Apparatus and method for small-volume fluid manipulation and transportation

a fluid manipulation and fluid transportation technology, applied in the field of miniature instruments, can solve the problems of difficult to arrange all the capillary tubes tightly to occupy a very small space, difficult to form zero-dead volume connectors using conventional capillary tubes, and difficult to connect fia conduits and pump capillaries via ion exchangeable membrane tubes. achieve the effect of simple fluid manipulation and transportation, and facilitate high throughput assays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Microfabrication of Glass Chips

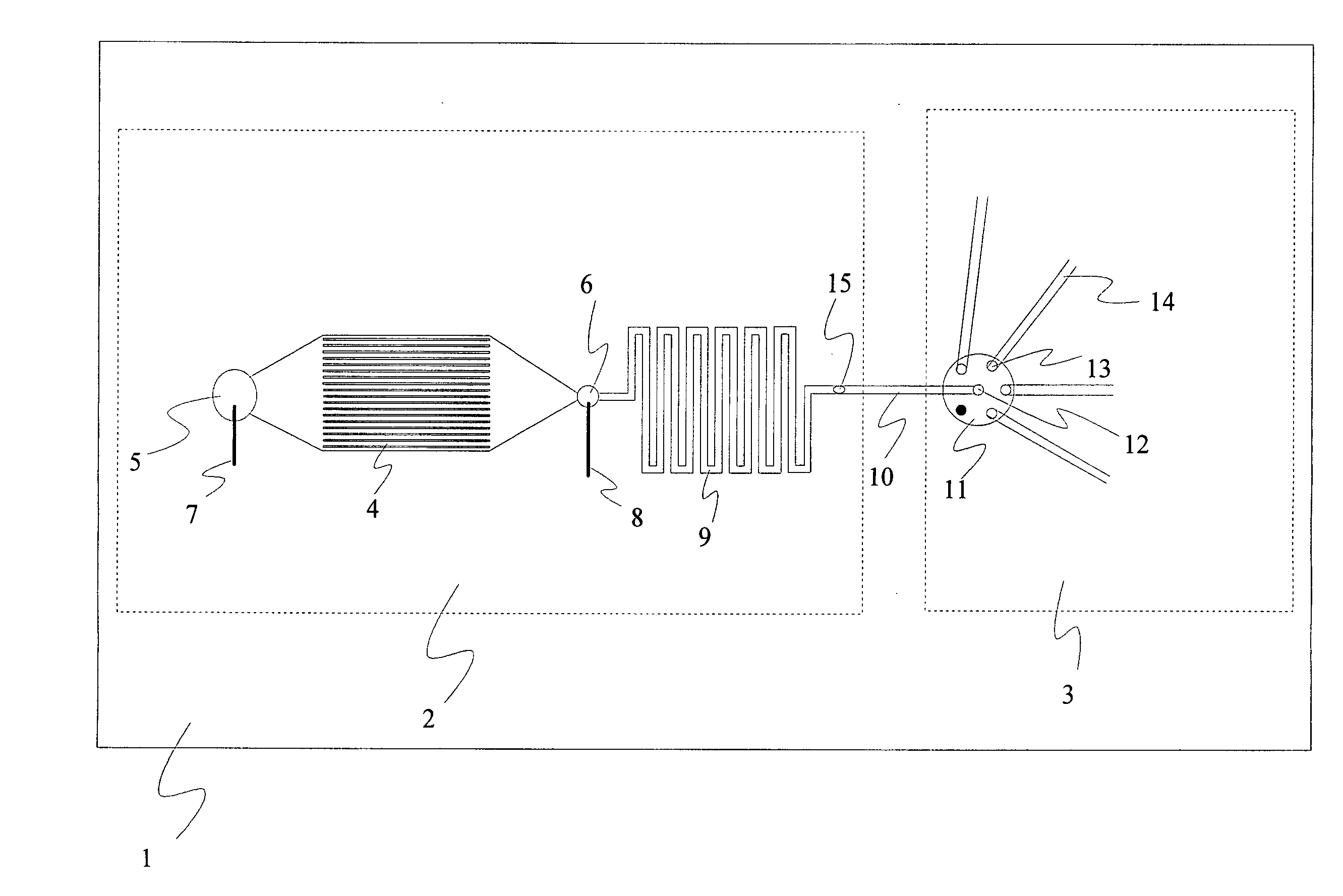

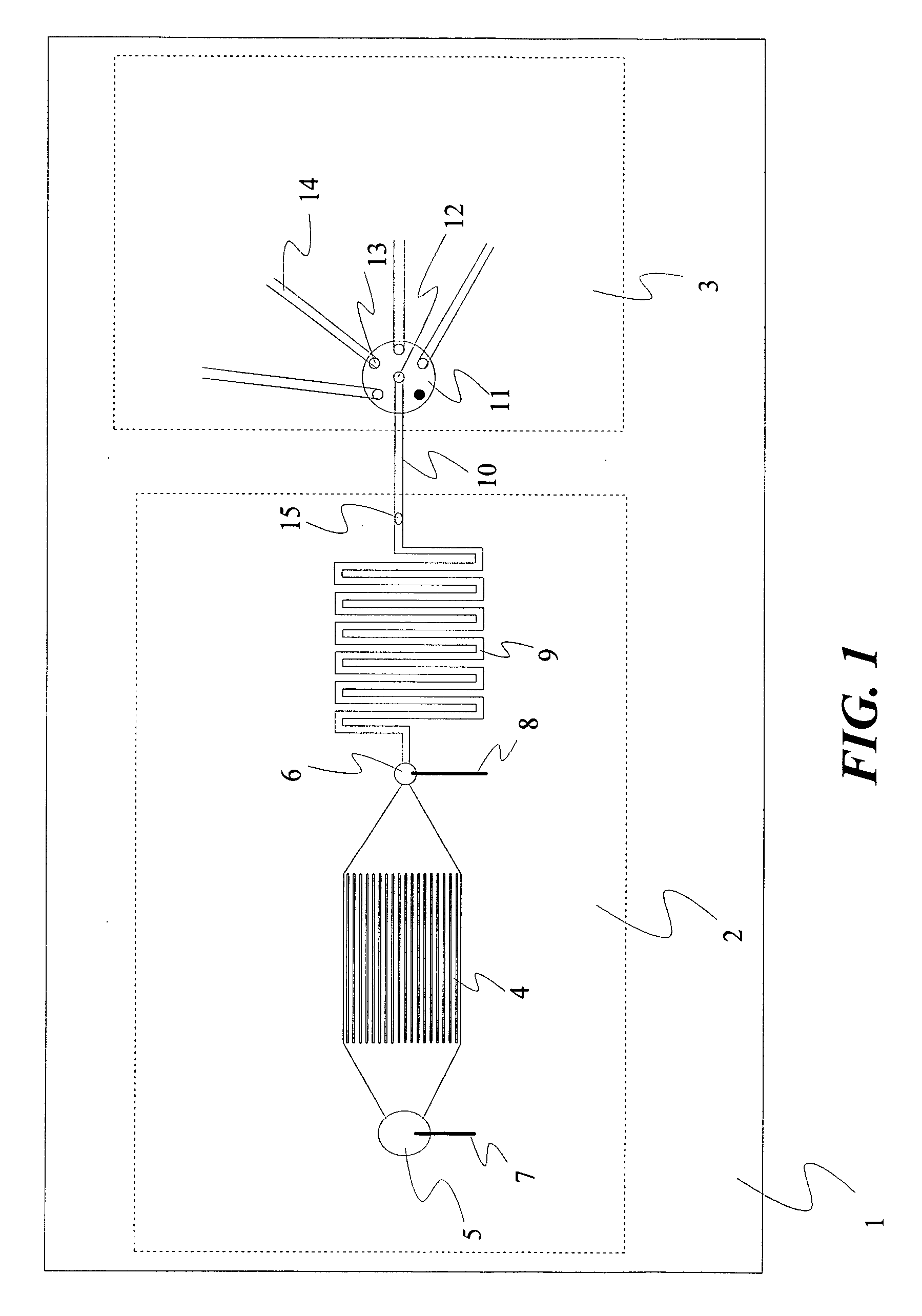

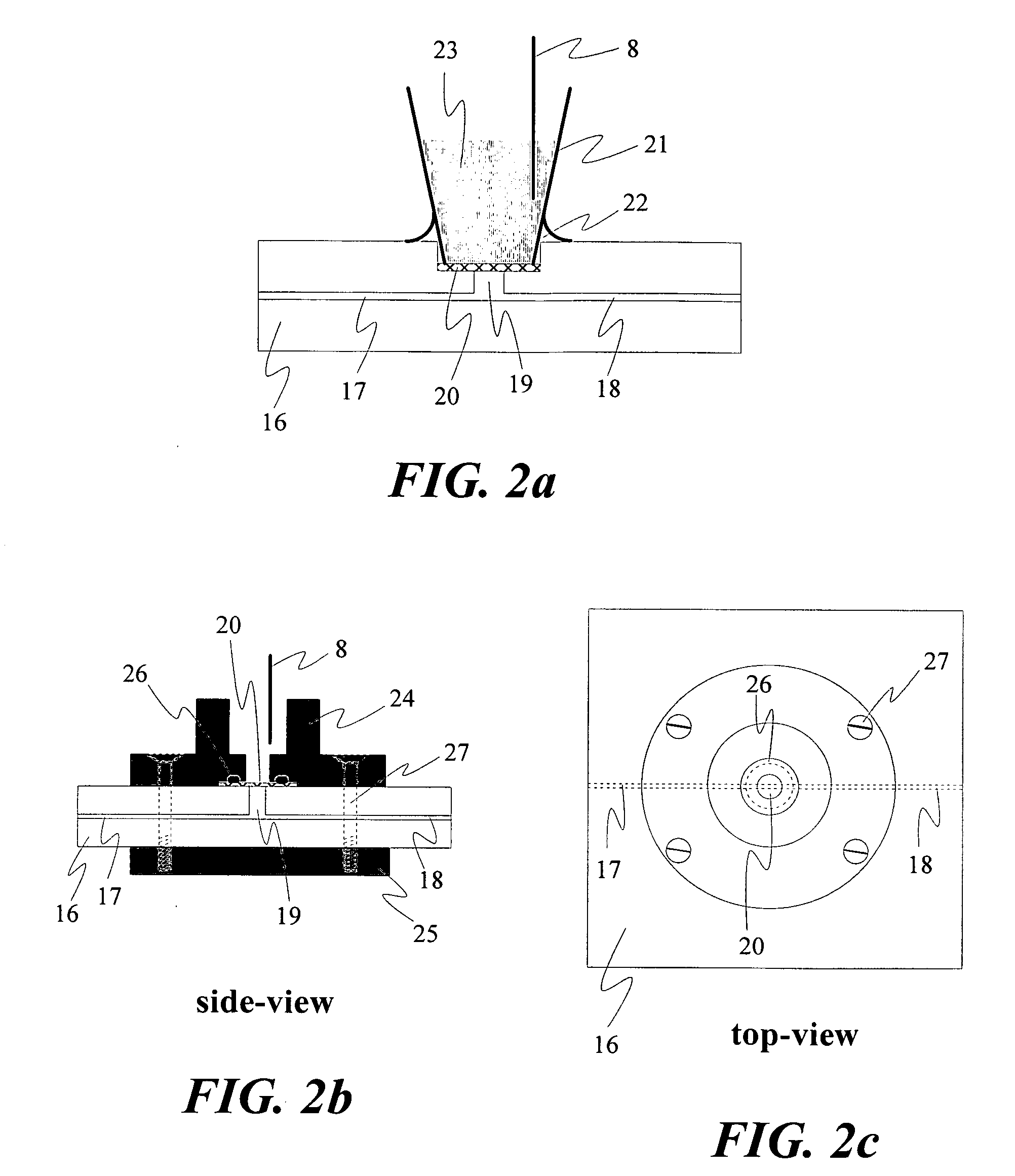

[0058] Schematic diagrams showing preferred embodiments of the small volume fluid manipulation and transportation devices of the present invention are provided