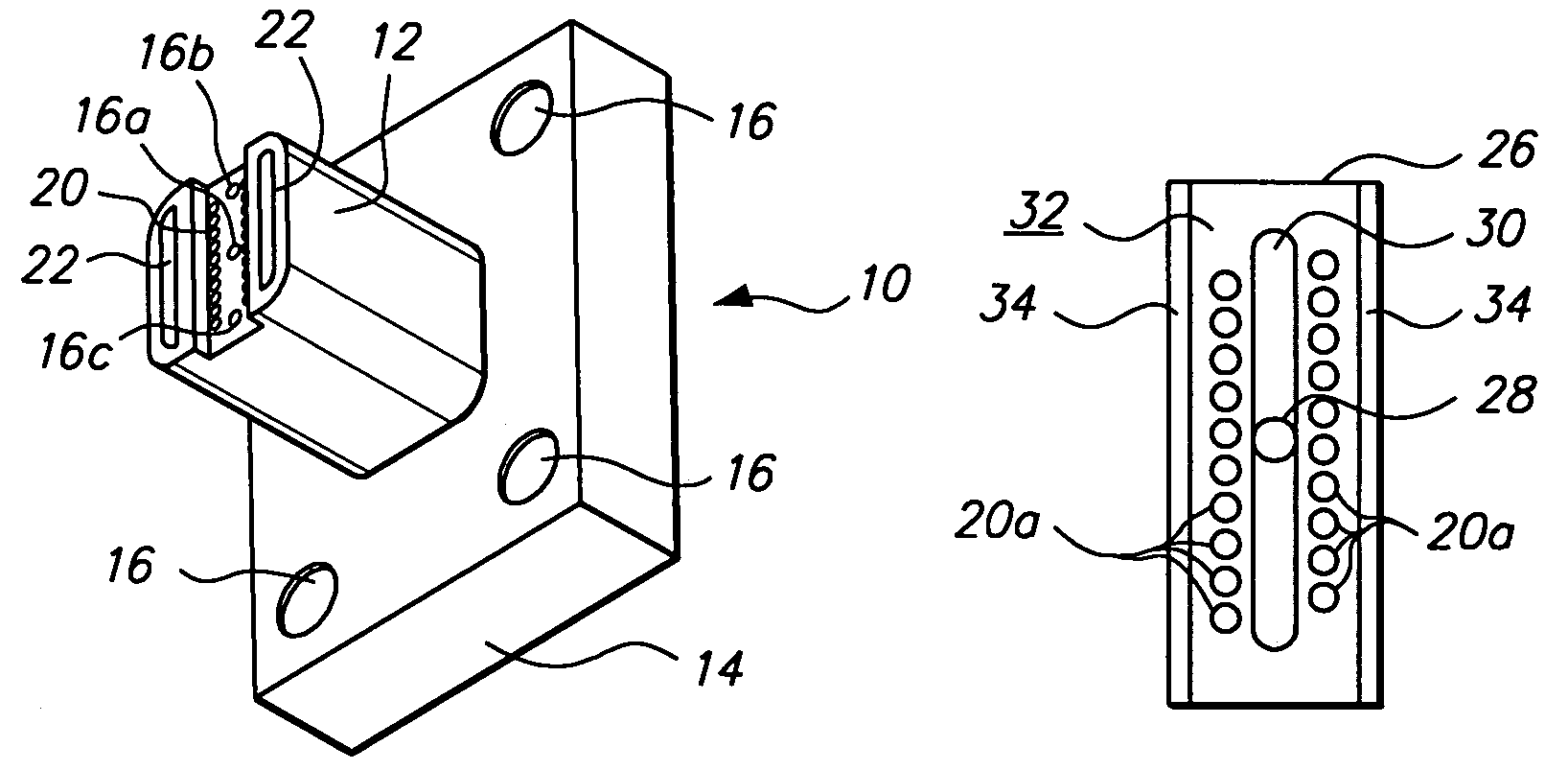

Pipetting device with a displacement device and a drive device releasably connected therewith

ActiveUS20050155438A1Easy to findEasy to assembleWithdrawing sample devicesBurettes/pipettesPipetteEngineering

Pipetting device with a displacement device with a displacement chamber with a displaceable limiter, a attachment for connecting to a pipette tip and a connecting channel between the displacement chamber and the free end of the attachment, a drive device for driving the displaceable limiter of the displacement device with a drive member, which has a releasable cooperation with the displaceable limiter, and a bayonet connection between the drive device and the displacement device which can be established by creating the cooperation between the drive member and the displaceable limiter and can be released by releasing the cooperation between the drive member and the displaceable limiter.

Owner:EPPENDORF SE

Fluid handling component with ultraphobic surfaces

InactiveUS6845788B2Reduce frictionImprove system efficiencyMaterial nanotechnologyFouling preventionVolumetric Mass DensityContact line

A fluid handling component having a durable ultraphobic fluid contact surface that is capable of exhibiting ultraphobic properties at liquid pressures of one atmosphere and above. The surface generally includes a substrate portion with a multiplicity of projecting regularly shaped microscale or nanoscale asperities disposed so that the surface has a predetermined contact line density measured in meters of contact line per square meter of surface area equal to or greater than a contact line density value “ΛL” determined according to the formula: ΛL=-10,330γcos(θa,0+ω-90°)where γ is the surface tension of the liquid in Newtons per meter, θa,0 is the experimentally measured true advancing contact angle of the liquid on the asperity material in degrees, and ω is the asperity rise angle in degrees.

Owner:ENTEGRIS INC

Test device for analyzing body fluids

ActiveUS20060216817A1Function increaseBioreactor/fermenter combinationsBiological substance pretreatmentsInstrument functionEngineering

A test instrument for analyzing body fluids such as blood or urine. The instrument includes a wound test tape which can be transported from a storage space into a waste space by advancing the tap. The test tape has a plurality of test sections to which body fluid can be applied at a receiving position and also includes a measuring unit for detecting a constituent of the body fluid on an active test section. In order to carry out auxiliary instrument functions, in addition to the test sections, the test tape has one or more functional sections which can be brought into a functional position by advancing the tape.

