Carbon fiber heating ground mattress

A technology of carbon fiber heating and carbon fiber heating wire, which is applied in the field of carbon fiber heating mats, can solve the problems of small heating area, low temperature resistance, high installation cost, etc., and achieve good radiation protection, good radiation protection and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

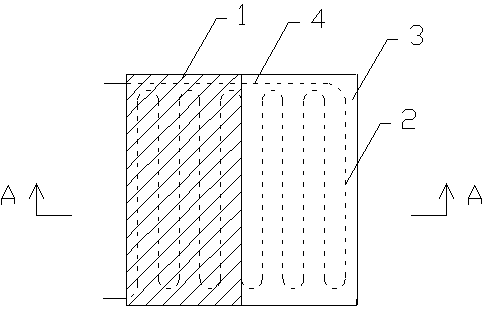

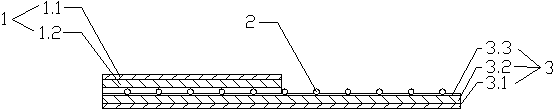

[0024] Embodiment one, see figure 1 It is a structural schematic diagram of a carbon fiber heating mat with a single carbon fiber heating wire connected between two inner conductors. The outer diameters of the three-layer heat-shrinkable tubing are 4.8mm, 6.4mm, and 7.9mm from the inside to the outside.

Embodiment 2

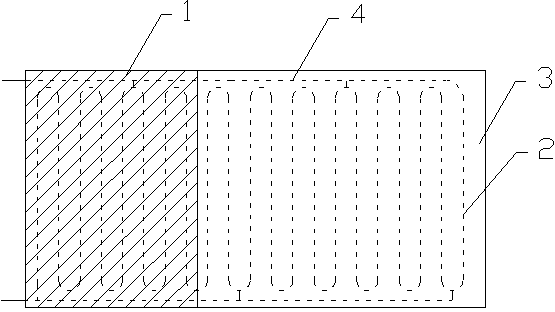

[0025] Embodiment two, see figure 2 It is a structural schematic diagram of a carbon fiber heating mat with four carbon fiber heating wires connected in parallel between two inner conductors. The outer diameters of the three-layer heat-shrinkable sleeves are 6.4mm, 7.9mm, and 9.5mm from the inside to the outside.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com