Forward pressing and lateral pushing concrete outer wall hanging plate forming machine and forming method

A concrete and molding machine technology, applied in ceramic molding machines, molding indenters, molds, etc., can solve the problems of high labor intensity, low production efficiency, and large floor space for workers, so as to reduce labor intensity of workers and reduce floor space. Small, the effect of improving the product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

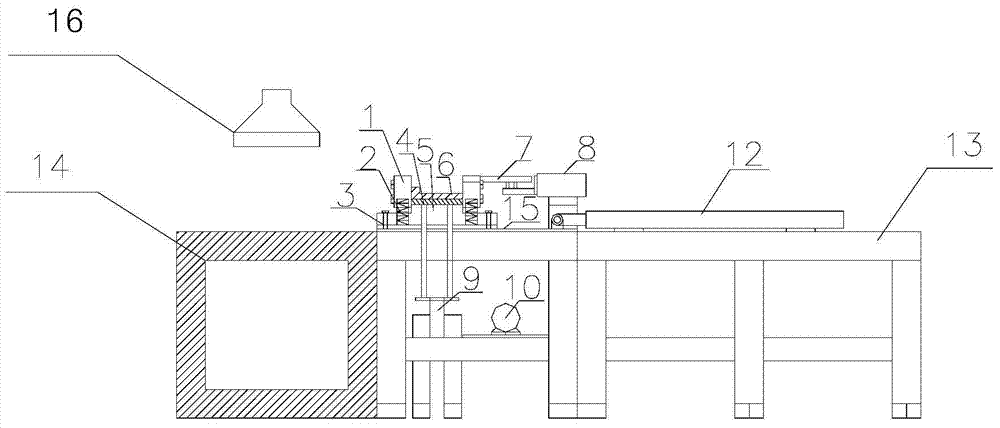

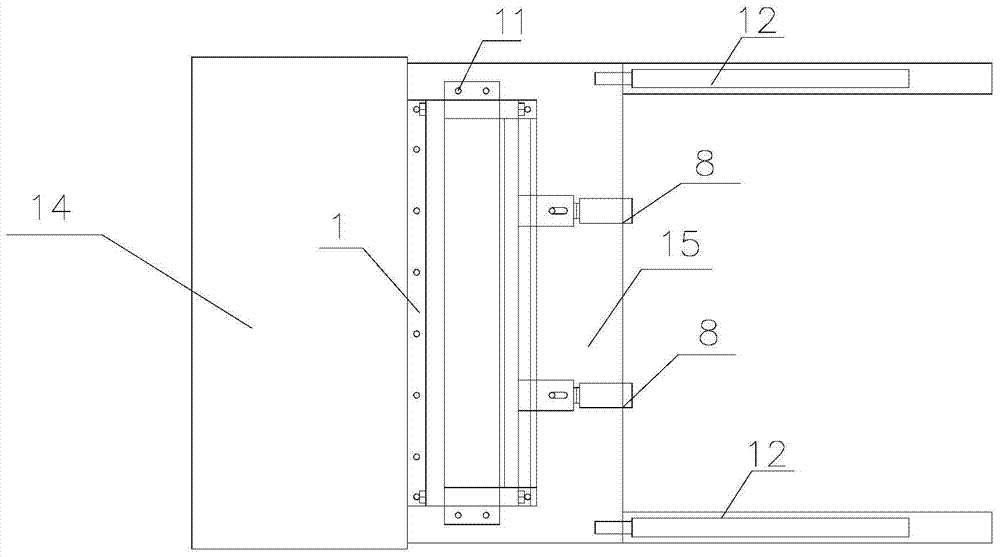

[0024] The invention is a positive pressurization and lateral pushing concrete exterior wall hanging board molding machine, which is equipment for producing concrete outer wall hanging boards. The equipment includes a fixed frame and a charging mold frame assembled on the fixed frame, a positive pressure part, a lateral pushing part and a push-pull part of the mold frame. side and has relative movement with the charging mold frame, and the charging mold frame is loosely installed on the table top of the fixed frame and is linked with the horizontal direction of the mold frame push-pull part.

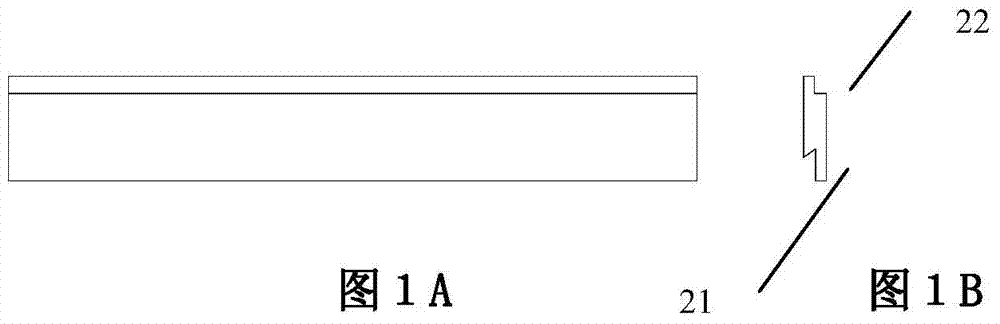

[0025] The equipment assembly diagram is as follows Figure 2A , Figure 2B and image 3 As shown, it includes a long side template 1, a compression spring 2, a positioning pin 3, a slab ejecting steel plate 4, a bottom template 5, a slab template 6, a lateral pushing plate 7, a lateral pushing cylinder 8, and a slab Ejection oil cylinder 9, vibrating motor 10, widthwise side template...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com