Holder for semiconductor production system

A technology for manufacturing devices and holding bodies, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc. It can solve the problems of unqualified products, leakage, aging of resistance heating elements, etc., and achieve the purpose of suppressing the drop of temperature and reducing cost. , Improve the effect of heat uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

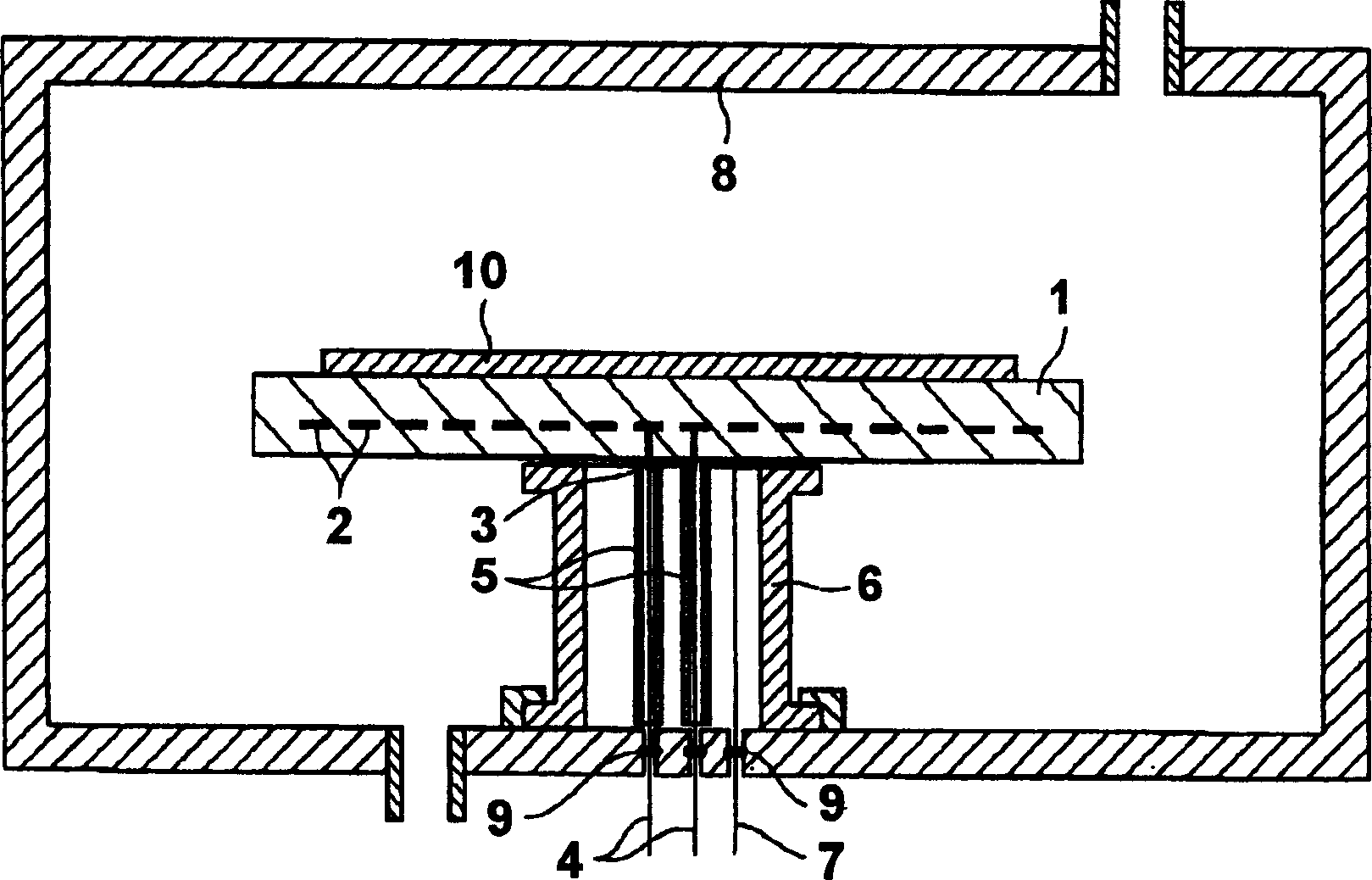

Embodiment 1

[0043] Adding yttrium oxide (Yttria) as a sintering aid to aluminum nitride (AlN) powder 2 o 3 ) 0.5% by weight, after adding an organic binder to disperse and mix, carry out granulation by spray drying. The granulated powder was molded with a uniaxial press, and sintered to obtain two disk-shaped compacts with a size of 350 mm in diameter and 5 mm in thickness. In addition, add sintering aids with the same composition to the same AlN powder, then add organic binders, dispersants, and solvents for extrusion, knead and extrude the resulting kneaded mixture, and obtain 2 diameters after sintering. It is a tubular molded body with an outer diameter of 10 mm x an inner diameter of 8 mm x a length of 100 mm.

