Flow equalizing apparatus used in heated air circulation sterilization dryer for heating cavity

A technology of heating cavity and hot air circulation, which is applied in the direction of drying gas arrangement, dryer, lighting and heating equipment, etc., can solve the problems of uneven heating of objects, difficult to control air volume, slow wind speed, etc. Simple and compact, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

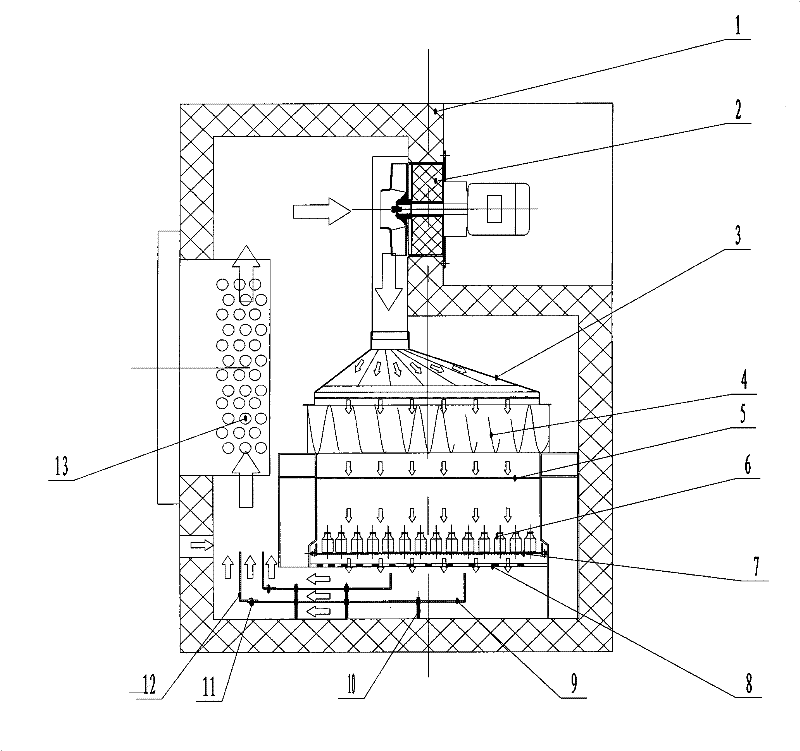

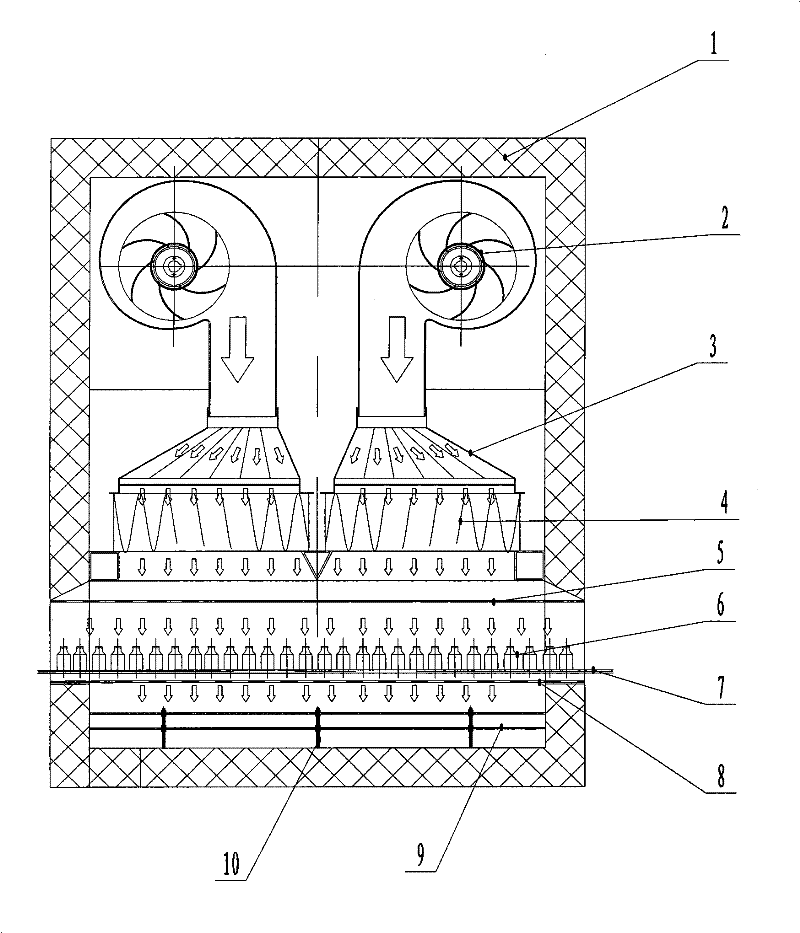

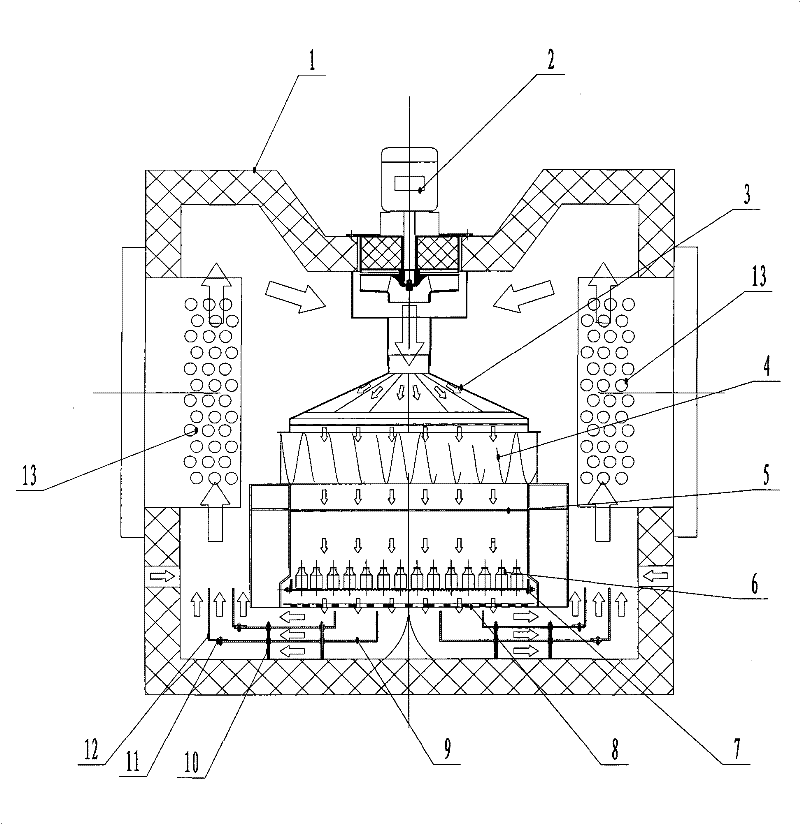

[0030] The current equalizing device used in the heating cavity of the hot air circulation type sterilization dryer of the present invention can be applied to such as figure 1 and figure 2 One-sided heaters shown, may also be used as image 3 and Figure 4 Dual side heaters shown.

[0031] Such as Figure 1 to Figure 9 As shown, the present invention is used in the flow equalization device in the heating chamber of the hot air circulation type sterilization dryer, which includes the flow equalizer 5, the flow control plate 8 and the diffused air arranged between the hot air blower 2 and the filter 4 of the dryer. Cover 3, the equalizer plate 5 is installed under the filter 4, and the flow control plate 8 is installed under the work object; the diffuser wind cover 3 includes a diffuser frame 16, a wind cover 15 connected to the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com