Cylindrical silicon rod clamp

A cylindrical and silicon rod technology, applied in the field of cylindrical silicon rod fixtures, can solve the problem of many defective silicon wafers, and achieve the effects of improving quality, accurate positioning, and reducing thickness errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

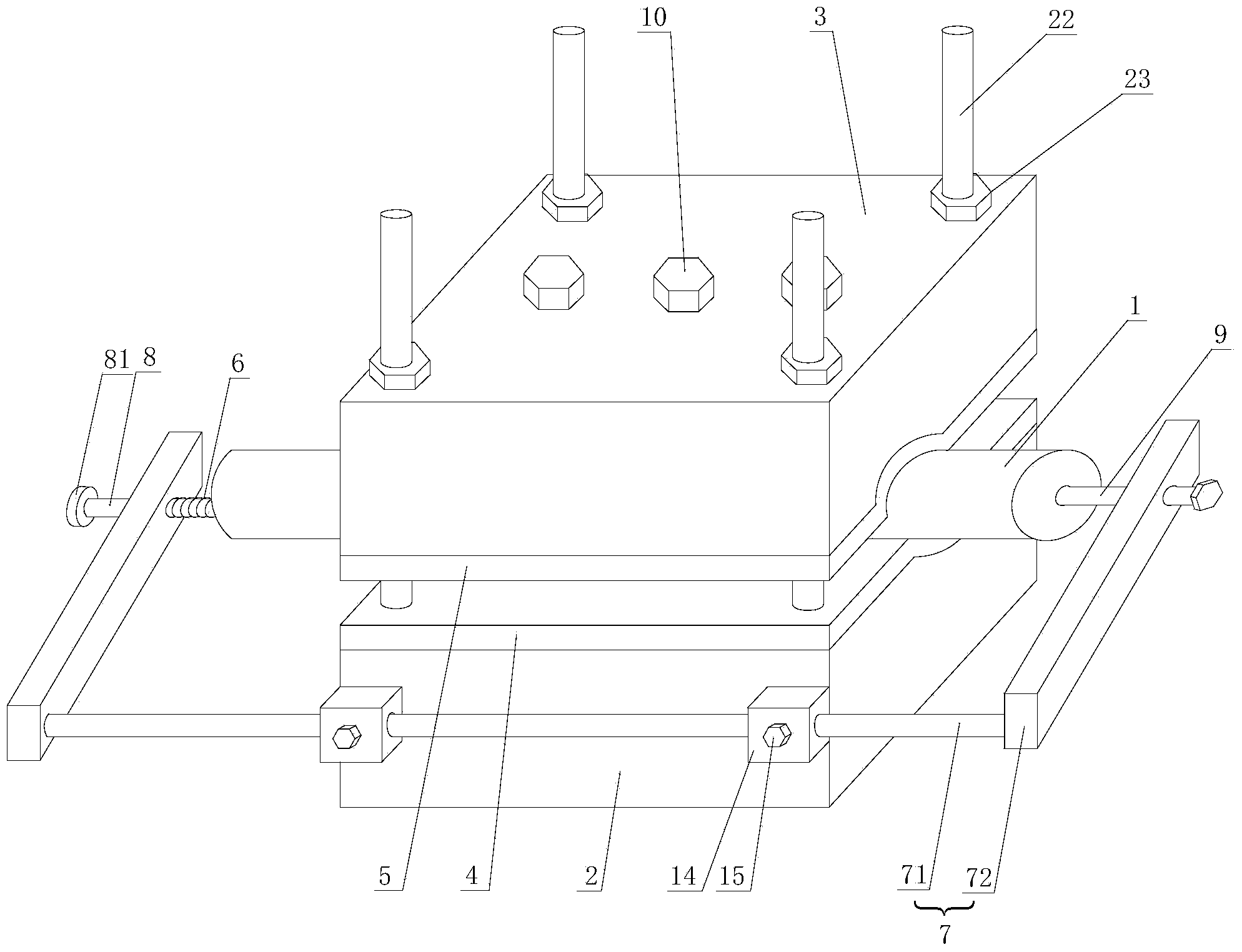

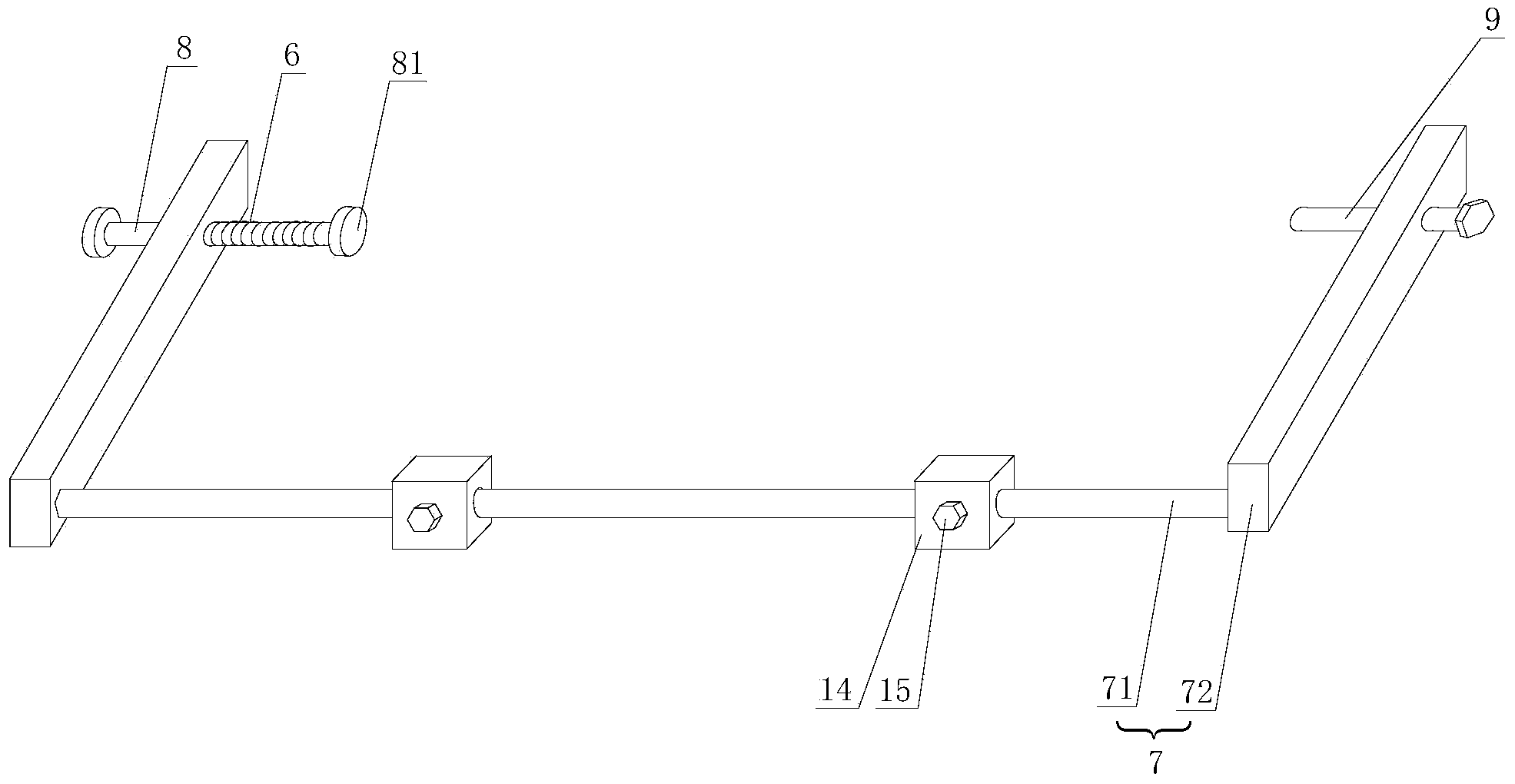

[0020] Refer to figure 1 , A cylindrical silicon rod clamp, comprising a fixing device for fixing the silicon rod 1 and a positioning device for transferring the fixing device and controlling the position of the silicon rod 1.

