Solvent-free type environment-friendly semi-curing optical adhesive tape and preparation method thereof

A semi-curing, solvent-free technology, used in adhesive types, adhesives, grafted polymer adhesives, etc., can solve the problems of insufficient adhesion, easy to overflow glue, thickness error, etc., to overcome the large thickness error , the preparation method is simple, the process design is reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

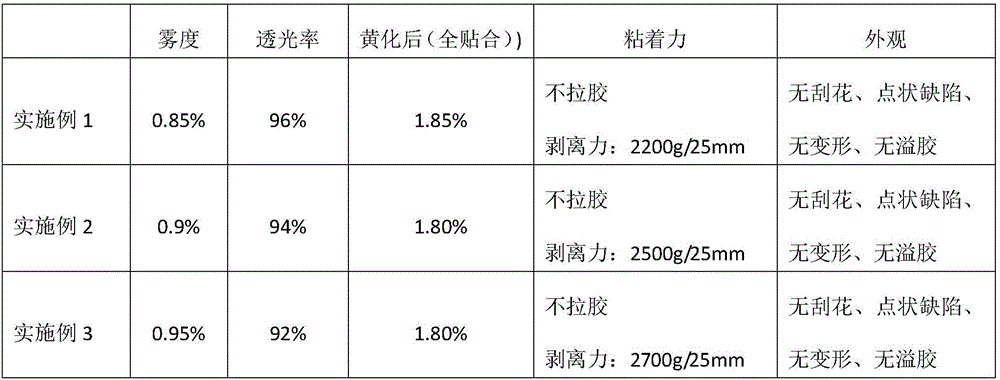

Embodiment 1

[0021] Add 210g of T5650J and 33g of Nadic acid anhydride to the reactor, feed nitrogen gas and start stirring, heat up to 165°C, keep warm for about 6 hours, acid value: 0.08, finish the reaction and cool down to normal temperature, then put it into a stirred reaction tank, Add 1015.2g of lauryl acrylate, 366.6g of 2-hydroxyethyl methacrylate, 1.61g of dialkoxyacetophenone into the reaction tank, blow in nitrogen, start stirring and then turn on the UVA lamp until the UVA energy accumulates to 950mj / cm 2 Afterwards, oxygen was introduced to obtain a prepolymer with a viscosity of 1456cP (25°C).

[0022] Add 3.5 g of methacryloxypropyl trimethoxysilane, 0.0035 g of α-aminoalkylphenone, and 0.00875 g of benzyl dithiobenzoate into the reaction tank, and stir evenly.

[0023] Apply the above mixture between two release films, and the UV light intensity is 10mW / cm 2 , the cumulative irradiation energy is 1050mj / cm 2 , to obtain a semi-cured optical adhesive tape with a thickne...

Embodiment 2

[0025] Add 250g of G3450J and 20.4g of maleic anhydride into the reaction kettle, feed nitrogen and start stirring, heat up to 165°C, keep the temperature for about 6 hours, acid value: 0.06, finish the reaction and cool down to normal temperature, then put it into a stirring reaction tank, Add 420g of n-propyl acrylate, 391.7g of 2-hydroxyethyl methacrylate, 1.08g of dialkoxyacetophenone into the reaction tank, feed nitrogen, start stirring, and then turn on the UVA lamp until the UVA energy is accumulated to 950mj / cm 2 Afterwards, oxygen was introduced to obtain a prepolymer with a viscosity of 1750cP (25°C).

[0026] Then add 2.7g of methacryloxypropyltrimethoxysilane, 0.0027g of α-aminoalkylphenone, and 0.00675g of benzyl dithiobenzoate into the reaction tank, and stir evenly.

[0027] Apply the above mixture between two release films, and the UV light intensity is 8mW / cm 2 , the cumulative irradiation energy is 850mj / cm 2 , to obtain a semi-cured optical adhesive tape...

Embodiment 3

[0029] Add 400g of G3450J and 60.7g of Nadic acid anhydride to the reactor, feed nitrogen and start stirring, heat up to 165°C, keep warm for about 6 hours, acid value: 0.075, finish the reaction and cool down to normal temperature, then put it into a stirred reaction tank , add 1978.8g lauryl acrylate, 790.4g-2-hydroxyethyl methacrylate, 3.24g dialkoxyacetophenone into the reaction tank, feed nitrogen, start stirring and then turn on the UVA lamp until the UVA energy is accumulated to 950mj / cm 2 Afterwards, oxygen was introduced to obtain a prepolymer with a viscosity of 2000cP (25°C).

[0030] Then add 7.03g of methacryloxypropyltrimethoxysilane, 0.007g of α-aminoalkylphenone, and 0.0175g of benzyl dithiobenzoate into the reaction tank, and stir evenly.

[0031] Apply the above mixture between two release films, and the UV light intensity is 16mW / cm 2 , the cumulative irradiation energy is 1650mj / cm 2 , to obtain a semi-cured optical adhesive tape with a thickness of 500 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com