Owner:ROCHE DIABETES CARE INC

Apparatus and methods for cleaning and priming droplet dispensing devices

Owner:AGILENT TECH INC

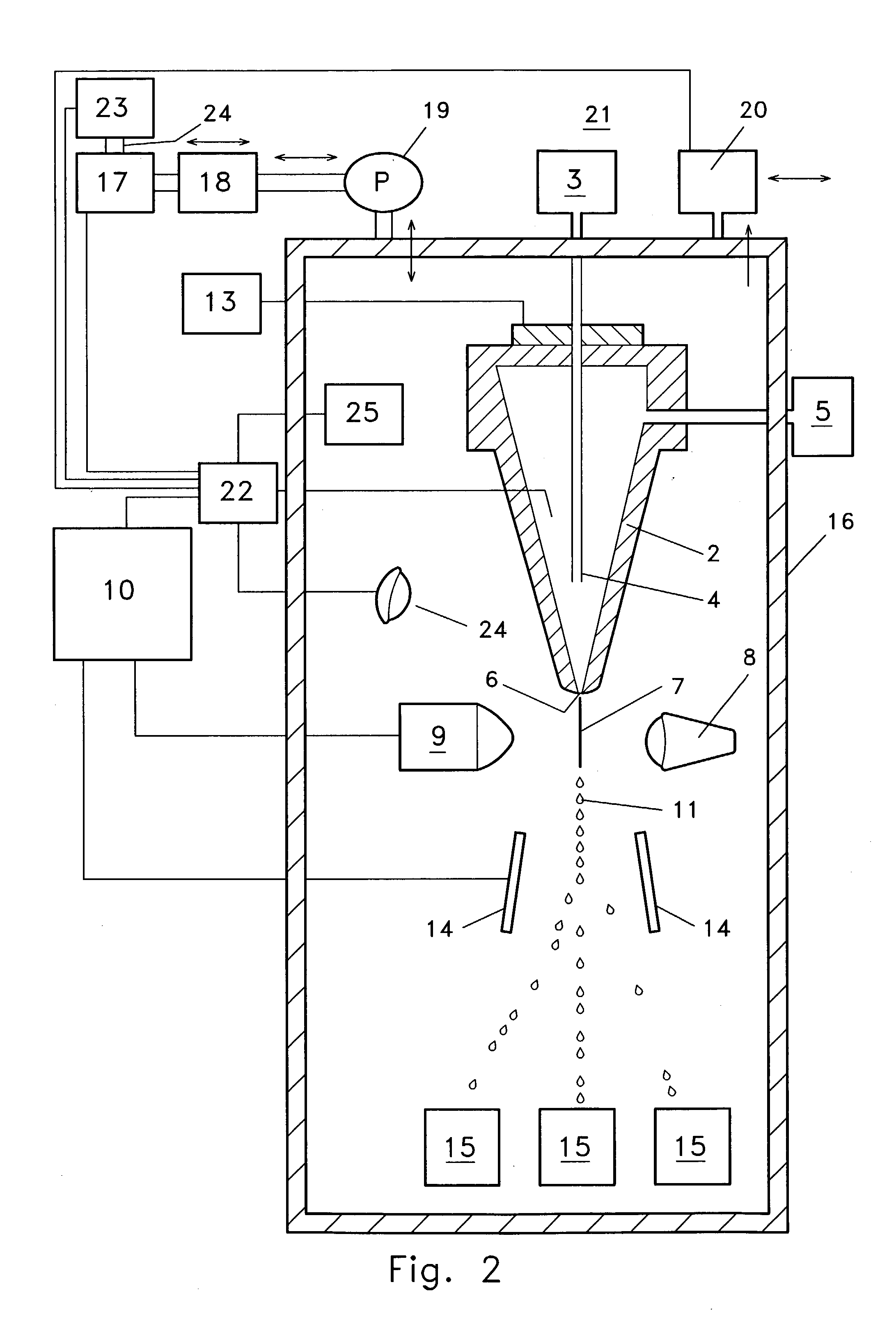

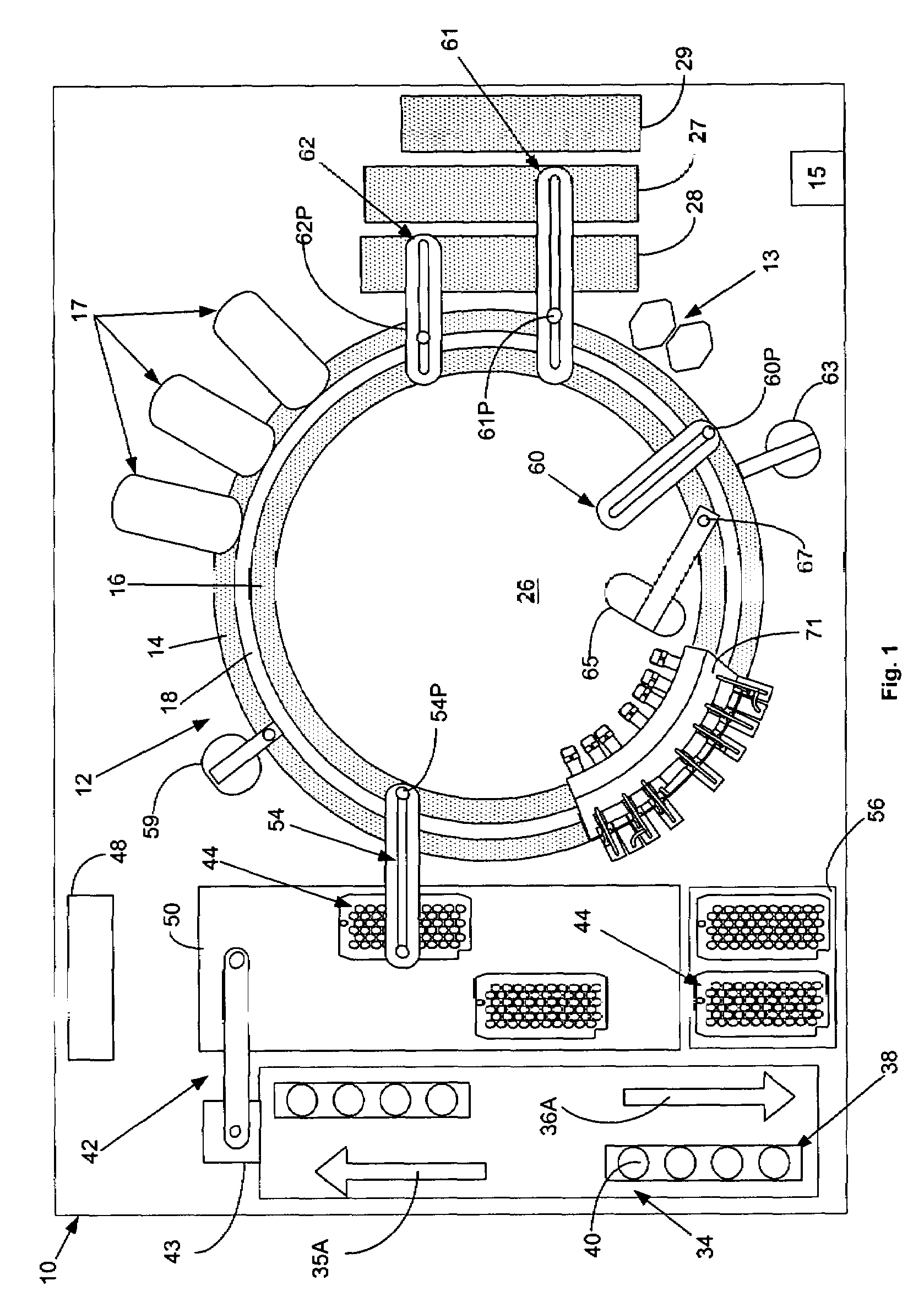

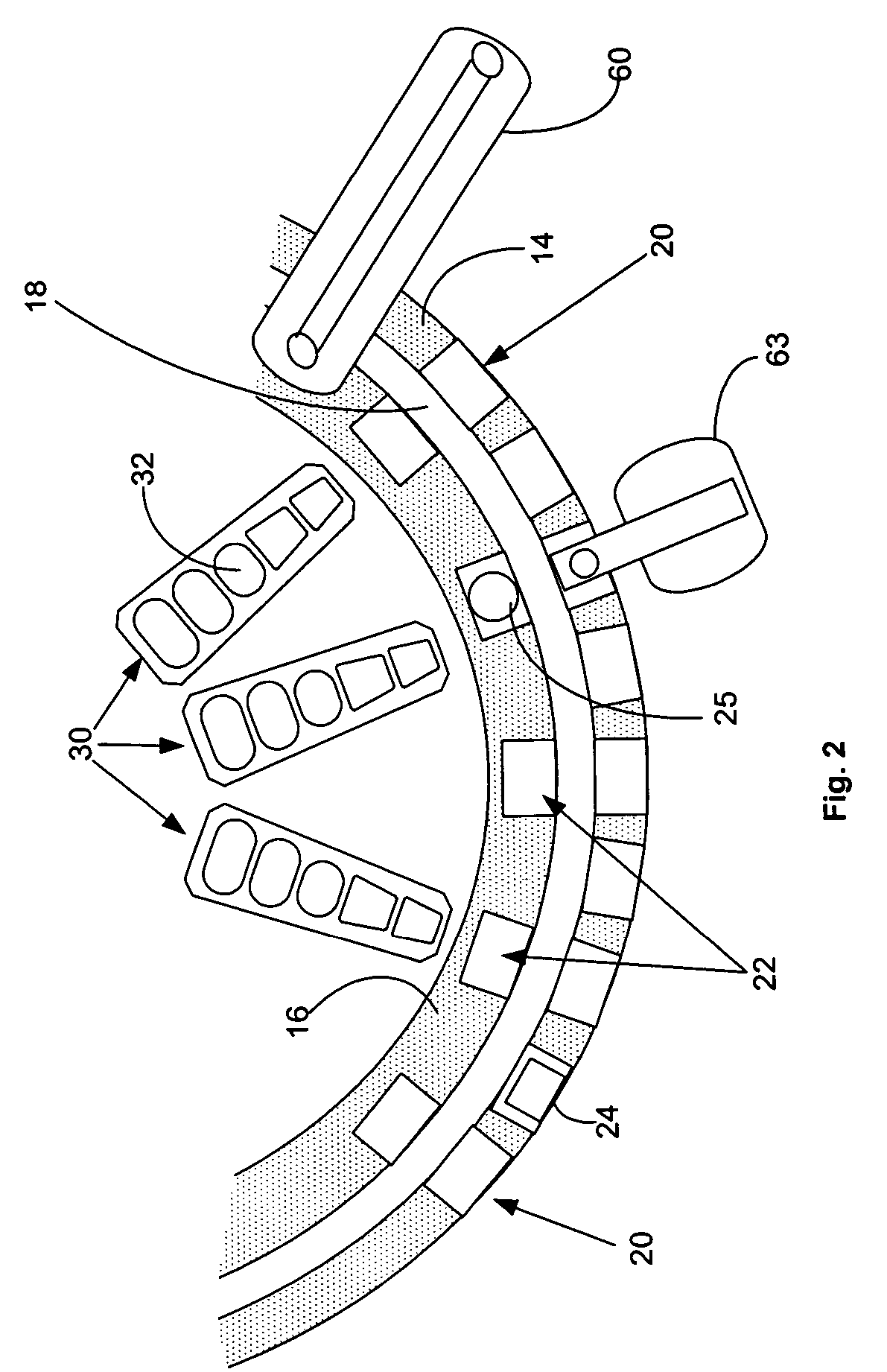

Environmental containment system for a flow cytometer

InactiveUS20030138967A1Easy to cleanKeep sterileMicrobiological testing/measurementWithdrawing sample devicesControl systemEngineering

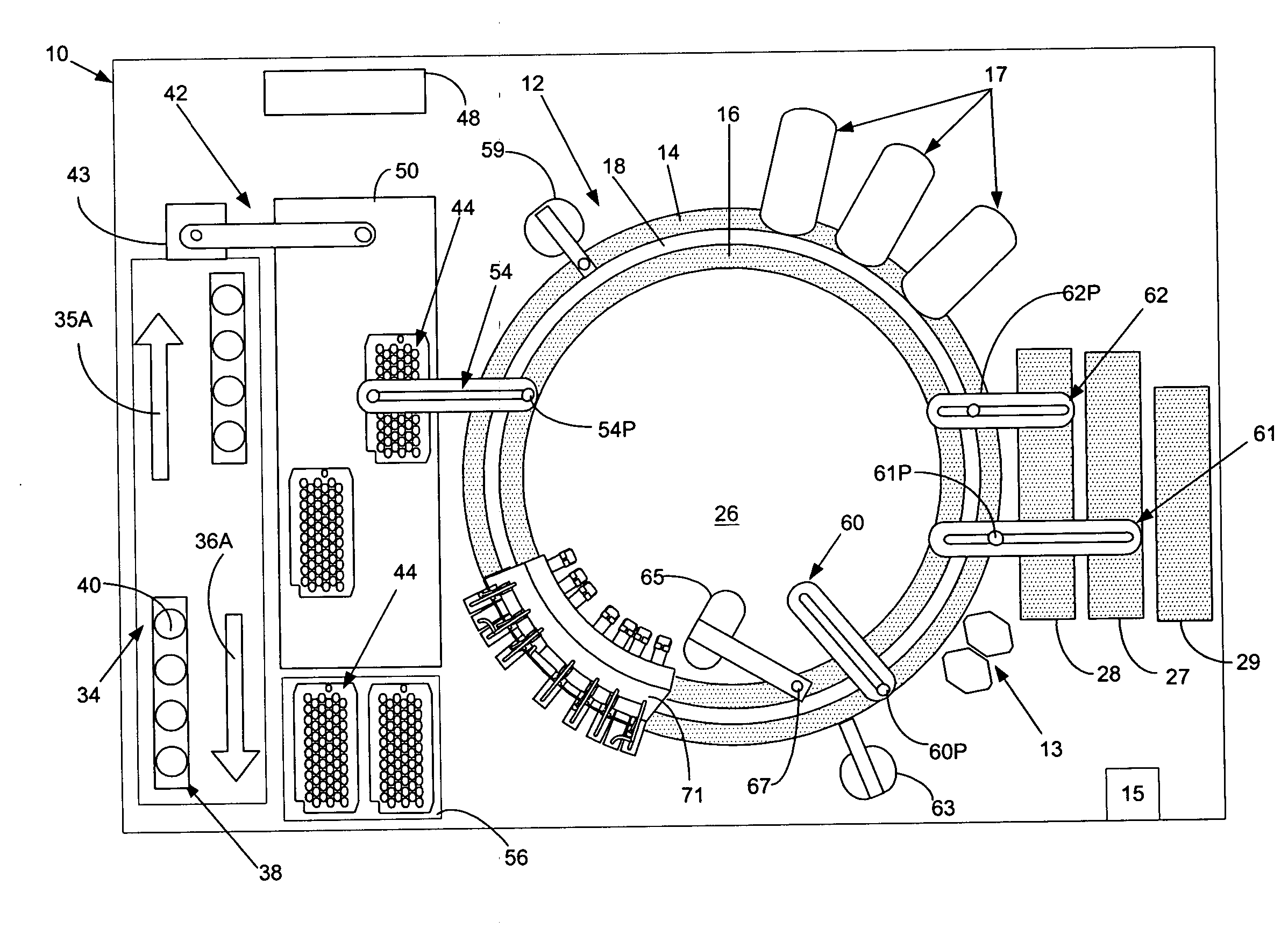

A environmental containment system (16) for a flow cytometer (21) which provides a adjustably controllable environment in which biological particles can be differentiated and droplets separated into collection containers (15).

