Forming method for improving ablation and controlling deformation of special-shaped structure product

A molding method and special-shaped technology, which is applied in the field of composite materials, can solve the problems of product bonding quality, affecting bonding quality, and poor heat resistance of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

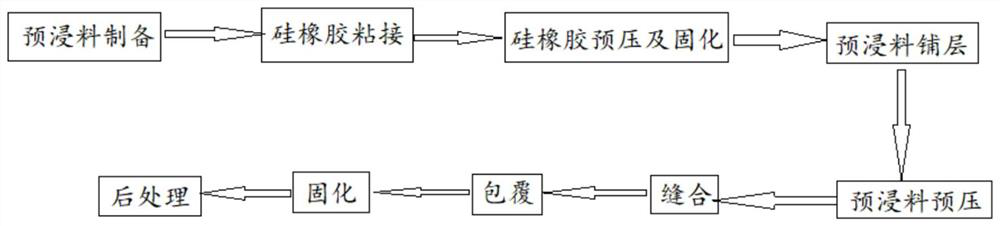

Method used

Image

Examples

Embodiment 1

[0082] Embodiment 1, the manufacture of the heat-resistant layer of the special-shaped cabin section with Ω deformed cross-section

[0083] The specific operation is:

[0084] (1) Prepreg preparation

[0085] According to the size of the special-shaped cabin structure on the Ω deformed surface, 2.5D quartz fiber woven fabric with a thickness of 2mm is used, impregnated with a medium-temperature cured flexible phenolic resin, coated in quantitative partitions, baked at a low temperature of 20°C, and dried to form a prepreg;

[0086] (2) Silicone rubber bonding

[0087] According to the size of the structure of the special-shaped cabin section on the Ω deformation surface, after making holes on the surface of the flexible silicone rubber, apply GD414 adhesive, and bond the flexible silicone rubber to the surface of the metal body of the special-shaped cabin section on the Ω deformation surface;

[0088] (3) Silicone rubber preloading and curing

[0089] Carry out vacuum pre-c...

Embodiment 2

[0103] Embodiment 2, the manufacture of S-shaped cross-section special-shaped cabin heat-proof layer

[0104] The specific operation is:

[0105] (1) Prepreg preparation

[0106] According to the size of the S-shaped cross-section special-shaped cabin structure, 2.5D ceramic fiber woven fabric with a thickness of 2mm is used, impregnated with a medium-temperature curing flexible phenolic resin, coated in quantitative partitions, baked at a low temperature of 40°C, and dried to form a prepreg;

[0107] (2) Silicone rubber bonding

[0108]According to the size of the structure of the S-shaped cross-section special-shaped cabin, after making holes on the surface of the flexible silicone rubber, apply GD414 adhesive, and bond the flexible silicone rubber to the surface of the metal body of the S-shaped cross-section special-shaped cabin;

[0109] (3) Silicone rubber preloading and curing

[0110] Carry out vacuum pre-pressing for 24h under the vacuum degree of the silicone rubb...

Embodiment 3

[0124] Embodiment 3, the manufacture of U-shaped section special-shaped cabin

[0125] The specific operation is:

[0126] (1) Prepreg preparation

[0127] According to the size of the U-shaped cross-section special-shaped cabin structure, 2.5D glass fiber woven fabric with a thickness of 2mm is used, impregnated with a medium-temperature curing flexible phenolic resin, coated in quantitative partitions, baked at a low temperature of 50°C, and dried to form a prepreg;

[0128] (2) Silicone rubber bonding

[0129] According to the size of the U-shaped cross-section special-shaped cabin structure, after making holes on the surface of the flexible silicone rubber, apply GD414 adhesive, and bond the flexible silicone rubber to the surface of the metal body of the U-shaped cross-section special-shaped cabin;

[0130] (3) Silicone rubber preloading and curing

[0131] Carry out vacuum pre-pressing for 48h under the vacuum degree of the silicone rubber after bonding, trim the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com