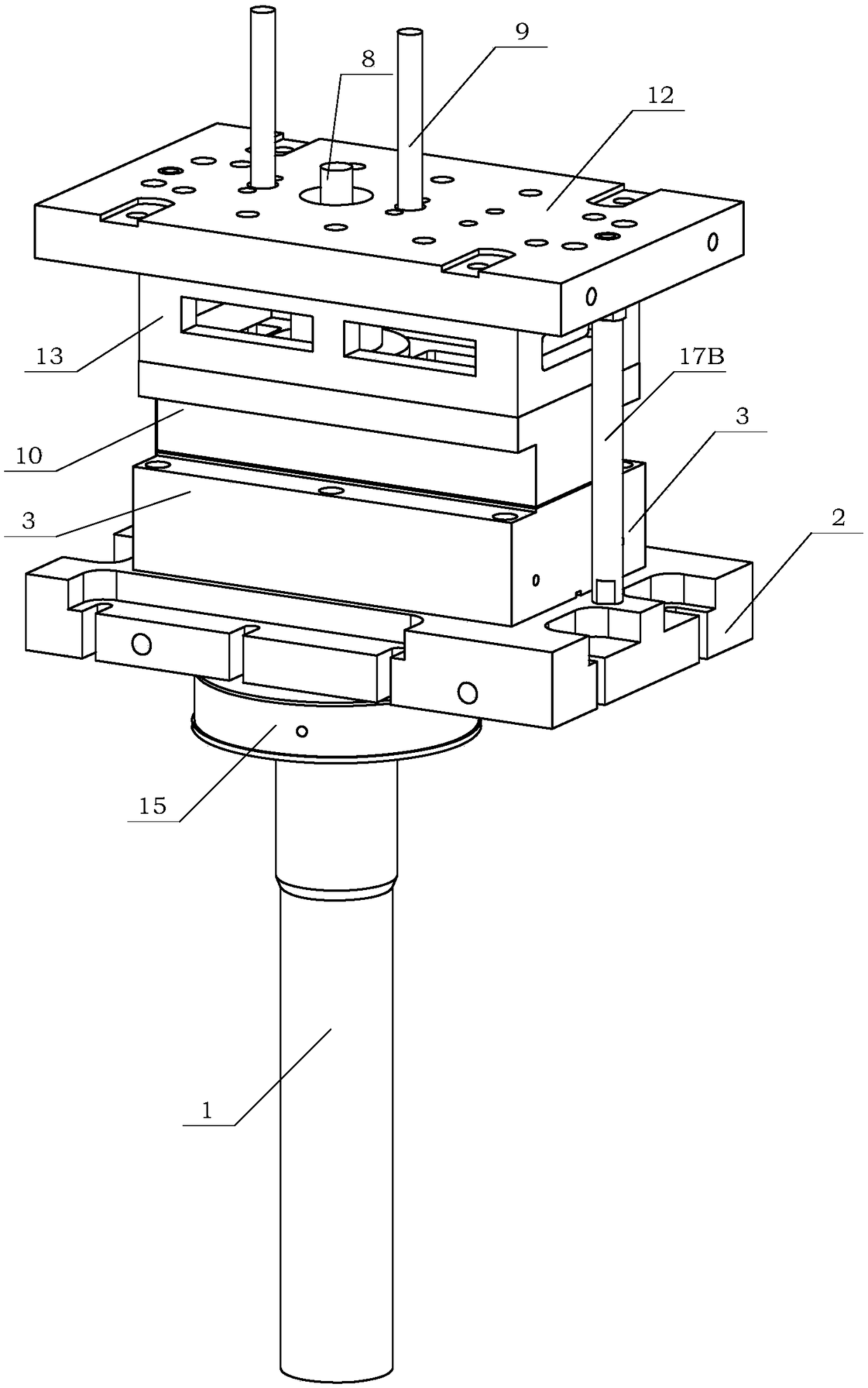

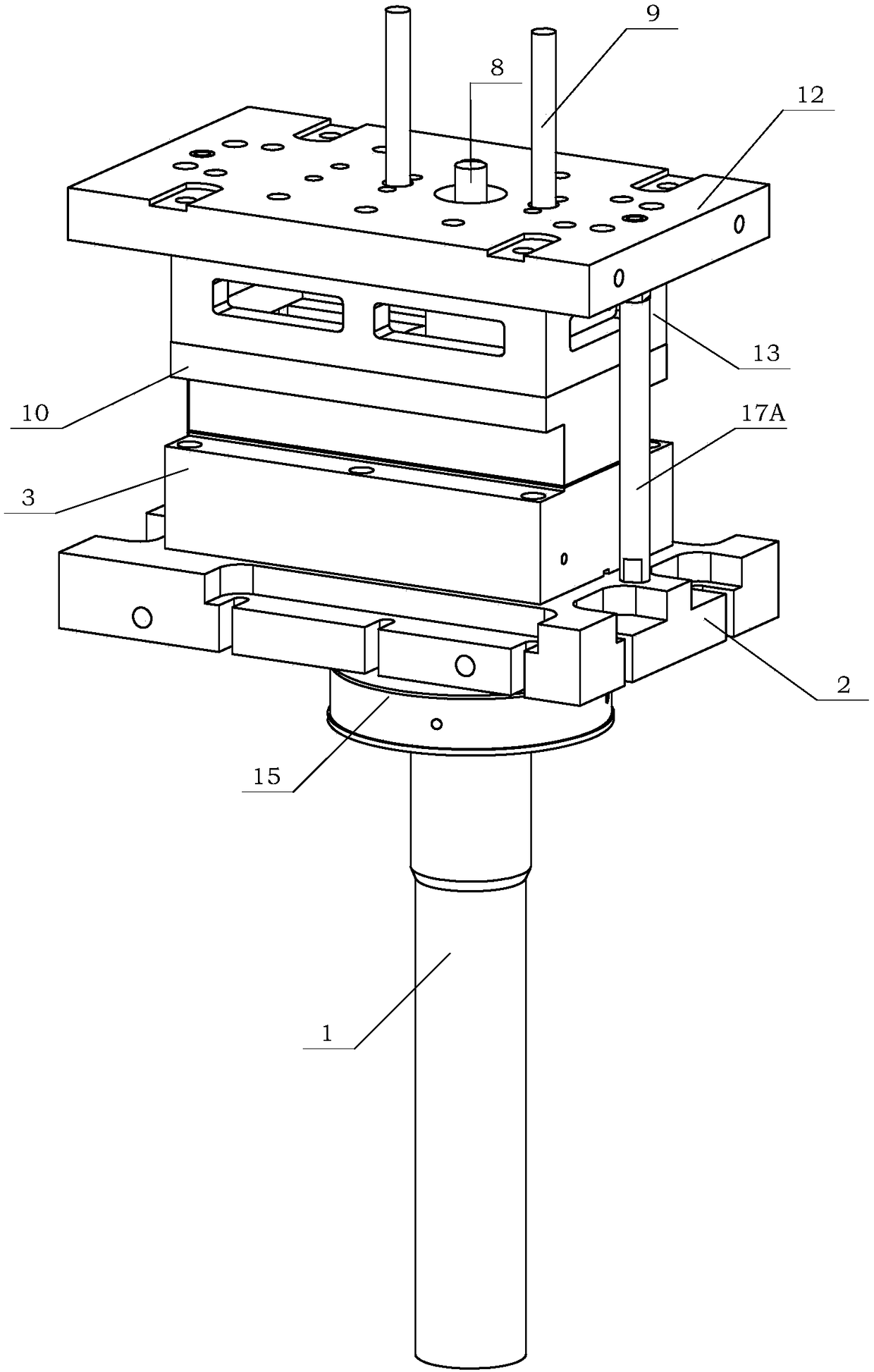

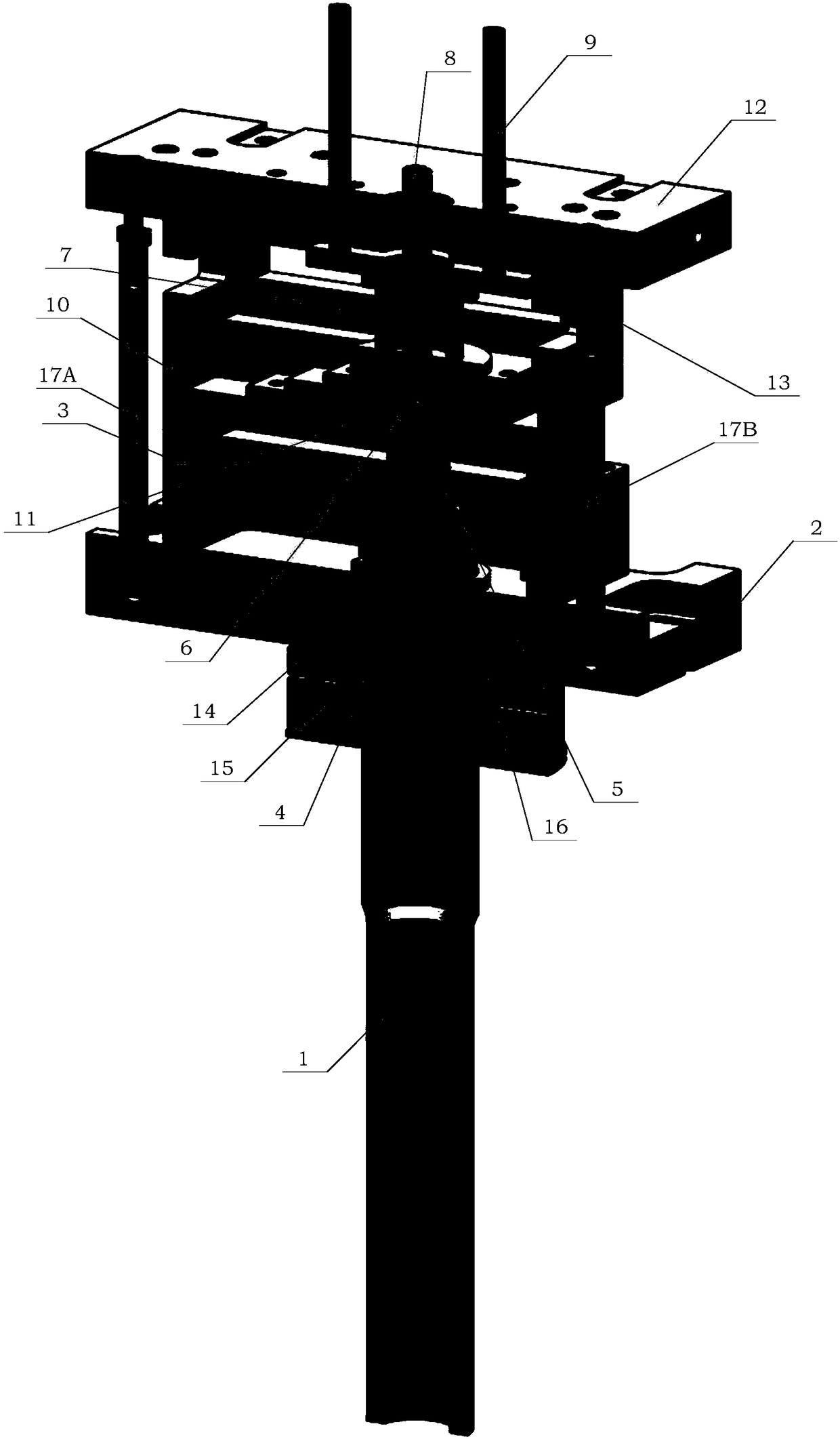

Low-pressure mold-filling high-pressure solidification casting device and casting method

A low-pressure, high-pressure technology, applied in the field of casting, can solve problems such as equipment structure difficulties, and achieve the effects of performance improvement, shape and structure optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] The low-pressure filling and high-pressure solidification casting device of the present invention is installed on the BH-1 type low-pressure pressurized casting machine, and the A356 aluminum alloy steering knuckle casting is carried out with low-pressure pressurized casting. The process is as follows:

[0101] (1) Prepare aluminum alloy according to a certain ratio, the specific mass percentage is: Si: 7.2%, Mg: 0.3%, Fe: 0.10%, Mn: 0.03%, Ti: 0.12%, Sr: 0.012%; Cu: 0.01 %, RE: 0.002%, Nb: 0.02%, Cr: 0.005%, Zr: 0.02%, B: 0.005%, Nd: 0.005%, Ni: 0.001%, Zn: 0.005%, and the balance is Al. After the alloy is melted in the melting furnace, add Al-5Ti-B refiner and Al-10Sr modifier at 750°C