Incline type double-belt diamond saw machine

A diamond saw and tilting technology, applied in stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of inability to cut granite and high cost of sawing machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

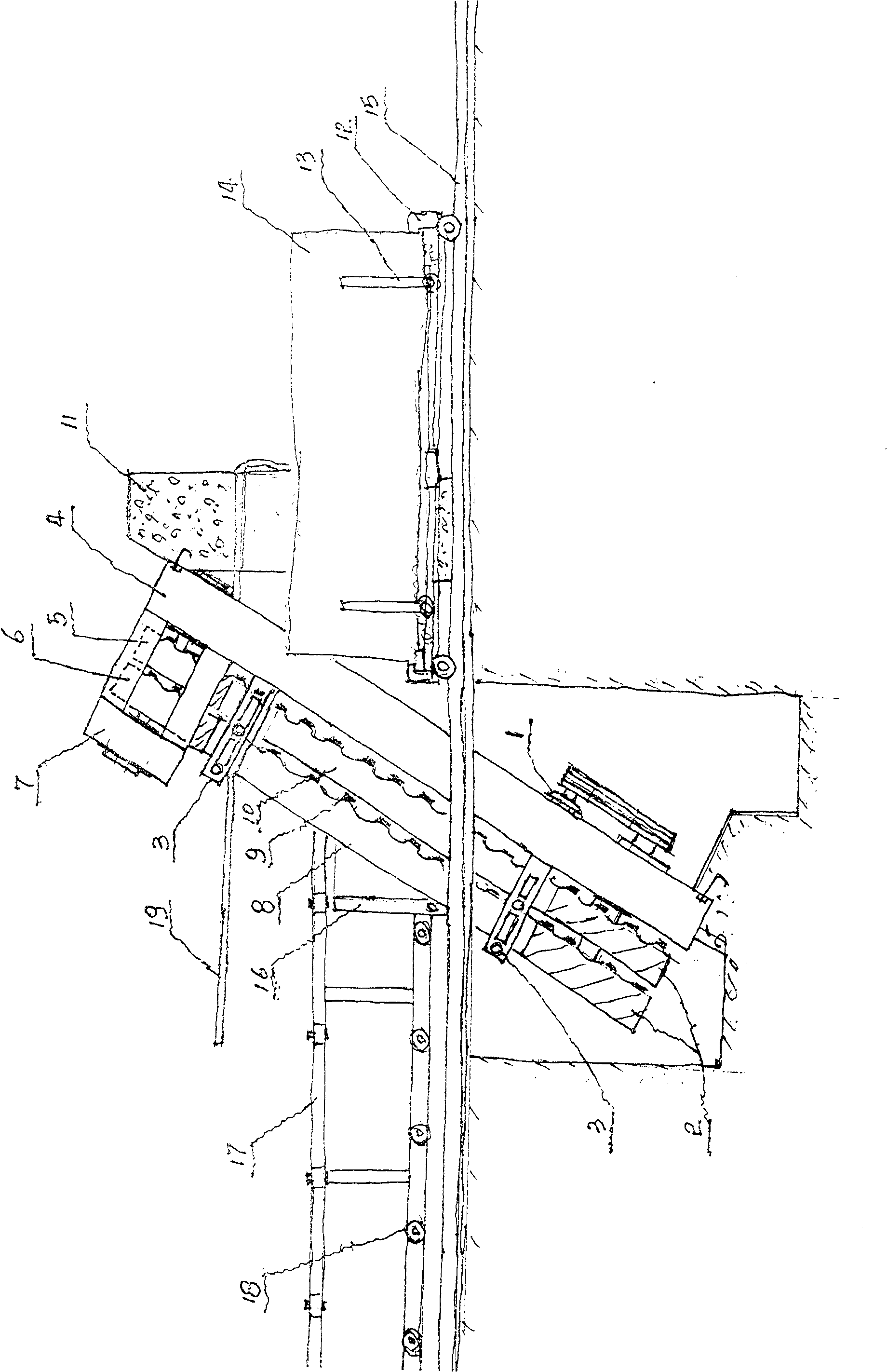

[0011] A preferred version of the present invention is now described with reference to the accompanying drawings. The big frame (4) of 6m * 1m * 0.3m on the column (11) becomes 60 ° of inclinations and is contained on the cement foundation below the track (15). Diameter 1600 and two driving flywheels of diameter 1610 and axle (2) above big and down small connect together and are contained in big frame (4) lower end. Diameter 1600B flywheel and axle (5) are contained on the slideway of tensioner, and slideway is contained in the upper end of big frame (4). Diameter 1610C flywheel and axle (6) are contained on the support (7) of big frame (5) upper end. Two 200mm wide × 1.4mm thick wavy saw blades (8) and diamond cutter heads (9) with different lengths are respectively installed on two pairs of flywheels with different diameters in a vertical state. The two wavy saw blades (8) are driven by B flywheel (5) After the C flywheel (6) is tensioned respectively, the verticality and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com