Box-shaped laminated heat exchanger provided with novel backing plate structure

A technology of heat exchangers and backing plates, which is applied in the field of box-shaped laminated heat exchangers, and can solve problems such as the sealing quality of backing plates, product scrapping, and heat exchange medium stringing chambers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Further description will be made below in conjunction with embodiments and illustrations.

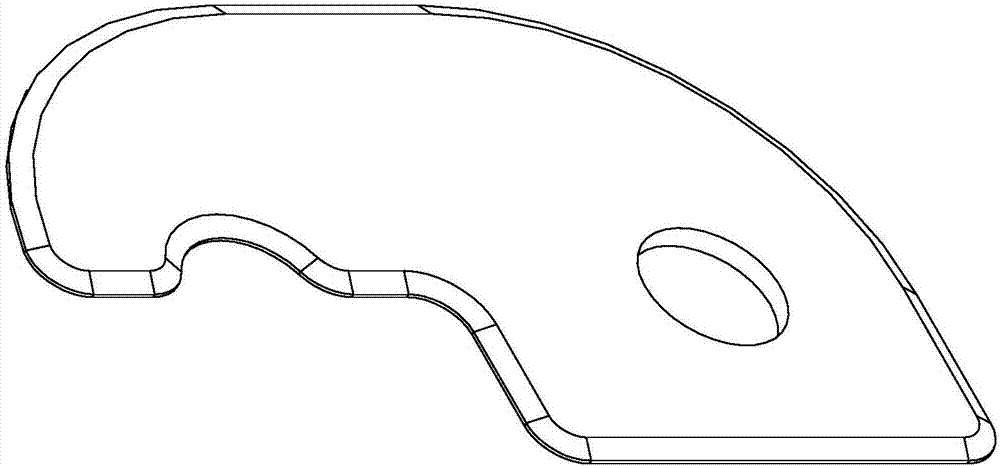

[0035] figure 1 The protruding structure of the backing plate with a protruding structure around it is continuous, and it can also be considered that the protruding structure around it is intermittent, and the meaning of the so-called protruding structure is intermittent should be the relevant engineering Those skilled in the art can understand and be familiar with, so do not draw and represent here again. In addition, it can be found that in figure 1 Indicates no assembly mark indents on backing plane.

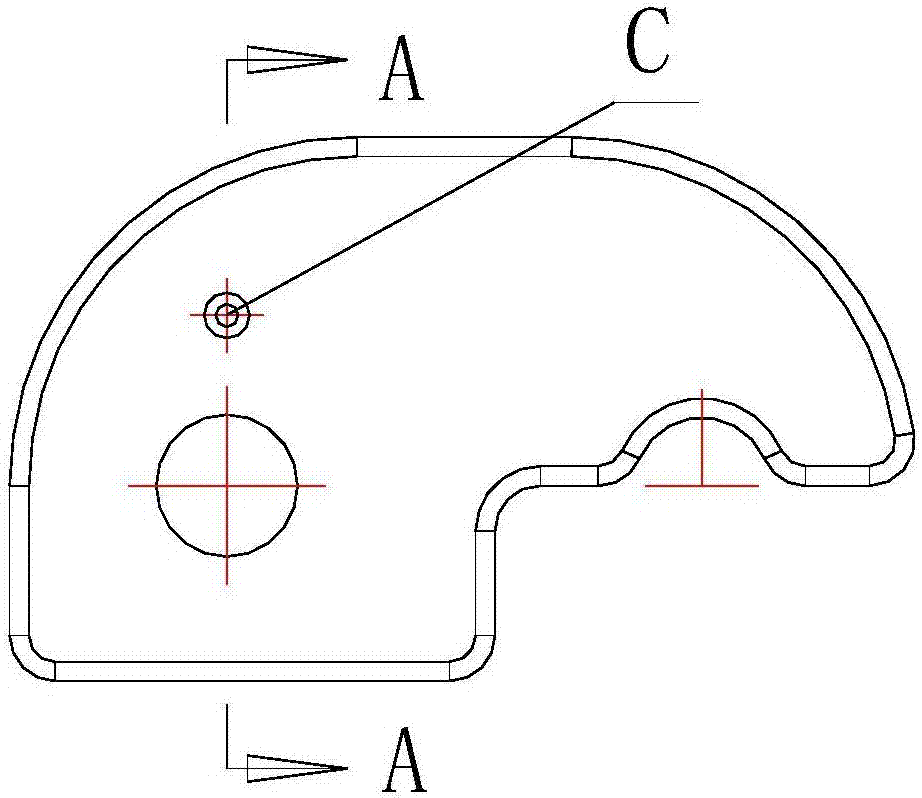

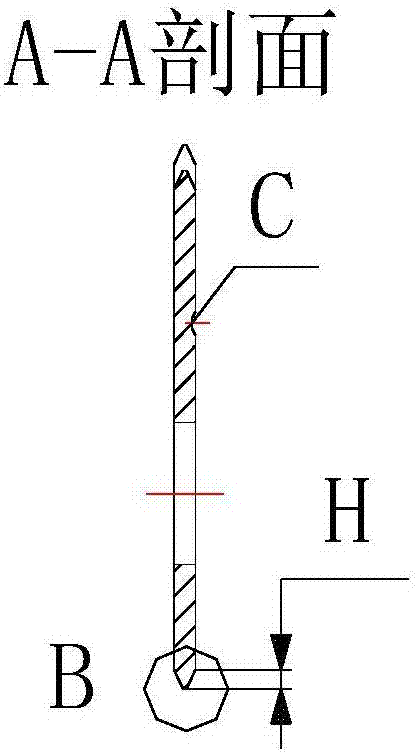

[0036] figure 2 with image 3 The C above means that there is an assembly mark indentation on a single surface of the backing plate, the indentation is shallow and obvious, and the depth, shape and position of the indentation should not hinder the sealing of the backing plate. In fact, it can also be understood as figure 1 The backing plate indicated is exactly figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com