[0044] The above-mentioned two disc shaped bodies and two tubular shaped bodies were degreased in a nitrogen flow at 900°C, and further sintered at 1900°C for 5 hours in a nitrogen flow. The thermal conductivities of the obtained AlN sintered bodies were all 180 W / mK. The...

Embodiment 2

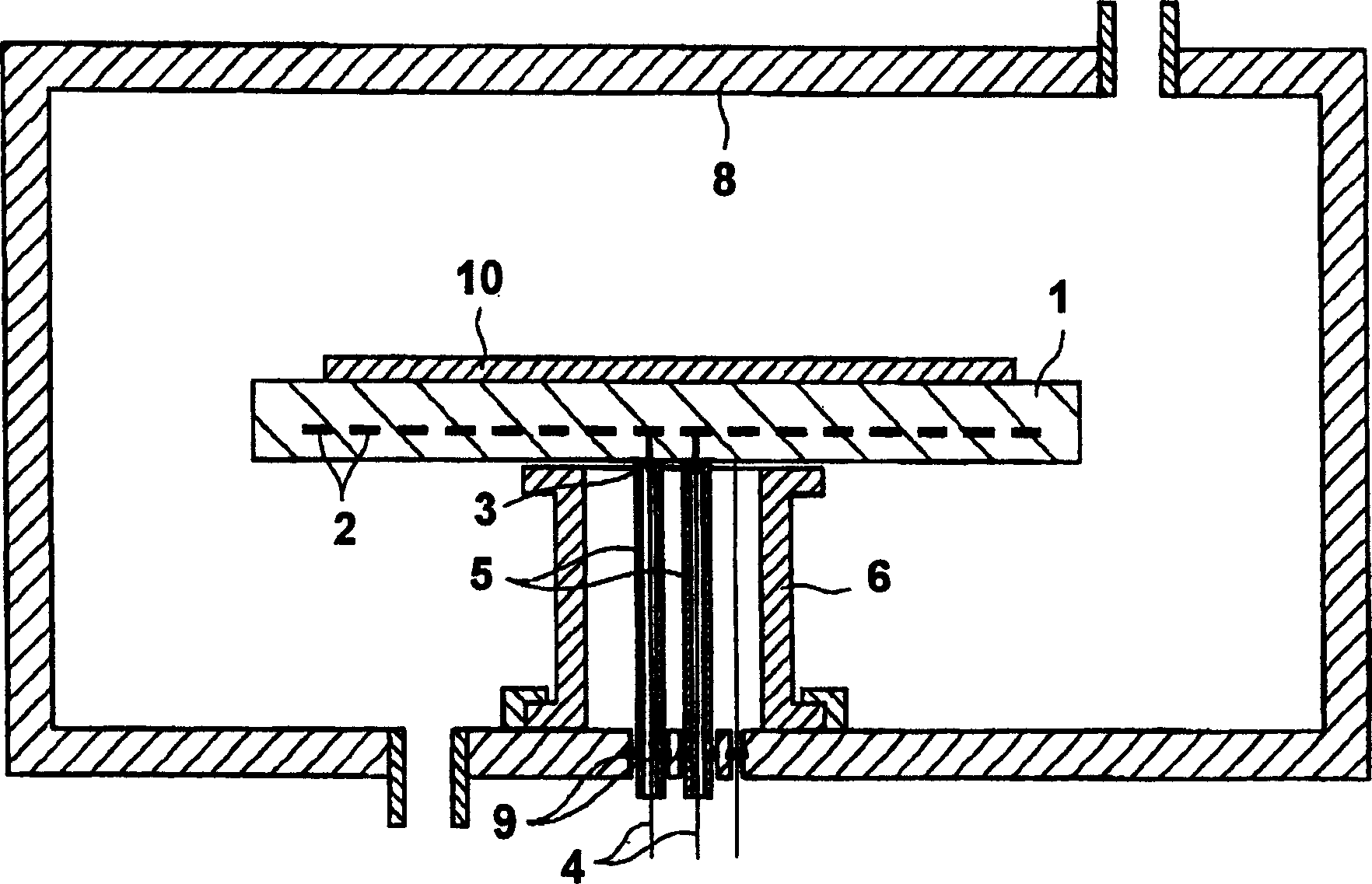

[0052] Such as figure 2 As shown, the other end of the insulating tube 5 made of AlN is extended through the bottom surface of the processing chamber 8, and the other end side of the insulating tube 5 and the bottom surface of the processing chamber 8 are hermetically sealed with an O-ring. In Example 1, a device was constructed in the same manner. On the device constructed as described above implemented and

[0053] Same evaluation as Example 1.

[0054] The ceramic holder was heated to 500°C under the same conditions as in Example 1. At this time, even if the power was turned on and off 500 times, there was no failure such as sparks between the electrode terminals and the lead wires. In addition, even if the temperature was raised and lowered 500 times, no problem occurred in any of the 10 ceramic holders. In addition, the thermal uniformity of the ceramic holder was 500° C.±0.46%.

