Manufacture method of synthetic paper

A manufacturing method and technology for synthetic paper, applied in the field of manufacturing synthetic paper, can solve the problem of inability to be processed into paper and the like

Inactive Publication Date: 2012-07-11

蔡茂友

View PDF2 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Synthetic paper production technology including the prior patent application CN101701433 of the applicant is based on CaCO 3 、TiO 2 Such materials are filled with polyolefin, flow calendered to make base paper film, and then stretched, which greatly improves the performance of synthetic paper, but the similar plastic processing method used can only add about 40% to 50% of inorganic powder If the filler exceeds this ratio, it cannot be processed into paper

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

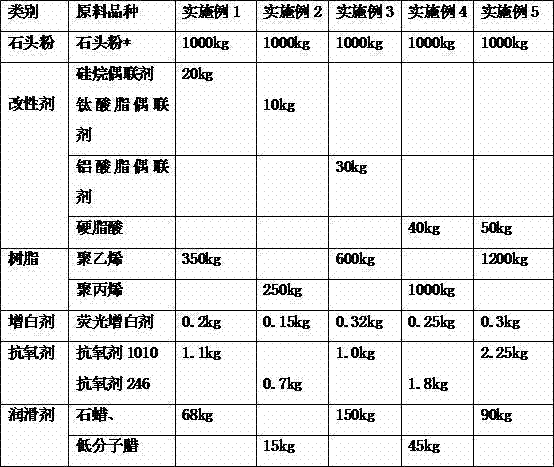

Embodiment 1-5

[0038] Example 1-5 Examples of raw material components and dosage for making synthetic paper

[0039]

[0040] * The water content of stone powder is below 0.5%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a manufacture method of synthetic paper, which is used for manufacturing the synthetic paper with resin as a base material and stone powder as filler. The process steps include stone power drying-stone power modifying-banburying pelleting of the stone powder and the resin-flow calendar extruding raw paper of the synthetic paper-raw paper heating drawing- corona processing-coating processing. Compared with the film blowing method, the manufacture method improves filling quantity of inorganic powder by more than 10% and especially increases the paper pattern processing process. Craquelure is formed on the surface of the synthetic paper after drawing, so that printing ink can be easily adsorbed, and the writing and printing performances of the synthetic paper are much closer to those of plant fiber paper.

Description

technical field [0001] The invention relates to a method for manufacturing synthetic paper, which belongs to the technical field of synthetic paper. Background technique [0002] Traditional paper is made of interwoven plant fibers, and the surface is covered with tiny pores, which have good permeability and adsorption to ink. In order to reduce the dependence on plant fibers and overcome the environmental pollution caused by paper production, modern times have developed the technology of making paper substitutes using polymer materials as substrates and filling them with inorganic substances. This kind of paper substitutes is called synthetic paper. Synthetic paper is highly praised by contemporary society because of its rich raw materials and little environmental pollution caused by the production process, also known as environmentally friendly synthetic paper. [0003] Currently commercially available synthetic paper is made of polymer materials filled with inorganic fi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/06C08L23/12C08K9/04C08K9/06C08K3/26B29C47/92B29C48/92

CPCB29C48/04B29C48/92B29C2948/92704B29C2948/92876B29C2948/92923

Inventor 蔡茂友朱均陈洵黄箭

Owner 蔡茂友

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com