Ceramic wall surface composite plug type heat flux sensor applicable to high-enthalpy, medium and low heat flux environment

A technology of heat flow sensor and composite plug, applied in calorimeters, instruments, measuring heat, etc., can solve the problems of slow thermal response, preparation of ceramic coatings, small thermal conductivity, etc., to achieve ease of thermal diffusion, small linear expansion coefficient, small difference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

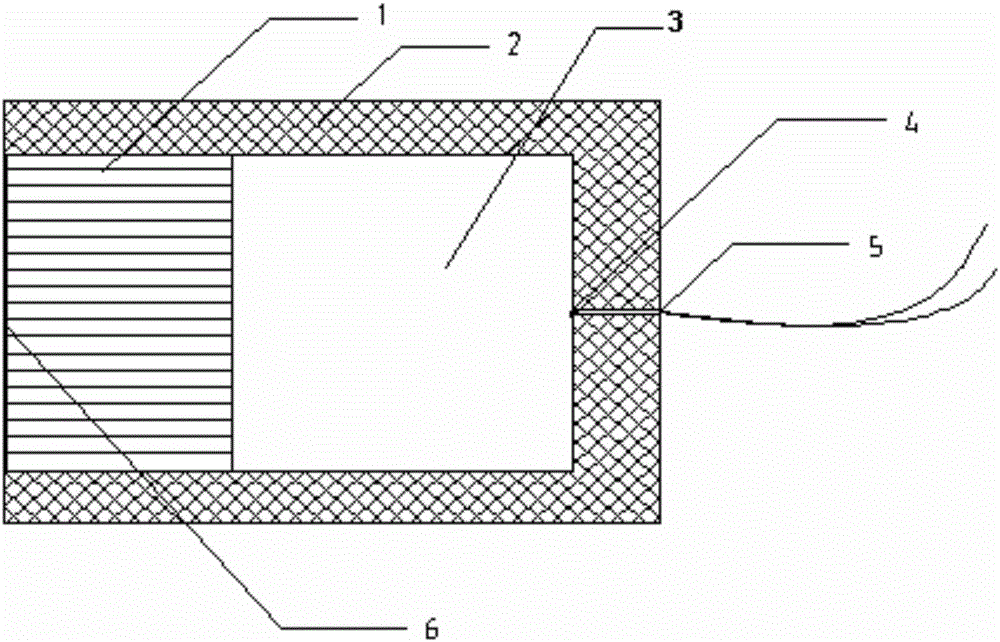

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0021] In order to solve the problem that due to the large difference in catalytic coefficient between the plug sensor used for heat flow testing and the material wall surface of the test piece, and the discrepancy between the measured heat flow and the actual heat flow on the surface of the test piece, the most direct method is to develop a heat flow sensor that is completely consistent with the catalytic characteristics of the surface of the test piece, that is, The same sheet or coating as the test material is prepared on the surface of the copper plug, but in the actual development process, two problems will be encountered: First, the ceramic coating prepared on the surface of the ceramic matrix composite material or heat-resistant material is in the development process. It usually needs to undergo high temperature treatment or high temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com