Manufacturing method of modified teflon copper-clad plate

A technology of polytetrafluoroethylene and its manufacturing method, which is applied in the field of copper clad laminates, can solve the problems of changes in dielectric properties and high thermal expansion coefficient, achieve good dimensional stability, overcome the braiding effect, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Recipe

[0041]

[0042] 2. Steps

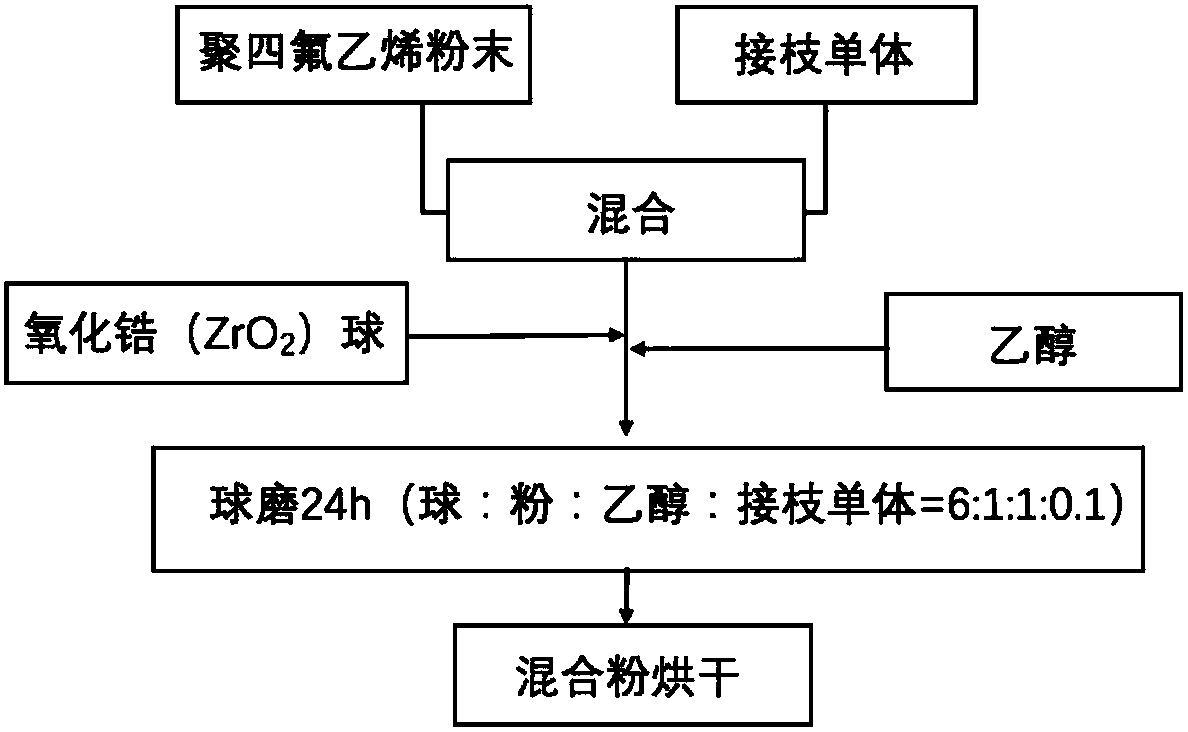

[0043] (1) Polytetrafluoroethylene modification: 100g of sodium-naphthalene-treated polytetrafluoroethylene powder, 10g of acrylic acid, 100g of absolute ethanol, and 600g of zirconia balls (diameter 1mm) were placed in a stirring ball mill at 10 to 20 °C for 24 hours of wet grinding (stirring speed 650r / min), washed and dried to obtain modified polytetrafluoroethylene.

