Computer control device and control method of product processing equipment

A technology of processing equipment and control devices, applied in computing, instruments, electrical digital data processing, etc., can solve the problems of device body work influence, dusty, ignoring the detection and regulation of control devices, etc., and achieve the effect of convenient and quick assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

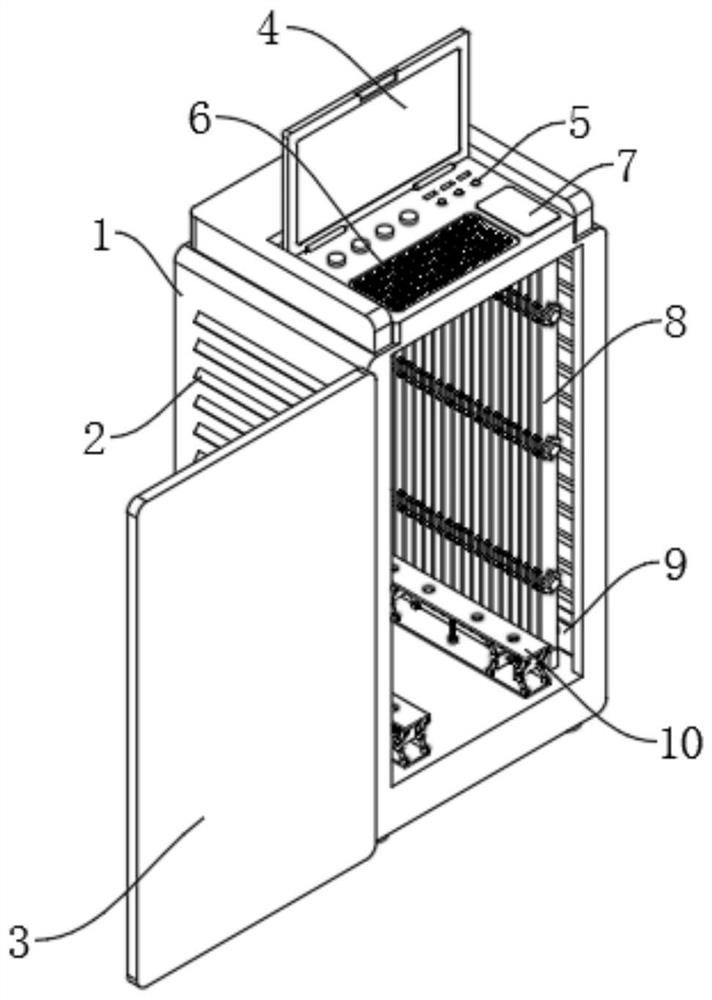

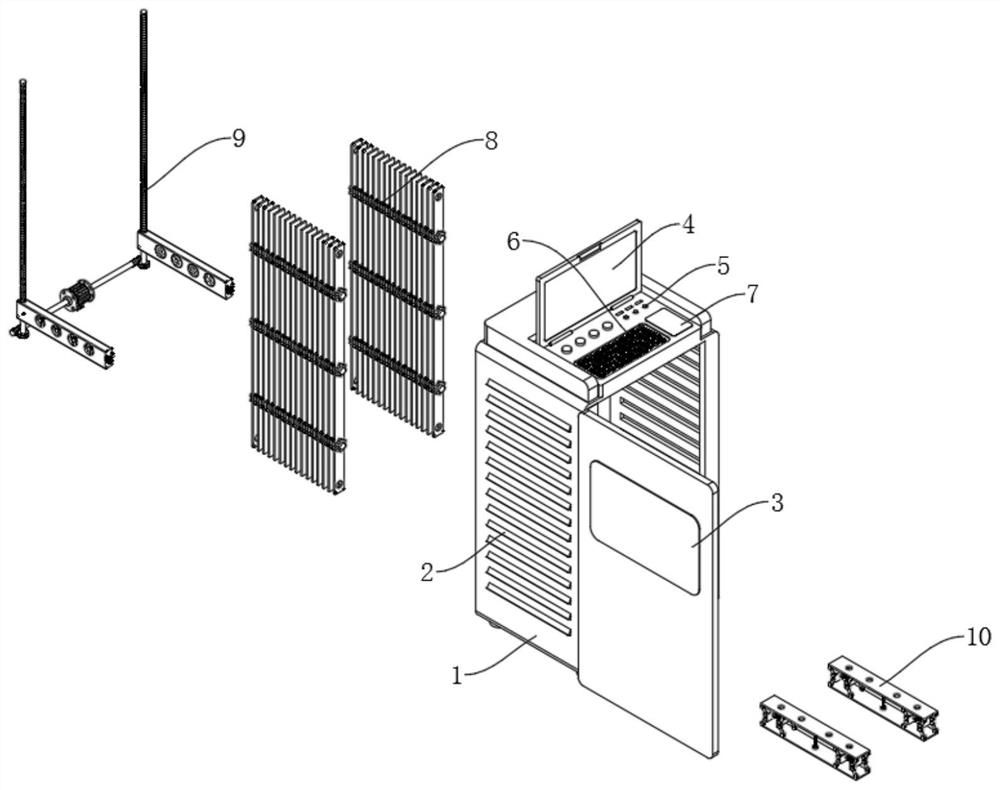

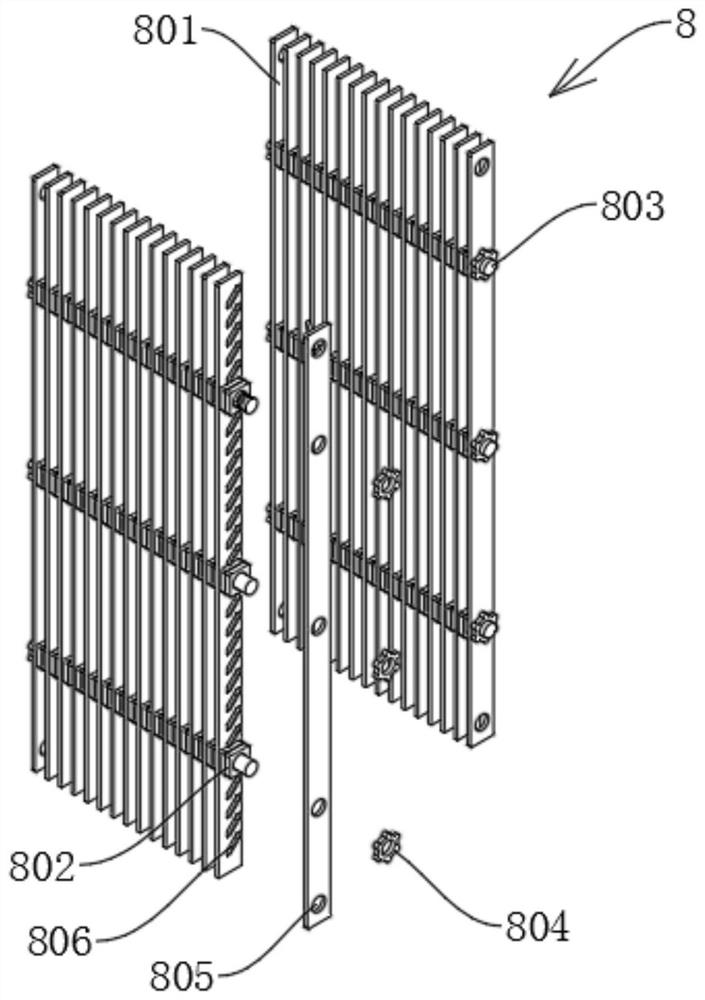

[0037] See Figure 1-3 , A computer control device and control method for product processing equipment, including an installation cabinet 1, a heat dissipation grille 2, and a cabinet door 3. The four corners of the bottom surface of the installation cabinet 1 are fixedly connected with non-slip support feet, and the heat dissipation grille 2 is set in the installation cabinet. On the side wall of 1, the vertical edge of the installation cabinet 1 is fixedly installed with hinges, the cabinet door 3 is movably connected to the installation cabinet 1 through the hinges, and the top of the installation cabinet 1 is rotatably connected with the display screen 4, and the installation cabinet 1 The interface module 5, the control input module 6 and the touch panel 7 are also fixedly installed on the top surface. The installation cabinet 1 is provided with a mounting cavity, and the side wall of the mounting cavity is connected with a heat-absorbing and dust-proof mechanism 8 to absorb...

Embodiment 2

