Efficient wet process mixing granulating machine

A technology of wet mixing and granulator, which is applied in the direction of granulation in static tanks/troughs, etc., can solve problems such as poor pharmaceutical quality, achieve the effects of ensuring cleanliness, avoiding process water leakage, and promoting mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

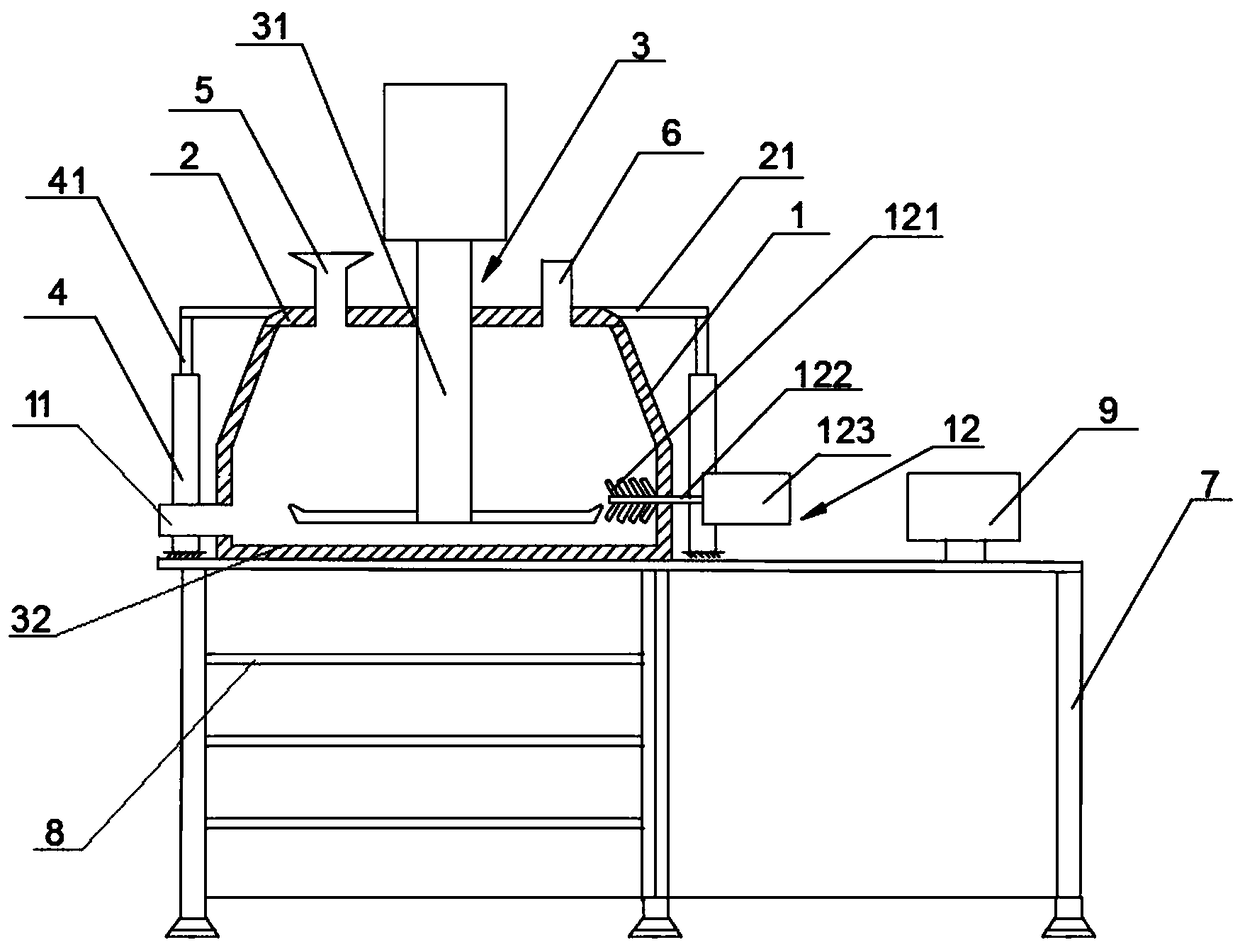

[0024] Such as figure 1 As shown, a high-efficiency wet mixing granulator includes a boiler 1, a pot cover 2 is arranged on the boiler 1, a stirring assembly 3 is arranged on the pot cover 2, and the stirring assembly 3 includes a stirring shaft 31 and a stirring paddle 32, the stirring shaft 31 is connected with the pot cover 2, and the stirring paddle 32 is located at the lower end of the stirring shaft 31, and the stirring paddle 32 is close to the bottom of the boiler 1; the upper end of the stirring shaft 31 is connected with the motor, and the motor is used to drive the stirring shaft to rotate, thereby realizing the stirring shaft to the material Stir to mix.

[0025] In the present invention, the stirring assembly is arranged on the pot cover, which avoids opening a hole at the bottom of the boiler to install the stirring assembly, so there is no nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com