Compound lithium strip production device and method

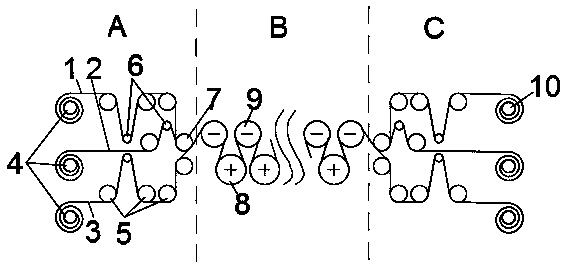

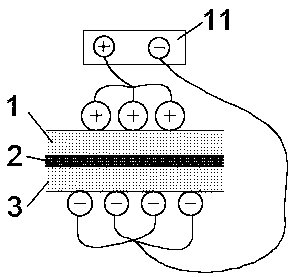

A production device and production method technology, applied in lamination devices, chemical instruments and methods, layered products, etc., capable of solving problems such as large thickness of lithium layer, uneven thickness of lithium layer, small thickness of lithium layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0034] Embodiment 2: The difference from Embodiment 1 is that the set current value of the DC constant current source is 1500A, and the strip speeds of the strip lithium source, solid electrolyte and composite lithium strip matrix are all 20m / min.

Embodiment 3

[0035] Embodiment 3: The difference from Embodiment 1 is that the set current value of the DC constant current source is 1500A, and the strip speeds of the strip lithium source, solid electrolyte and composite lithium strip matrix are all 30m / min.

Embodiment 4

[0036] Embodiment 4: The difference from Embodiment 1 is that the set current value of the DC constant current source is 3000A, and the strip speeds of the strip lithium source, the solid electrolyte and the composite lithium strip matrix are all 20m / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com