Positioning self-centering main shaft chuck capable of overturning plus or minus 180 degrees

A spindle chuck and self-centering technology, which is applied in chucks, metal processing, etc., can solve problems such as inability to achieve 0-180o flipping, achieve unmanned processing, improve processing efficiency, reduce difficulty and labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

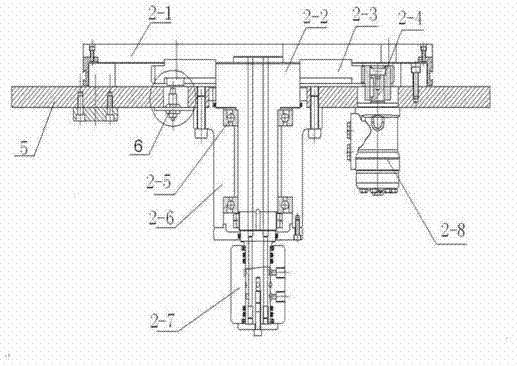

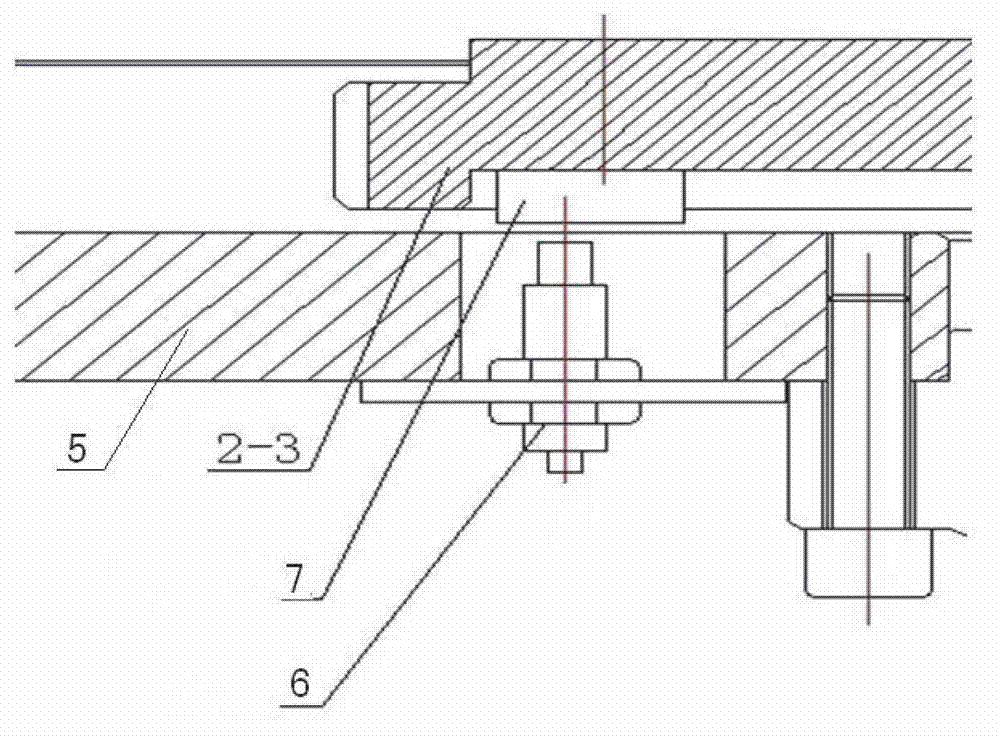

[0011] Depend on figure 1 It is known that a reversible 180° positioning spindle chuck includes a swingable clamping chuck 1, a spindle rotating mechanism 2, a turning mechanism 3 and a three-circuit rotary joint 4, and the swingable clamping chuck 1 is set on the spindle chuck Above, the two sides of the spindle chuck are connected with a spindle rotation mechanism 2 and a turning mechanism 3 .

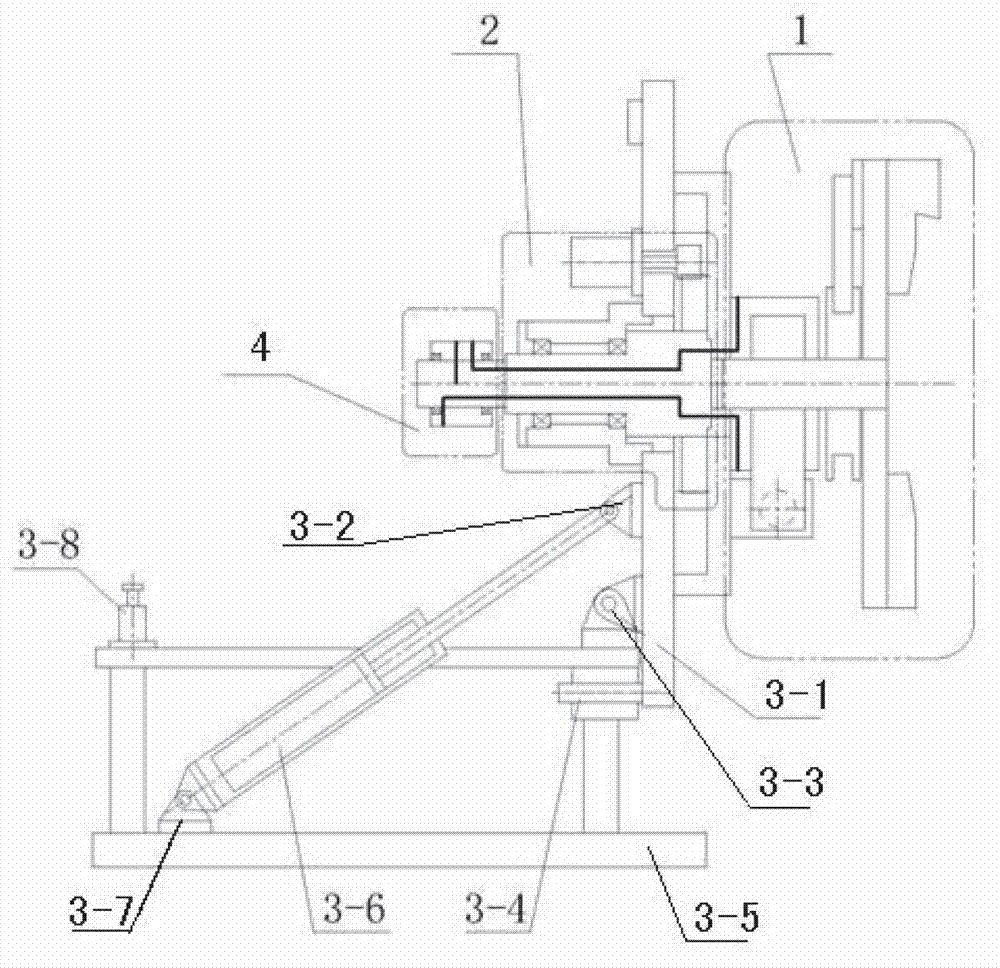

[0012] Depend on figure 2 Known, the sectional view of the spindle rotation mechanism. Turning mechanism 3 includes main shaft seat plate 3-1, oil cylinder rod end support seat 3-2, turning support seat 3-3, base 3-5, turning drive oil cylinder 3-6, oil cylinder support seat 3-7, horizontal adjustment support 3 -8, the main shaft seat plate 3-1 is connected on the main shaft chuck, and the oil cylinder rod end support seat 3-2, the turning support seat 3-3 and the horizontal adjustment support 3-8 are provided with the bottom of the main shaft seat plate 3-1. The base 3-5 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com