[0041] See Figure 4-6 , Combined with the basis of embodiment 1, the difference is that the movable heat sink 9 includes a reciprocating drive mechanism, the reciprocating drive mechanism includes a dual-axis servo motor 901, and the output shaft of the dual-axis servo motor 901 is fixedly connected with a transmission shaft 902 The end of the transmission rod 902 away from the single-axis servo unit 901 is fixedly connected with a worm 903. The worm 903 is meshed and connected with the worm wheel 904. The worm wheel 904 is fixedly connected to the double-threaded reciprocating drive rod 905. .

[0042] The movable heat sink 9 also includes a heat dissipation mechanism. The heat dissipation mechanism includes a mounting shell 907, which is fixedly connected to the connecting block 906, a mounting frame 908 is fixedly connected to the mounting shell 907, and a cooling fan is fixedly mounted on the mounting frame 908, A dust-proof filter 909 is fixedly connected to the inner side...

Embodiment 3

[0046] See Figure 7 The difference between the foundation of embodiment 1 or 2 is that the shock-absorbing installation mechanism 10 includes a mounting bottom plate 1001 and a mounting top plate 1002. The mounting bottom plate 1001 is fixedly connected to the mounting plate, and the mounting top plate 1002 is provided with a mounting hole 1003. , The mounting bottom plate 1001 and the mounting top plate 1002 are rotatably connected with a mounting link 1004, the mounting link 1004 is also rotatably connected to the mounting block 1005, the first shock-absorbing spring 1006 is fixedly connected between the mounting blocks 1005, the mounting bottom 1001 and the mounting A second shock-absorbing spring 1007 is fixedly connected between the top plates 1002.

[0047] The mounting top plate 1002 of the shock-absorbing installation mechanism 10 of the present invention is provided with a mounting hole 1003. The computer equipment used to control product processing can be fixedly instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com