Owner:BECKMAN COULTER INC

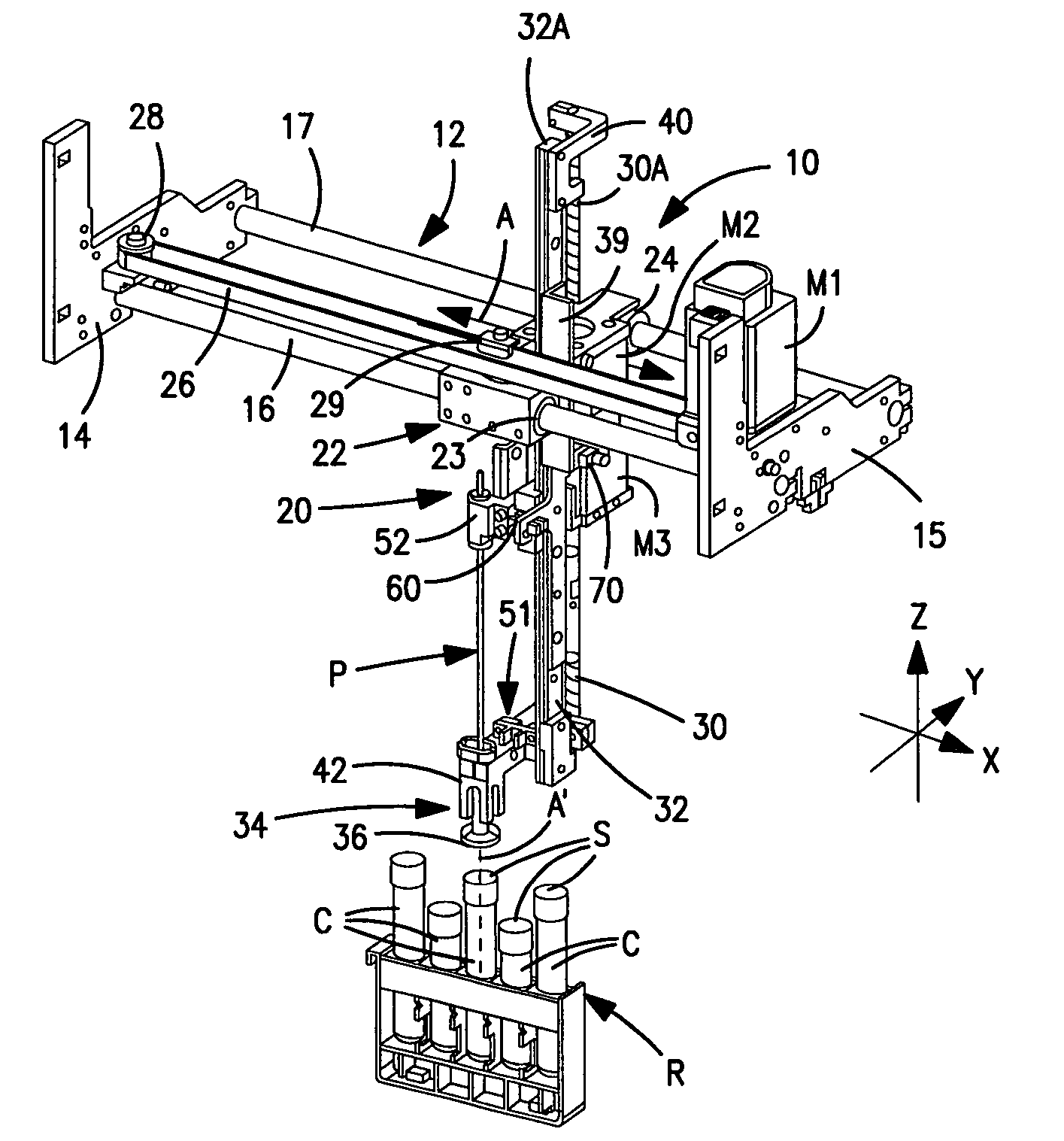

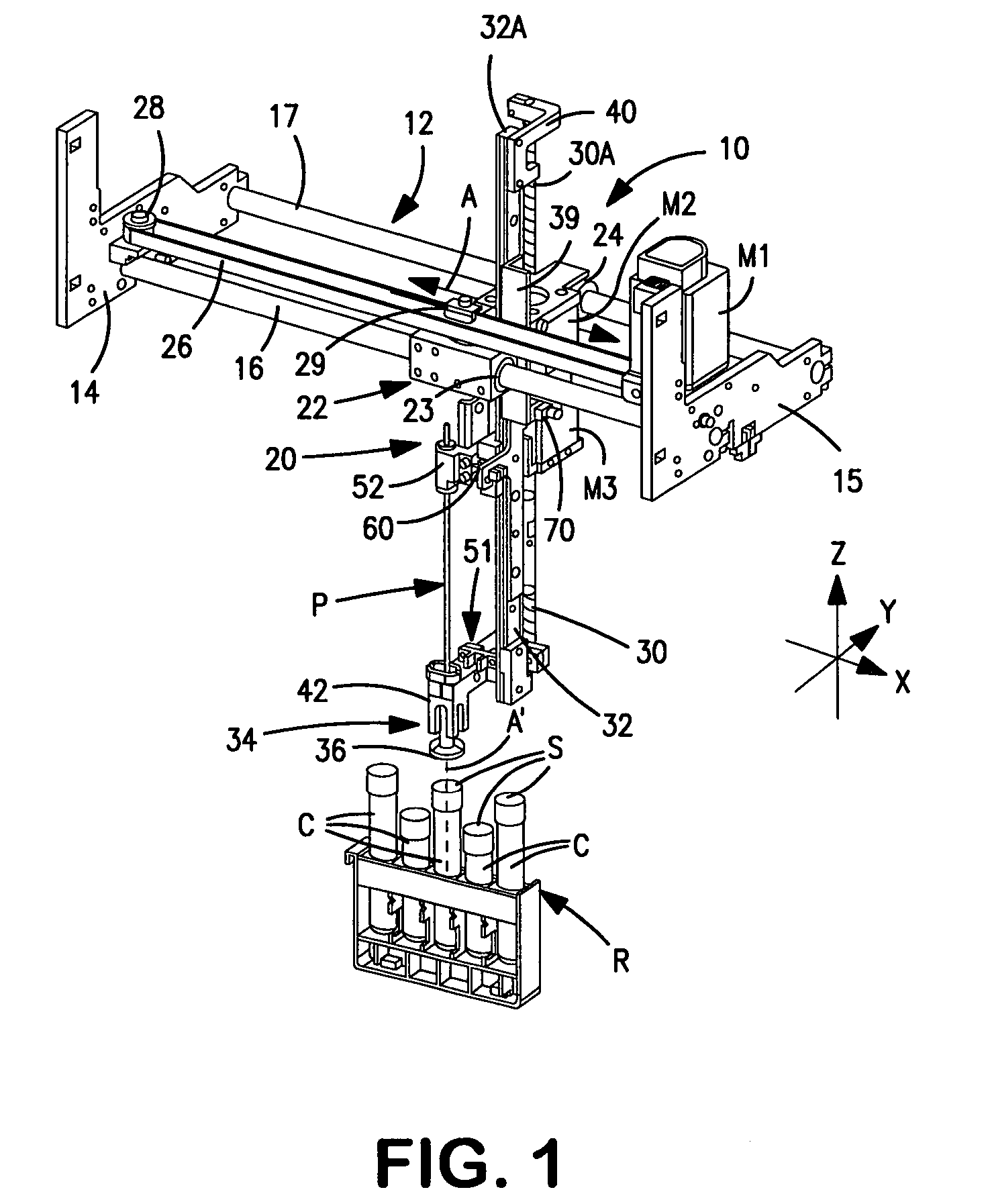

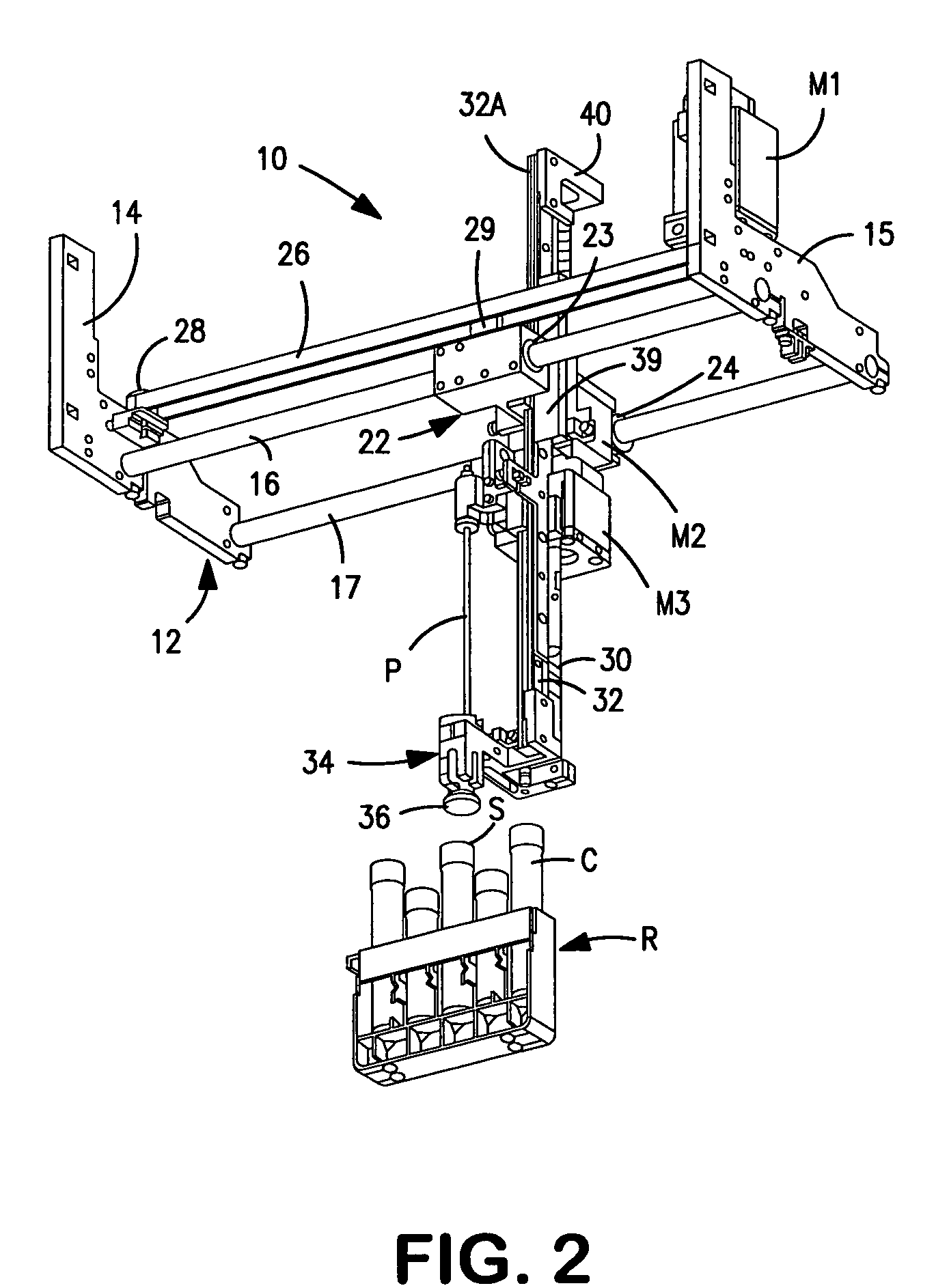

Apparatus for aspirating liquids from sealed containers

ActiveUS20060216208A1Reduce component countLow costWithdrawing sample devicesMaterial analysis by optical meansEngineeringLinear actuator

Apparatus for aspirating liquid from a container, e.g., a test tube, having a puncturable stopper includes a pair of stepper motors that share a common linear actuator or drive member. One motor operates to axially advance the linear drive member (preferably a lead screw) to a position in which it serves to position a rigidly connected tube-detector / stripper member in engagement with the top of a stopper on a tube. Thereafter, the second motor operates to move along the surface of the same drive member to advance an aspiration probe through the engaged stopper and into a liquid aspirating position within the tube. Preferably, a linear guide rail, slidably-mounted on a frame that supports the liquid-aspirating apparatus, serves to guide both the movement of the aspiration probe and the linear drive member. As a result of the shared components, the apparatus is highly precise and reliable.

Owner:BECKMAN COULTER INC

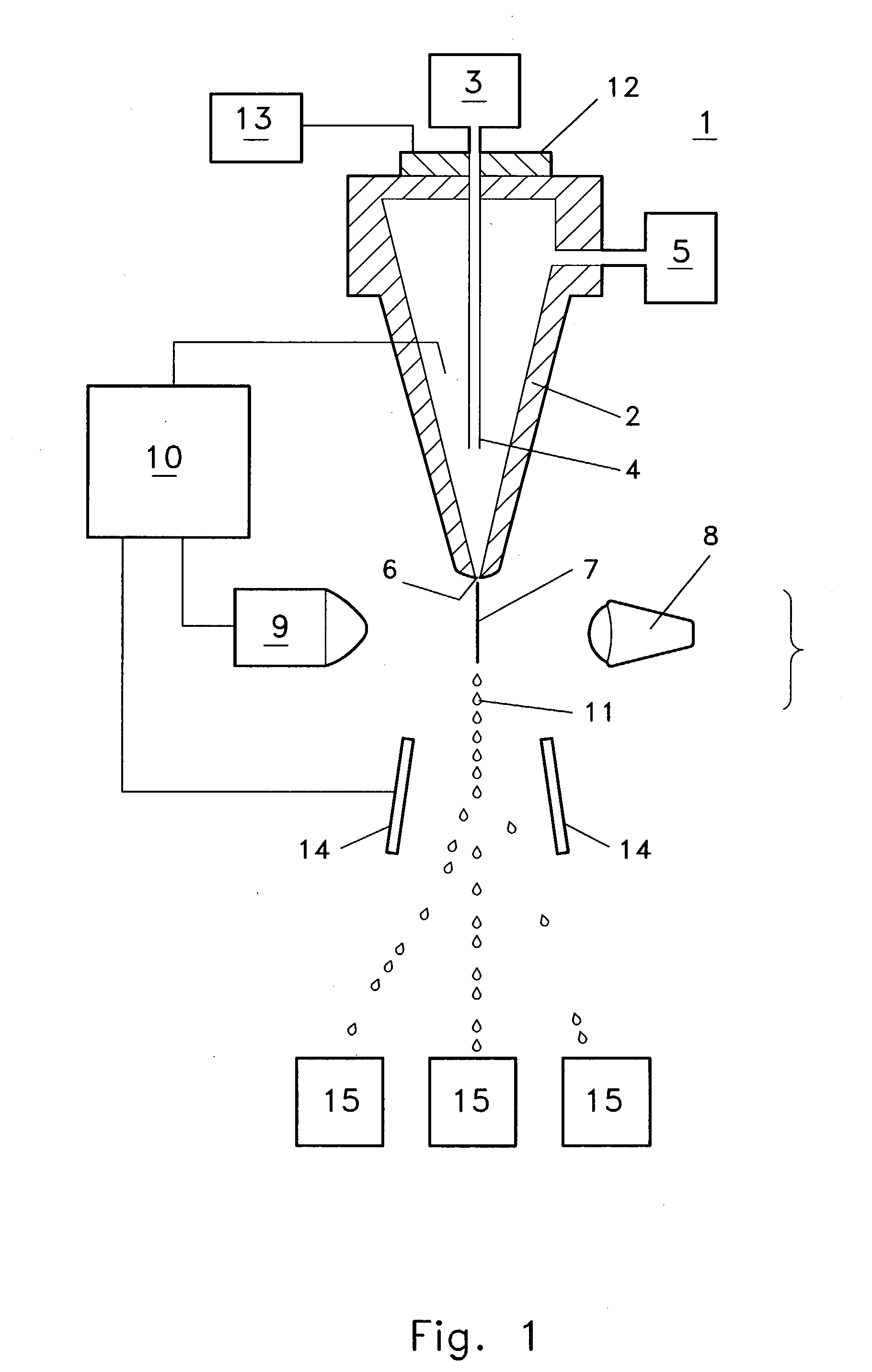

Methods and apparata for precisely dispensing microvolumes of fluids

InactiveUS6874699B2Reduce vibrationUniform sizeTesting/calibration apparatusMachines/enginesMicrometerEngineering

Owner:WISCONSIN ALUMNI RES FOUND

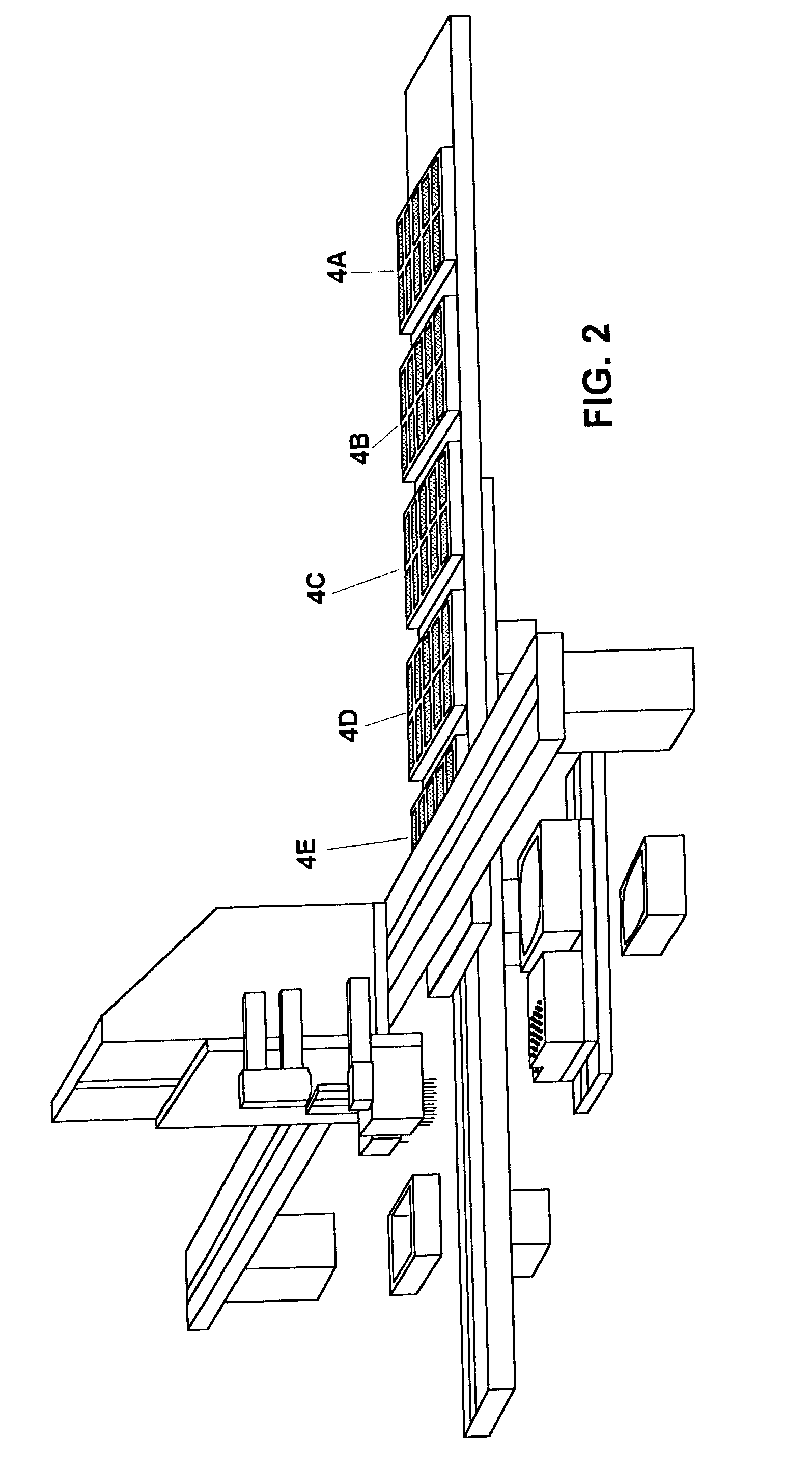

Apparatus for Assay, Synthesis and Storage, and Methods of Manufacture, Use, and Manipulation Thereof

InactiveUS20120021951A1Amplification of signalAvoid cross contaminationSequential/parallel process reactionsComponent separationHigh densityLow density

