Containing frame for die steel production

A technology for placing racks and die steel, applied in the field of die steel, can solve the problem of mixing the die steel together, and achieve the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

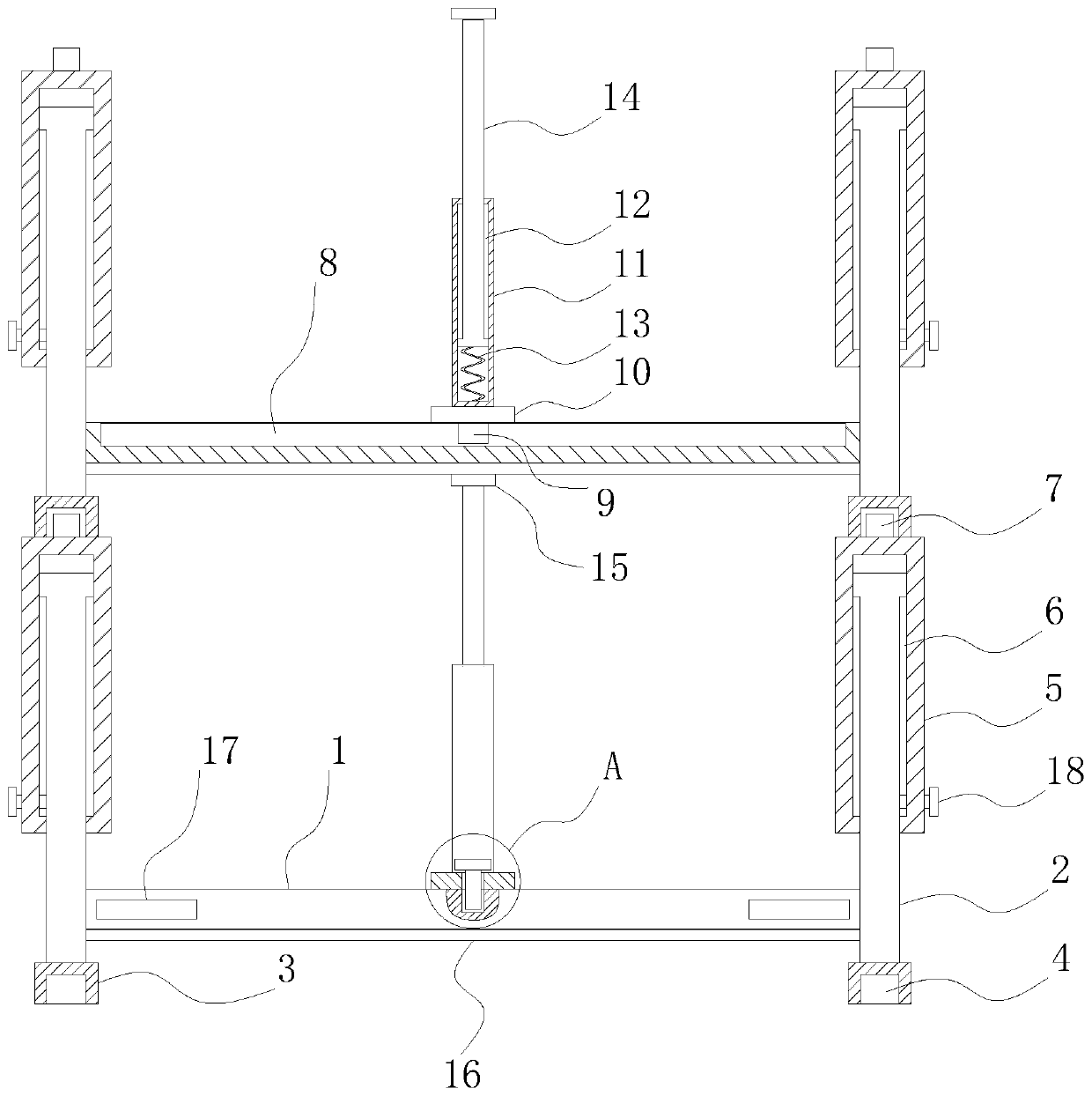

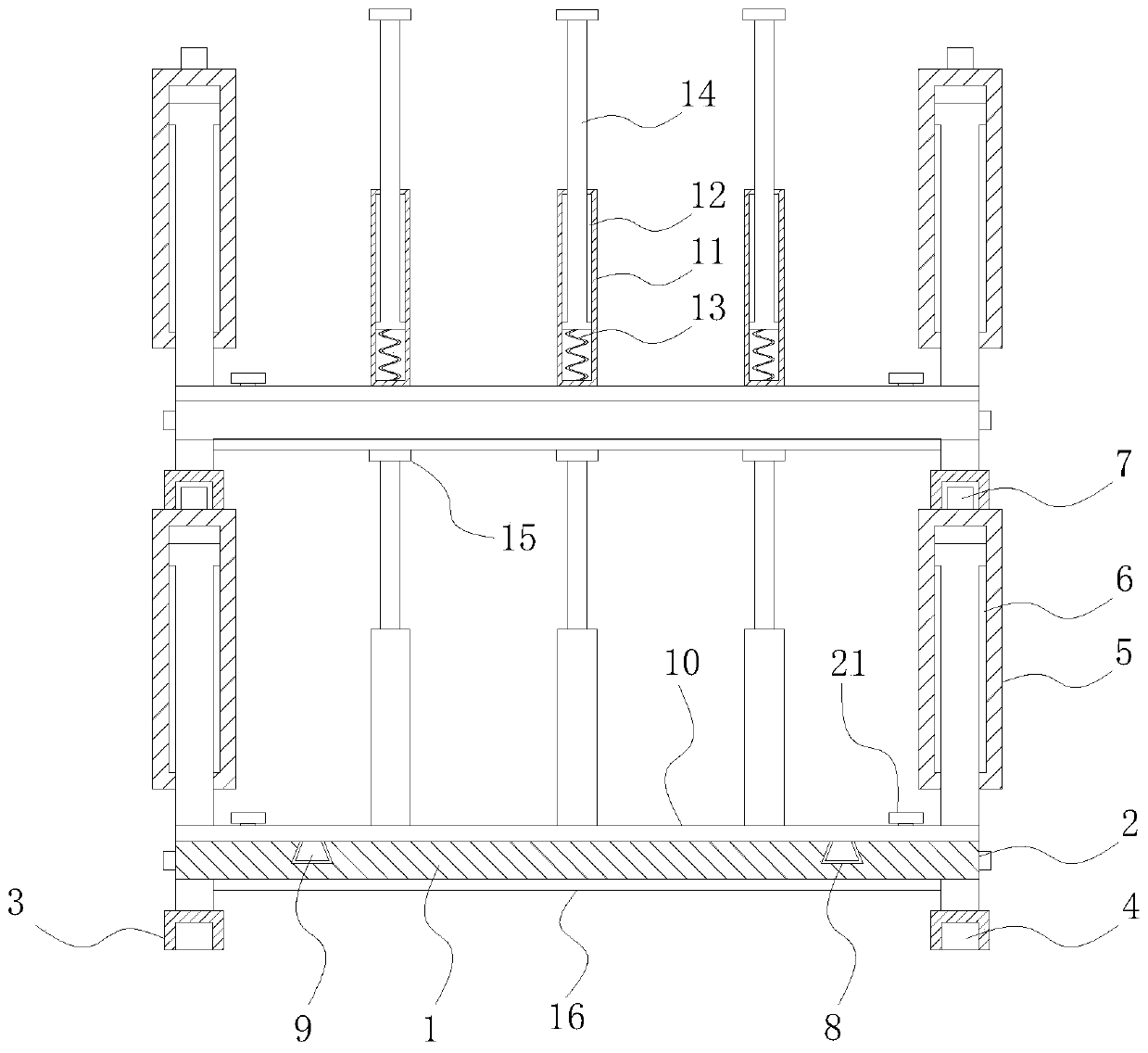

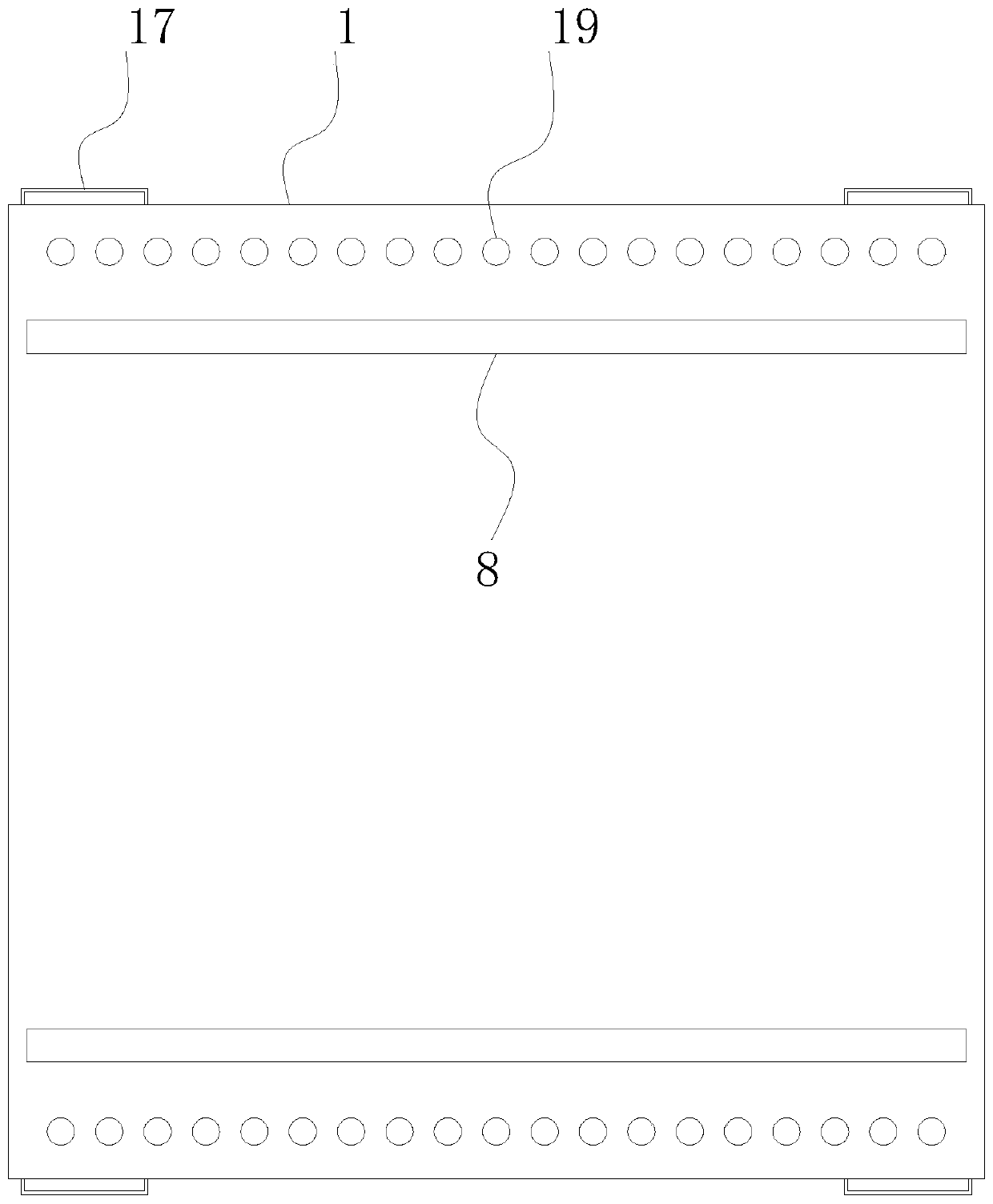

[0023] refer to Figure 1-4 , a placement frame for mold steel production, including a placement plate 1, the four corners of the placement plate 1 are welded with support rods 2, the bottom end of the support rod 2 is welded with a connecting block 3, and the middle part of the bottom end of the connecting block 3 is provided with a card slot 4. The outer surface of the support rod 2 is slidably connected with the adjustment rod 5, and the support rod 2 and the adjustment rod 5 are fixed by the first fastening screw 18, and one side of the support rod 2 is uniformly provided with the first fastening screw. Screw 18 matches the threaded hole, the middle part of the bottom end of the adjustment rod 5 is provided with the first chute 6 that matches the support rod 2, the top of the adjustment rod 5 is integrally formed with a block 7, and the top of the placement plate 1 is symmetrically provided with The second chute 8 is slidably connected with a slider 9 in the second chute 8...

Embodiment 2

[0026] refer to Figure 1-4 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the fixing mechanism includes threaded grooves 19 evenly opened on both sides of the placement plate 1, and the two sides of the fixing plate 10 are provided with threaded holes 20, and the threaded holes 20 The internal thread is connected with a second fastening screw 21, and the second fastening screw 21 extends into the thread groove 19. The diameter of the thread groove 19 is equal to that of the threaded hole 20. Between the thread groove 19, the threaded hole 20 and the second fastening screw 21 The cooperating arrangement can further fix the fixed plate 10 and prevent the fixed plate 10 from moving, thereby preventing a large number of die steels from pushing the fixed plate 10 when they are piled up.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com