Battery module with flat heat pipes and cooling method

A flat heat pipe, battery module technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as reducing battery cycle life, affecting battery consistency and balance, and battery cell expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A battery module with a flat heat pipe provided in an embodiment of the present invention will be further described in detail below with reference to the drawings and specific examples.

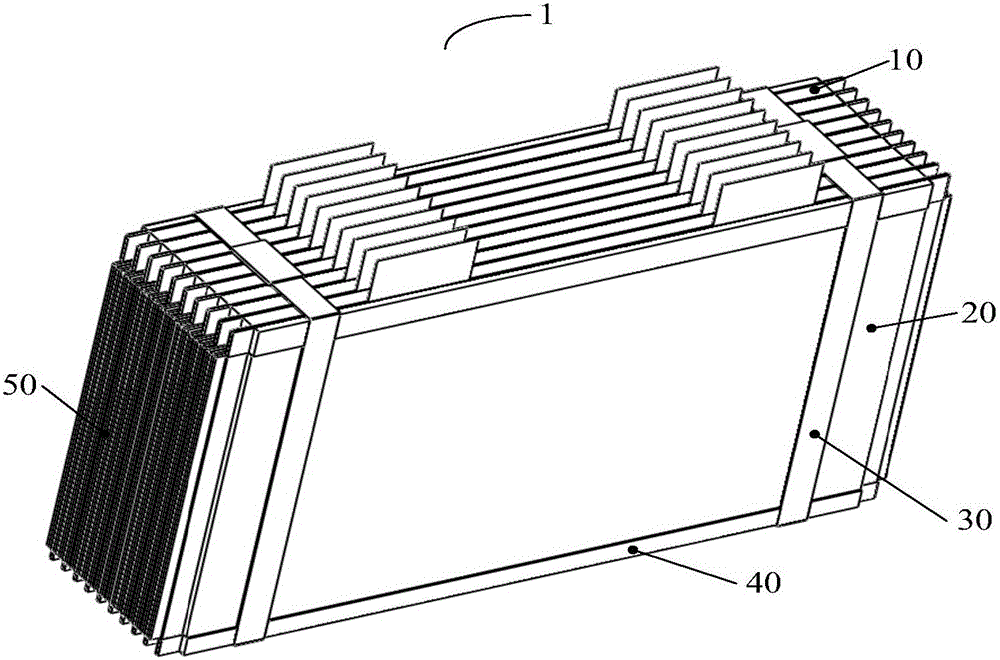

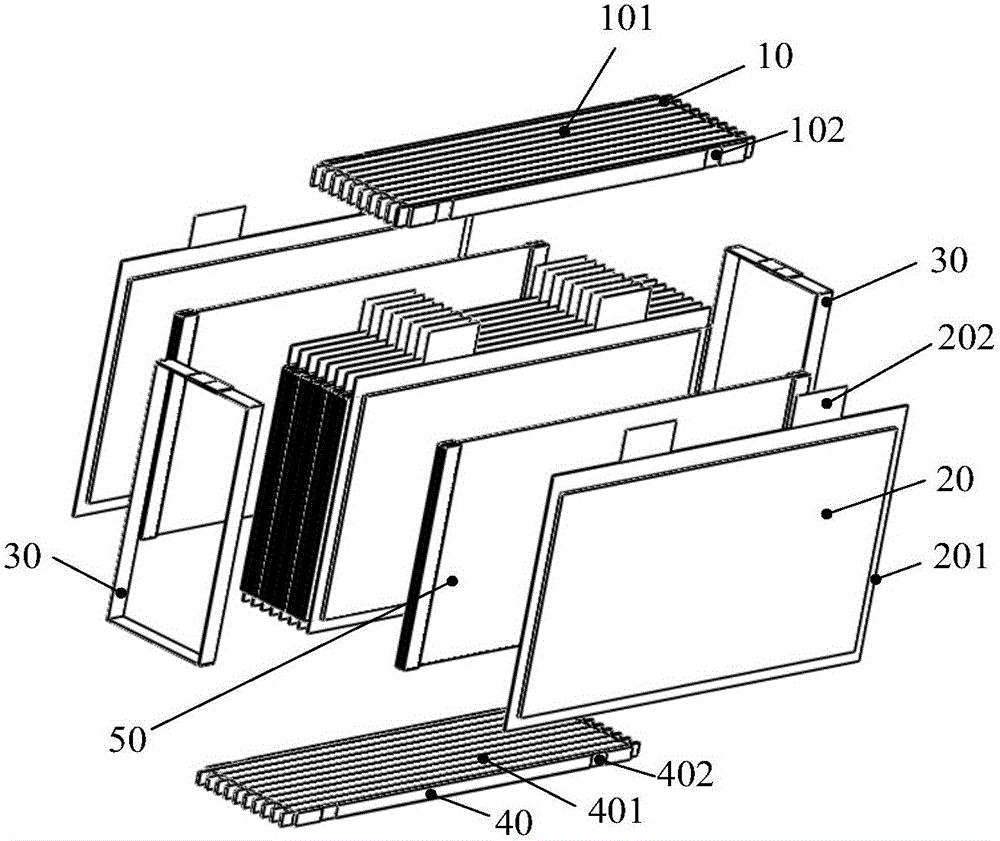

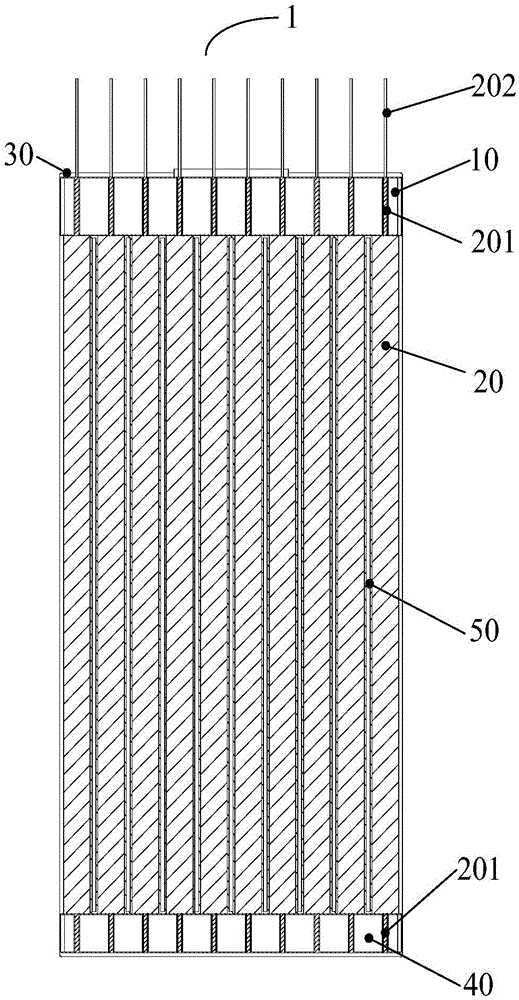

[0024] Please also refer to Figure 1 to Figure 7 , the present invention provides a battery module 1 with a flat heat pipe, comprising: a tab fixing device 10, a packing belt 30, a bottom fixing device 40, a plurality of battery cells 20 and a plurality of flat heat pipes 50; every two battery cells 20 A flat heat pipe 50 is arranged between them; the packing belt 30 is hooped in the notch 102 of the tab fixing device and the notch 402 of the bottom fixing device, and then the edge 201 of the battery cell 20 is pressed and fixed in the through groove 101 of the tab fixing device and The bottom fixing device is in the through groove 401.

[0025] The battery cell 20 is a soft-pack lithium-ion battery. Each battery cell 20 is a lithium-ion battery that can be independently charged and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com