Multi-disc frame saw assembly

A frame saw and frame technology, applied in the direction of work accessories, manufacturing tools, stone processing equipment, etc., can solve problems such as difficulty in ensuring accuracy, and achieve the effects of reducing thickness errors, ensuring accuracy requirements, and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

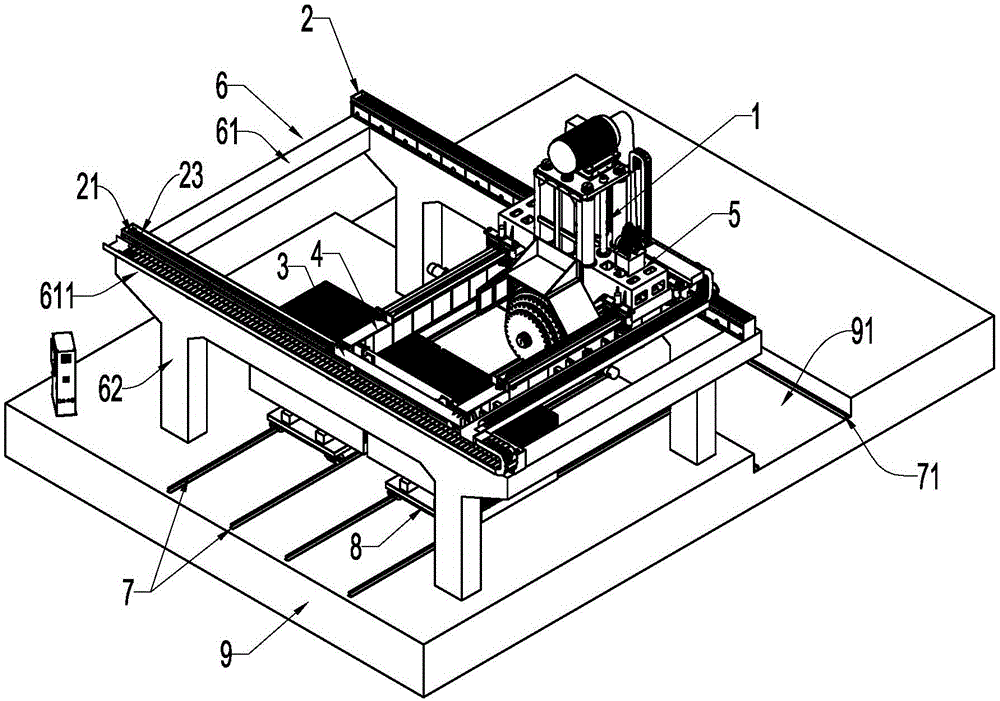

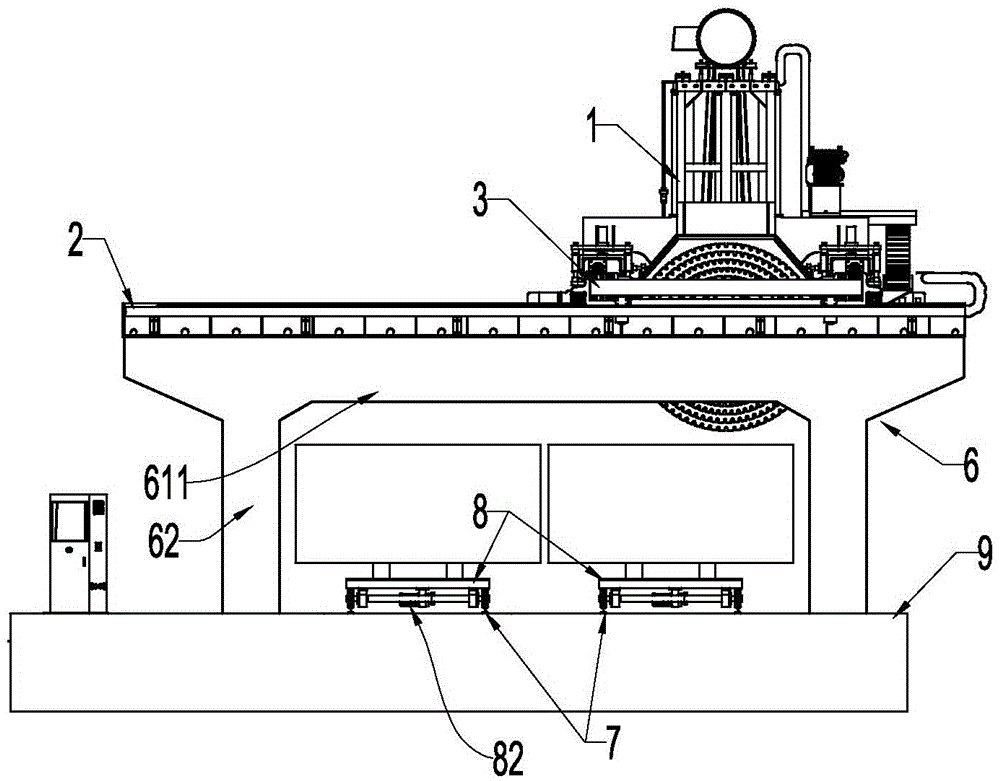

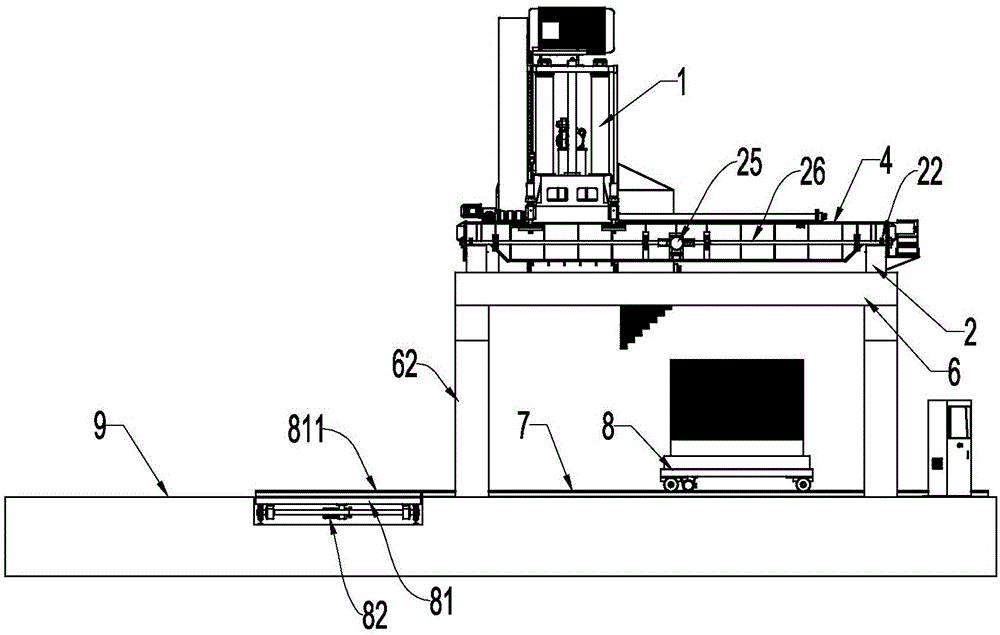

[0025] refer to Figure 1 to Figure 4 , a multi-disc frame saw assembly, including a frame saw and a workbench, and the frame saw includes a saw machine 1 and a walking frame 3 that can walk on the longitudinal rail 2, and the walking frame 3 is provided with two vertical rails 2 There is a horizontal rail 4 on the horizontal rail 4, a walking girder 5 is placed on the horizontal rail 4, and the saw machine 1 is installed on the walking girder 5, which can reciprocate and lift to complete the cutting operation from shallow to deep; The screw mandrel 41 and the transverse linear guide rail 43, the screw nut 42 matched with the screw mandrel 41 and the transverse slider 44 matched with the transverse linear guide rail 43 are locked on the walking beam 3, and the transverse slider 44 bears the weight of the walking beam 3, The horizontal travel motor 45 drives the traveling girder 5 through the screw rod 41 to move the slicing; the slicing means that after a stone slab is cut, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com