Building Gallery Truss Integrated Structure and Its Construction Method

A main structure and building technology, applied to truss structures, truss beams, building structures, etc., can solve the problems of poor architectural aesthetics and integrity, inconsistent decorative layers, and the inability to install decorative bricks in steel truss areas, etc., to achieve Excellent aesthetics and integrity, and the effect of reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

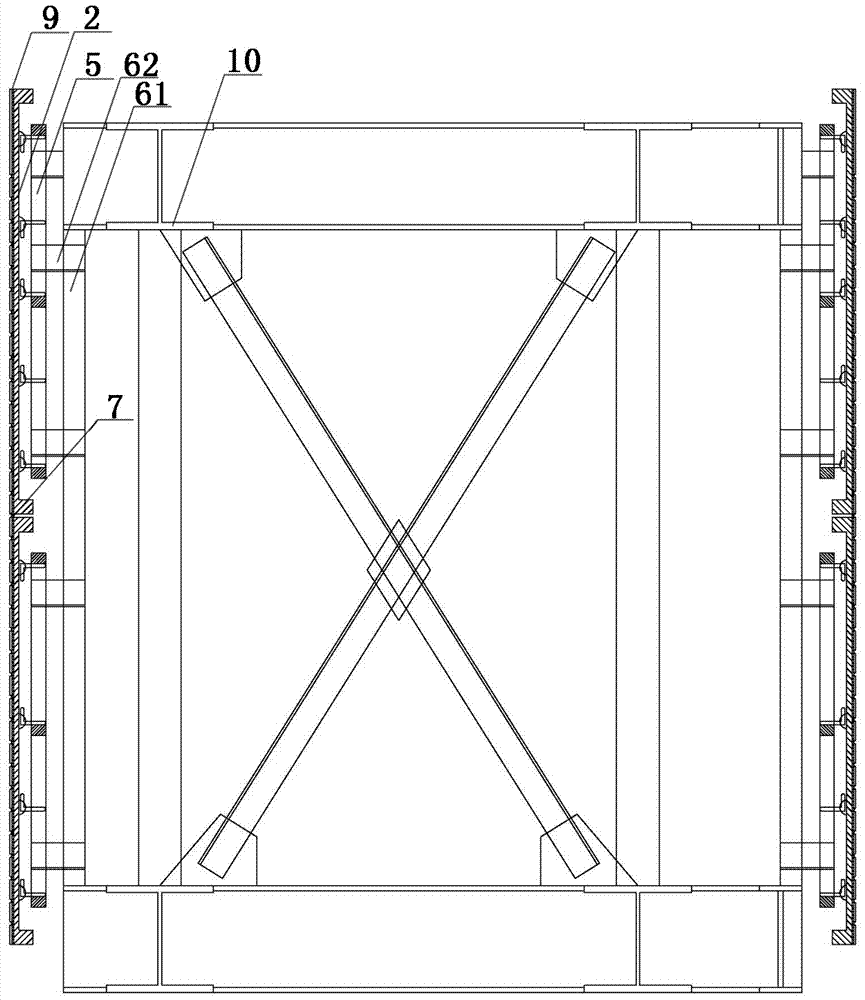

[0046] Examples see figure 1 As shown, in this kind of building corridor truss integrated structure, a steel truss 10 is connected between the tops of two adjacent buildings 11, and the front and back of the steel truss 10 are connected with glass fiber reinforced with the same pattern as the outer side of the building. The decorative layer of the cement decorative brick hanging board, the glass fiber reinforced cement decorative brick hanging board decorative layer is formed by splicing the hanging boards 1 with each other.

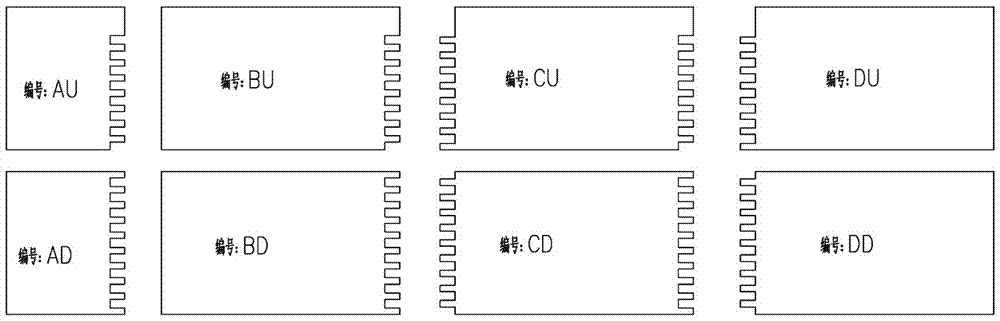

[0047] See figure 2 This kind of glass fiber reinforced cement decorative brick hanging board is installed on the steel truss 10 of the building. If the area of the steel truss area is not very large, the glass fiber reinforced cement decorative brick hanging board is composed of a hanging board unit, but for convenience Assemble and transport, in general, the glass fiber reinforced cement decorative tile hanging board is formed by splicing multiple hangi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com