Owner:LIFE TECH CORP

Liquid sampling probe and cleaning fluidics system

Owner:SIEMENS HEALTHCARE DIAGNOSTICS INC

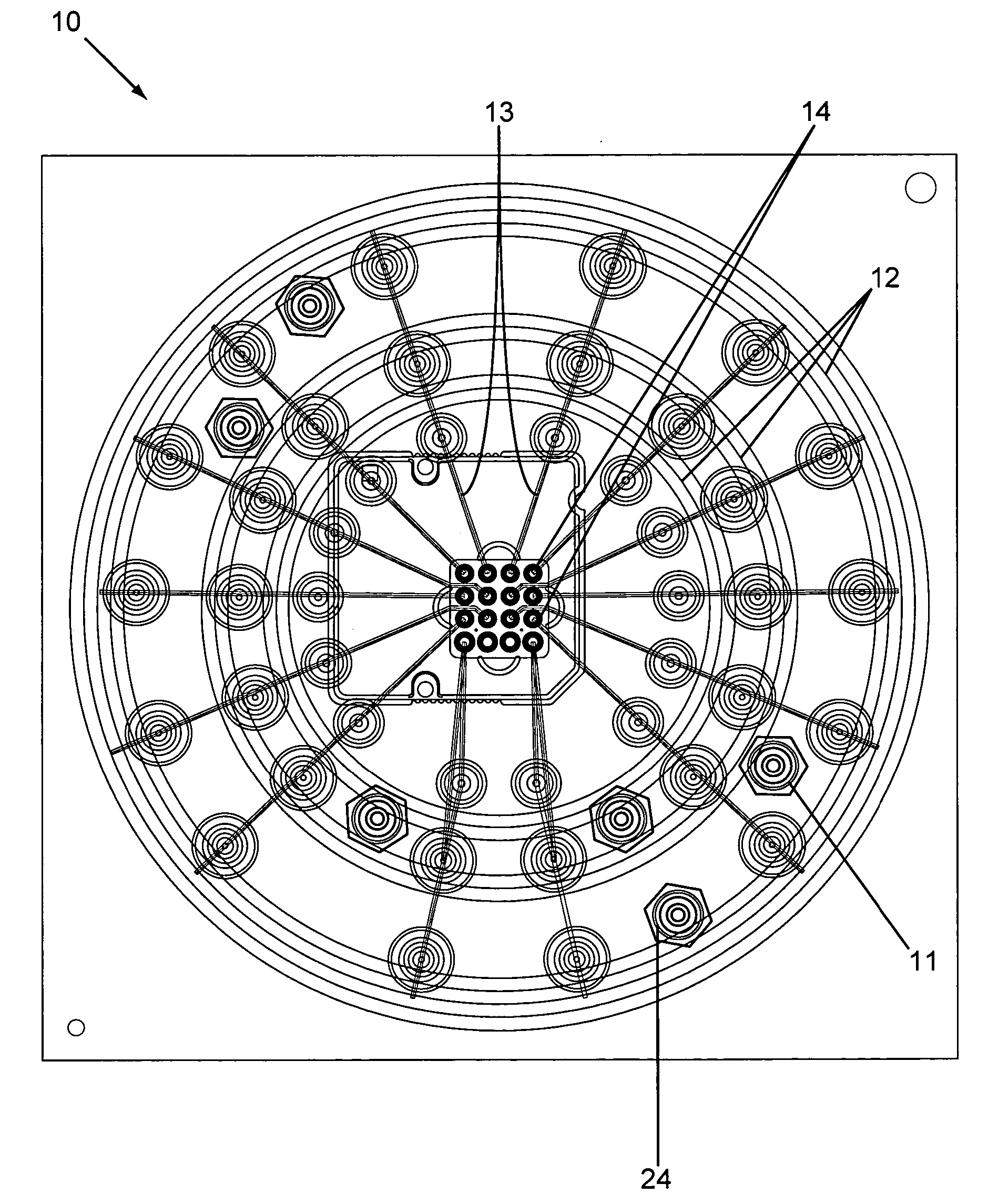

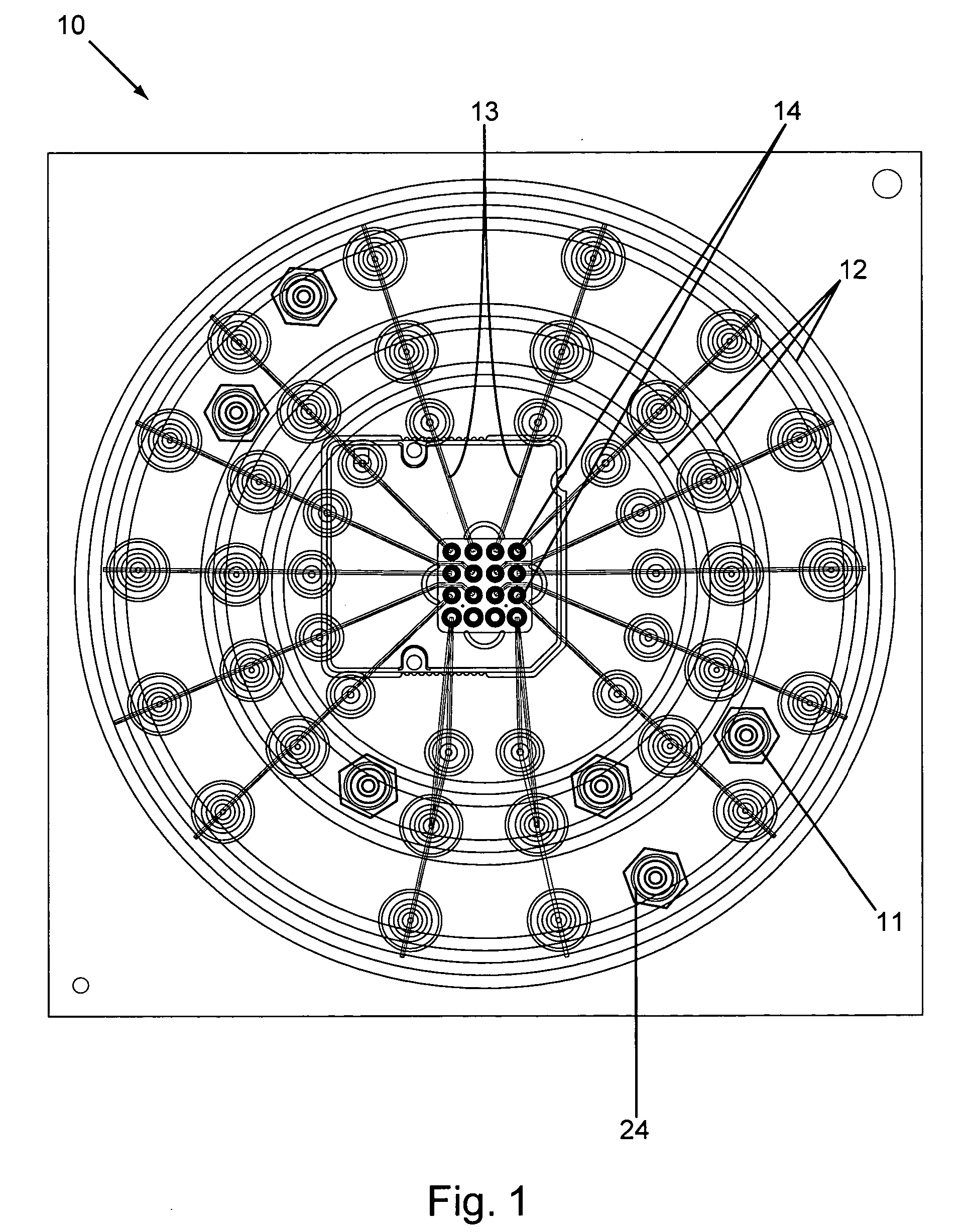

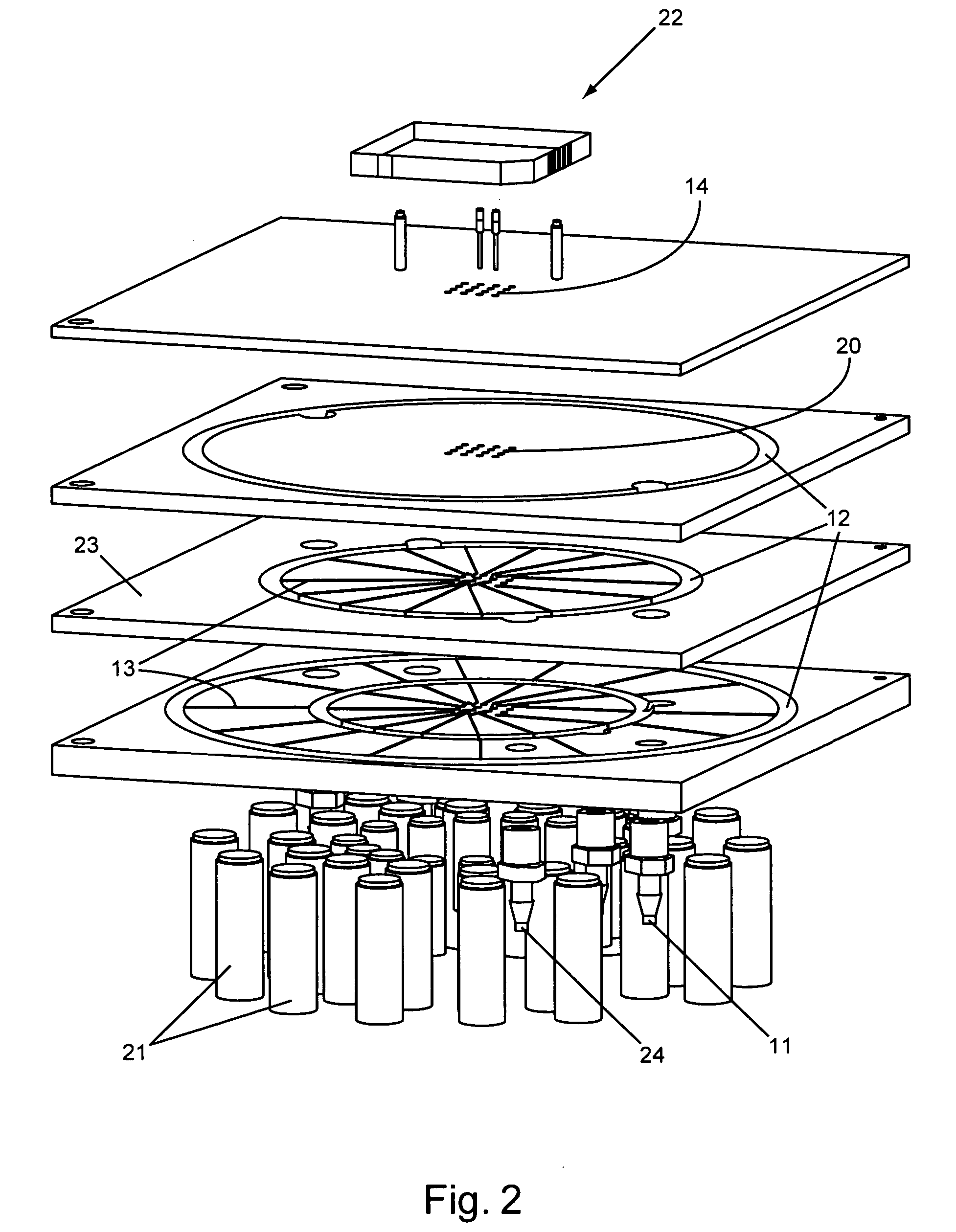

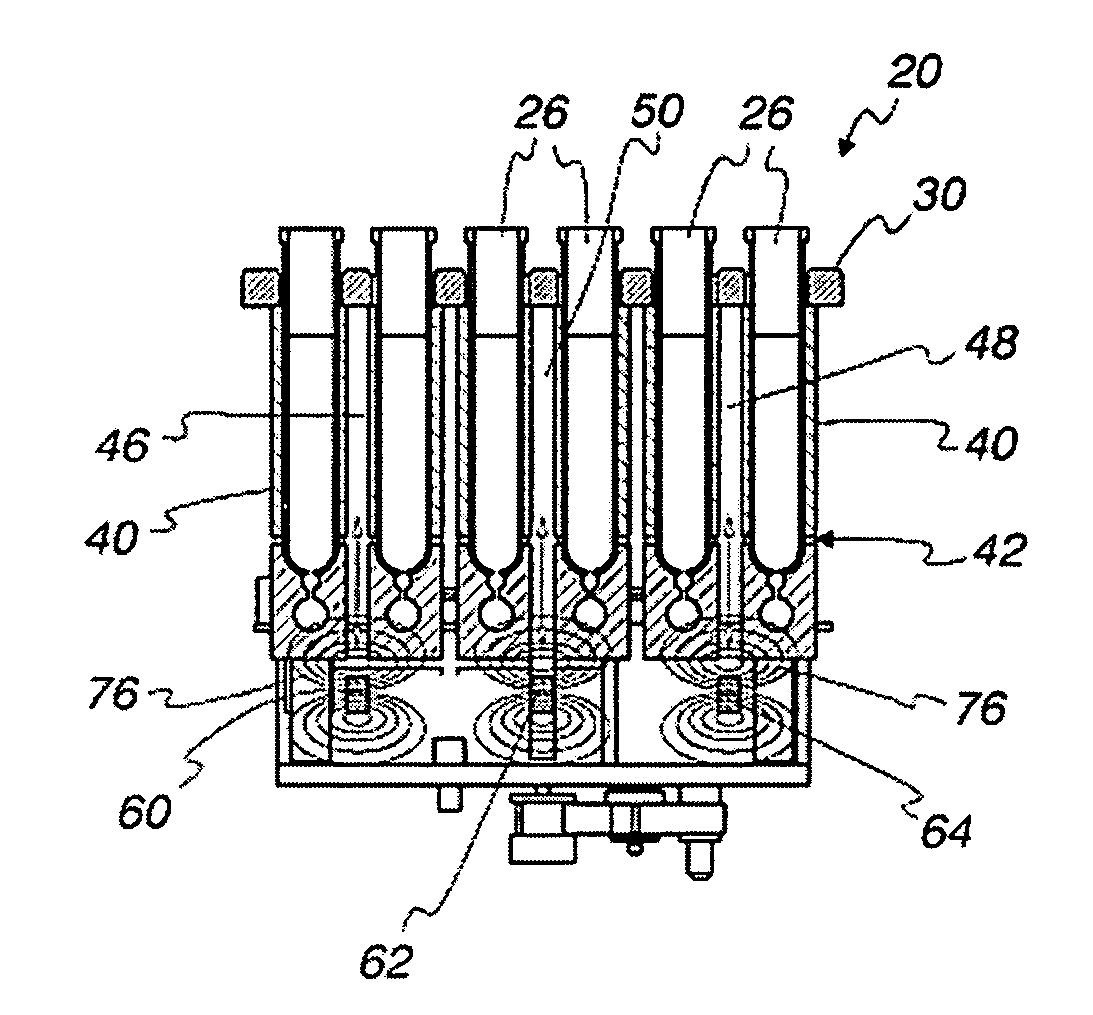

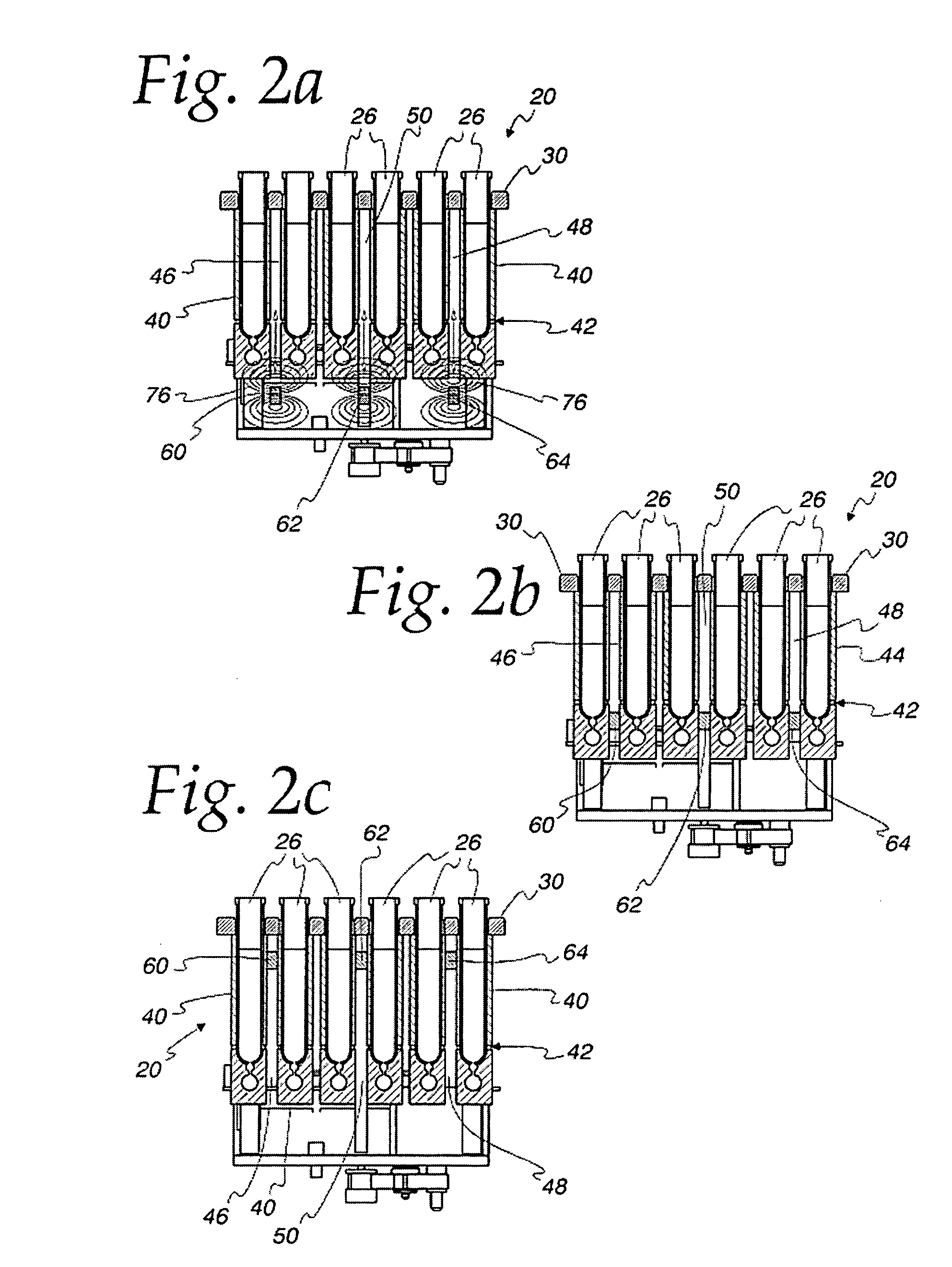

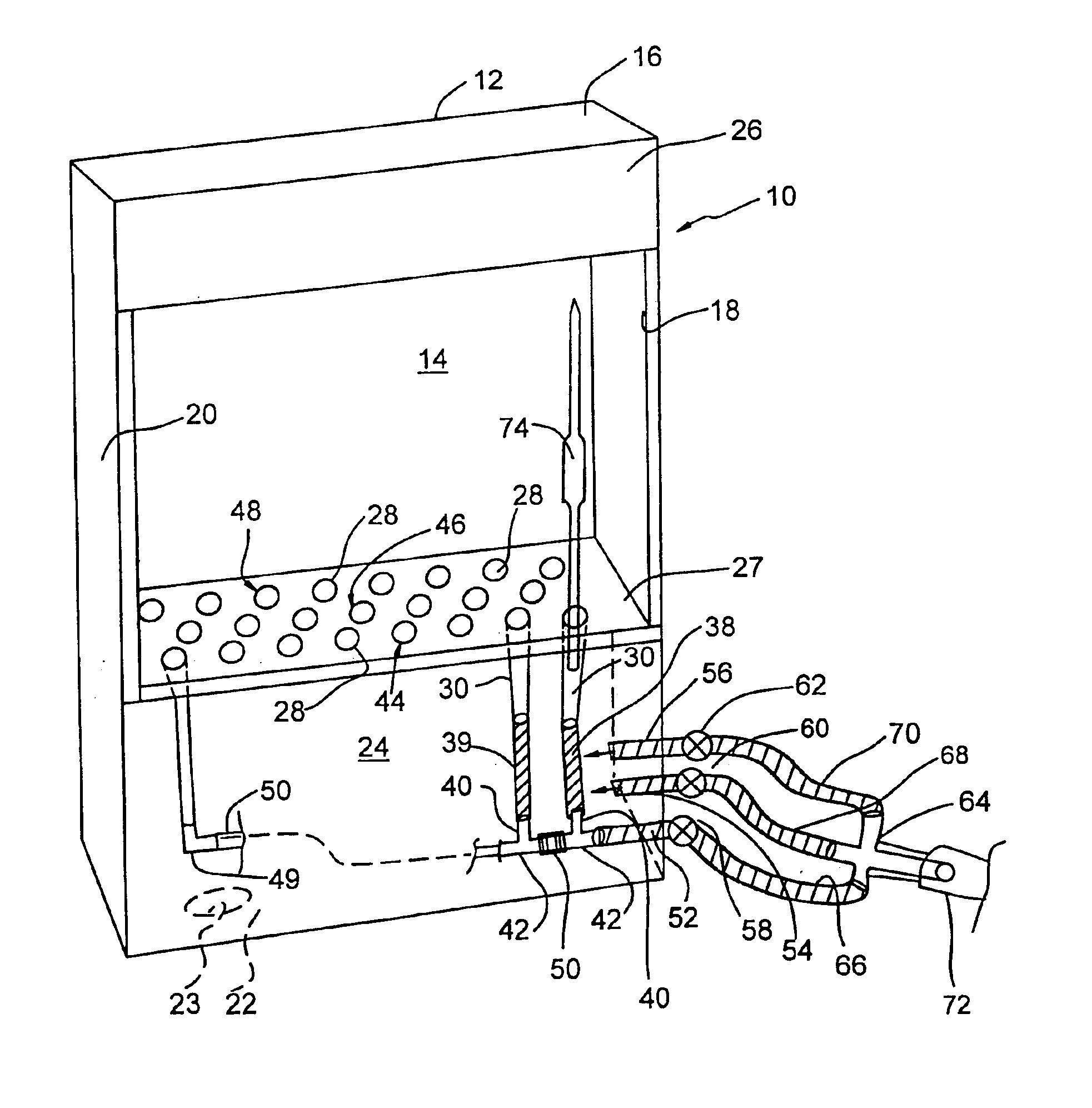

Apparatus and method for handling fluids for analysis

A reaction vessel with a bottom drain opening supporting a selected unpressured head of fluid by the surface tension of the fluid. A device processing zone includes a support for spaced rows of reaction vessels, passages communicating with their drain openings of supported vessels, and a pressure source for selectively draining fluid through the drain openings. Generally horizontal bar magnets are supported for selected vertical movement between the vessel rows. A dispensing head has X discharge openings selectively positionable over X selected reaction vessels. A metering pump mechanism selectively meters X a selected quantity of fluid a bulk supply (where X is at least four), and selectively pumps the metered selected quantities through the drain openings to the selected reaction vessels. Methods of drawing fluid from the vessels using the pressure source, and moving the magnets to form a pellet of analyte are also included.

Owner:ABBOTT MOLECULAR INC

Fluid handling component with ultraphobic surfaces

InactiveUS20050145285A1Reduce frictionImprove system efficiencyMaterial nanotechnologyConveyorsVolumetric Mass DensityEngineering

A fluid handling component having a durable ultraphobic fluid contact surface that is capable of exhibiting ultraphobic properties at liquid pressures of one atmosphere and above. The surface generally includes a substrate portion with a multiplicity of projecting regularly shaped microscale or nanoscale asperities disposed so that the surface has a predetermined contact line density measured in meters of contact line per square meter of surface area equal to or greater than a contact line density value “ΛL” determined according to the formula: ΛL=-10,330γ cos(θa,0+ω-90°)where γ is the surface tension of the liquid in Newtons per meter, θa,0 is the experimentally measured true advancing contact angle of the liquid on the asperity material in degrees, and ω is the asperity rise angle in degrees.

Owner:ENTEGRIS INC

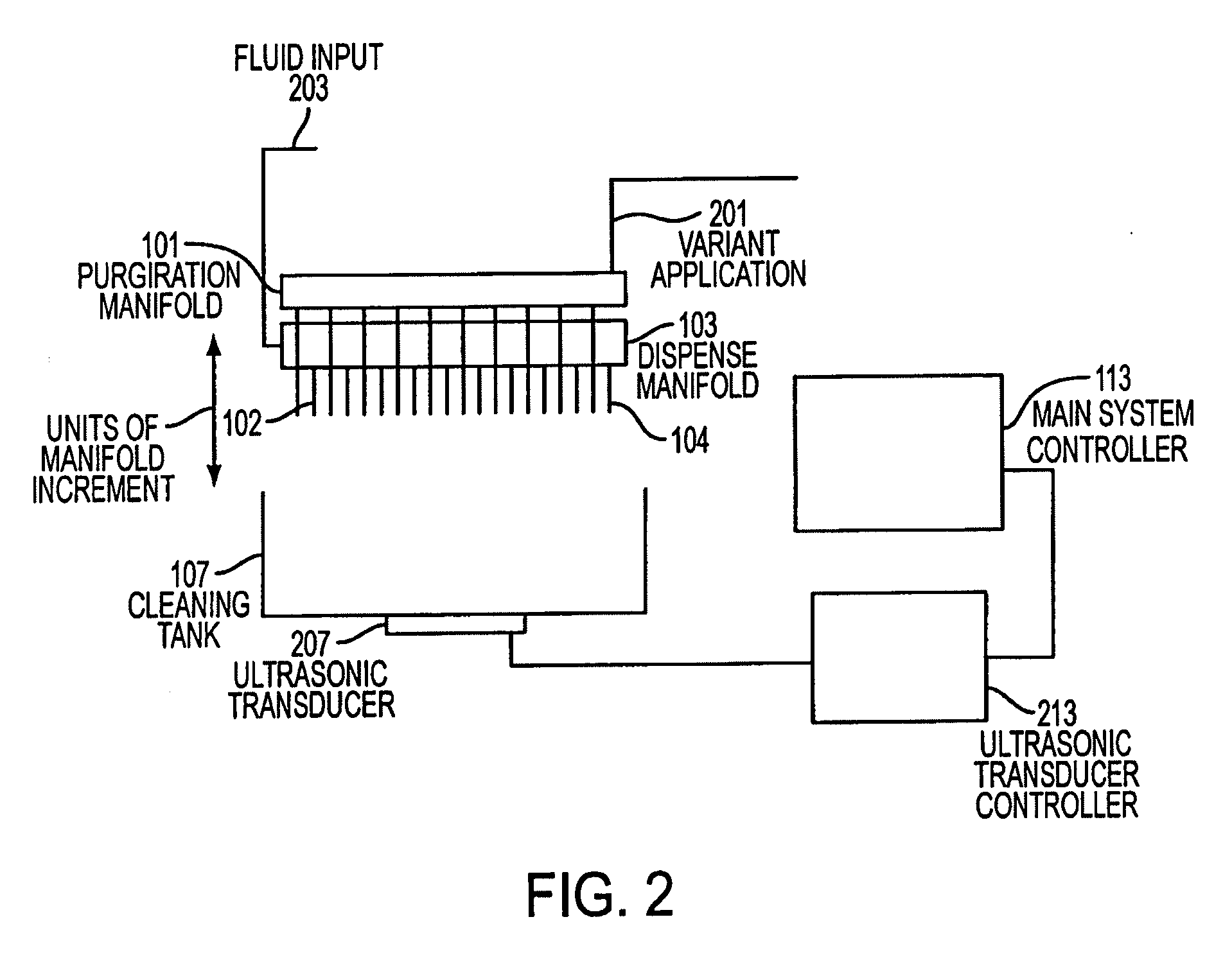

Plate washing system with ultrasonic cleaning of pipes and a control method thereof

ActiveUS20090032064A1Functional impairmentHollow article cleaningLaboratory glasswaresInstrument functionUltrasonic sensor

An automated method of cleaning the pipes of a plate washing system is provided. The plate washing system includes at least one manifold having a plurality of pipes configured to be provided within wells of a plate in order to wash the wells, an ultrasonic transducer mounted to a tank, and a control system. The plate washing system also includes sensors to sense the position of the pipes relative to plate and the tank, and the fluid level within the wells of the plate. The method includes dispensing fluid to the tank, submerging the tips of the pipes within the fluid, activating the ultrasonic transducer in order to vibrate the fluid, and aspirating the fluid from the tank. The control system may initiate a cleaning operation at the request of the user, at a scheduled interval, or when the level sensing system detects a decrease in instrument function.