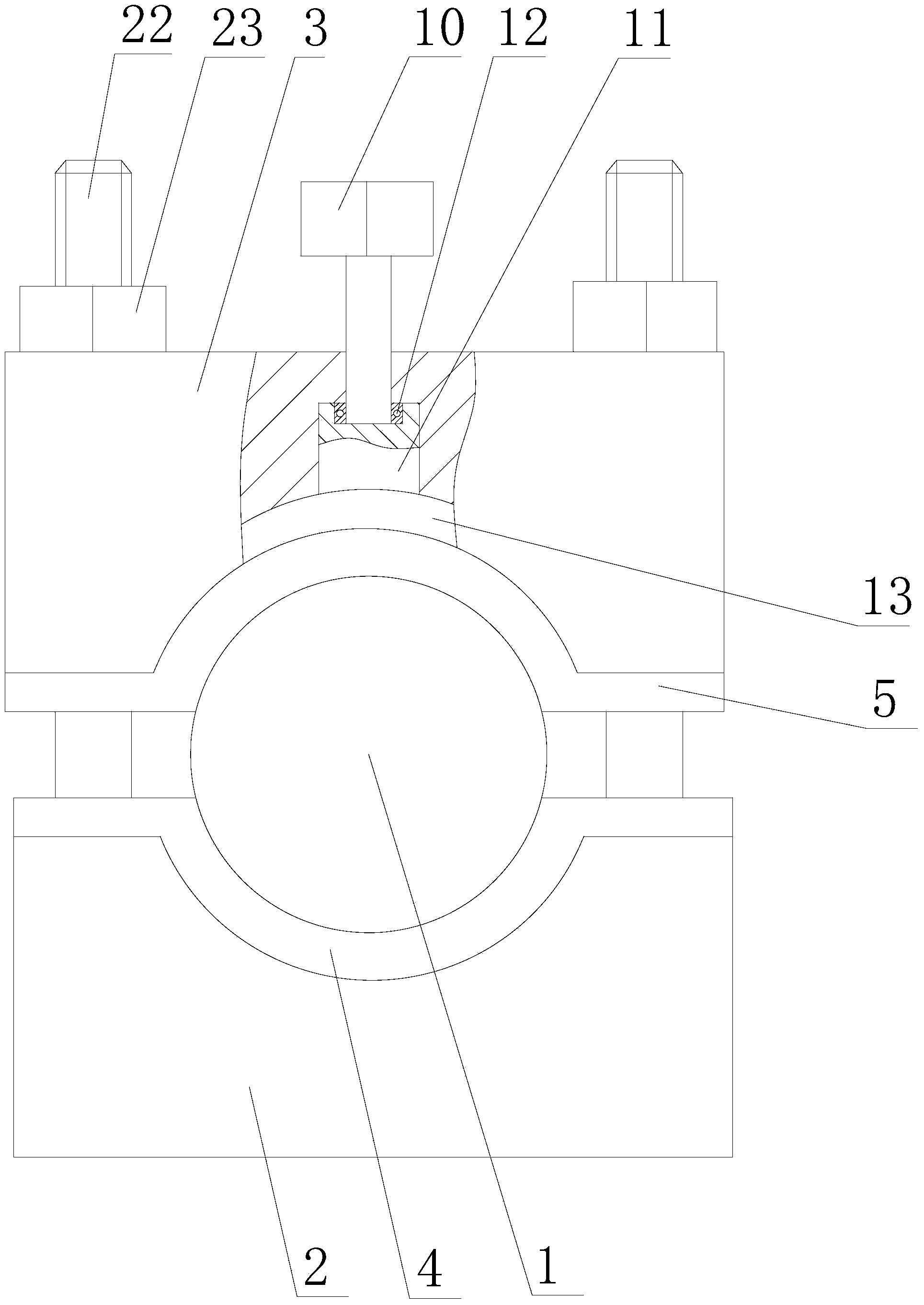

[0021] Refer to figure 1 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 The fixing device includes four lower pressing blocks 2 with four guide posts 22 perpendicular to the upper surface at the four corners of the upper surface, and the upper part of each guide post 22 is provided with a thread; the fixing device also includes a top to bottom The lower module 4, the upper module 5, the upper pressing block 3, and the four compression nuts 23 respectively arranged on the four guide posts 22 are sequentially sleeved on the four guide posts 22; the lower surface of the upper module 5 is provided with There is an upper arc groove 51 matching the silicon rod 1, and the upper surface of the lower module 4 is provided with a lower arc groove 41 ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com