for refinement and modification, and add self-sinking pollution-free refining agent for degassing at 740°C After refining and slag removal, pour the molten aluminum alloy into the low-pressure casting holding furnace. At this time, the density of the molten aluminum is 2.54g / m 3 ;

[...

Embodiment 2

[0110] The low-pressure filling mold high-pressure solidification casting device of the present invention is installed on the APC1500A type differential pressure boost casting machine, and the aluminum alloy automobile motor casing casting is subjected to differential pressure boost casting, and the process is as follows:

[0111] The method for performing differential pressure casting of aluminum alloy castings using the low-pressure filling and high-pressure solidification casting device includes the following steps:

[0112] (1) Prepare aluminum alloy according to a certain ratio, the specific mass percentage is: Si: 7.0%, Mg: 0.45%, Fe: 0.12%, Mn: 0.1%, Ti: 0.15%, Sr: 0.015%; Cu: 0.10 %, RE: 0.010%, Nb: 0.05%, Cr: 0.008%, Zr: 0.01%, B: 0.005%, Nd: 0.005%, Ni: 0.005%, Zn: 0.009%, and the balance is Al. After the alloy is melted in the melting furnace, add Al-5Ti-B refiner and Al-10Sr modifier at 750°C for refinement and modification, and add self-sinking pollution-free refi...

Embodiment 3

[0121] Install the low-pressure mold-filling and high-pressure solidification casting device of the present invention on a pressure-regulating casting machine, and perform pressure-regulating casting on aluminum alloy automotive motor fan castings. The process is as follows:

[0122] (1) Prepare aluminum alloy according to a certain ratio, the specific mass percentage is: Si: 7.5%, Mg: 0.60%, Fe: 0.20%, Mn: 0.1%, Ti: 0.15%, Sr: 0.05%; Cu: 0.01 %, RE: 0.10%, Nb: 0.01%, Cr: 0.001%, Zr: 0.01%, B: 0.01%, Nd: 0.002%, Ni: 0.005%, Zn: 0.008%, and the balance is Al. After the alloy is melted in the melting furnace, add Al-5Ti-B refiner and Al-10Sr modifier at 750°C for refinement and modification, and add self-sinking pollution-free refining agent for degassing at 730°C After refining and slag removal, inject the molten aluminum alloy into the holding furnace of the casting machine. At this time, the density of the molten aluminum is 2.55g / m 3 ;

[0123] (2) Prepare the casting mach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com