Owner:AGILENT TECH INC

Tray carrier with ultraphobic surfaces

InactiveUS6938774B2Easy to cleanThe process is convenient and fastMaterial nanotechnologySemiconductor/solid-state device manufacturingProcess qualityBiomedical engineering

A tray carrier with ultraphobic surfaces for promoting more effective cleaning and drying of the tray carrier. In the invention, entire surfaces or portions of surfaces of a tray carrier are made ultraphobic. The ultraphobic surfaces of the tray carrier cause liquids that may come in contact with the surface, such as may be used in cleaning, to quickly and easily “roll off” without leaving a liquid film or substantial quantity of liquid droplets. As a result, less time and energy is expended in drying the surfaces, and redeposited residue is minimized, thereby improving overall process quality and facilitating economical reuse of the tray carrier. In addition, the ultraphobic surfaces may be resistant to initial deposition of contaminants, where the contaminants may be in liquid or vapor form.

Owner:ENTEGRIS INC

Anti-fouling apparatus and method

InactiveUS7341695B1Reduce the overall heightBrush bodiesVehicle cleaning apparatusUltravioletComputer science

An anti-fouling apparatus and method includes a configurable cleaner connected to an object for physically removing foulants on the object. A UV light device is connected to the object for preventing the growth of foulants on the object and a camera is connected to the object for observing the presence of foulants on the object. The configurable cleaner removes foulants from the object as well as the UV light and the camera.

Owner:MEASUREMENT SPEC

Apparatus and method for small-volume fluid manipulation and transportation

InactiveUS20050189225A1Facilitate high throughput assayFacilitate complicated fluid manipulationSludge treatmentFixed microstructural devicesFluid transportElectrolysis

A microfluidic system has an electroosmotic flow pumping means for propelling fluids through a series of microchannels and selection valves. Pump channels are configured in groups which may be fabricated singly or in multiple groups onto a substrate. A tube filled with an immobilized polymer provides a means to apply voltages across pump channels, while prevents passages of fluids through it. It also avoids electrolysis and bubble formation in or close to the microfluidic channels. The selection valves provide for routing functions within the microfluidic system and can also be configured to route fluids outside the system. A rate monitoring system is provided for determining and compensating for flow rates. In one application the microfluidic system may be configured to operate as a small volume pipettor or other fluid transport or analysis device. A micro-dialysis jacket is additionally provided to permit desalting, pH adjustment, concentration adjustment, and other functions.

