Full-automatic sponge disk horizontal cutting machine

A flat cutting machine, fully automatic technology, applied in the field of flat cutting machines, can solve problems such as high labor intensity, insufficient sponge weight, and reduced work efficiency, and achieve the effects of simple and convenient operation, high product accuracy, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

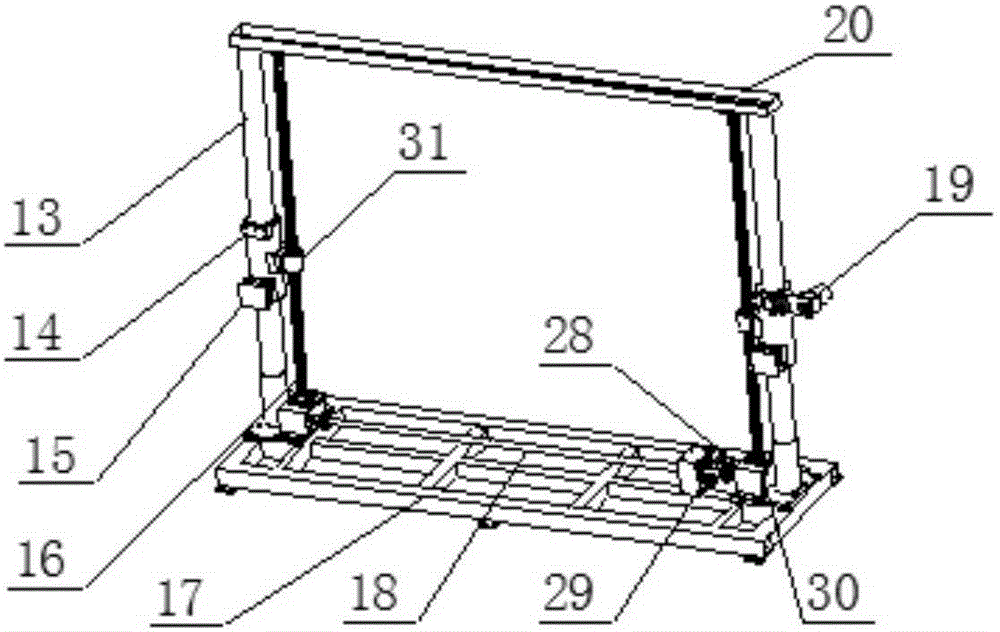

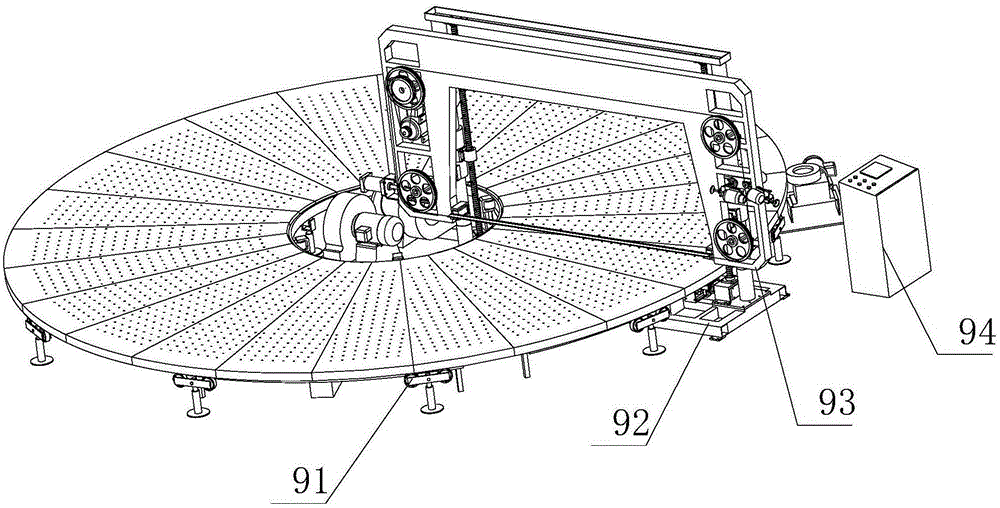

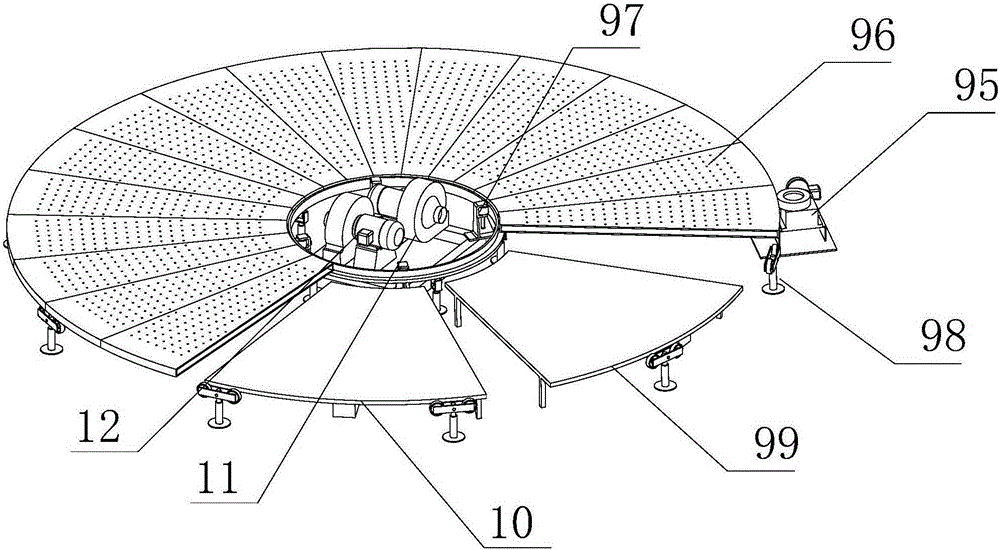

[0027] refer to figure 1 , figure 2 , image 3 with Figure 4 , the present invention comprises platform 91, main frame 92, knife rest 93 and electric control box 94 four parts and is formed. Platform 91 is made up of friction drive wheel 95, platen 96, inner ring 97, outer roller 98, suction platform 99, blowing platform 10, suction fan 11 and blower 12. The mainframe 92 consists of a column 13, a sliding sleeve 14, a hinge 15, a ball screw 16, a screw nut 31, a base 17, a drive shaft 18, a servo motor 28, a reducer 29, a reversing reducer 30, an angle adjustment part 19 and Composed of beams 20. Knife rest 93 is made up of knife rest body 21, knife belt 22, cutter wheel 23, knife belt motor 24, pneumatic tensioner 25, knife box 26, sharpening device 27 and safety shield.

[0028] Main frame 92 is connected together with knife rest 93, and a platform 91 is horizontally placed below knife rest 93, and platform 91 side is provided with an electric control box 94 that some...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com