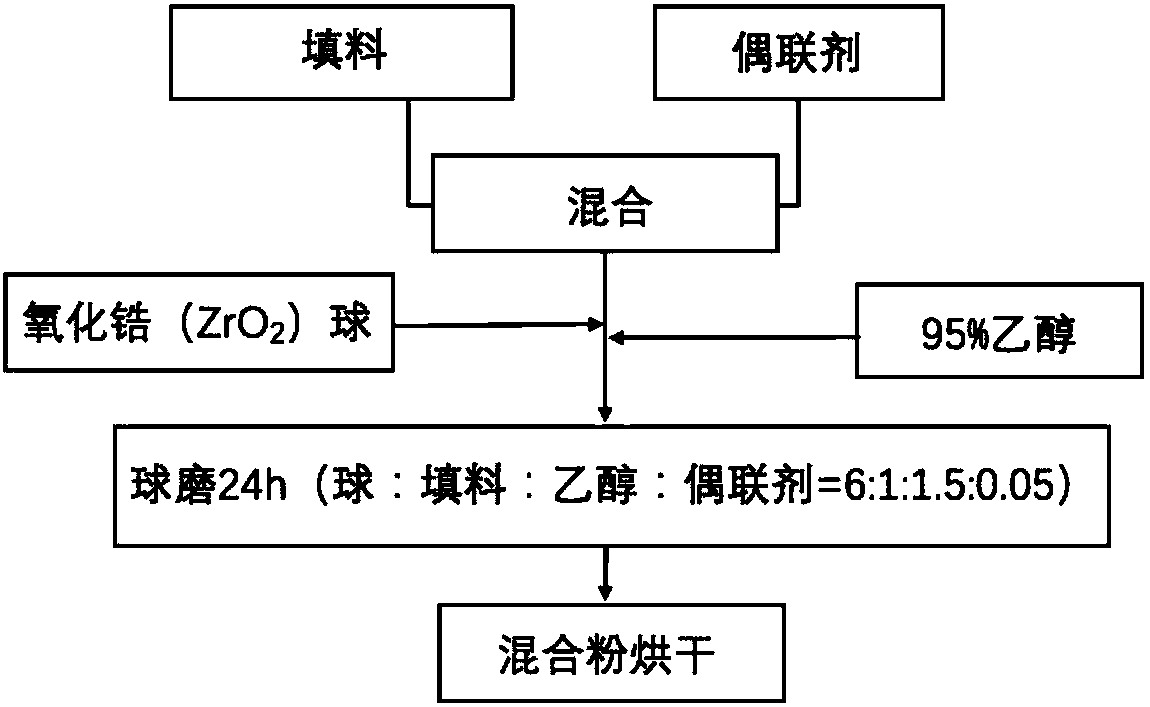

[0044] (2) Filler modification: 30g of silica, 1.5g of silane coupling agent, 45g of absolute ethanol, and 180g of zirconia balls (1mm in diameter) were placed in a stirring ball mill for wet grinding at room temperature for 24 hours (stirring speed 650r / min) after washing and drying to obtain modified fillers.

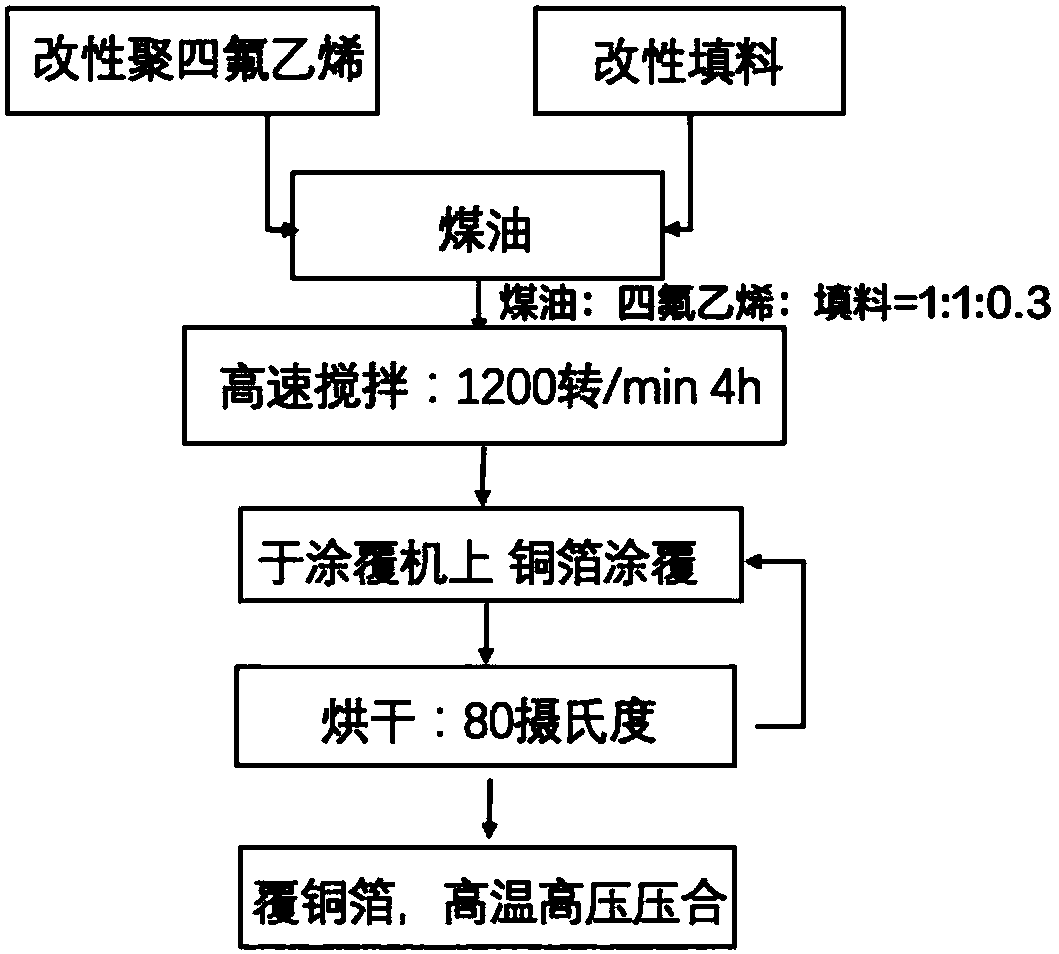

[0045] (3) Disperse the modified polytetrafluoroethylene and the modified filler in 100 g of kerosene, and stir at a high speed for 4 hours to obtain a mixed slurry.

[0046] (4) Put the copper foil on the coating machine, use a 200 micron roller to...

Embodiment 2

[0048] 1. Recipe

[0049]

[0050] 2. Steps

[0051] (1) Polytetrafluoroethylene modification: 100g of sodium-naphthalene-treated polytetrafluoroethylene powder, 10g of acrylic acid, 100g of absolute ethanol, and 600g of zirconia balls (diameter 1mm) were placed in a stirring ball mill at 10 to 20 °C for 24 hours of wet grinding (stirring speed at 650 / min), then washed and dried to obtain modified polytetrafluoroethylene.

[0052] (2) Filler modification: 30g of silica, 1.5g of silane coupling agent, 45g of absolute ethanol, and 180g of zirconia balls (1mm in diameter) were placed in a stirring ball mill for wet grinding at room temperature for 24h (stirring speed Turn 650 / min) after washing and drying to obtain the modified filler.

[0053] (3) Disperse the modified polytetrafluoroethylene and the modified filler in 100 g of kerosene, and stir at a high speed for 4 hours to obtain a mixed slurry.

[0054] (4) Put the copper foil on the coating machine, use a 200-micron ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com