Owner:LIU SHAORONG +1

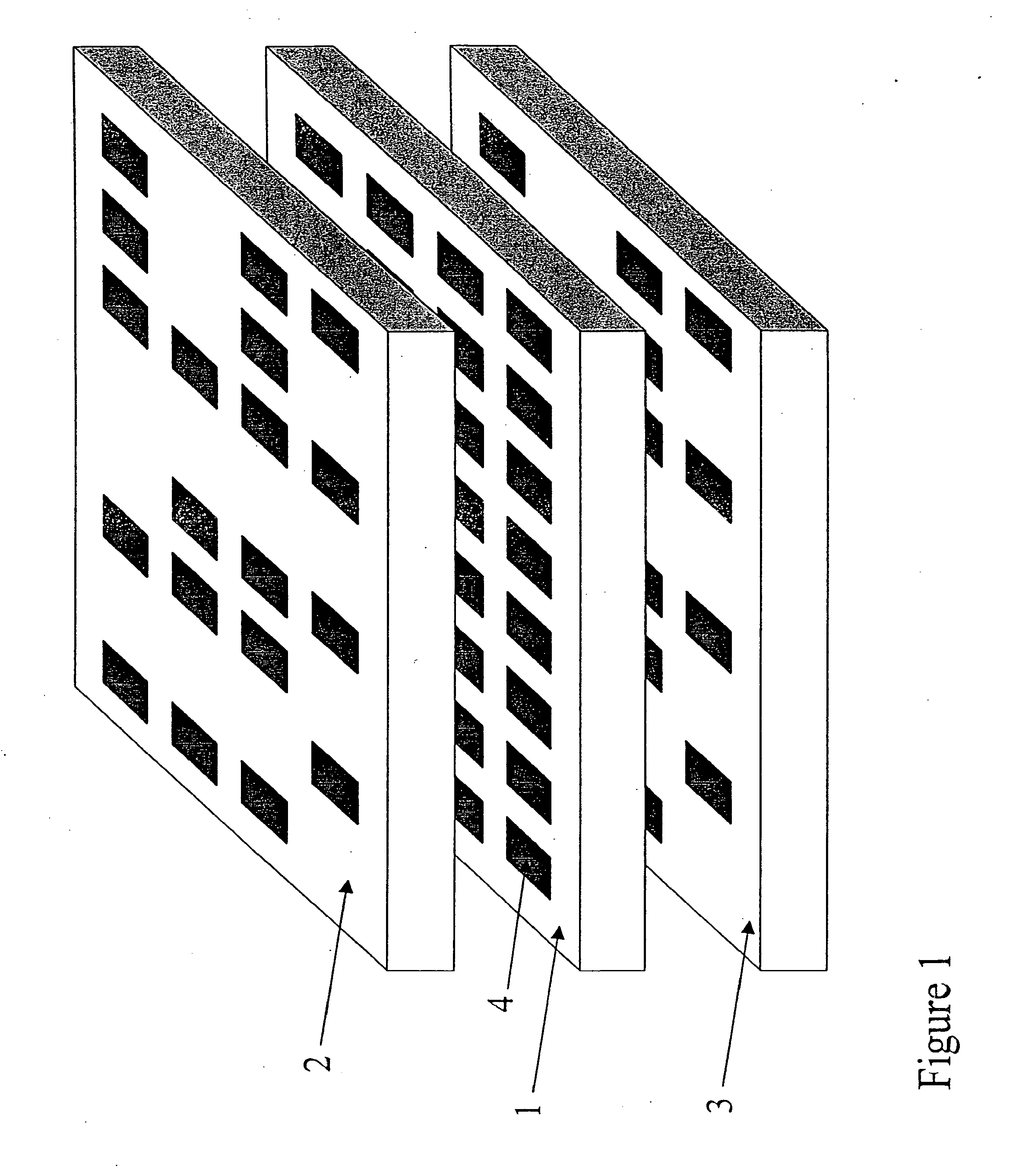

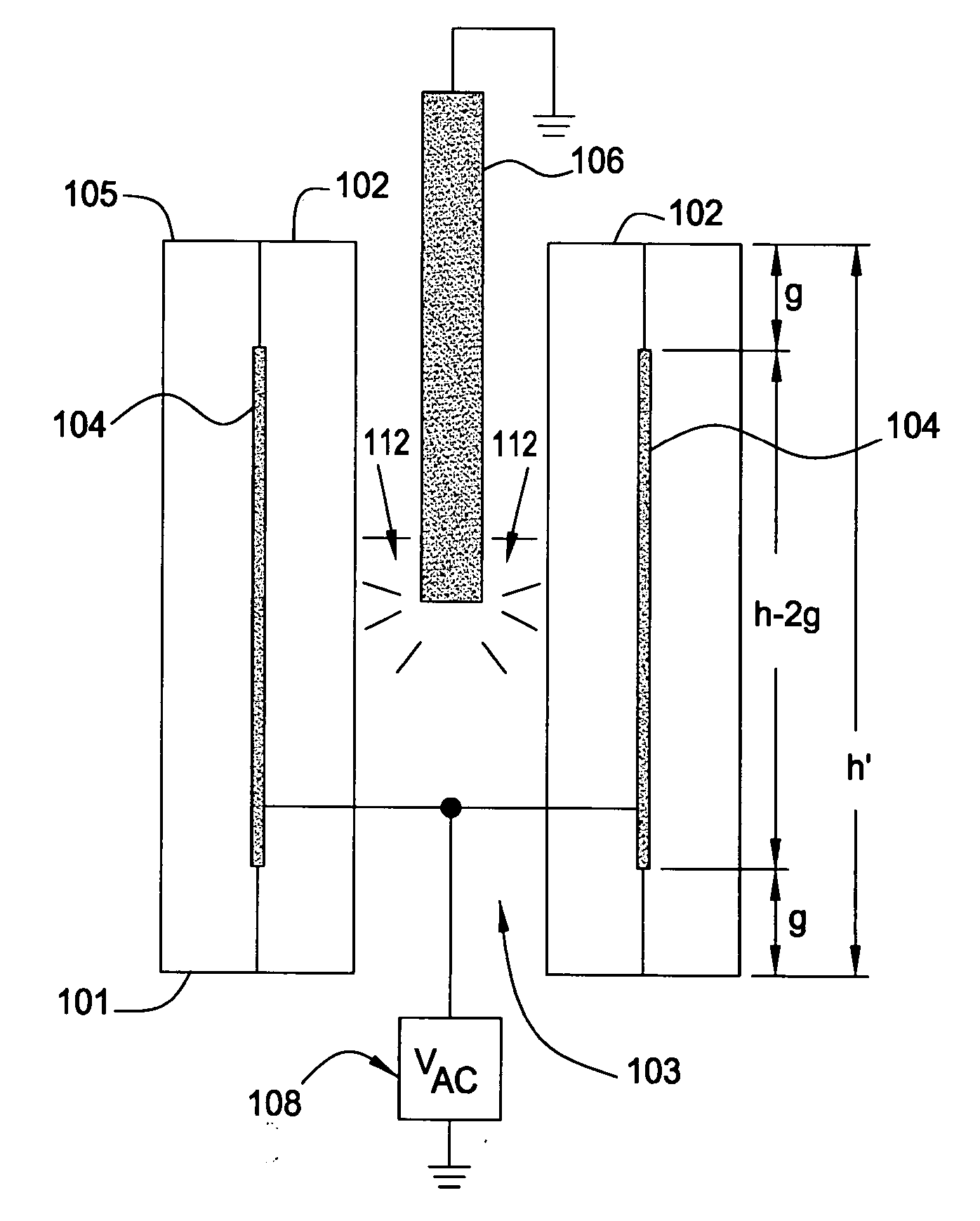

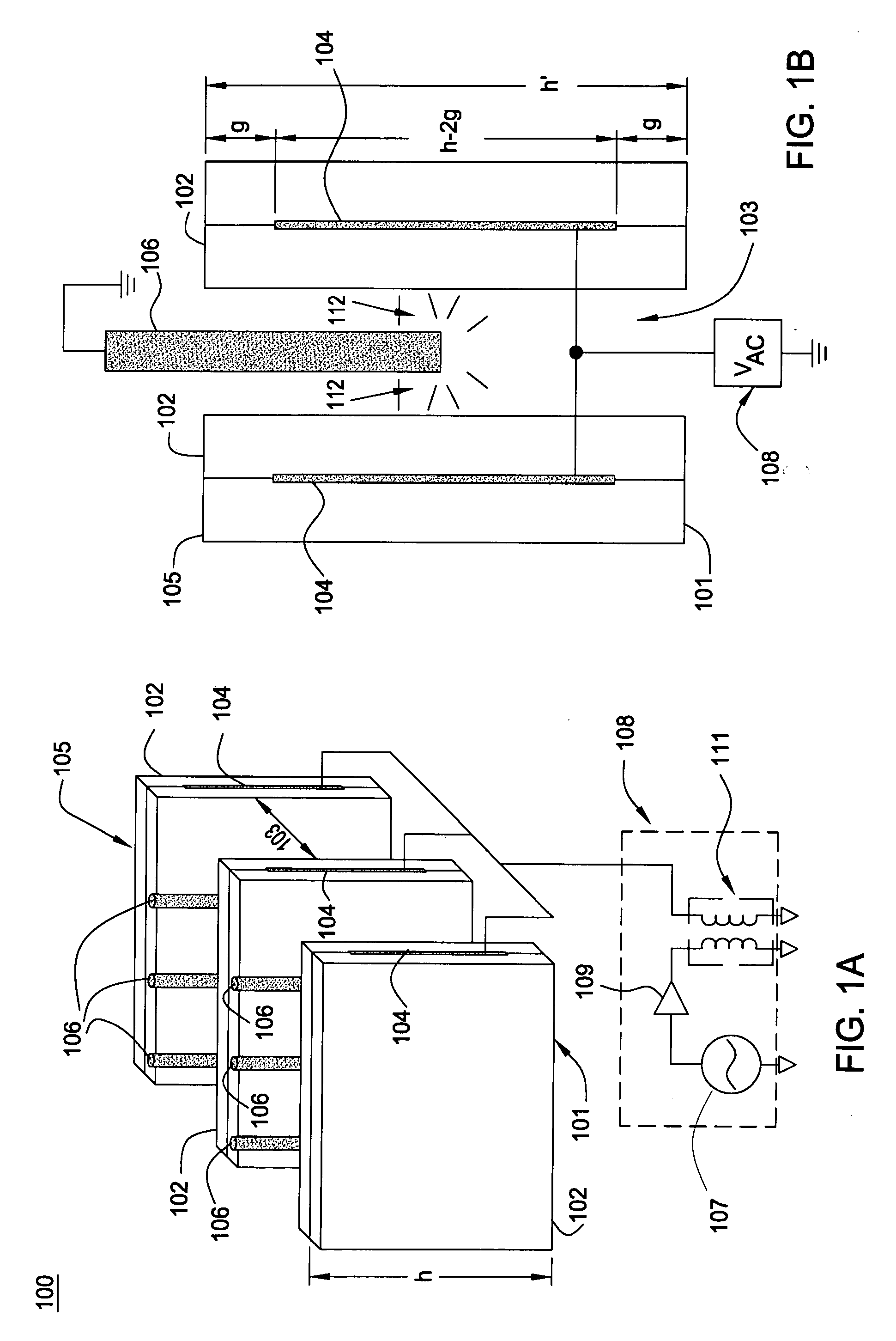

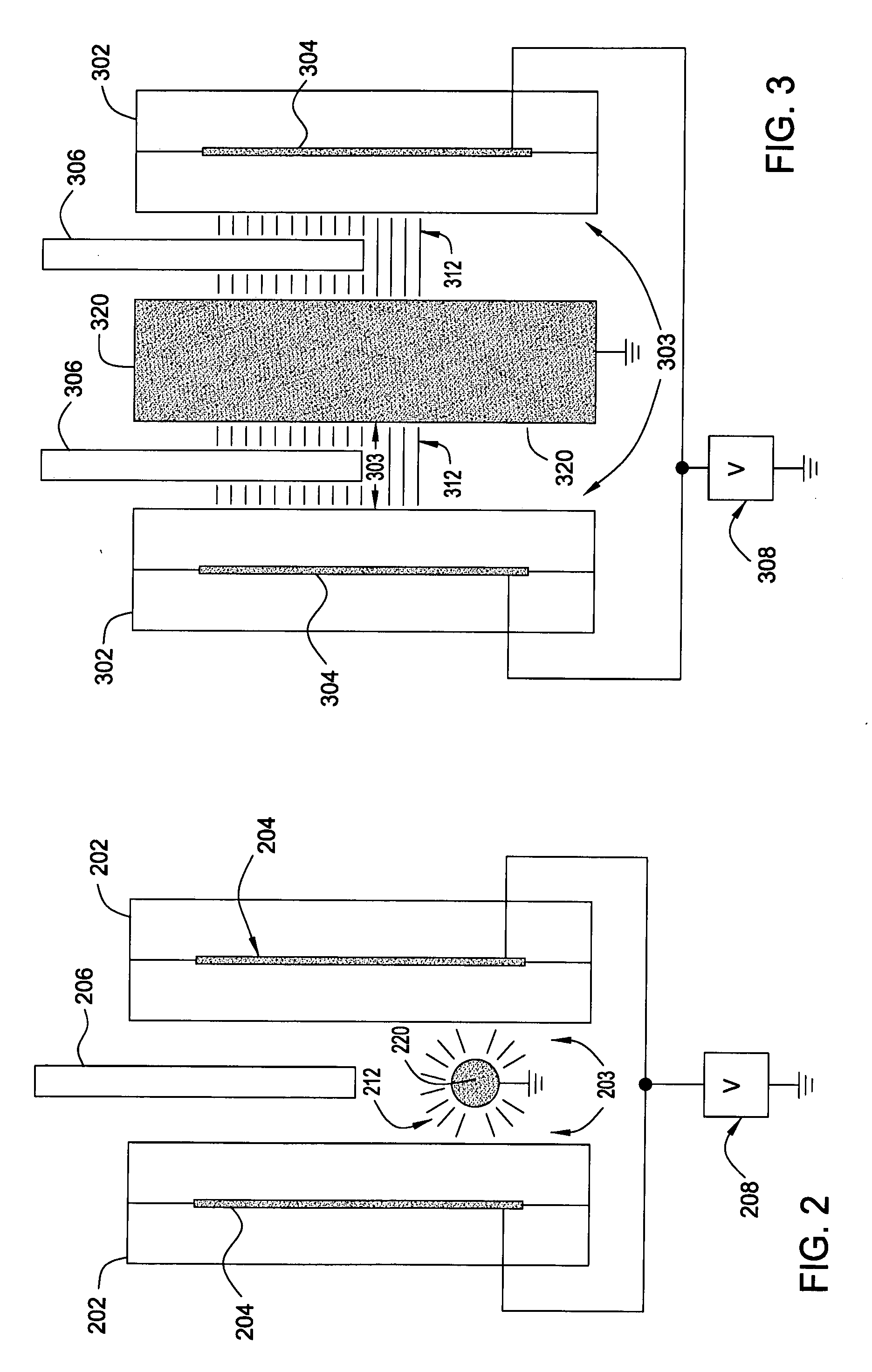

Method and apparatus for cleaning and surface conditioning objects with plasma

InactiveUS20060162741A1Electric discharge tubesElectrostatic cleaningElectrical resistance and conductanceEngineering

A method and apparatus for cleaning and surface conditioning objects using plasma is disclosed. One embodiment of the method discloses providing a plurality of elongated dielectric barrier plates arranged adjacent each other, the plates having inner electrodes connected therein, introducing the objects proximate the plates, and producing a dielectric barrier discharge to form plasma between the objects and the plates for cleaning at least a portion of the objects. One embodiment of the apparatus for cleaning objects using plasma discloses a plurality of elongated dielectric barrier plates arranged adjacent each other, and a plurality of inner electrodes, each contained within, and extending substantially along the length of, respective ones of the elongated dielectric barrier plates.

