Container consisting of synthetic resin

A synthetic resin and container technology, applied in the field of synthetic resin containers, to achieve the effect of improving shape retention and increasing surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Now, preferred embodiments of the synthetic resin container of the present invention will be specifically described with reference to the accompanying drawings.

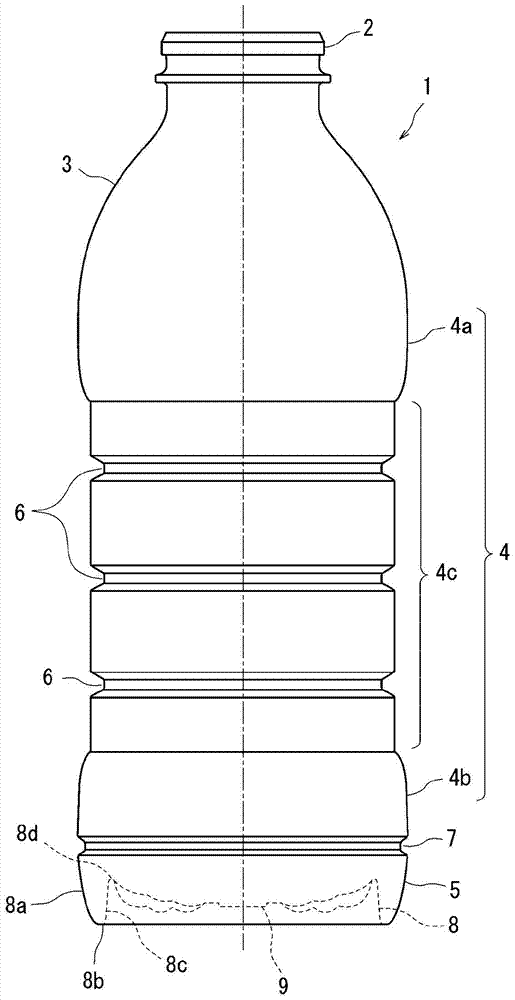

[0038] figure 1 A synthetic resin container 1 (hereinafter also referred to as a container 1 ) of the present invention shown in , includes a mouth 2 , a shoulder 3 , a main body 4 , and a bottom 5 . The body portion 4 includes an upper body portion 4a continuous from the shoulder 3, a lower body portion 4b continuous to the bottom, and a central body portion 4c positioned between the upper body portion 4a and the lower body portion 4b.

[0039] The central body portion 4c has three circumferential ribs 6, 6, 6 formed in parallel and kept at equal intervals to maintain the mechanical strength of the body portion and to maintain the shape of the body portion against Deformation caused by internal pressure. In addition, the outer peripheral surface of the main body except for the rib 6 is formed linearly in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com