Composite cooling-type motor

A motor and cooling technology, applied in bearing cooling, electric components, electromechanical devices, etc., can solve the problems of inability to ensure the normal use of the front end cover and the bearing in the rear end cover, affecting the normal use of the bearing, and inability to cool the front end cover, etc. Improved cooling effect, improved reliability and service life, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

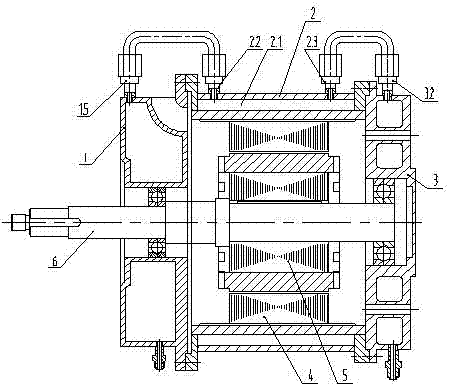

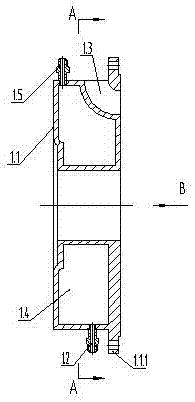

[0027] The composite cooling motor shown in the accompanying drawings includes a front end cover 1 , a housing 2 and a rear end cover 3 .

[0028] The housing 2 is provided with an inner cavity interlayer II 2.1, and the outer wall of the housing 2 is provided with a water inlet joint II 2.2 and an outlet joint II 2.3 communicating with the inner cavity interlayer II 2.1.

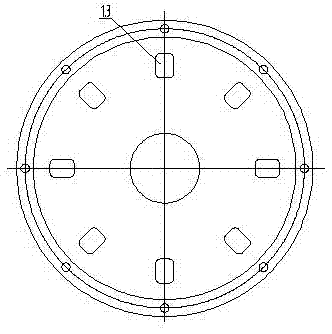

[0029] The front end cover 1 includes a disc body I1.1 with an inner cavity interlayer I1.4; a bearing hole is provided in the middle of the disc body I1.1, and the outer wall part of the right end extends radially outward to form a flange edge I1.1.1; the disc body I1.1. 1 The outer wall is provided with water inlet joint I1.2 and water outlet joint I1.5, and the inner holes of water inlet joint I1.2 and water outlet joint I1.5 are respectively connected with the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com