Production process for calendering lipophilic rubber thin products

A production method and lipophilic technology, which can be used in flat products, applications, household appliances, etc., and can solve the problems of complicated process and increased production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is a calendering production method of lipophilic rubber thin products, which can continuously produce thin products with a uniform thickness by a calender, and the thickness can be less than 0.5mm (the minimum thickness is 0.05mm), and the width can reach more than 800mm. Using the present invention The production method can make thin products easier and less costly in the production process.

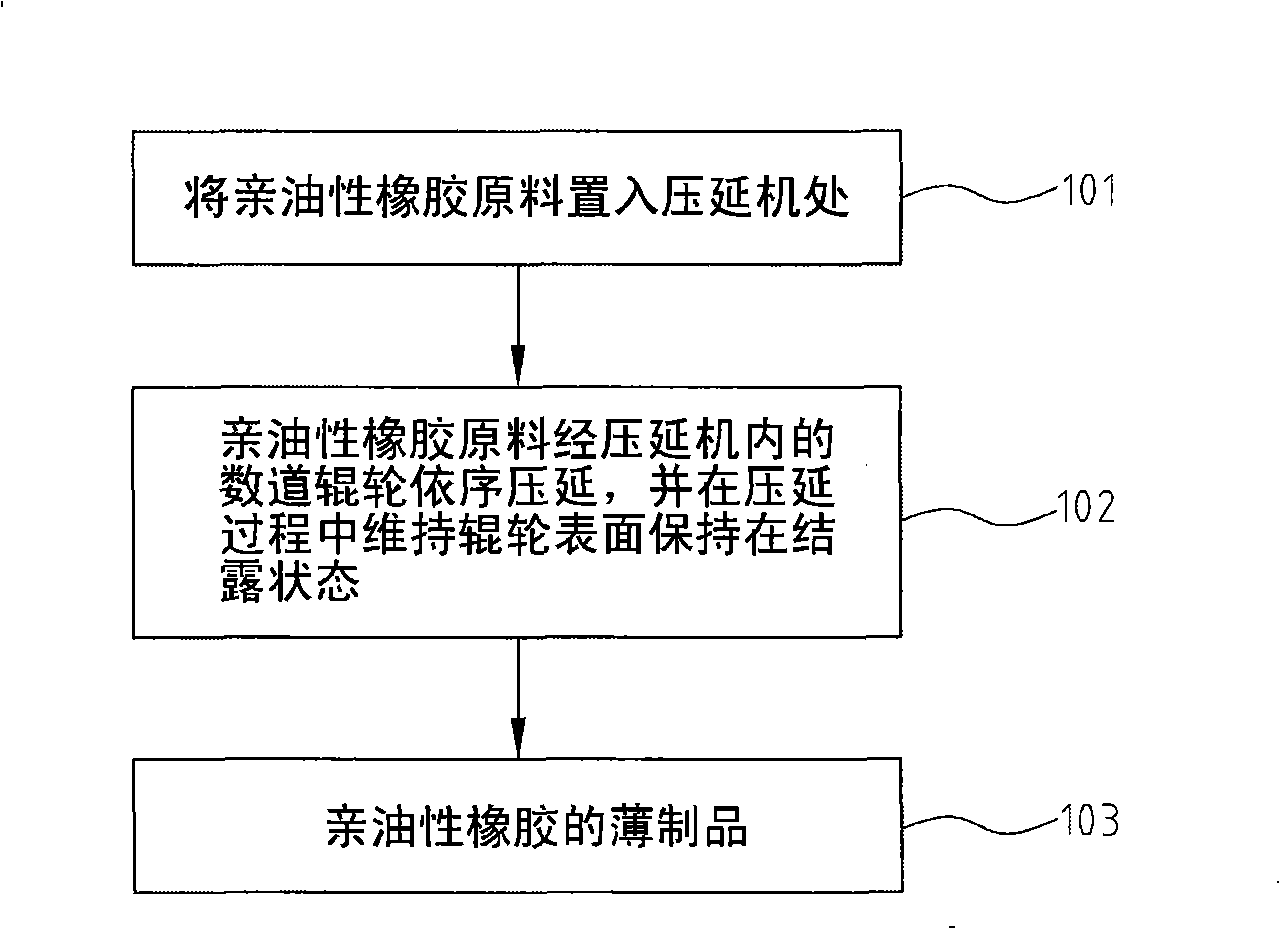

[0025] like figure 1 Shown, the production flowchart of the present invention, its steps are as follows:

[0026] In step 101, the lipophilic rubber raw materials are mixed according to the relevant formula and then put into the calender.

[0027] In step 102, when the raw material is sequentially rolled by multiple rollers in the calender, the circumferential surface of each roller is kept in a dew condensation state.

[0028] In step 103, a continuous wide lipophilic rubber thin product can be formed finally.

[0029] In addition, in step 102, according...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com