in FIGS. 1 through 8. A variety of methods known in the art may be used to make and use the claimed fixed-volume-injectors. For example, the chip microfabrication protocols disclosed in Analytical Chemistry 71 (1999) 566-573, or their equivalents known in the art are readily be adapted to produce the chip component of the hybrid apparatus of the present invention.

[0059] Alternative methods known in the art may be employed within the scope of the present invention. For example, for photolithograpy a thin sacrificial layer of Cr / Au (300 Å Cr and 0.5 μm Au) may be deposited onto a glass wafer, followed by photoresist coating (Shipley photoresist 1818). After soft baking at 80 C°, the photoresist may be exposed to UV radiation through a mask. The mask pattern will be transferred to the wafer after...

example 2

Preparation of an Immobilized Polymer Coupler

[0061] A piece of bare capillary (150-μm-id, 375-μm-od and 50-cm-long) is flushed with 1 M NaOH for 45 min, ultra-pure water and acetonitrile for 15 min each, and then dried with helium. A solution of 0.4% (vol / vol) of 3-(trimethoxysilyl) propyl methacrylate and 0.2% (vol / vol) acetic acid in acetonitrile is flushed into the dried capillary with a syringe pump at 50 μl / min for 1 h. The capillary is then rinsed with acetonitrile and dried with helium. The bi-functionalized capillary is cut into desired lengths (e.g. 5 cm) for the immobilization of polyacrylamide.

[0062] 5 mL solution containing 4% (w / v) of acrylamide and a small amount (e.g. 0.003%) of N, N′-methylene-bis-acrylamide (Bis) is purged with helium for about 30 min. Then, 2 μL of 10% APS and 2 μL of TEMED are added to the solution using micro-syringes. Mixing is carried out automatically as the purging helium bubbled up. Promptly (<5 s) after the APS and TEMED are mixed with ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com