Embodiment 3

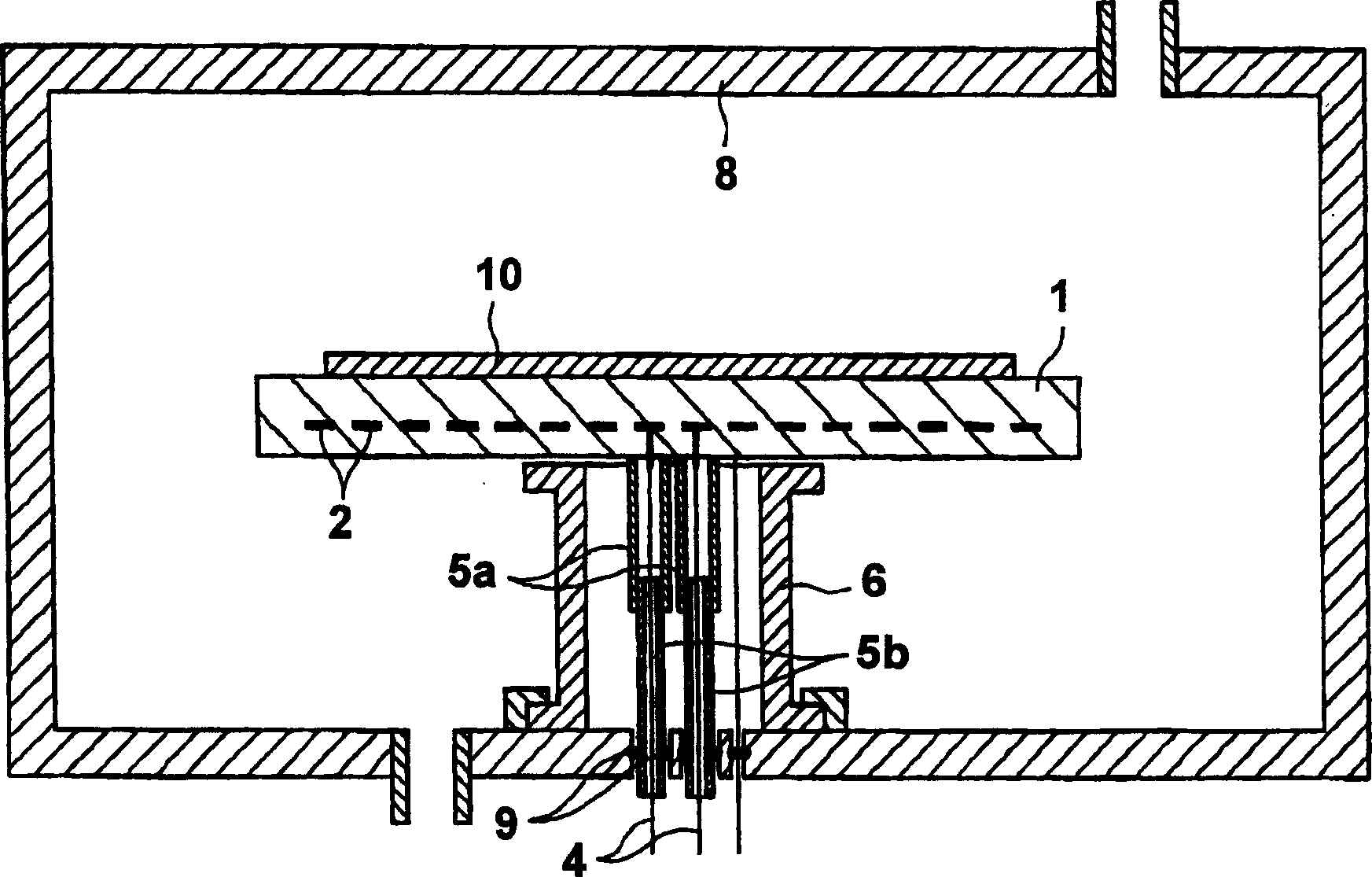

[0056] Such as image 3 As shown, the apparatus was configured in the same manner as in Example 2, except that two AlN insulating tubes 5a and 5b having different diameters were fitted and used as the insulating tubes. In addition, the dimensions of the insulating tube 5a are 12 mm in outer diameter, 10.5 mm in inner diameter, and 60 mm in length. In addition, the dimensions of the insulating tube 5b are 10 mm in outer diameter, 8 mm in inner diameter, and 60 mm in length.

[0057] The device constructed as above was evaluated under the same conditions as in Example 1. That is, when the holder made of ceramics was heated to 500° C., and then the power was turned on and off 500 times, no troubles such as sparks occurred between the electrode terminals and the lead wires. In addition, even if the temperature was raised and lowered 500 times, no problem occurred in any of the 10 ceramic holders. In addition, the thermal uniformity of the ceramic holder was 500° C.±0.46%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com