Aluminum alloy vacuum lifting degassing device

A technology of aluminum alloy and gas device, applied in the fields of casting and experimental equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

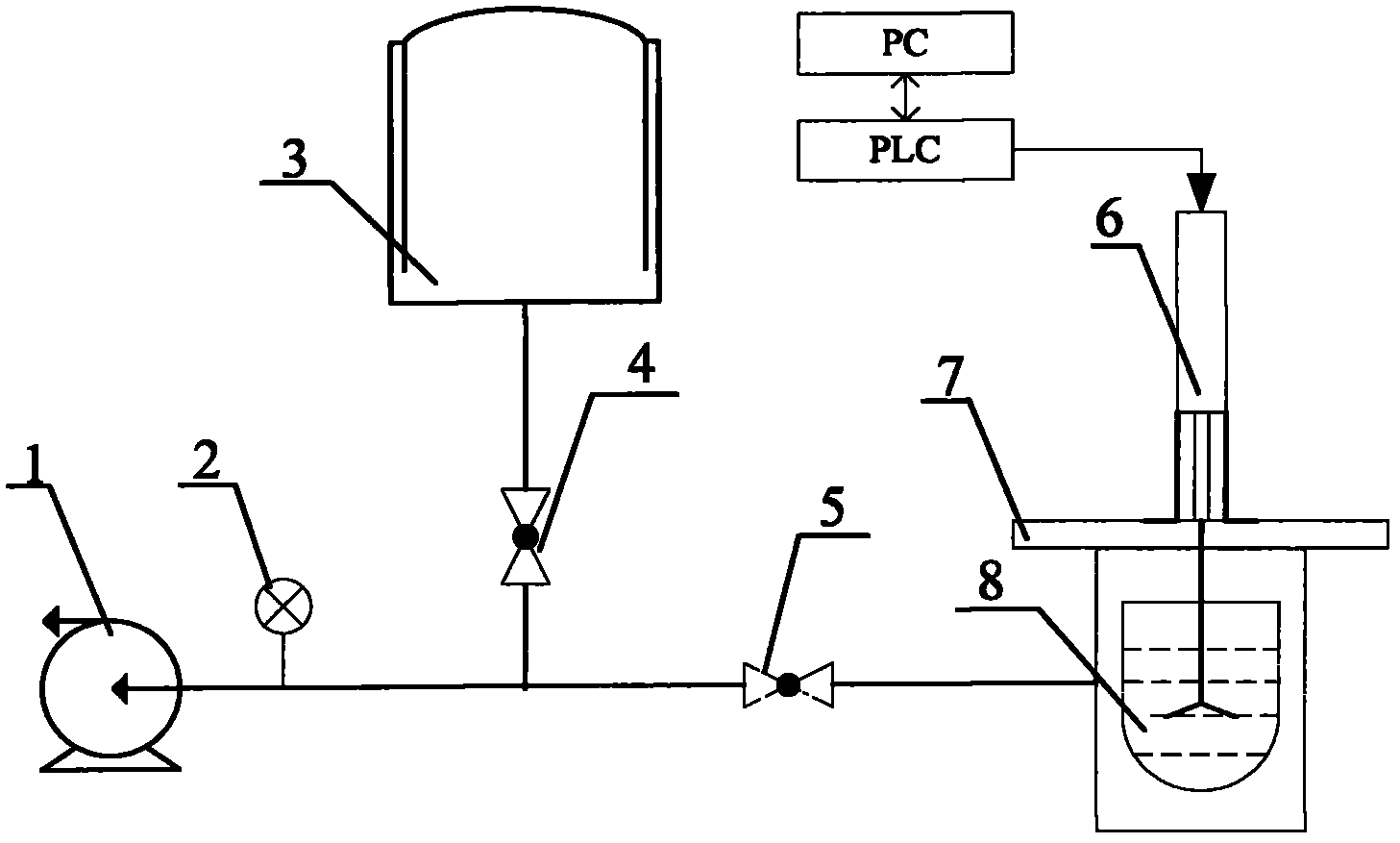

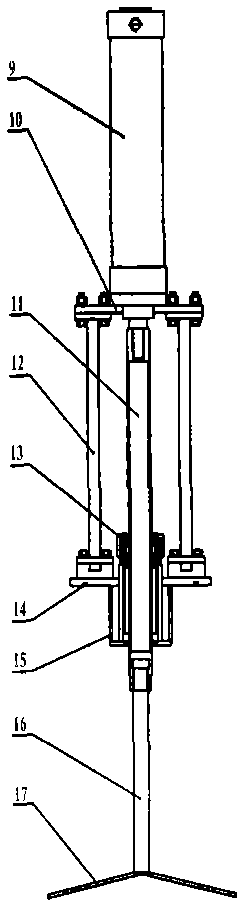

[0017] This embodiment is an aluminum alloy vacuum pulling degassing device.

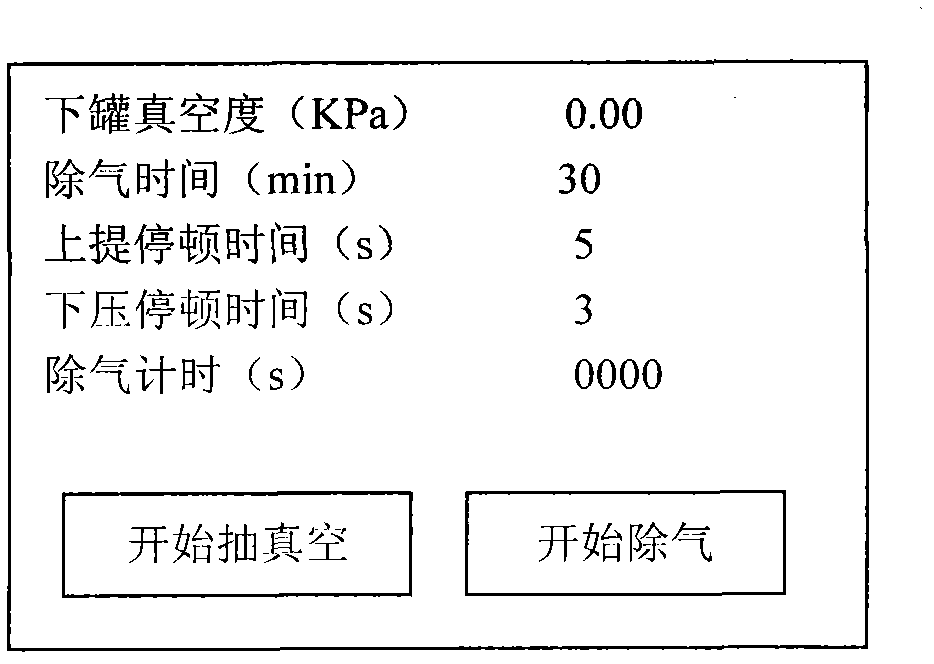

[0018] Such as figure 1 , figure 2 As shown, the aluminum alloy vacuum degassing device includes a vacuum pump 1, a vacuum gauge 2, a vacuum buffer tank 3, 1# electromagnetic stop valve 4, 2# electromagnetic stop valve 5, a lifting vacuum degasser 6, a sealed septum Plate 7, crucible 8, "O" type high temperature resistant sealing ring 14, heat insulation guide sleeve 15. Wherein, the vacuum pump 1 is connected with the vacuum buffer tank 3 and the lower tank of the equipment by using a seamless steel pipe. The front end pipeline of the vacuum pump 1 is provided with a vacuum gauge 2, which can detect the pressure value in the pipeline in real time. Between the vacuum pump 1 and the vacuum buffer tank 3, and between the vacuum pump 1 and the lower tank where the melting and holding furnace is installed, 1# electromagnetic cut-off valve 4 and 2# electromagnetic cut-off valve 5 are respectively arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com