Compound-based semiconductor ultrathin substrate manufacturing method

A production method and compound technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of difficult operation, large error, poor substrate flatness, etc., achieve good thickness controllability, and reduce thickness error , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

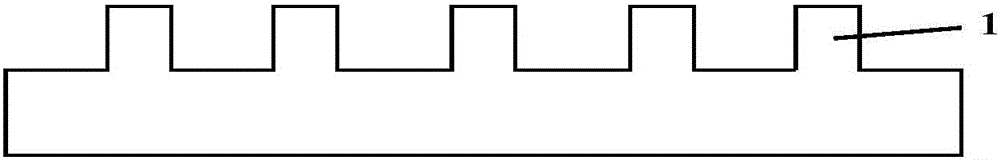

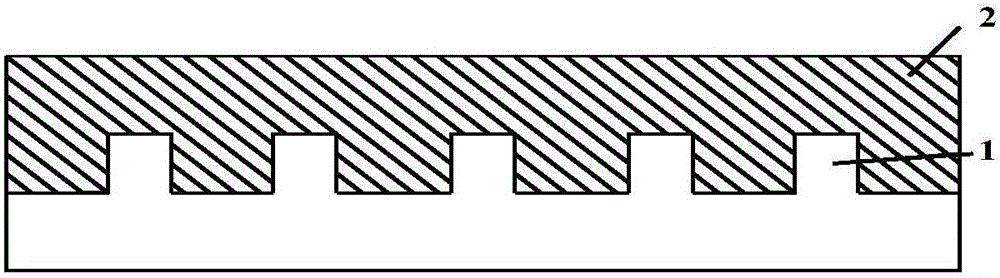

[0038] This embodiment provides a method for thinning a compound semiconductor gallium arsenide substrate, including the following steps:

[0039] (1) The Schottky diode terahertz device is fabricated on the gallium arsenide compound epitaxial material layer;

[0040] (2) Use AZ4620 photoresist as a mask to define a deep isolation mesa around the terahertz device, use ICP etching, the etching gas is chlorine and boron trichloride, the etching depth is 6 microns, and remove the glue with acetone , and cleaned with acetone, ethanol, deionized water;

[0041] (3) On the gallium arsenide epitaxial wafer etched with isolation deep grooves, first apply PMMA electron beam photoresist 4 microns, bake at 180 for 2 minutes; then apply PMMA electron beam photoresist 6 microns, 180 degrees hot plate The thickness of the glue was 2 minutes, and a total of 10 microns of PMMA electron beam photoresist was coated on it.

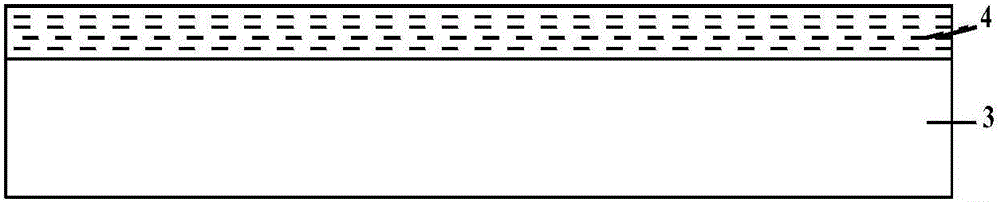

[0042] (4) growing protective medium silicon dioxide 20 nanometers on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com