Mixed material containing graphite geothermal cushion and production technique thereof

A technology of mixing materials and graphite, applied in the field of mixed materials and indoor geothermal cushion building materials, can solve the problems of slow heat transfer of geothermal cushion materials, affecting the average life of the floor, and high density of cement mud, etc., to achieve good heating effect and space. The effect of low occupancy rate and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

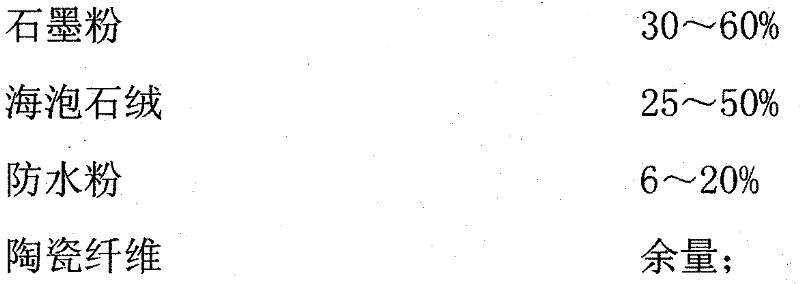

Embodiment 1

[0036] 1. Pretreatment: Put the graphite into a pulverizer and pulverize to make the particle size less than 350μm;

[0037] 2. Ingredients (by weight): graphite powder 55%, sepiolite velvet 30%, waterproof powder 10% and ceramic fiber 5% for ingredients;

[0038] 3. Mixing: Mix the above raw materials uniformly to obtain the finished product.

[0039] The geothermal cushion building material made in this example can be sold directly, and a specialized decoration company can carry out on-site construction.

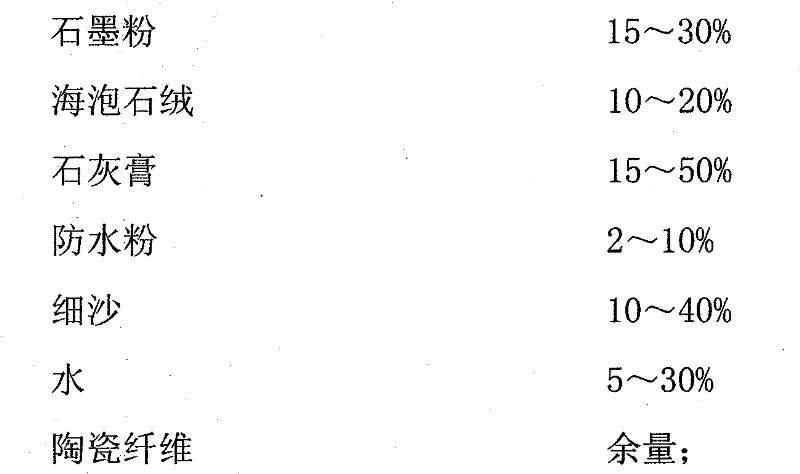

Embodiment 2

[0040] Example 2: Making a mixed material blank containing graphite geothermal cushion

[0041] 1. Pretreatment: Add graphite to the pulverizer and pulverize to make the particle size less than 350μm;

[0042] 2. Ingredients (by weight): 22% graphite powder, 10% sepiolite velvet, 20% lime paste, 5% waterproof powder, 30% fine sand, 10% water, 3% ceramic fiber;

[0043] 3. Mixing: add the above-mentioned graphite powder, sepiolite velvet, lime paste, waterproof powder, fine sand, water and additives into the mixer according to the above-mentioned ratio, and unload after mixing evenly;

[0044] 4. Forming: Use a mold to make the mixed slurry into a blank;

[0045] 5. Drying: the formed blank is dried in natural air or placed in a drying oven;

[0046] 6. Curing: The curing time of natural air drying at room temperature is 3 days, and the finished product is obtained;

[0047] The apparent density of the graphite-containing thermal cushion layer mixed material prepared according to the produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com