Container for material and oil compatibility tests

A technology for compatibility and testing, applied in the direction of analyzing materials, material thermal analysis, instruments, etc., can solve problems such as unsealable, affecting the reliability of test results, thermal expansion of transformer oil, etc., and achieve the effect of preventing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

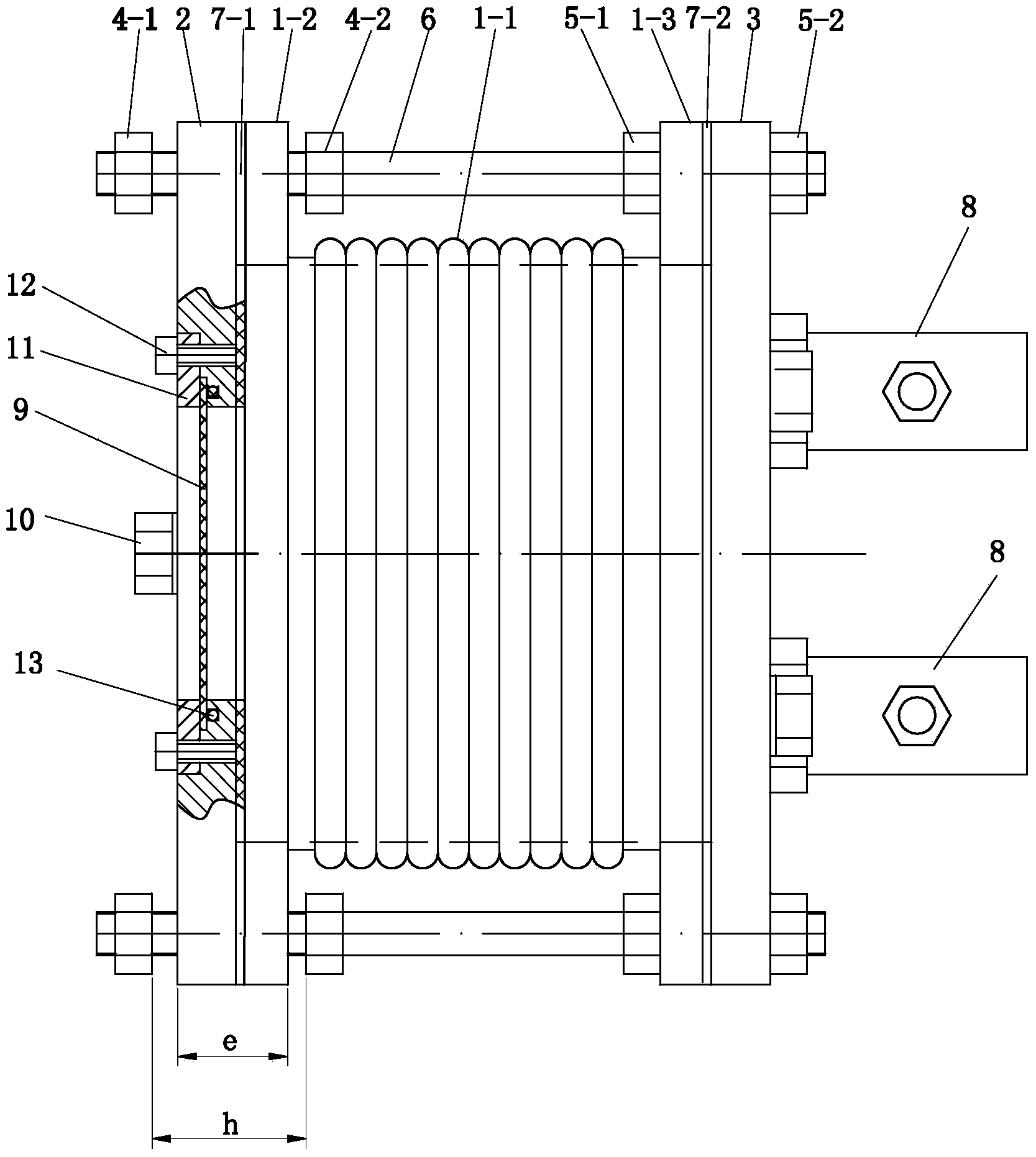

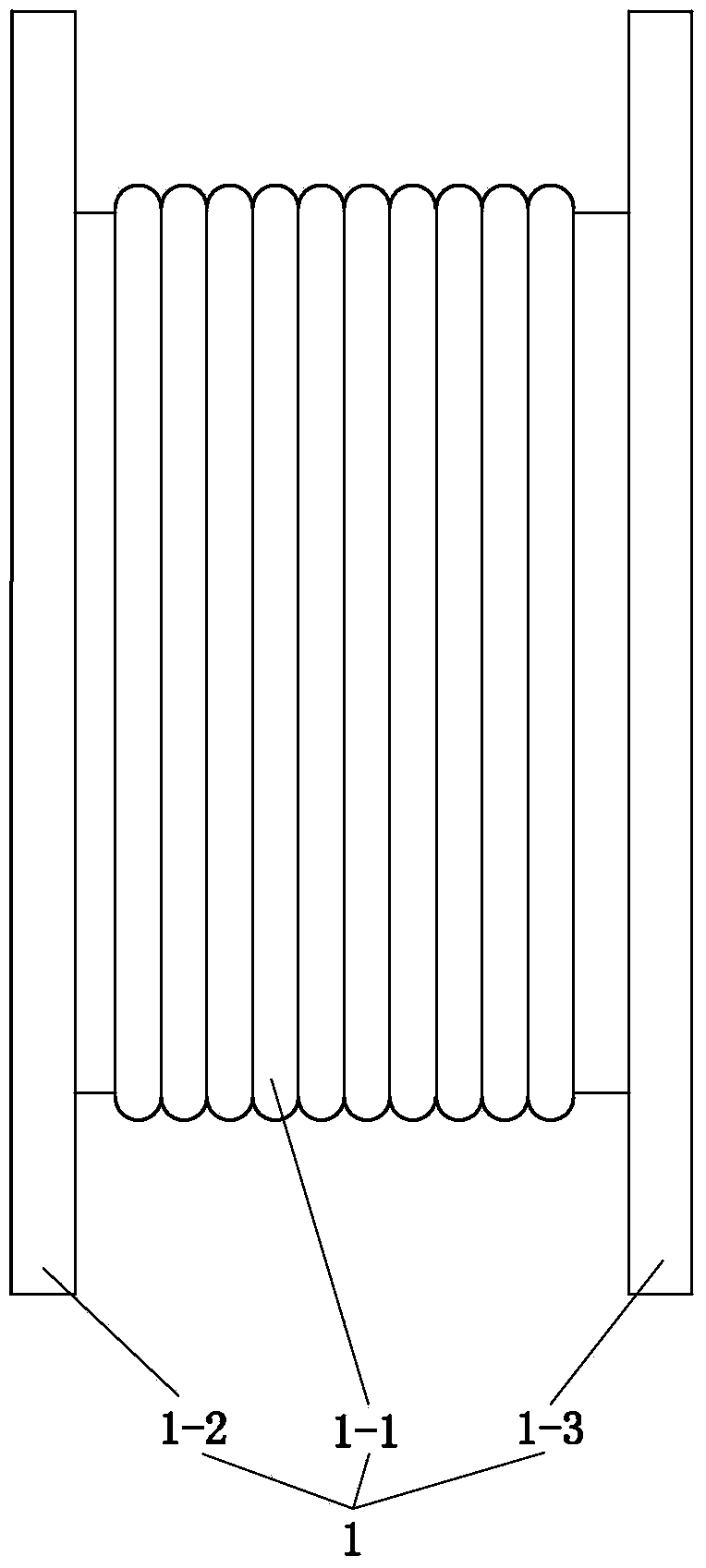

[0010] See figure 1 , the material and oil compatibility test container has a main body 1, a front cover 2, a rear cover 3 and a plurality of guide rods 6 with threads at both ends, preferably 3 to 4, and 4 are used in this embodiment Root guide rod 6. The main body 1 is composed of a bellows 1 and front and rear flanges 1-2 and 1-3 welded at the front and rear ends of the bellows 1-1. The front cover 2 covers the front flange 1-2, and several front covers 2 are connected to the front flange 1-2 by bolts 10. The rear cover 3 covers the rear flange 1-3. In order to ensure good airtightness of the container, and to ensure that the rubber seal is aging during the long-term thermal aging test, a red copper sealing ring 7-1 is used between the front cover 2 and the front flange 1-2, and the rear seal A red copper sealing ring 7-2 is also used between the cover 3 and the rear flange 1-3.

[0011] The guide rod 6 passes through the guide holes on the front cover 2, the front flan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com