Washing device for drilling equipment

A cleaning device and equipment technology, which is applied in the direction of lighting and heating equipment, drying gas arrangement, cleaning method and utensils, etc., can solve the problems such as difficult cleaning of drill bits and difficult removal of sundries, and achieve the effect of fast putting into use and accelerating drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

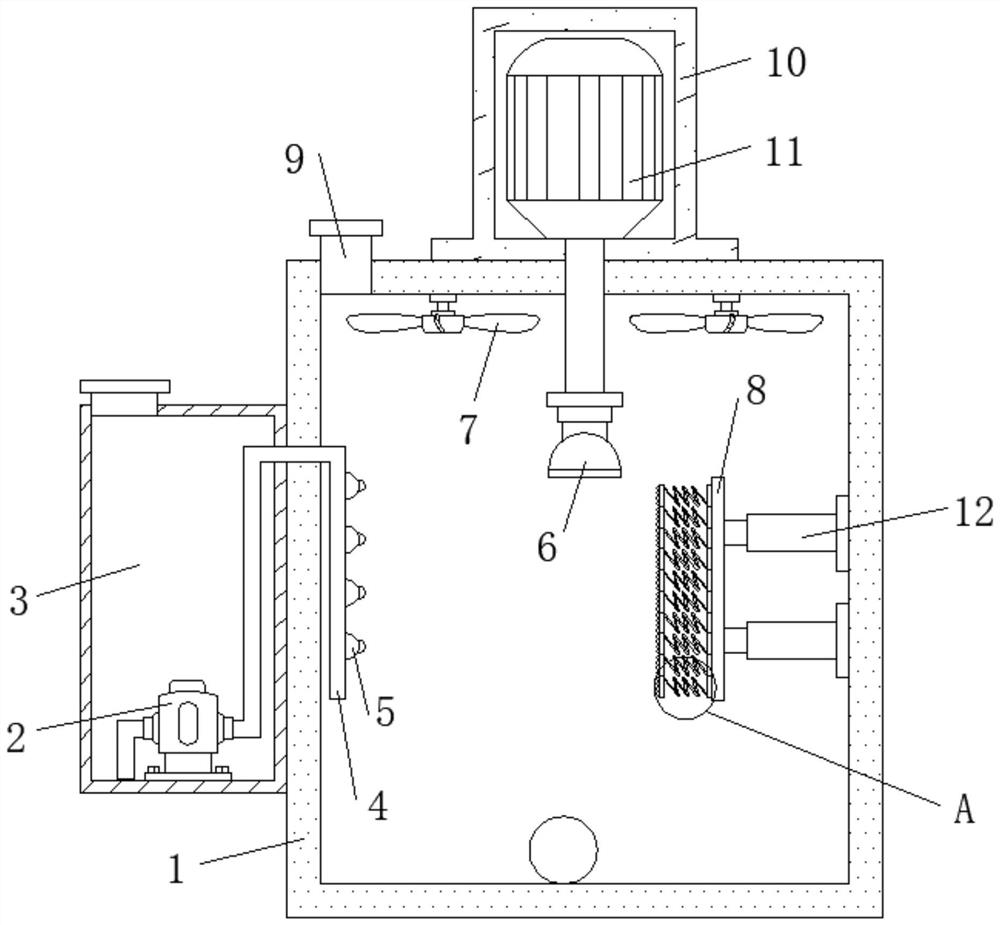

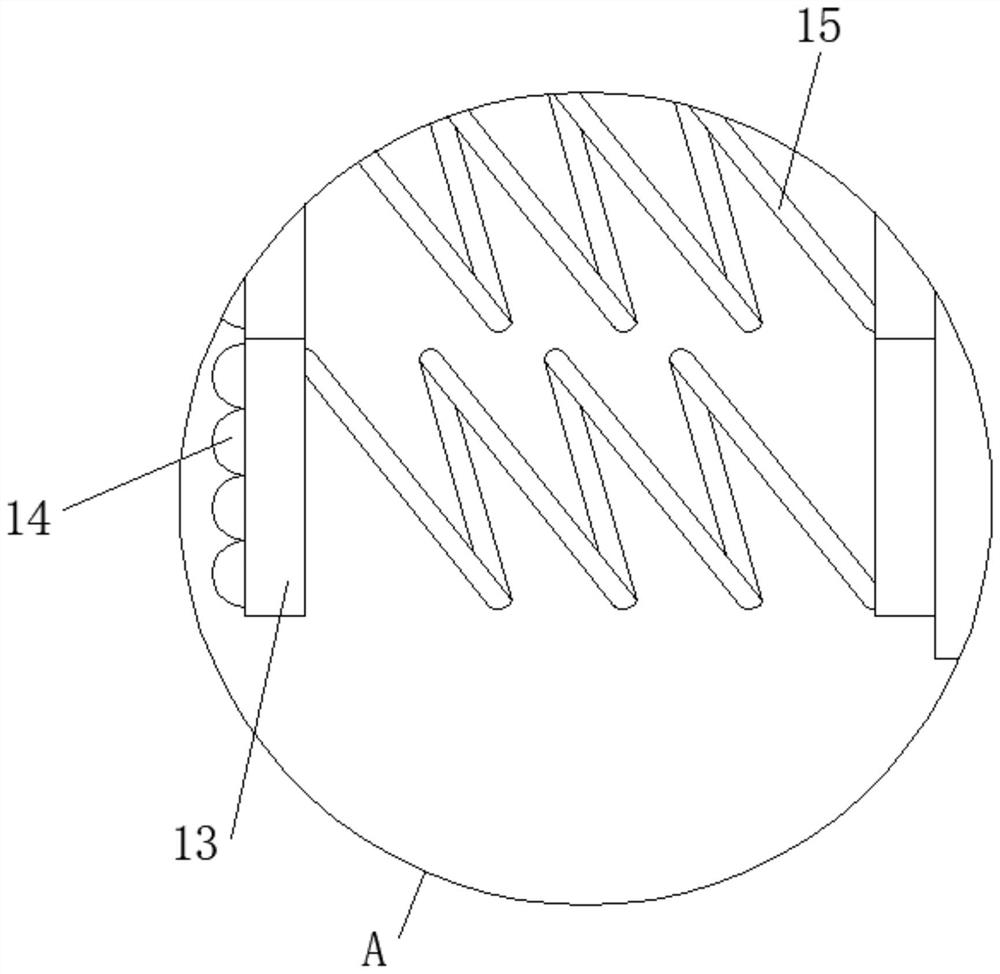

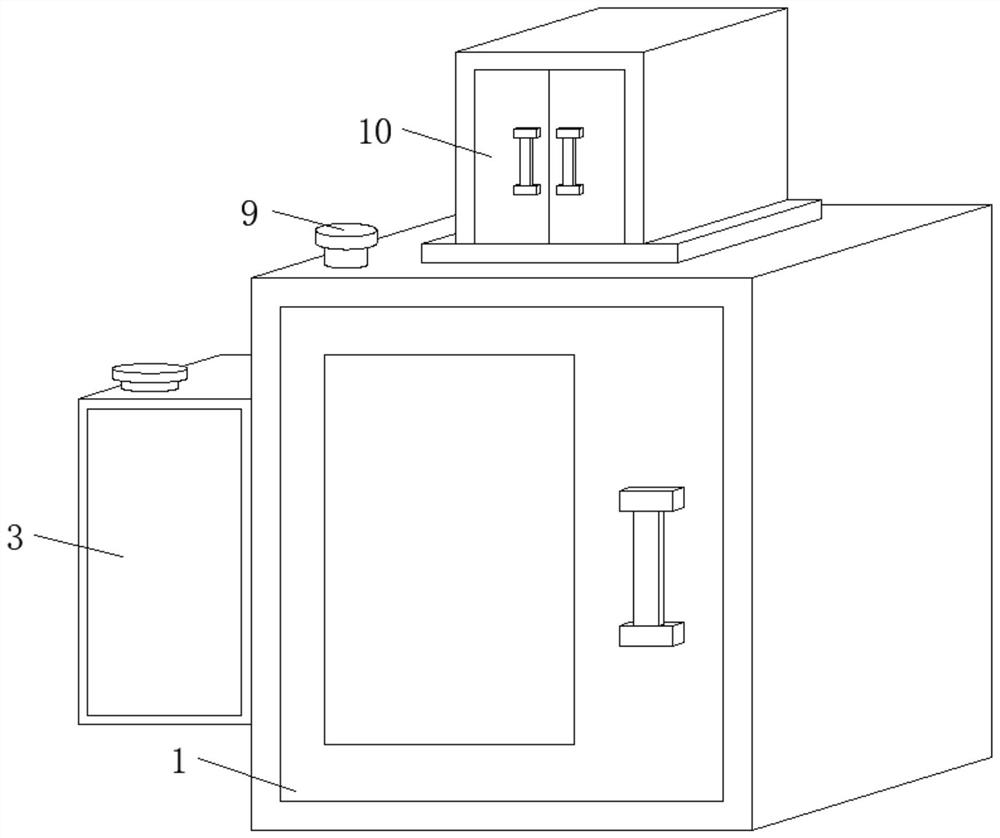

[0024] refer to Figure 1-3 , a cleaning device for drilling equipment, comprising a box body 1, a flushing mechanism is provided on one side of the outer wall of the box body 1, a motor box 10 is fixed on the middle position of the top outer wall of the box body 1 by bolts, and the bottom inner wall of the motor box 10 passes through The motor 11 is fixed by bolts, and one end of the output shaft of the motor 11 is keyed to a transmission shaft. One end of the transmission shaft is located inside the box body 1, and one end of the transmission shaft is fixed with an electromagnetic chuck 6 by bolts. The side of the box body 1 away from the flushing mechanism There is a scrubbing mechanism on the inner wall, fans 7 are fixed by bolts on both sides of the inner wall of the top of the box body 1, a box door is hinged on one side of the outer wall of the box body 1, and a box door is inserted on one side of the outer wall of the box body 1 near the bottom. drain pipe.

[0025] I...

Embodiment 2

[0028] refer to Figure 4 , a cleaning device for drilling equipment. Compared with Embodiment 1, in this embodiment, a heater 17 is fixed on one side of the outer wall of the box body 1 near the top by bolts, and an air bucket 18 is plugged into one end of the heater 17. One end of bucket 18 is positioned at the inside of box body 1, and fan 16 is fixed with bolt on one side outer wall of heater 17, and the output end of fan 16 communicates with the inside of heater 17.

[0029] During use, after the drill bit is cleaned, start the heater 17 to heat, and then the blower fan 16 blows air to bring the heat into the inside of the box body 1 to dry the drill bit so that it reaches a dry state quickly. Drying is for checking the drill bit. Check the wear condition to see if it can be reused. Whether the drill bit is dry or not will not affect its use. The purpose is to prevent the damaged drill bit from being put into use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com