Owner:CERIONX

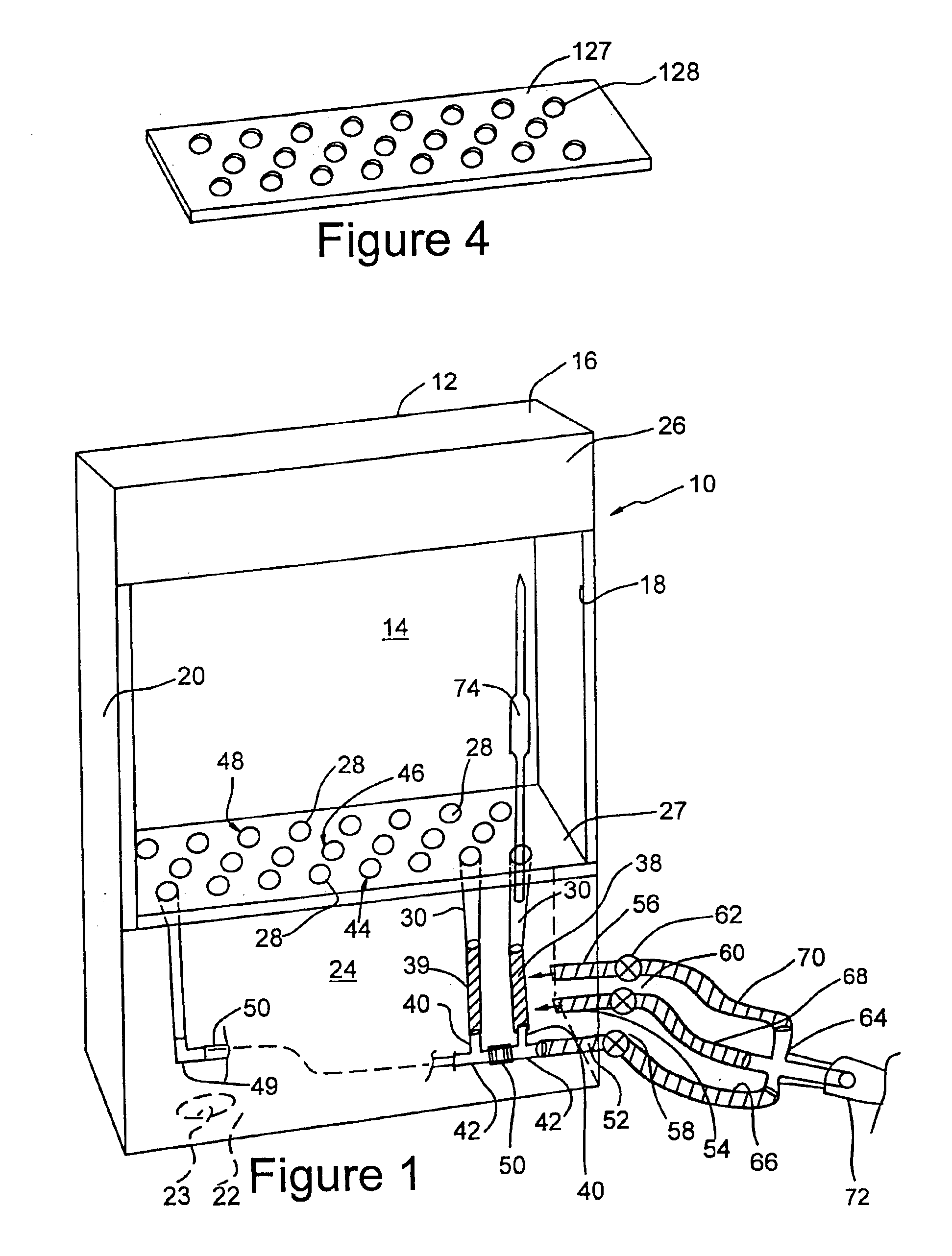

Pipette washer

InactiveUS6955180B2Easy to disassembleQuick placementHollow article cleaningElectrostatic cleaningPipetteEngineering

A pipette washer comprising a plurality of cells for receiving pipettes is disclosed. Each of the cells comprises a top opening for receiving pipettes to be washed and a bottom opening. A support member supports the cells with the top opening accessible to receive pipettes to be washed. A hose system is coupled to the bottom opening on the cells. A supply hose is connected to the hose system. Each of the cells is supported in the support member with an orientation extending transverse to the horizontal. Each of the support cells comprises a cell member having a top width and a bottom width. The width is wider at the top and narrower at the bottom. In accordance with the preferred embodiment, each cell member is conical in shape. A housing contains and rechannels washing liquid while at the same time having an open front to allow for convenient access to the cells.

