Blade of wind-driven generator and manufacturing method thereof

A technology for wind power generators and manufacturing methods, applied to wind power generator components, wind power engines, wind power generation, etc., can solve the problems of reduced strength of formed blades, inconvenient maintenance, time-consuming, etc., and achieve enhanced stress strength and life, The effect of reducing the probability of defective blades and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

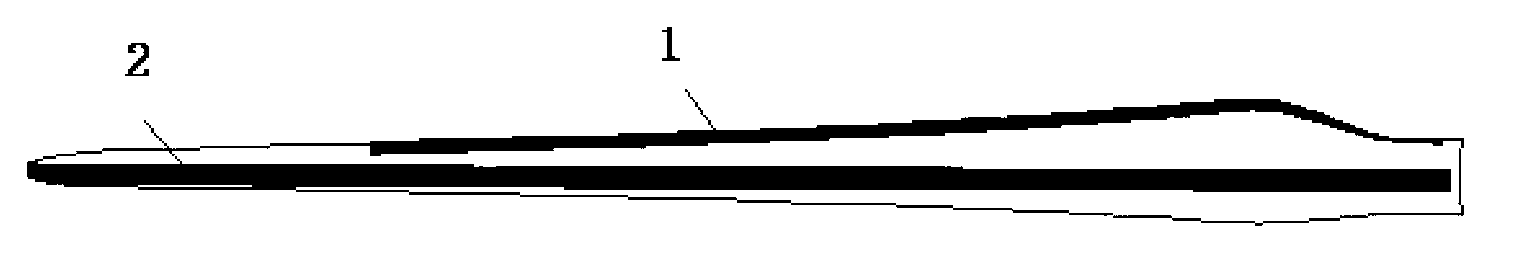

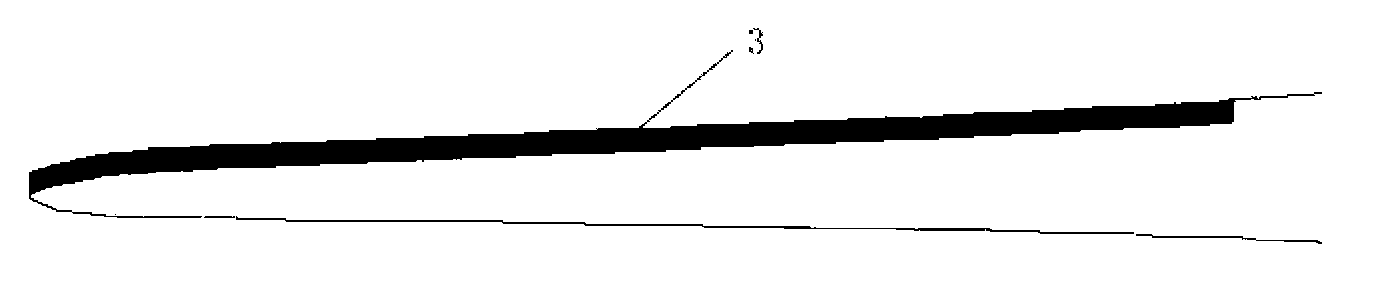

[0045] A wind turbine blade, characterized in that it includes: a shell, a web, and a root flange, wherein the shell is composed of an upper shell and a lower shell, and the upper shell and the lower shell respectively include Main girder 1, prefabricated part 2, root preforming, and laying; the laying includes glass fiber cloth, balsa wood core material, and foam core material; the web is located between the upper shell and the lower shell of the blade; The root flange is used to connect the blade and the main body of the wind power generator.

Embodiment 2

[0047] Embodiment 2 is a further optimization of Embodiment 1. The blade of a wind power generator as described above is characterized in that the prefabricated part is located at the rear edge of the casing, and its shape deformation area is in line with the rear edge of the casing. The shape of the deformation area is completely consistent.

[0048] Adding prefabricated parts at the trailing edge of the shell can improve the strength and force bearing capacity of the blade.

Embodiment 3

[0050] On the basis of the above embodiments, the design is further optimized, and a lightning rod is installed inside the blade housing.

[0051] Wind turbines are generally installed in relatively open places in the field. Relative to the surrounding objects, the blades are located at a higher position, and they are vulnerable to lightning strikes in thunderstorms. Therefore, installing lightning rods can prevent damage to wind turbines in thunderstorms.

[0052] Method embodiment one

[0053]A method of manufacturing a wind turbine blade, characterized in that it comprises the following steps:

[0054] Step 1: Prepare the root preform, the main beam, and the preform separately by vacuum infusion process in a separate mold;

[0055] Step 2: Lay the root flange, root preform, main girder, and prefabricated parts together with fiberglass cloth, balsa wood, foam core material, and lightning rod in the blade shell mold, and inject resin into the shell through vacuum infusion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com