Blast deflector

A deflector and panel technology, applied in the field of deflectors, can solve the problems of slow heat dissipation, short service life, and increased cost of deflectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Carry out the description of specific embodiment below in conjunction with accompanying drawing:

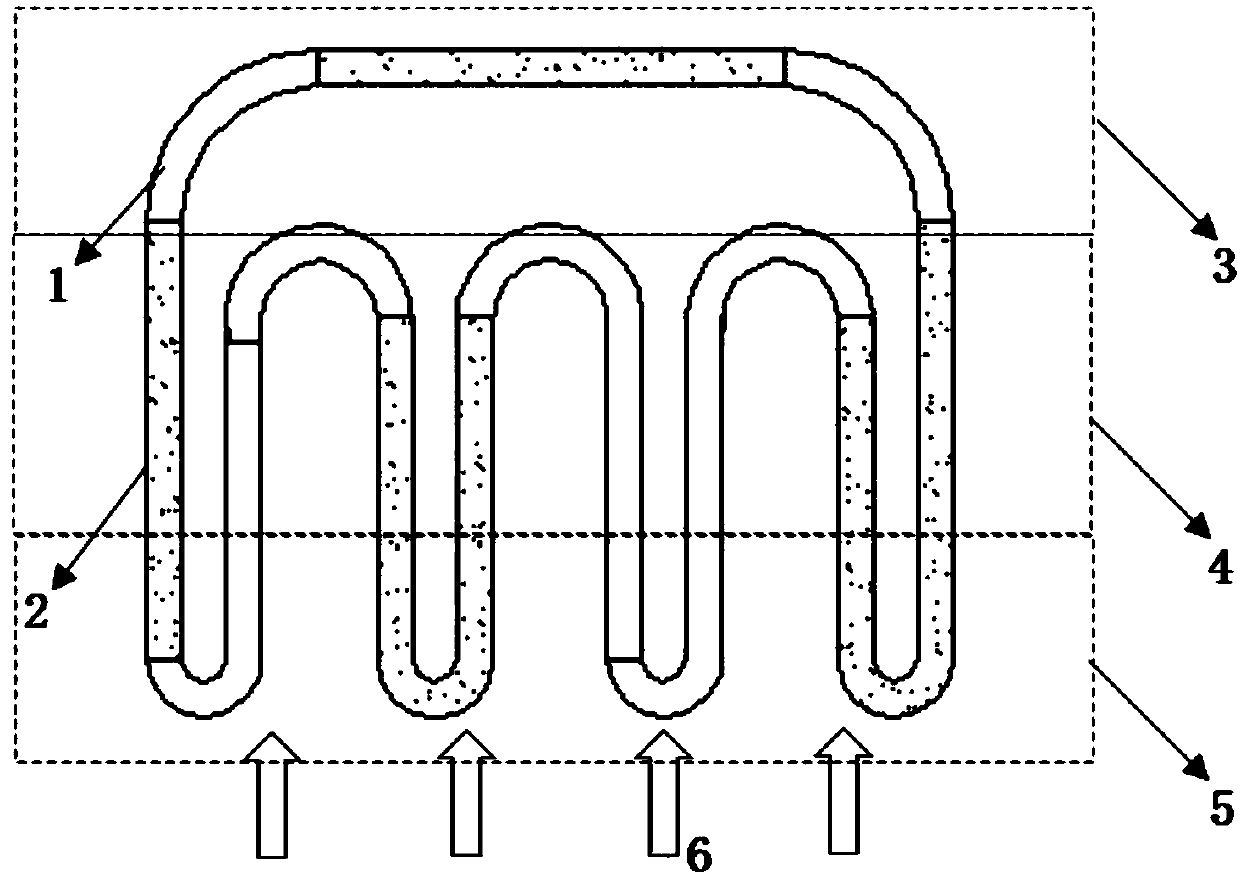

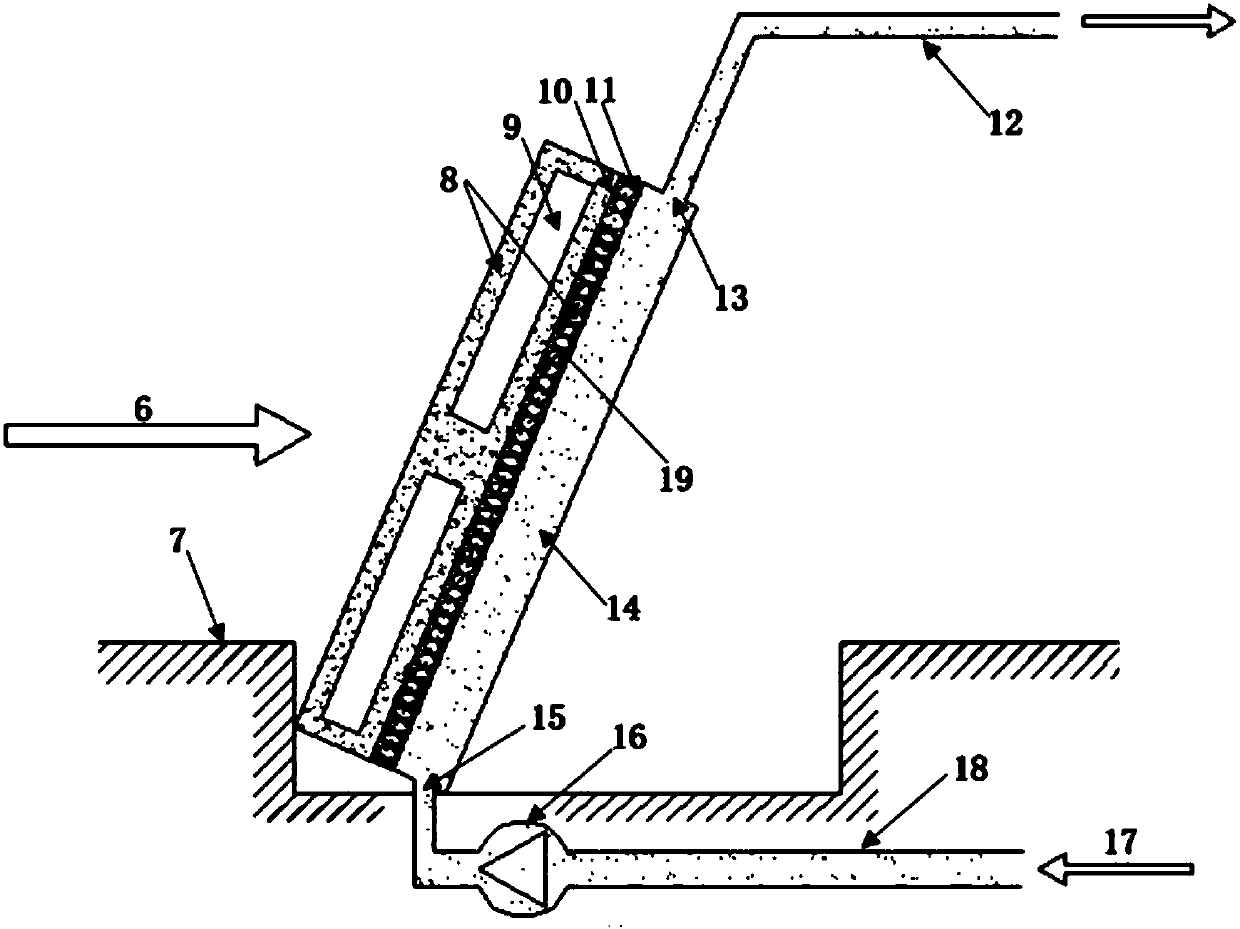

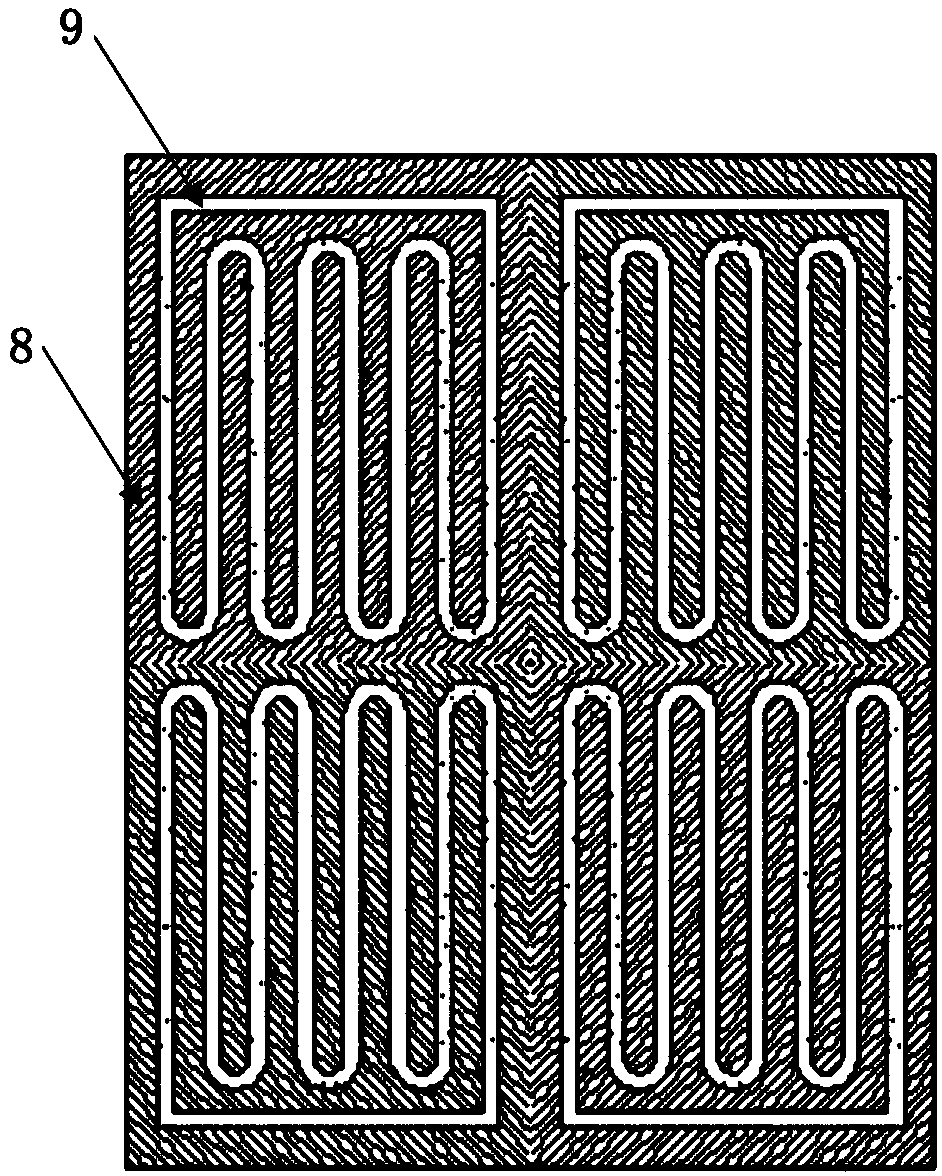

[0041] figure 1 The working principle of a closed-loop pulsating heat pipe 9 on the deflector plate is given. When the high-temperature and high-speed gas 6 hits the lower half of the closed-loop pulsating heat pipe 9, a heating section 5 is formed in the lower half. The working medium is heated and evaporated at a temperature lower than normal pressure in a serpentine airtight vacuum space to generate bubbles. The bubbles expand rapidly and increase the pressure to form an evaporation end, pushing the working medium to flow to the low-temperature condensation section 3, where the bubbles condense Shrink and burst, the pressure drops, and the working fluid flows back. In addition, under the action of capillary force and bending force, the steam generated by heating and the liquid generated by condensation will finally form an oscillating state in which the air plug 1 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com