Owner:SPEX CERTIPREP

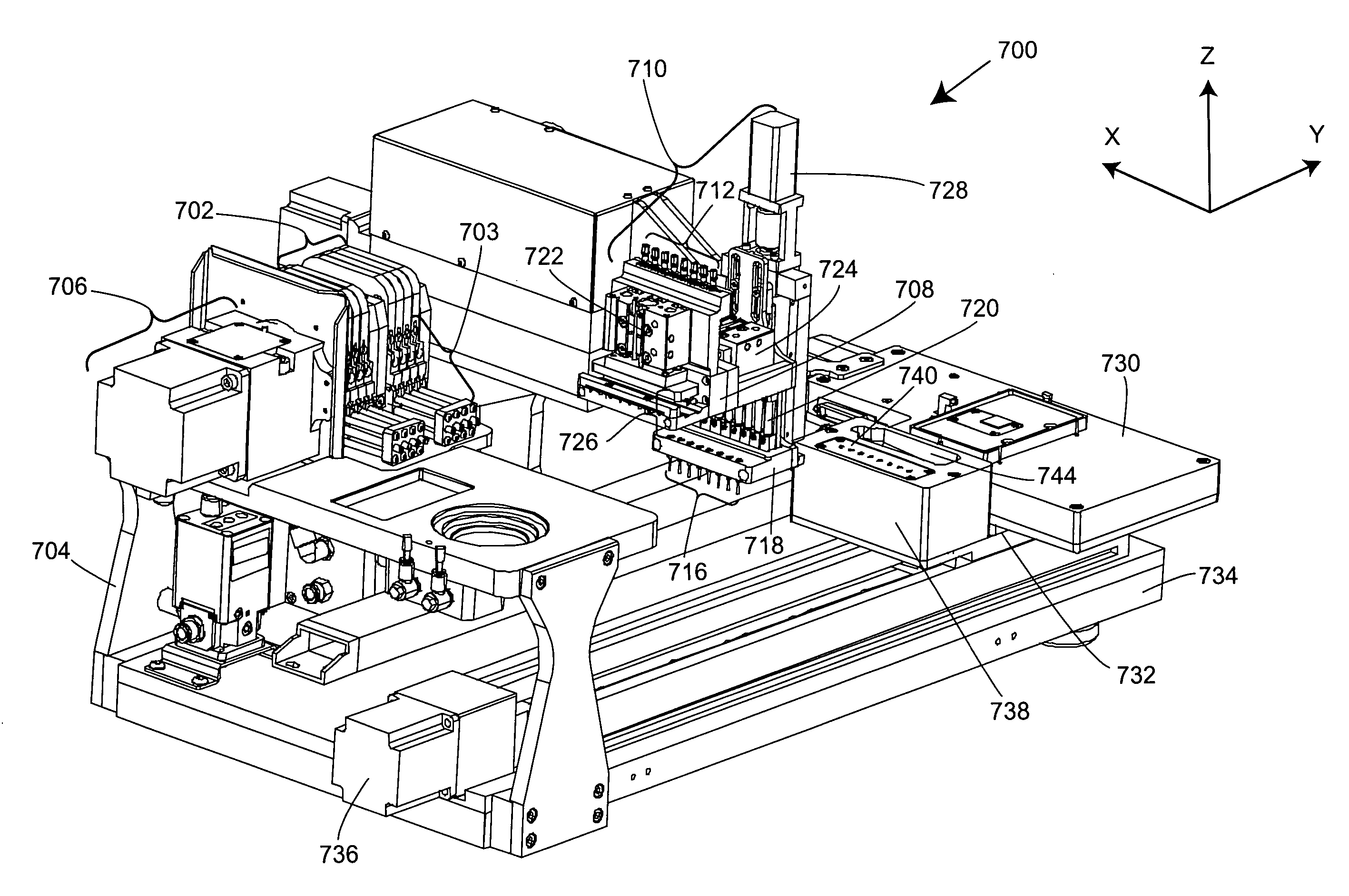

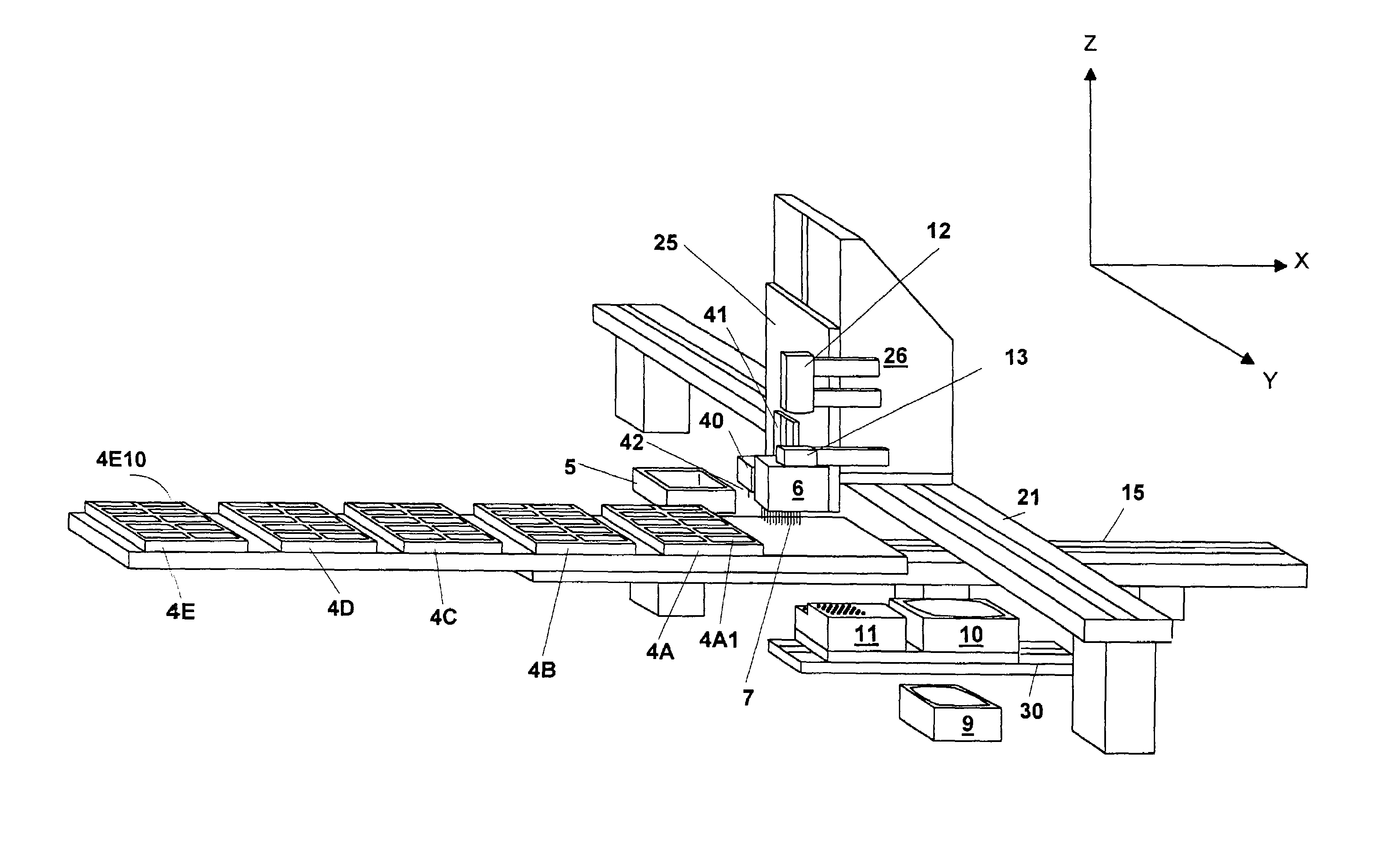

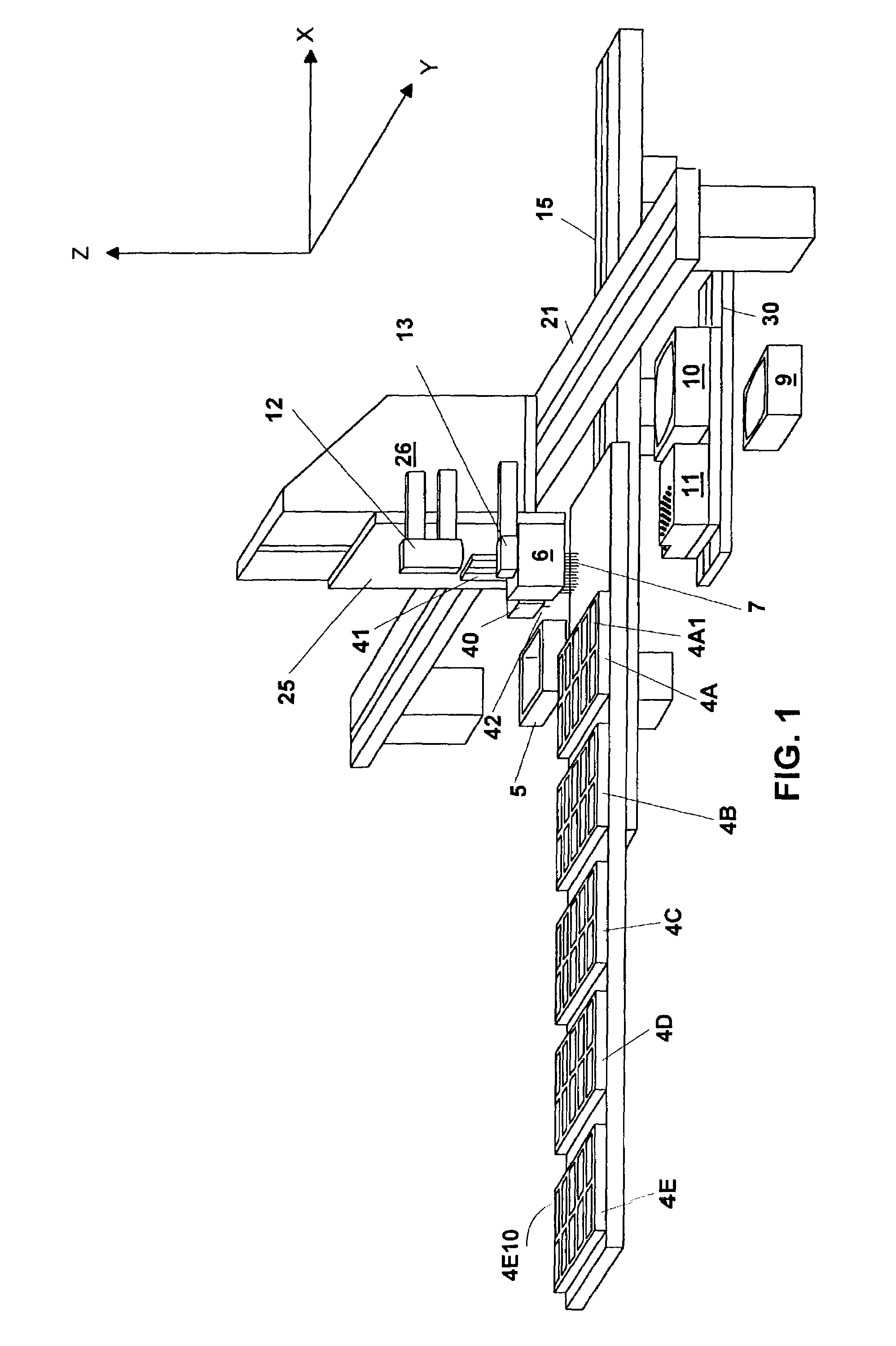

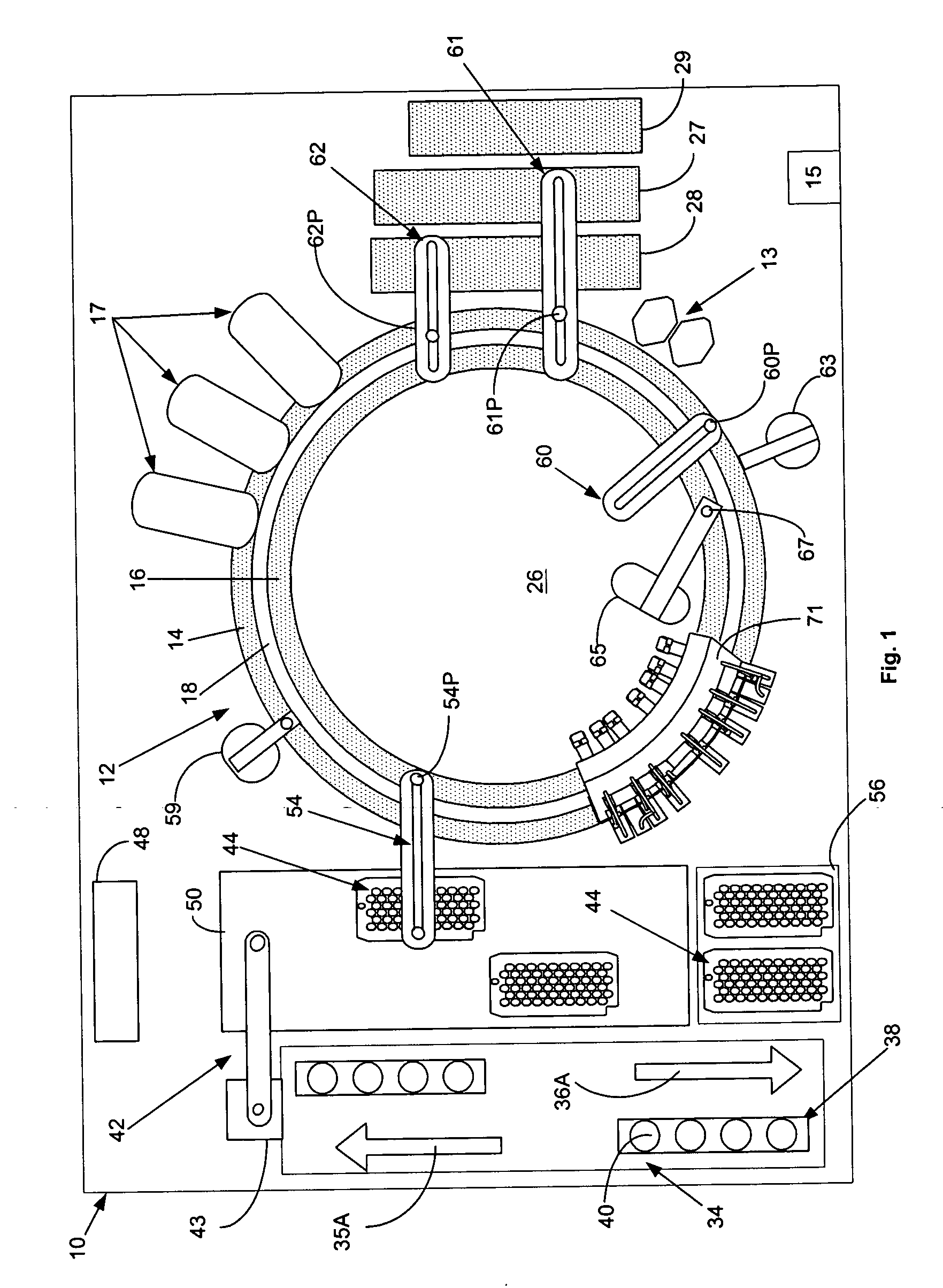

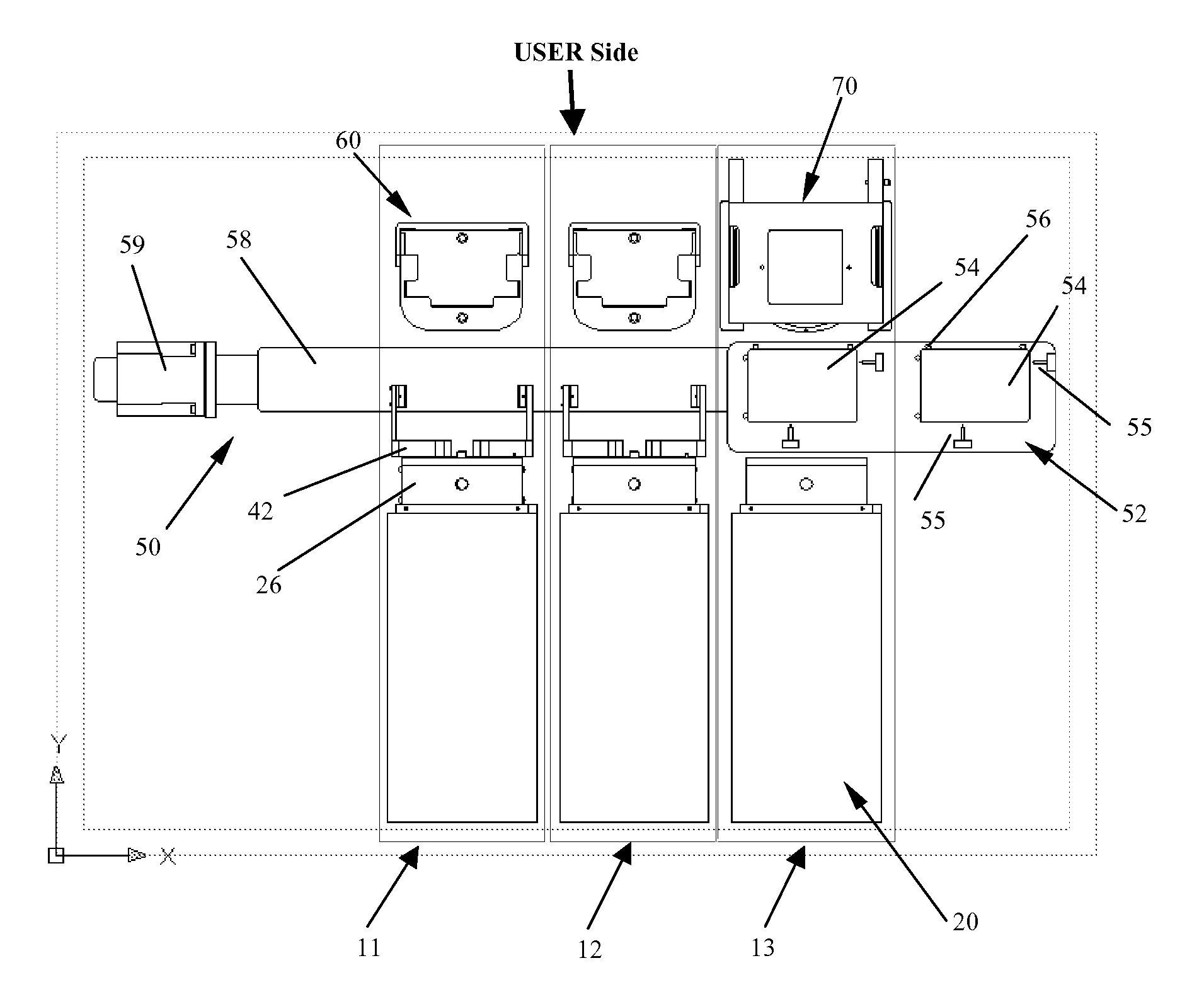

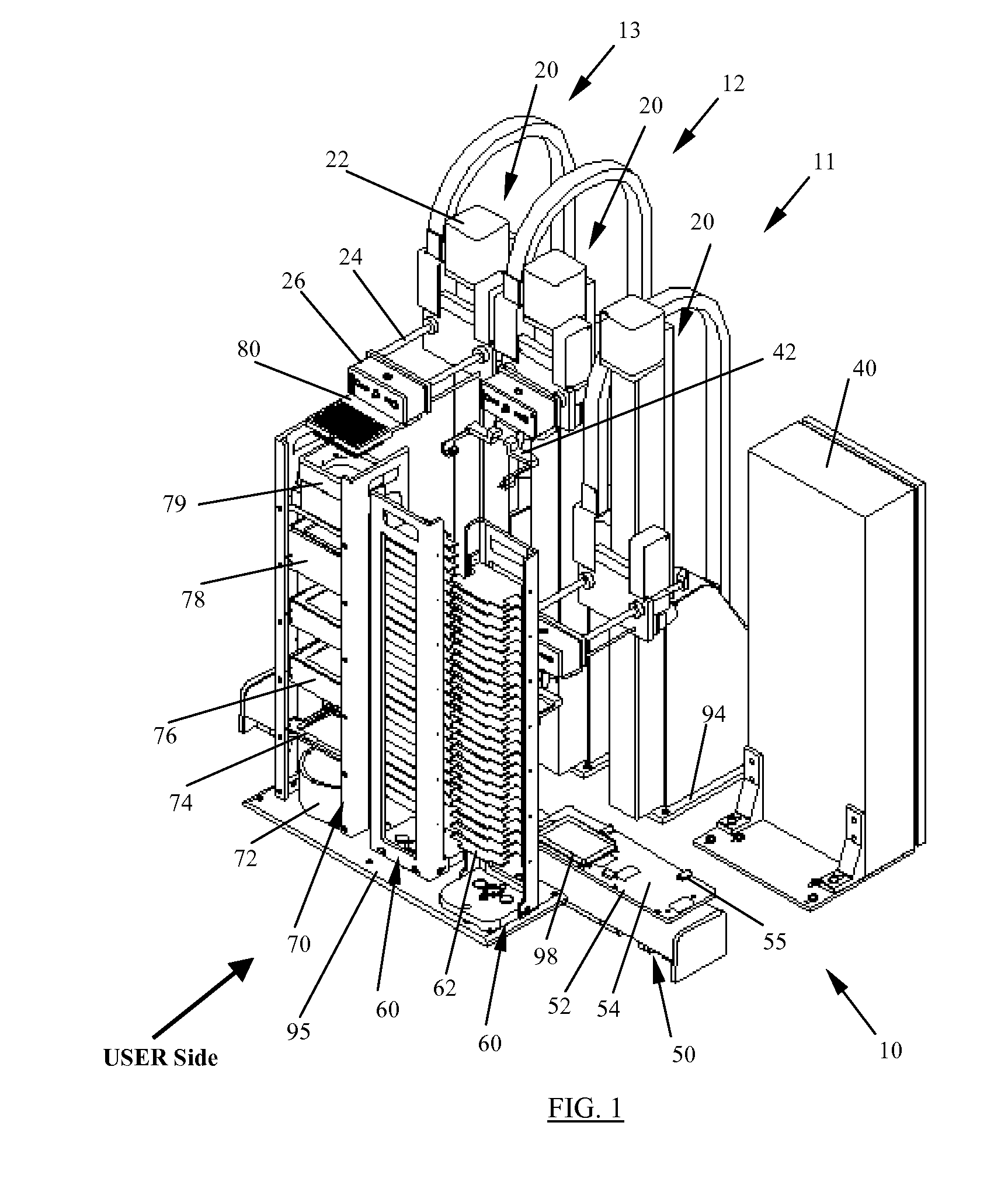

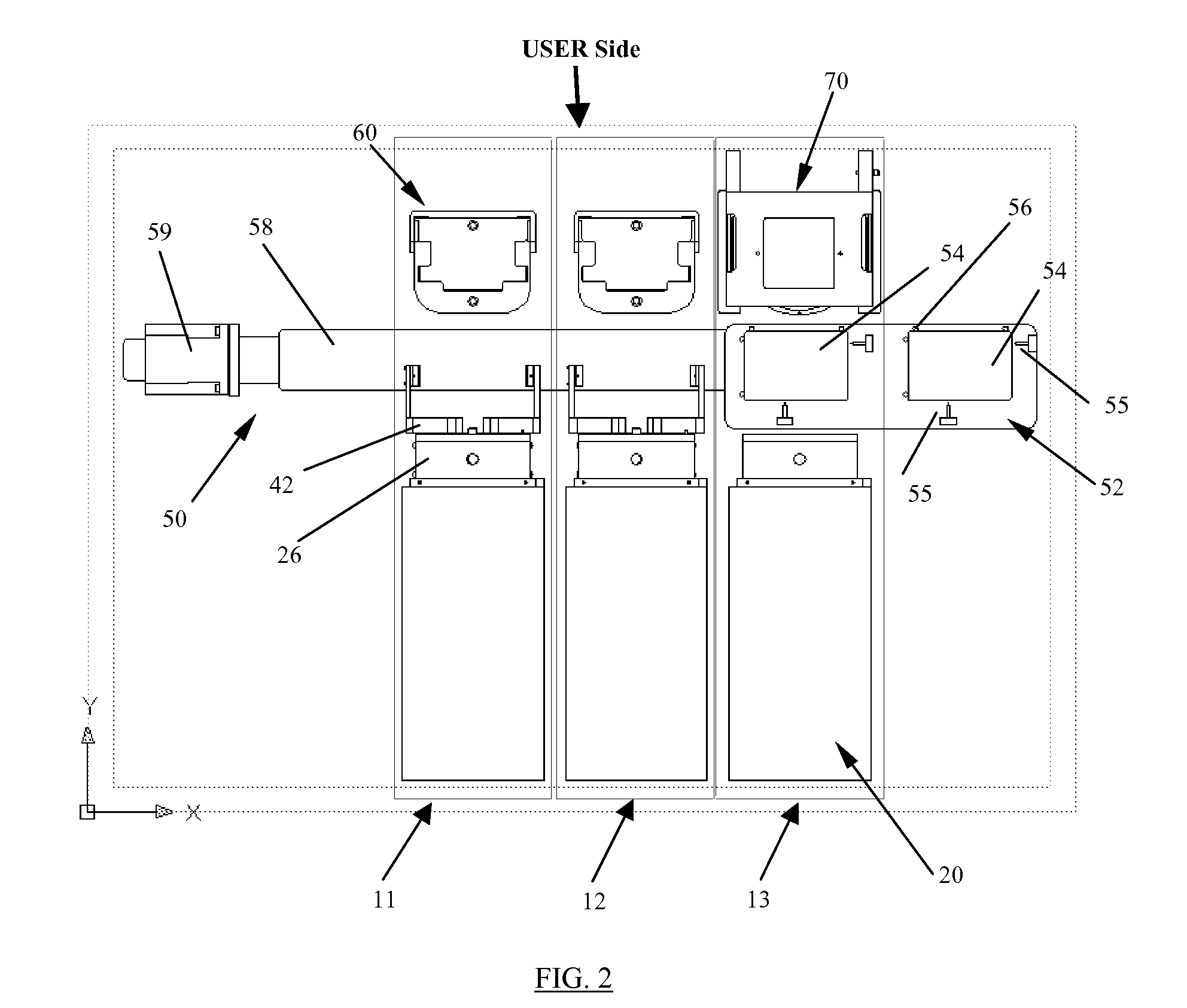

Modular and Scalable Apparatus for Process Automation

ActiveUS20070123999A1Minimized footprintEffectively using the available vertical spaceComputer controlDigital data processing detailsGeneral purposeHuman–machine interface

An apparatus comprises one or more functional modules, conveyers, tools, and sub-modules. A functional module comprises at least one general-purpose tool interface and a device for moving the tool interface in one or more directions. A functional module may include a rotary positioning device, which rotates the tool interface about an axis. At least one functional module is used in an apparatus, and at least one tool is attached to the tool interface of a functional module. A tool performs a specific operation on a work sample. For example, a gripping tool is used to hold and release a sample container, or a scanning tool is used to scan multiple work samples. At least one conveyer is used to transfer work sample containers from one functional module to another. In addition to functional modules, conveyers, and tools, an apparatus may include one or more sub-modules. A sub-module can be a shelf for stacking sample containers, a carousel, a wash tower for sterilizing and cleaning a tool, a centrifuge device, a shaker, an incubator, a plate sealer, etc. A functional module uses one or more tools and one or more sub-modules to complete an operation. A base is provided for installing and integrating the functional modules, conveyers, tools, and sub-modules of an apparatus. At least one Computer Processing Unit (CPU) with a Human-Machine Interface (HMI) is used to control, synchronize, and integrate the operation of functional modules, conveyers, tools, and sub-modules and to provide a Graphical User Interface (GUI) through which the user can define and run a procedure.

Owner:RAGHIBIZADEH SASAN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com