Pressure adjusting assembly

A component and pressure regulating technology, applied in the direction of controlling the pressure of the lubricant, can solve the problem of not always effectively stabilizing the oil pressure in the main oil passage, and achieve the effect of avoiding irregular deformation and uniform oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

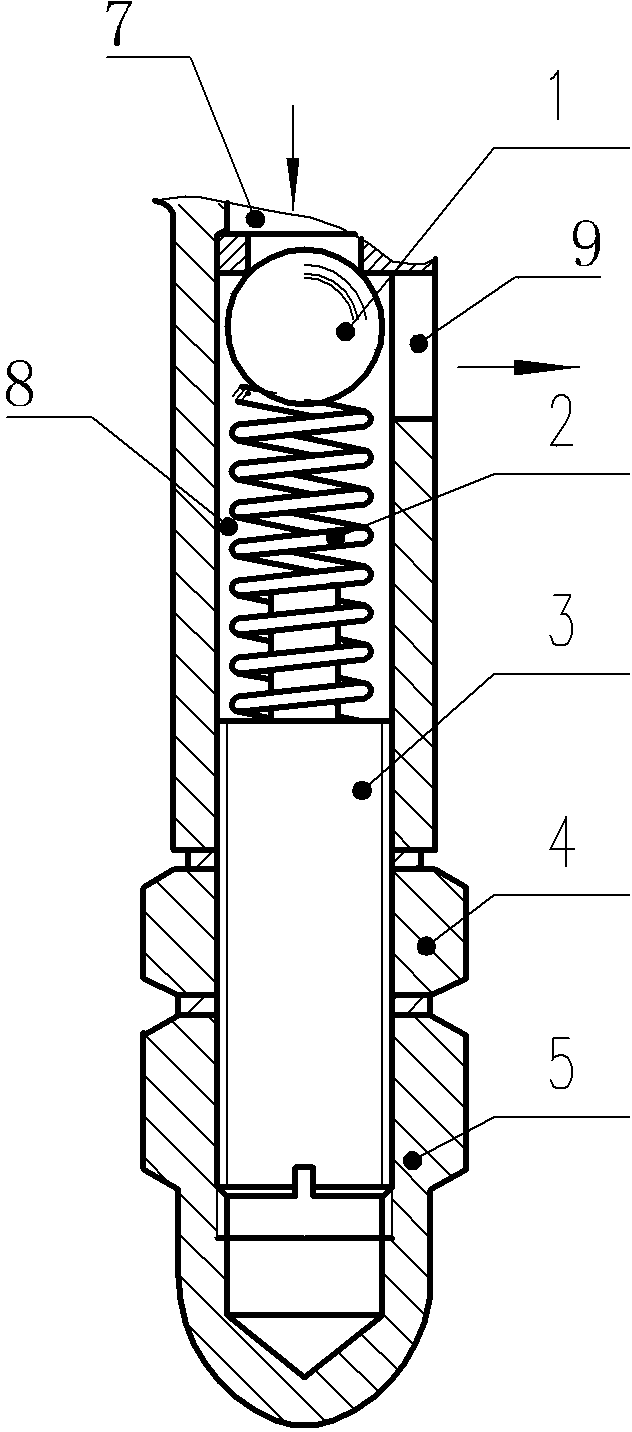

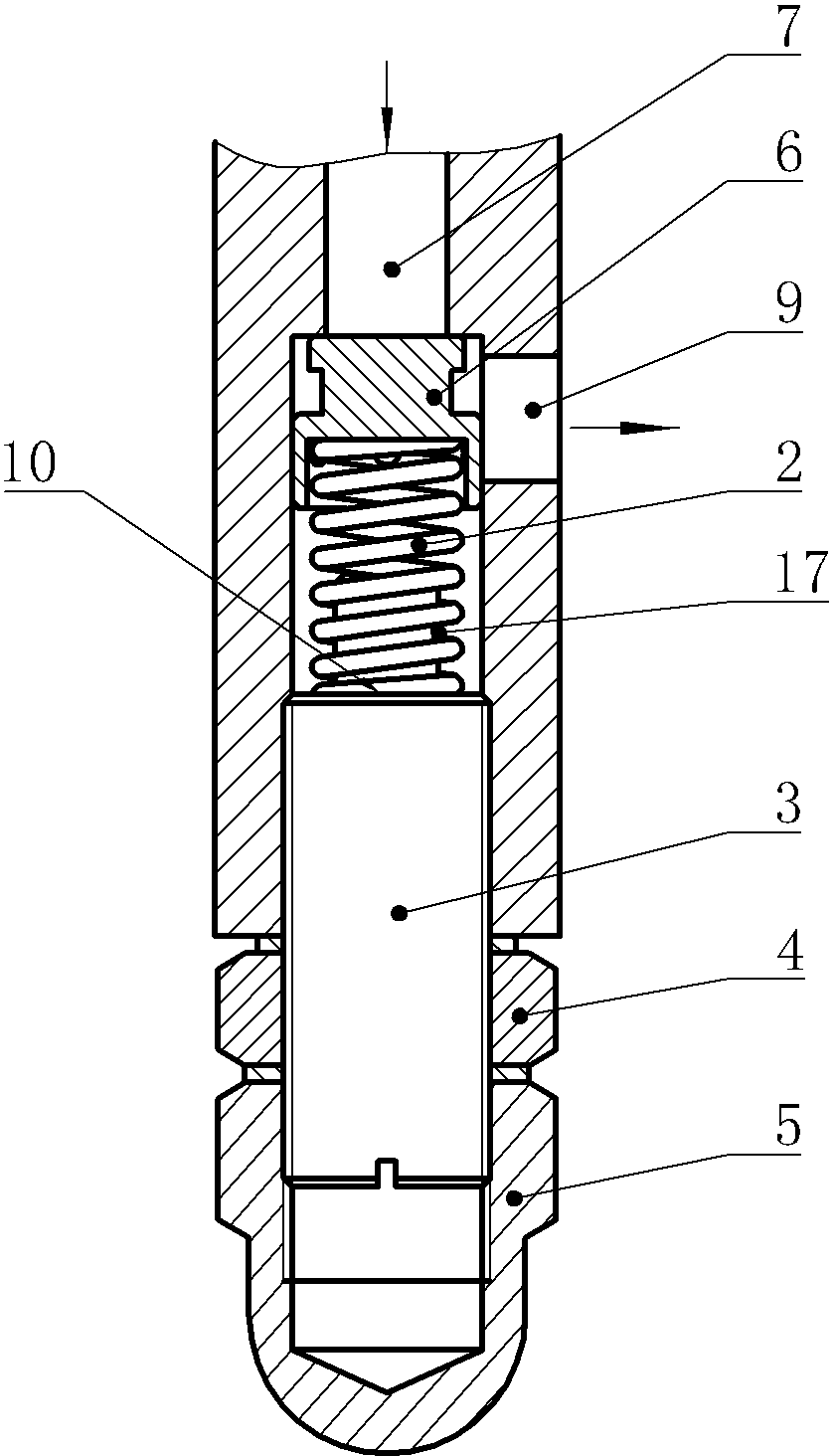

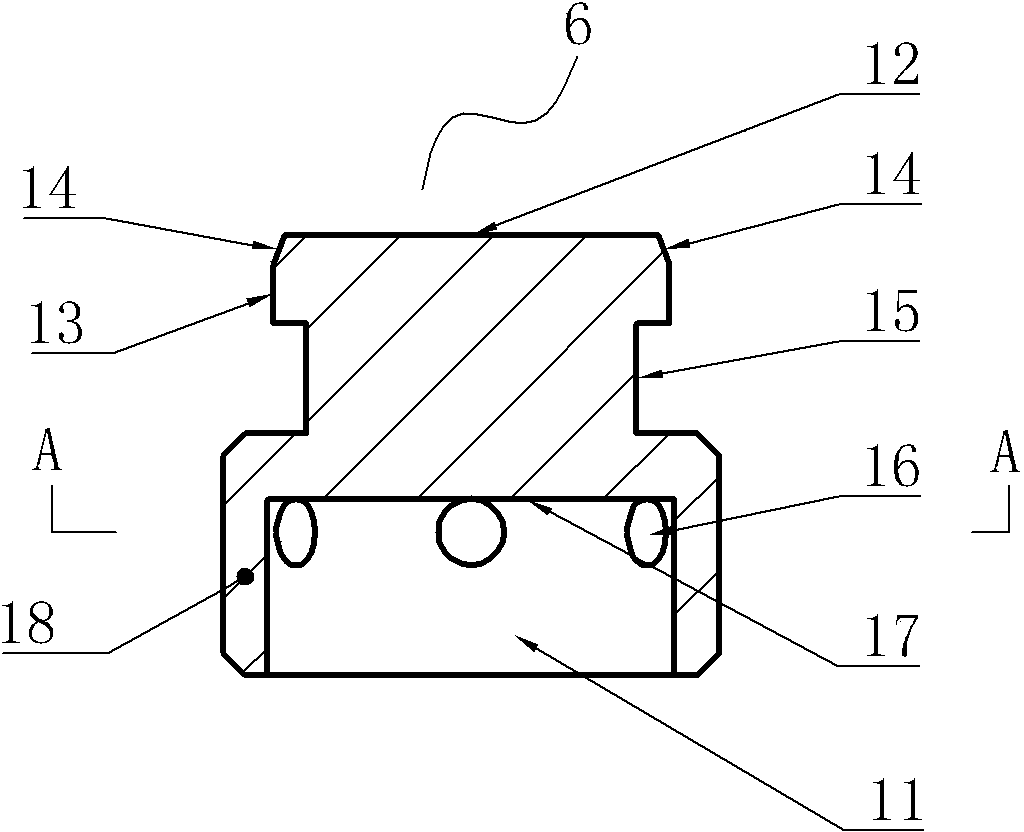

[0015] See figure 2 , image 3 and Figure 4 The pressure regulating assembly of the present invention includes an adjusting screw 3, a spring 2 and an adjusting plunger 6. Both the adjusting screw 3 and the spring 2 are installed in the section 8 of the pressure regulating assembly at the end of the main oil passage 7, and the adjusting screw 3 and the section of the pressure regulating assembly The inner wall of the slideway of section 8 is threaded and locked and positioned by the lock nut 4. The spring 2 is set on the positioning shaft 17 of the adjusting screw 3 and the bottom end of the spring 2 is fixedly connected with the top surface 10 of the adjusting screw. The end of the section 8 is closed by the oil sealing nut 5, the oil drain port 9 is opened on the wall of the oil passage near the main oil passage in the section 8 of the pressure regulating assembly, the bottom end of the regulating plunger 6 is provided with a restraint groove 11, and the top of the spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com